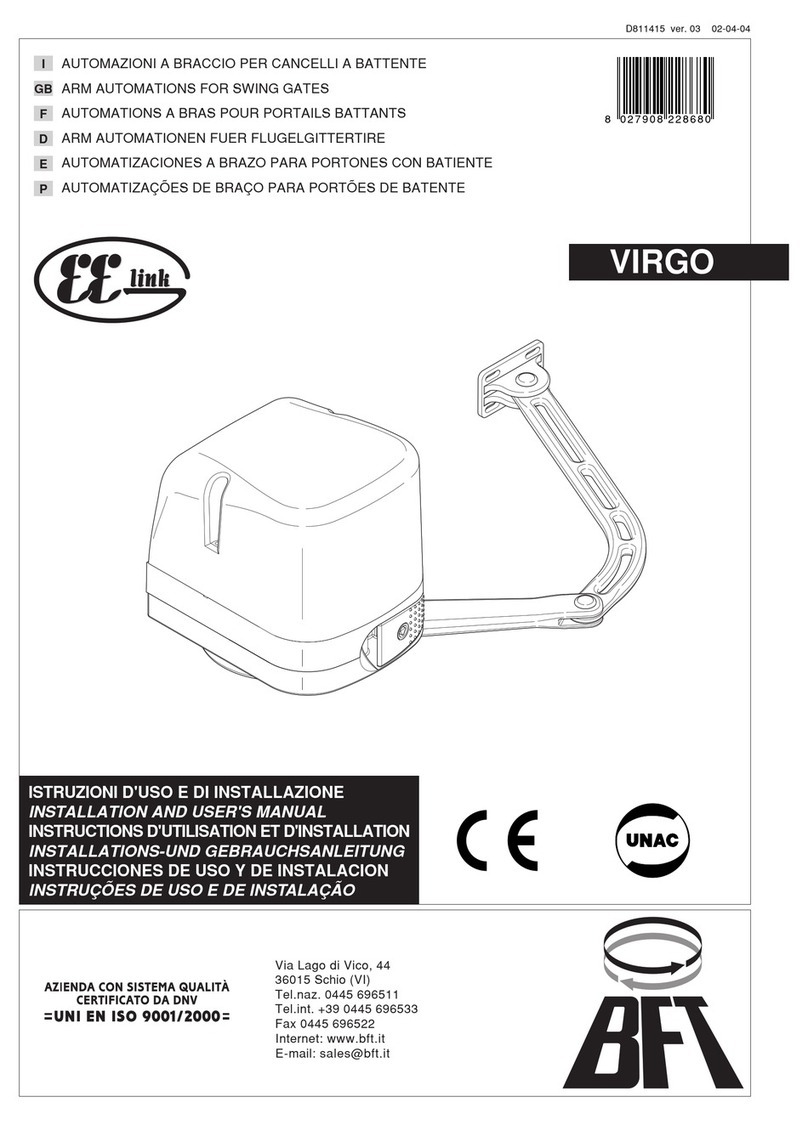

Eelink Virgo User manual

ISTRUZIONI D’USO E DI INSTALLAZIONE

INSTALLATION AND USER’S MANUAL

INSTRUCTIONS D’UTILISATION ET D’INSTALLATION

INSTALLATIONS-UND GEBRAUCHSANLEITUNG

INSTRUCCIONES DE USO Y DE INSTALACION

INSTRUÇÕES DE USO E DE INSTALAÇÃO

VIRGO

AUTOMAZIONI A BRACCIO PER CANCELLI A BATTENTE

ARM AUTOMATIONS FOR SWING GATES

AUTOMATIONS A BRAS POUR PORTAILS BATTANTS

ARM AUTOMATIONEN FUER FLUGELGITTERTIRE

AUTOMATIZACIONES A BRAZO PARA PORTONES CON BATIENTE

AUTOMATIZAÇÕES DE BRAÇO PARA PORTÕES DE BATENTE

I

GB

F

D

E

P

D811415A ver.03 26-01-10

8027908 282781

2 - VIRGO

D811415A_03

USER’S MANUALENGLISH

Thank you for buying this product. Our company is sure that you will

be more than satised with the product’s performance. Carefully read

the “WARNINGS” pamphlet and the “INSTRUCTION BOOKLET” which

are supplied together with this product, since they provide important

information regarding the safety, installation, use and maintenance of

the product.This product complies with recognised technical standards

and safety regulations. We declare that this product is in conformity

with the following European Directives: 2006/95/ EEC, 2004/108/EEC,

2006/42/EEC and subsequent amendments.

