Edwards VS16K User manual

D059-15-880

Issue D Original

Instruction Manual

Adjustable Vacuum Interlock Switch VS16K

Description Item Number

Adjustable Vacuum Interlock Switch VS16K D059-15-000

© Edwards Limited 2009. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

D059-15-880 Issue D

Contents

Section Page

1 INTRODUCTION ....................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Description ................................................................................................................ 1

2 TECHNICAL DATA .................................................................................2

2.1 Operating conditions .................................................................................................... 2

2.2 Performance .............................................................................................................. 2

2.3 Mechanical data .......................................................................................................... 2

2.4 Electrical data ............................................................................................................ 2

2.5 Product item number ................................................................................................... 3

3 INSTALLATION .....................................................................................4

3.1 Unpacking and inspection .............................................................................................. 4

3.2 General .................................................................................................................... 4

3.3 Connection to the Vacuum System .................................................................................... 4

3.4 Connection to the Electrical Circuit .................................................................................. 4

4 OPERATION ........................................................................................6

4.1 Adjustment ............................................................................................................... 6

5 MAINTENANCE .....................................................................................7

6 STORAGE AND DISPOSAL .........................................................................8

6.1 Storage .................................................................................................................... 8

6.2 Disposal ....................................................................................................................8

Index ................................................................................................9

For return of equipment, complete the HS Forms at the end of this manual.

gea/0035/02/09

D059-15-880 Issue D

Page ii © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

Illustrations

Figure Page

1 Vacuum switch plug connections ...................................................................................... 5

2 Dimensions of VS16K vacuum switch .................................................................................. 7

Tables

Table Page

1 Maximum switch ratings ................................................................................................ 2

© Edwards Limited 2009. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

INTRODUCTION

D059-15-880 Issue D

1 INTRODUCTION

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards VS16K Adjustable Vacuum

Switch. Read this manual before attempting to install and operate the VS16K.

This manual contains essential safety information which supplements the safety features of the VS16K. Safety

procedures are highlighted as WARNING and CAUTION instructions. You must obey these instructions. The use of

WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

1.2 Description

The Edwards VS16K adjustable vacuum switch contains a pressure sensitive diaphragm which operates a non latching

snap action microswitch. The switch can be used to operate an electrical circuit when the system pressure rises or

falls through an operator-determined pressure set point between 30 and 1000 mbar.

The diaphragm is enclosed within the vacuum switch housing which is surrounded by atmospheric pressure and is

coupled to the vacuum system by a NW16 Flange. The absolute switch point pressure will therefore vary by the same

amount as the atmospheric pressure. This must be allowed for when setting the switch point close to the low pressure

end of the range.

The vacuum switch is factory set to operate at about 30 mbar on falling pressure.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

WARNING

This switch should not be used for safety critical applications. For many interlock applications the

Edwards IS16K may be more suitable.

D059-15-880 Issue D

Page 2 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

TECHNICAL DATA

2 TECHNICAL DATA

2.1 Operating conditions

2.2 Performance

2.3 Mechanical data

2.4 Electrical data

Maximum switch ratings for different loads and voltages:

Temperature range - operating -5°C to 40°C

Temperature range - storage -20°C to 70°C

Relative humidity (non condensing) 10 to 90%

Maximum operating altitude 3000 m

Installation category (IEC1010) 2 (IEC664/664A)

Pollution category (IEC1010) 2

Enclosure rating IP40

Leak rate <1 x 10-9 mbar litre/sec-1

Maximum overpressure 1 bar gauge (2 bar absolute)

Switch point range 30 to 1000 mbar

Switch point differential less than 30 mbar

Weight (unpacked) 0.5 kg

Weight (packed) 0.6 kg

Vacuum connection NW16 Flange

Volume added to vacuum system 7 cm3

Materials exposed to vacuum system Stainless steel and Armco 17/7PH

Electrical connection mPm 283 plug

Accessory supplied mPm 183 mating electrical socket

Table 1 - Maximum switch ratings

Volts

a.c. 50/60Hz Resistive Load

Amps Motor Load

(HP)

125 10 0.125

250 10 0.25

d.c. volts

125 0.5 -

250 0.25 -

© Edwards Limited 2009. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

TECHNICAL DATA

D059-15-880 Issue D

2.5 Product item number

Description Item Number

Adjustable vacuum switch D059-15-000

D059-15-880 Issue D

Page 4 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

3 INSTALLATION

3.1 Unpacking and inspection

Remove all packing materials and protective coversand check the VS16K for damage. If the VS16K is damaged, notify

your supplier and the carrier in writing within three days; state the Item Number of the VS16K together with your

order number and your supplier's invoice number. Retain all packing materials for inspection. Do not use the VS16K.