1) GENERAL OUTLINE

Low-voltage operator (24V ) suitable for residential use. Designed for

swinggateshavingsmall-sizedpillars.The operating arm,withitsspecial

antishearing shape, allows the leaves to be manoeuvred even when the

operator is positioned well away from their fulcrum. The irreversible

electromechanical gearmotor keeps the gate locked in the closing and

opening positions.

Thereleaselever,ttedtotheoutsideofeachoperator,allowsthemanual

manoeuvre to be carried out very easily.

2) SAFETY

ATTENTION! The VIRGO model controller is not equipped with mecha-

nical torque adjustment. It is compulsory to use a control panel of the

same manufacturer, in compliance with the basic safety requirements

of directives 2006/95/CEE, 2004/108/CEE, 2006/42/CEE equipped with

appropriate electric adjusment of the torque.

WARNING. Important safety instructions. For the safety of persons,

itisimportanttofollowtheseinstructionsCarefullyreadtheinstruc-

tions for use and keep them for future reference.

When correctly installed and used, the operator meets the required

degree of safety. However, it is recommended to observe a few rules of

behaviour to avoid accidental problems.

- Keep children, adults and things outside the operator range, in parti-

cular during operation.

- Donotleaveradiotransmittersorotherdeviceswithinchildren’sreach,

in order to avoid unintentional operator movements.

- Do not intentionally contrast the leaf movement.

- Do not try to open the door manually, if the operator has not been

released with the appropriate release handle.

- Do not make changes to the operator components.

- In case of malfunction, disconnect the power supply, activate the

emergency release to allows access, and request the assistance of a

qualied technician (professional installer).

- Before any external cleaning or other maintenance operation, discon-

nect the power supply.

- If tted, keep the photocell optical elements and the luminous signal

devices clean. Check that there are no branches or shrubs obstructing

the safety devices (photocells).

- Foranyworktobecarriedoutdirectlyontheoperator,contactqualied

personnel (professional installer).

- Have the operator checked by qualied personnel once a year.

3) EMERGENCY MANOEUVRE (Fig. 1)

In the case where the power supply is o, or any faults are present, the

manual emergency manoeuvre can be carried out by operating the

external release lever (Fig.1 ref.”S”).

1) Insert the release key and turn it clockwise (Fig.1 ref.”1”).

2) Move lever “S” until the lock is released (Fig.1 ref.”2”).

3) Keep the lever in the release position by turning the key clockwise

(Fig.1 ref.”3”).

4) Push the leaf slowly to open or close the gate.

To reactivate motor-driven operation, turn the key clockwise to free the

lever from its released position, then return it to its initial position for

normal operation.

WARNING! Before carrying out the manual manoeuvre make sure that

this operation will not create dangerous situations.

4) DEMOLITION

WARNING! This operation should only be carried out by qualied

personnel.

Materials must be disposed of in conformity with the current regula-

tions.

In case of scrapping, the automation devices do not entail any particular

risksordanger.Incaseofmaterialsto berecycled,theseshouldbe sorted

out by type (electrical components, copper, aluminium, plastic etc.).

5) MAINTENANCE

WARNING! This operation should only be carried out by qualied

personnel.

When the automation system is disassembled to be reassembled on

another site, proceed as follows:

• Disconnectthepowersupplyandtheentireexternalelectricalin-

stallation.

• Inthecasewheresomeofthecomponentscannotberemovedor

are damaged, they must be replaced.

WARNINGS

Correct controller operation is only ensured when the data contai-

ned in the present manual are observed. The Company is not to

be held responsible for any damage resulting from failure to

observetheinstallation standardsandtheinstructionscontained

in the present manual.

The descriptions and illustrations contained in the present manual

are not binding.The Company reserves the right to make any alte-

rations deemed appropriate for the technical, manufacturing and

commercialimprovementoftheproduct,whileleavingtheessential

product features unchanged, at any time and without undertaking

to update the present publication.

Fig. 1

S

4 - VIRGO

D811415A_03

INSTALLATION MANUAL ENGLISH

Thank you for buying this product. Our company is sure that you will be

more than satised with the product’s performance.

Carefully read the “WARNINGS” pamphlet and the “INSTRUCTION

BOOKLET” which are supplied together with this product, since they

provide important information regarding the safety, installation, use

andmaintenanceof theproduct.Thisproduct complieswithrecognised

technical standards and safety regulations. We declare that this product

is in conformity with the following European Directives: 2006/95/ EEC,

2004/108/EEC, 2006/42/EEC and subsequent amendments.

1) GENERAL SAFETY

WARNING! An incorrect installation or improper use of the product can

cause damage to persons, animals or things.

• The“Warnings”leaet and“Instruction booklet”supplied with this

product should be read carefully as they provide important informa-

tion about safety, installation, use and maintenance.

• Scrappackingmaterials(plastic,cardboard,polystyreneetc)accor-

ding to the provisions set out by current standards. Keep nylon or

polystyrene bags out of children’s reach.

• Keeptheinstructionstogetherwiththetechnicalbrochureforfuture

reference.

• Thisproductwasexclusivelydesignedandmanufacturedforthe

use specied in the present documentation. Any other use not

specied in this documentation could damage the product and be

dangerous.

• TheCompanydeclinesallresponsibilityforanyconsequencesresul-

ting from improper use of the product, or use which is dierent from

that expected and specied in the present documentation.

• Donotinstalltheproductinexplosiveatmosphere.

• Theconstructioncomponentsofthisproductmustcomplywiththe

following European Directives: 2004/108/CEE, 2006/95/EEC, 2006/42/

EEC and subsequent amendments. As for all non-EEC countries, the

above-mentioned standards as well as the current national standards

should be respected in order to achieve a good safety level.

• TheCompanydeclinesallresponsibilityforanyconsequences

resulting from failure to observe Good Technical Practice when

constructing closing structures (door, gates etc.), as well as from any

deformation which might occur during use.

• Theinstallationmustcomplywiththeprovisionssetoutbythefol-

lowing European Directives: 2004/108/CEE, 2006/95/EEC, 2006/42/

EEC and subsequent amendments.

• Disconnecttheelectricalpowersupplybeforecarryingoutanyworkon

the installation. Also disconnect any buer batteries, if tted.

• Fitan omnipolarormagnetothermalswitchon themainspower

supply, having a contact opening distance equal to or greater than

3,5 mm.

• Checkthatadierentialswitchwitha0.03Athresholdisttedjust

before the power supply mains.

• Checkthatearthingiscarriedoutcorrectly:connectallmetalparts

for closure (doors, gates etc.) and all system components provided

with an earth terminal.

• Fitallthesafetydevices(photocells,electricedgesetc.)whichare

needed to protect the area from any danger caused by squashing,

conveying and shearing, according to and in compliance with the

applicable directives and technical standards.

• Positionatleastoneluminoussignalindicationdevice(blinker)where

it can be easily seen, and x a Warning sign to the structure.

• TheCompanydeclinesallresponsibilitywithrespecttotheautomation

safety and correct operation when other manufacturers’ components

are used.

• Onlyuseoriginalpartsforanymaintenanceorrepairoperation.

• Donotmodifytheautomationcomponents,unlessexplicitlyautho-

rised by the company.

• Instructtheproductuseraboutthecontrolsystemsprovidedand

the manual opening operation in case of emergency.

• Donotallowpersonsorchildrentoremainintheautomationope-

ration area.

• Keepradiocontrolorothercontroldevicesoutofchildren’sreach,

in order to avoid unintentional automation activation.

• Theusermustavoidanyattempttocarryoutworkorrepaironthe

automation system, and always request the assistance of qualied

personnel.

• Anythingwhichisnotexpresslyprovidedforinthepresentinstruc-

tions, is not allowed.