3.2 General

The vacuum switch should be mounted as close as possible to the point at which the pressure is to be measured. Use

a short branch tube with an internal diameter no less than that of the switch vacuum connection. Long, narrow and

angled connections can cause significant errors.

This equipment is not protected from dripping water from above, unless mounted with the vacuum flange pointing

downwards.

3.3 Connection to the Vacuum System

The vacuum switch may be mounted in any orientation but mounting with the vacuum switch vertical will prevent

the possibility of debris falling into the vacuum port and affecting the performance of the switch.

3.4 Connection to the Electrical Circuit

CAUTION

Ensure that the circuit connected to the vacuum switch is suitably fused to prevent the switch contact rating

being exceeded. The fuse rating must not exceed 10 amps.

WARNING

Do not allow the internal pressure to be higher than 1 bar gauge (2 bar absolute). If the pressure

in your system can be higher than 1 bar gauge, you must fit a suitable pressure relief valve.

Overpressure of the switch could cause injury to persons.

WARNING

Ensure that the electrical installation of the Vacuum Switch conforms with your local and national

safety requirements. It must be connected to a suitably fused and protected electrical supply and

a suitable earth point.

© Edwards Limited 2009. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

D059-15-880 Issue D

Connect the vacuum switch to the equipment using the four pole mPm connector supplied. The contacts on this

connector are internally wired as follows:-

Figure 1 - Vacuum switch plug connections

CAUTION

To ensure that the socket cable gland strain relief is effective a cable with a minimum diameter of 6 mm must

be used.

Select a three or four core cable of a rating suitable for the power supply to be switched. One core should be

coloured green/yellow for the earth connection.

Thread the cable through the cable gland on the mPm socket cover and connect to the appropriate terminals as

shown on the diagram.

Tighten the cable gland and connect the socket to the switch using the sealing gasket and locking screw provided.

Earth Connection.

Com Common.

Lo Contact made when system pressure is lower than set point.

Hi Contact made when system pressure is higher than set point.

D059-15-880 Issue D

Page 6 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

OPERATION

4OPERATION

4.1 Adjustment

The pressure at which the switch operates is controlled by the adjusting screw located under the removable plug

located on the top of the vacuum switch cover.

Turning the screw clockwise reduces the switch point pressure.

The following procedure can be used to set, change or measure the switch point at any time:-

1. Externally disconnect the electrical supply from the vacuum switch.

2. Set and maintain the system pressure, measured by a vacuum gauge, to the desired switch point pressure.

3. Unscrew and remove the mPm socket. Remove the plug covering the adjusting screw.

4. Connect an electrical continuity meter between the pin marked 'com' and The pin marked 'Hi' or 'Lo' as

appropriate to the application.

5. Turn the adjusting screw until the switch just operates.

6. Change the system pressure and check the operation of the vacuum switch.

Note: The switching differential (between rising and falling pressure) is about 30 mbar.

7. Repeat steps 5 and 6 as necessary.

8. Replace the plastic plug and reconnect the mPm socket.

9. Reconnect the electrical supply.

© Edwards Limited 2009. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

MAINTENANCE

D059-15-880 Issue D

5 MAINTENANCE

1. To ensure correct operation this vacuum switch should be tested once per year or every 10 000 cycles whichever

is sooner. This may be done by carrying out steps 1, 2, 3, 4 and 6 in Section 4.1.

2. The outer surfaces of the switch may be cleaned by wiping with a dry cloth. Avoid the use of solvents that may

attack the moulded cover.

3. This product contains no user serviceable parts.

Figure 2 - Dimensions of VS16K vacuum switch

WARNING

Ensure that maintenance is done by a suitably trained and supervised technician. Obey your local

and national safety requirements.

D059-15-880 Issue D

Page 8 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

STORAGE AND DISPOSAL

6 STORAGE AND DISPOSAL

6.1 Storage

Store in a cool dry place. Do not exceed the limits specified in Section 2.

6.2 Disposal

Dispose of the switch in accordance with any local or national safety requirements.

Particular care must be taken if the switch has been used in a hazardous environment.