• Installationmustbecarriedoutusingthesafetydevicesandcontrols

prescribed by the EN 12978 Standard.

• Checkthatthestatedtemperaturerangeiscompatiblewiththeplace

where the operator is to be installed.

• Themotorcannotbeinstalledondoorswhichincorporatepedestrian

doors.

• Makesurethatsquashingisavoidedbetweenmovingparts and

nearby xed parts, checking that the following minimum safety

distances between the above-mentioned moving and xed parts

are respected: at least 25 mm to protect ngers, 50mm to protect

toes, 100mm for hands, 120 mm for arms and feet, 180 mm for legs,

300mm for the head and 500 mm for the body. Otherwise, t all the

safety devices (photocells, safety edges etc.) required to protect the

area from any danger of squashing, drawing in and shearing.

• Ifpresent,theholdbutton(hold-to-runcontrol)mustbettedwithin

sight of the door but away from moving parts, at a height of 1.5 m,

and must not be accessible to the public.

• Aftercarryingouttheinstallation,ensurethatmotorsettingiscorrect,

and that protection and release systems operate correctly.

2) GENERAL OUTLINE

Low-voltage operator (24V ) suitable for residential use. Designed for

swinggateshavingsmall-sizedpillars.The operating arm,withitsspecial

antishearing shape, allows the leaves to be manoeuvred even when the

operator is positioned well away from their fulcrum. The irreversible

electromechanical gearmotor keeps the gate locked in the closing and

opening positions.

Thereleaselever,ttedtotheoutsideofeachoperator,allowsthemanual

manoeuvre to be carried out very easily.

ATTENTION! The VIRGO model controller is not equipped with mecha-

nical torque adjustment. It is compulsory to use a control panel of the

same manufacturer, in compliance with the basic safety requirements

of directives 2006/95/CEE, 2004/108/CEE, 2006/42/CEE equipped with

appropriate electric adjusment of the torque.

Before carrying out the manual manoeuvre make sure that this operation

will not create a dangerous situations.

Check in the relevant literature that the thermal eld in the working area

is suitable for the operator.

Make sure that the movement of the door does not cause entrapment

risks between the movable and xed parts of the door.

If swing gates with built-in doors are used, the motor must not run when

the door is left open.

WARNING! The operator must be installed by a qualied technician as

special safety components are used for every specic site and therefore

safety depends on installation.

3) TECHNICAL SPECIFICATIONS

3.1) VIRGO OPERATOR

Motor: ..........................................................................................24V 2500 min-1

Power: ..................................................................................................................110W

Insulation class:..........................................................................................................F

Lubrication:................................................................................Permanent grease

Reduction ratio:.............................................................................................. 1-1224

Output shaft revolutions: .................................................................2 min-1 MAX

Opening time 90°:................................................................................................ 14s

Torque supplied: ..........................................................................................170 Nm

Max leaf weight and length:....................2000N (~200kg) for 2m long leaf

Impact reaction: .........................................................Integrated torque limiter

.................................................................................................on LINX control panel

Motion drive:............................................................................................. Lever arm

Stop:................ Incorporated electrical limit switches + mechanical locks

Manual manoeuvre: ...............................................Release lever with CLS key

Number of manoeuvres in 24h: ........................................................................ 60

Environmental conditions:...................................................from -15 to +50 °C

Degree of protection:........................................................................................ IPX4

Operator weight: ......................VIRGO:80N (~8kg) - VIRGO SQ:60N (~6kg)

Dimensions:...................................................................................................see g.1

3.2) LINX CONTROL PANEL

Power supply: ....................................................................... 230V~ ±10% 50Hz*

Mains/low voltage insulation: ............................................> 2MOhm 500Vdc

Working temperature ............................................................from -15 to +50 °C

Dielectric strength: ....................................... mains/l.v. 3750V~ for 1 minute

Motor output current: .................................................................3.5A+3.5A max

VIRGO - 17

D811415A_03

Motor relay commutation current: .............................................................. 10A

Maximum motor power:...............................................................110W (24V )

Power supply for accessories: ...................24V~ (180mA max absorption)

......................................................................24V~ safe (180mA max absorption)

Gate-open warning light: .................................N.O. contact (24V~/1A max)

Blinker: .............................................................................................. 24V~ 25W max

Dimensions: ...........................................................................................see gure 1

Fuses: ........................................................................................................ see g.9-15

(*other voltages available on request)

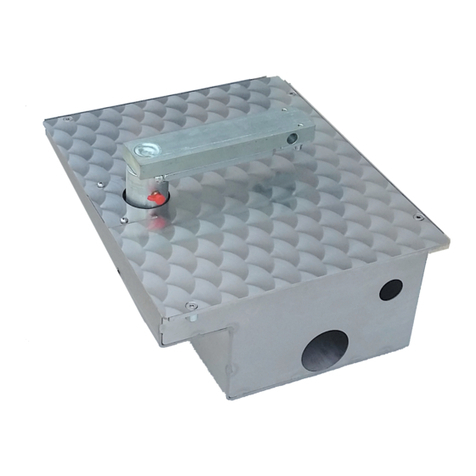

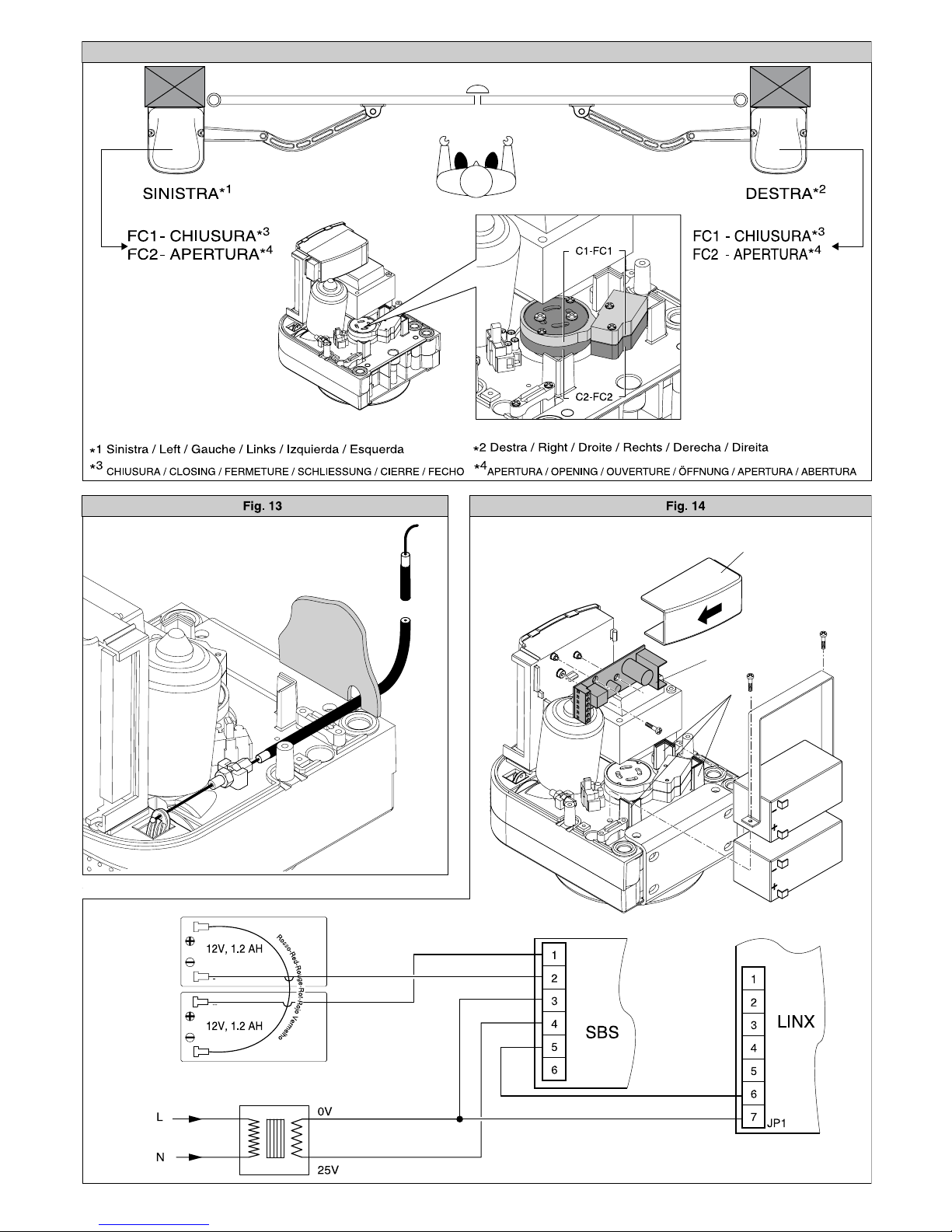

3.3) VIRGO BAT BATTERY KIT (OPTIONAL - Fig.14)

Allows operation to continue even when the mains power supply is o

for a short time.

Charge voltage: .............................................................27.2V Charge cur-

rent: ...................................................................................................................130mA

Data detected with external temperature of: .........................................25°C

Battery capacity: .............................................................................2x (12V 1.2Ah)

Exhausted battery protection threshold: ..........................................20.4V

Battery recharge time: ...............................................................................12/14 h

NOTE: In case of operation with battery back up, the outputs to termi-

nals 8-9 (Vsafe 24V~) and 10-11 (Vsafe 24V~) show a voltage of 24V

polarised as indicated in Fig.16.

At the time of installing theVIRGO BAT Kit, check that the safety devices

are connected correctly.

4) OPERATOR INSTALLATION

4.1) Preliminary checks

Check that:

• Thegatestructureissucientlysturdyandrigid.

The xing position must be worked out according to the leaf structu-

re. In any case, the manoeuvring arm must push against a reinforced

leaf point.

• Theleavescanbemovedmanuallyalongtheirentirestroke.

If the gate has not been installed recently, check the wear condition of

all its components. Repair or replace defective and worn parts.