Index

D059-15-880IssueD

© Edwards Limited 2009. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

A

Adjustment .................................................6

C

Connection to the Electrical Circuit ....................4

Connection to the Vacuum System .....................4

D

Description .................................................1

E

Electrical data .............................................2

G

General .....................................................4

I

INSTALLATION ..............................................4

Introduction ................................................1

M

MAINTENANCE ..............................................7

Mechanical data ...........................................2

O

Operating conditions ......................................2

OPERATION .................................................6

P

Performance ...............................................2

Product item number .....................................3

S

Scope and definitions .....................................1

STORAGE AND DISPOSAL ..................................8

T

TECHNICAL DATA ..........................................2

U

Unpacking and inspection ................................4

Index

D059-15-880 Issue D

Page 10 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Index

This page intentionally blank.

This page intentionally blank.

Return of Edwards Equipment - Procedure

Form HS1

INTRODUCTION

Before returning your equipment, you must warn Edwards if substances you used (and

produced) in the equipment can be hazardous. This information is fundamental to the safety

of our Service Centre employees and will determine the procedures employed to service your

equipment.

Complete the Declaration (HS2) and send it to Edwards before you dispatch the

equipment. It is important to note that this declaration is for Edwards internal use only,

and has no relationship to local, national or international transportation safety or

environmental requirements. As the person offering the equipment for shipment, it is your

responsibility to ensure compliance with applicable laws.

GUIDELINES

• Equipment is 'uncontaminated' if it has not been used, or if it has only been used with

substances that are not hazardous. Your equipment is 'contaminated' if it has been used

with any substances classified as hazardous under EU Directive 67/548/EEC (as amended)

or OSHA Occupational Safety (29 CFR 1910).

• If your equipment has been used with radioactive substances, biological or infectious

agents, mercury, polychlorinated biphenyls (PCB’s), dioxins or sodium azide, you must

decontaminate it before you return it to Edwards. You must send independent proof of

decontamination (for example a certificate of analysis) to Edwards with the Declaration

(HS2). Phone Edwards for advice.

• If your equipment is contaminated, you must either:

• Remove all traces of contamination (to the satisfaction of laws governing the

transportation of dangerous/hazardous substances).

• Or, properly classify the hazard, mark, manifest and ship the equipment in accordance

with applicable laws governing the shipment of hazardous materials.

Note: Some contaminated equipment may not be suitable for airfreight.

PROCEDURE

1. Contact Edwards and obtain a Return Authorisation Number for your equipment.

2. Complete the Return of Edwards Equipment - Declaration (HS2).

3. If the equipment is contaminated, you must contact your transporter to ensure that you

properly classify the hazard, mark, manifest and ship the equipment, in accordance with

applicable laws governing the shipment of contaminated/hazardous materials. As the

person offering the equipment for shipment, it is your responsibility to ensure compliance

with applicable law. Note: Equipment contaminated with some hazardous materials,

such as semiconductor by-products, may not be suitable for airfreight - contact your

transporter for advice.

4. Remove all traces of hazardous gases: pass an inert gas through the equipment and any

accessories that will be returned to Edwards. Where possible, drain all fluids and

lubricants from the equipment and its accessories.

5. Seal up all of the equipment's inlets and outlets (including those where accessories were

attached) with blanking flanges or, for uncontaminated product, with heavy gauge tape.

6. Seal equipment in a thick polythene/polyethylene bag or sheet.

7. If the equipment is large, strap the equipment and its accessories to a wooden pallet. If

the equipment is too small to be strapped to a pallet, pack it in a suitable strong box.

8. E-mail via scan, fax or post a copy of the original with signature of the Declaration (HS2)

to Edwards. The Declaration must arrive before the equipment.

9. Give a copy of the Declaration (HS2) to the transporter. You must tell your transporter

if the

equipment is contaminated.

10. Seal the original Declaration in a suitable envelope: attach the envelope securely to the

outside of the equipment package, in a clear weatherproof bag.

WRITE YOUR RETURN AUTHORISATION NUMBER CLEARLY ON THE OUTSIDE OF THE

ENVELOPE OR ON THE OUTSIDE OF THE EQUIPMENT PACKAGE.

P900-70-000 Issue L

Return of Edwards Equipment – Declaration

Form HS2

You must:

•Knowaboutallof the substances which have been used and produced in the equipment before you complete this Declaration

• Read the Return of Edwards Equipment – Procedure (HS1) before you complete this Declaration

• Contact Edwards to obtain a Return Authorisation Number and to obtain advice if you have any questions

• Send this form to Edwards before you return your equipment as per the procedure in HS1

Return Authorisation Number:

Manufacturer's Product Name ________________________

Manufacturer's Part Number _________________________

Manufacturer's Serial Number ________________________

Has the equipment been used, tested or operated?