Operator reliability and safety are directly aected by the condition

of the gate structure.

5) SUPPORT PLATE FIXING (Fig.5)

The operator is supplied with a xing bracket and lever arm.

Having identied the leaf reinforcement point, with the gate closed,

trace an imaginary horizontal line from the centre of the reinforcement

point to the pillar (g. 3-4).

Fig. 2 illustrates the most common types of installation:

- with the leaf hinge pivot not aligned with the xing plate (90° opening

- maximum distance between hinge pivot and plate: 210mm).

- with the hinge pivot aligned with the xing plate

Position the anchoring bracket observing the dimensions shown in

g.3 for opening up to 90°, or in g.2-4 for opening over 90° up to a

max of 120°.

The pillar surface, where the bracket is xed, must be at and parallel

to the leaf. Use screws and expansion plugs adequate for the type of

pillar. In the case where the pillar surface is irregular, use expansion

plugs with studs, in order to be able to adjust the xing bracket parallel

to the leaf (g.5).

• Assembletheleverarmasing.7.

DX = tting to right leaf

SX = tting to left leaf

Choose the most suitable position for xing bracket“F”to the leaf.

• InsertleverLintothegearmotoroutputshaft,andxitusingappro-

priate pivot P and self-locking nut D (g.7).

• Releasetheoperatorbyactivatingthereleaselevertoallowthearm

to move easily (see paragraph “EMERGENCY MANOEUVRE”).

• OpenthegearmotorcoverandxittotheplateasindicatedinFig.8.

• Fixtowinganglebar“F”totheleaf.

• Thecorrectpositionfortheoperatorarmisillustrateding.6.Theleaf

attachment point can be identied by positioning the arm according

to the dimension indicated in g.6.

• Withtheoperatorreleased,checkthearmforcorrectmovement.

• Repeatthesameprocedurefortheotherleaf.

6) BACKSTOP FIXING

TheVIRGOoperatorisprovidedwithmechanical end-of-strokebackstops,

which make the installation of ground stop plates redundant.

With reference to Fig. 10 proceed as follows:

- Identify the opening and closing end-of-stroke points and x the

backstops accordingly.

- Fix protection cover C.

7) ELECTRICAL INSTALLATION SET-UP

Arrange the electrical installation as shown in g.11.

Keep the mains voltage connections denitely separate from the very

low voltage connections (24V).

For thispurpose,theoperatorisprovidedwith appropriatettings,indicated

in Fig.9, for a spiral exible raceway with an inside diameter of 20:

- P1 input for mains power supply + GND.

- P2/P3 inputs for safety devices and accessories.

For the mains power supply, use the appropriate cable clamp (Fig.9 -”S”),

the terminal bar with an incorporated protection fuse (Fig.9 -”L-N”) and

the GND terminal.

Connect the yellow/green cable to the earth terminal.

Fig.16 shows the cross-section and the number of connections.

8) TERMINAL BAR CONNECTIONS (Fig.16)

NOTE:TheVIRGOoperatorsprovidedwithincorporatedLINXcontrol

panels are preset for tting to the left leaf, whereas the operators

without panels (VIRGO-SQ) are preset for tting to the right leaf, as

illustrated by the example given in Fig.11.

Should it be necessary to reverse the operator opening direction, pro-

ceed as follows:

1 – Reverse motor polarity (JP1 terminals 1-2)

2 – Reverse motor polarity (JP2 terminals 14-15)

WARNING – During the wiring and installation operations, refer to the

current standards as well as principles of good technical practice.

The (24V) very low voltage conductors must be physically separated

from the low voltage conductors or otherwise be adequately isolated

by means of an additional insulation of at least 1 mm.

The wires must be clamped by an extra fastener near the terminals, for

example by bands.

All the connection cables must be kept at an adequate distance from

the dissipator(Fig.15“D”).

WARNING! For connection to the mains, use a multipolar cable with

a minimum of 3x1.5mm2cross section and complying with the pre-

viously mentioned regulations. For example, if the cable is out side

(in the open), it has to be at least equal to H07RN-F, but if it is on the

inside (or outside but placed in a plastic cable cannel) it has to be

or at least egual to H05VV-F with section 3x1.5mm2.

JP1

1-2 Motor 2 connection (VIRGO with LINX panel):

3-5 Opening limit switch SWO M2 (N.C.)

4-5 Closing limit switch SWC M2 (N.C.)

6-7 24 V~ power supply input from the transformer

JP2

8-9 24V~Vsafe180mAmax output–powersupplyforphotocell

transmitters with check (Fig.17)

10-11 24V~ 180mA max output – power supply for photocells or

other devices

12-13 Blinker connection (24V~ 25W max)

14-15 Motor 1 connection (VIRGO-SQ – without LINX panel -):

16-18 Opening limit switch SWO M1 (N.C.)

17-18 Closing limit switch SWC M1 (N.C.)

19-24 Pedestrian opening button PED (N.O.). Controls partial

opening of Motor M2.

20-24 Fault input (N.O.). Input for photocells or safety devices

provided with an N.O. check contact.

21-24 Photocell input (N.C.). If not used, leave bridged (Fig.17).

22-24 STOP button (N.C.). If not used, leave bridged.

23-24 START button (N.O.).

25-26 Output for gate-open warning light (N.O. contact (24V~/1A

max) or alternatively for 2nd radio channel (see congura-

tion -“logics” menu)

27-28 Antenna input for incorporated radio-receiver board (27

braid - 28 signal).

INSTALLATION MANUAL

ENGLISH

18 - VIRGO

D811415A_03

INSTALLATION MANUAL ENGLISH

9) PROGRAMMING

The control panel provided with a microprocessor is supplied with

function parameters preset by the manufacturer, suitable for standard

installations. The predened parameters can be altered by means of

either the incorporated display programmer or Universal palmtop

programmer.

In the case where programming is carried out by means of Universal

palmtopprogrammer,carefullyreadtheinstructionsrelatingtoUniversal

palmtop programmer, and proceed in the following way.

Connect the Universal palmtop programmer to the control unit through

the UNIFLAT and UNIDA accessories (See g. 18). The LINX control unit

does not supply the Universal palmtop programmer with power, and

therefore requires an appropriate supply unit.