YES

R

Go to Section 2 NO

R

Go to Section 4

IF APPLICABLE:

Tool Reference Number _____________________

Process _______________________________________

Failure Date _______________________________

Serial Number of

Replacement Equipment ______________________

Are any substances used or produced in the equipment:

•

Radioactive, biological or infectious agents, mercury,

poly chlorinated biphenyls (PCBs), dioxins or

sodium azide? (if YES, see Note 1) YES

R

NO

R

•

Hazardous to human

health and safety? YES

R

NO

R

Note 1: Edwards will not accept delivery of any equipment

that is contaminated with radioactive substances, biological/

infectious agents, mercury, PCB’s, dioxins or sodium azide,

unless you:

• Decontaminate the equipment

• Provide proof of decontamination

YOU MUST CONTACT EDWARDS FOR ADVICE BEFORE YOU RETURN

SUCH EQUIPMENT

Print your name: _________________________________ Print your job title: ____________________________________

Print your organisation: ____________________________________________________________________________________

Print your address: _____________________________________________________________________________________

_____________________________________________________________________________________________________

Telephone number: ___________________________ Date of equipment delivery: ____________________________________

I have made reasonable enquiry and I have supplied accurate information in this Declaration. I have not withheld any

information, and I have followed the Return ofEdwards Equipment – Procedure (HS1).

Signed: _____________________________________ Date: ______________

• who did you buy the equipment from? ______________________________

____

•

give the supplier’s invoice number

____________________________

______

If you have a warranty claim:

Substance name Chemical

Symbol Precautions required (for example,

use protective gloves, etc.) Action required after a spill,

leak or exposure

Note: Please print out this

form, sign it and return the

signed form as hard copy.

SECTION 1: EQUIPMENT

SECTION 2: SUBSTANCES IN CONTACT WITH THE EQUIPMENT

SECTION 3: LIST OF SUBSTANCES IN CONTACT WITH THE EQUIPMENT

SECTION 4: RETURN INFORMATION

SECTION 5: DECLARATION

P900-71-000 Issue M

Reason for return and symptoms of malfunction: ____________________________________________________________

______________________________________________________________________________________________________

This page intentionally blank.

Manor Royal

Crawley

West Sussex, RH10 9LW

Tel:

Office +44 1293 528844

Sales & Service 08459 21 22 23

Fax:

Office +44 1293 533453

Sales & Service +44 1293 534149

301 Ballardvale Street

Wilmington, MA 01887

Tel +1 978 658 5410

Fax +1 978 658 7969

Toll Free (USA only):

Tel +1 800 848 9800

5860 Chedworth Way

Mississauga, Ontario

Canada, L5R 0A2

Tel +1 800 387 4076

Fax +1 905 501 1225

Rua Bernardo Wrona, 222

02710-060, Sao Paulo, SP

Brasil

Tel +55 11 3952 5000

Fax +55 11 3965 2766

Via Carpaccio 35

20090 Trezzano sul Naviglio

Milan

Office +39 02 48 4471

Sales +39 02 48 447242

Service +39 02 48 447217

Fax +39 02 48 401638

Bergensesteenweg 709

B 1600 Sint-Pieters-Leeuw

Tel + 32 2 3630030

Fax + 32 2 3630064

Ammerthalstraße 36

85551 Kirchheim

Munich

Tel:

Sales 0 800 000 14 56

Service 0 800 000 14 57

Fax:

Office +49 89 99191899

Sales & Service +49 89 99191888

125 Avenue Louis Roche

92238 Gennevilliers, Cedex

Paris

Tel:

Office +33 147 98 24 01

Sales +33 141 21 12 56

Service +33 141 21 12 45

Fax:

Office +33 147 98 44 54

Sales & Service +33 141 21 12 38

203 Surya Kiran Building

19 Kasturba Gandhi Marg

New Delhi - 110 001

India

Tel +91 11 4151 0065

Fax +91 11 4151 0245

5 Habarzel Boulevard

Gat 2000 Industrial Zone

Qiryat Gat 82000

Tel +972 8 681 0633

Fax +972 8 681 0640

23 Fu Te Road(N)

Wai Gao Qiao Free Trade Zone

Pudong, Shanghai

200131, China

Tel +86 21 5866 9618

Fax +86 21 5866 9993

1078-1, Yoshihashi

Yachiyo-shi, Chiba

Japan, 276-8523

Tel +81 47 458 8831

Fax +81 47 458 8835

42 Loyang Drive

Loyang Industrial Estate

Singapore 508962

Tel +65 6546 8408

Fax +65 6546 8407

No. 434 Chung-Hwa Road

Toufen Town, Miaoli County

351 Taiwan

Tel +886 37 611422

Fax +886 37 611401

Daewoo Engineering Building

5th Floor

9-3 Sunae-dong

Bundang-gu, Sungnam City

Kyungki-do, Korea

Tel +82 31 716 7070

Fax +82 31 738 1001

1688 Ipswich Road

Rocklea Qld, 4106

Australia

Tel: +61 4 0199 1193

Fax: +61 2 9886 9249

UNITED KINGDOM

AMERICAS

CANADA

BRAZIL

ITALY

ISRAEL

INDIA

FRANCE

GERMANY

BELGIUM CHINA

JAPAN

SINGAPORE

TAIWAN

KOREA

AUSTRALIA

PLEASE CONTACT ANY OF THE ABOVE FOR DETAILS OF OTHER SALES AND SERVICE CENTERS IN YOUR AREAS.

Edwards and the Edwards logo are trade marks of Edwards Limited

© Edwards Limited 2007

WWW.EDWARDSVACUUM.COM

INFO@EDWARDSVACUUM.COM

P800-80-000 Issue M 01A09-010

Table of contents

Other Edwards Switch manuals

Popular Switch manuals by other brands

Brocade Communications Systems

Brocade Communications Systems A7533A - Brocade 4Gb SAN Switch Base Command reference

Avocent

Avocent AutoView Wireless Installer/user guide

D-Link

D-Link DGS-6600-48T Cli reference guide

Black Box

Black Box LGB708A-R3 user manual

mCubed

mCubed sensorHUB installation guide

Larson Electronics

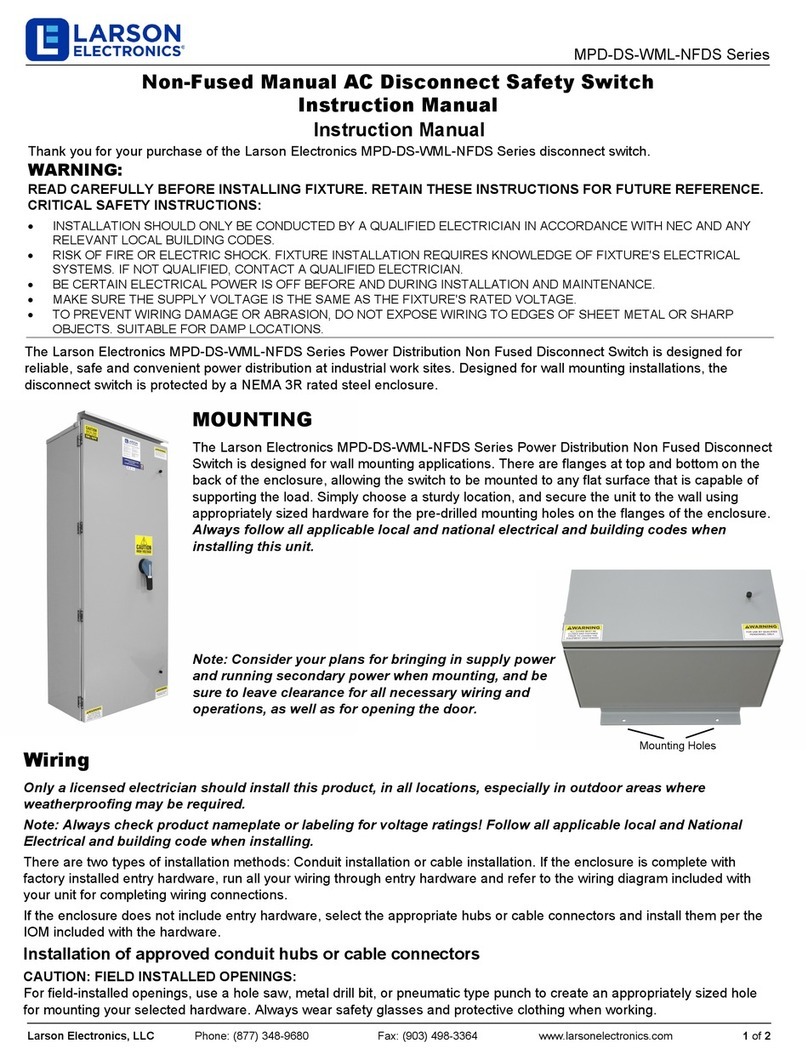

Larson Electronics MPD-DS-WML-NFDS Series instruction manual