Enter the “CONTROL UNITS” menu, and the “PARAMETERS” submenu,

then scroll the display screenfuls using the up/down arrows to set the

numerical values of the parameters listed below.

For the function logics, refer to the“LOGIC”submenu.

In the case where programming is carried out by means of the incor-

porated programmer, refer to Fig. A and B and to the paragraph on

“Conguration”.

10) CONFIGURATION

The display programmer is used to set all the LINX control panel fun-

ctions.

The programmer is provided with three pushbuttons for menu scrolling

and function parameter conguration:

+ menu scrolling/value increment key

- menu scrolling/value reduction key

OKEnter (conrm) key

The simultaneous pressure of the + and - keys is used to exit the active

menu and move to the preceding menu.

The modications made are only set if the OK key is subsequently

pressed.

When the OK key is pressed for the rst time, the programming mode

is entered.

The following pieces of information appear on the display at rst:

- Control unit software version

- Number of total manoeuvres carried out (the value is expressed in

thousands, therefore the display constantly shows 0000 during the

rst thousand manoeuvres).

- Numberofmanoeuvrescarriedoutsincethelatestmaintenanceopera-

tion(the valueis expressedin thousands,thereforethe displayconstantly

shows 0000 during the rst thousand manoeuvres).

- Number of memorised radio control devices.

When the OK key is pressed during the initial presentation phase, the

rst menu can be accessed directly.

Herefollowsalistofthemainmenusandtherespectivesubmenusavaila-

ble.The predened parameter is shown between square brackets [ 0 ].

The writing appearing on the display is indicated between round

brackets.

Refer to Figures A and B for the conguration procedure.

10.1) PARAMETER MENU (PARAm)

- Automatic Closing Time (TCA) [ 10s ]

Set the numerical value of the automatic closing time from 3 to 90

seconds.

- Motor 1 torque (m1 t) [ 50% ]

Set the numerical value of the motor 1 torque between 1% and

99%.

- Motor 2 torque (m2 t) [ 50% ]

Set the numerical value of the motor 2 torque between 1% and

99%.

- Motor 1 slow-down torque (m1 t slow) [ 45% ]

Set the numerical value for slow-down torque of motor 1 between

1% and 99%.

- Motor 2 slow-down torque (m2 t slow) [ 45% ]

Set the numerical value for slow-down torque of motor 2 between

1% and 99%.

NOTES: In case of obstacle detection, the Ampere-stop function

stops the leaf movement, reverses the motion for 1 sec. and then

halts in the STOP status.The motor slow-down torque represents the

maximumtorquesuppliedtothemotorduringtheslow-downphase.

It must be set to a lower value with respect to the motor torque, in

order to allow the Ampere-stop function to be also activated during

the slow-down phase.

WARNING: Check that the impact force value measured at

the points established by the EN 12445 standard is lower than

that specied in the EN 12453 standard.

Incorrect sensitivity setting can cause injuries to persons or

animals, or damage to things.

- Opening delay time (open delay time) [ 1s ]

Set the opening delay time for motor 2 relative to motor 1, between

1 and 10 seconds.

- Closing delay time (cls delay time) [ 1s ]

Set the closing delay time for motor 1 relative to motor 2, between

1 and 30 seconds.

- Motor 1 Normal Speed Time (m1 fast time) [ 15s ]

Set the time to normal speed (not slowed down), ranging from 1 to

30 seconds.

- Motor 2 Normal Speed Time (m2 fast time) [ 15s ]

Set the time to normal speed (not slowed down), ranging from 1 to

30 seconds.

Note: The slow-down time, on closing and on opening, is obtained

by timing one manoeuvre, and setting a lower value within this pa-

rameter. If, forexample,one manoeuvrelasts25 seconds,set“normal

speed time”to 20s to obtain 5s of slow-down time, both on closing

and on opening.

- Slow-down speed (slov speed) [ 0 ]

Set the slow-down speed by choosing from the following values:

0 – slow-down disabled

1 – slow-down to 50% of normal speed

2 – slow-down to 33% of normal speed.

3 – slow-down to 25% of normal speed.

10.2) LOGIC MENU (logic.)

- TCA (TCA) [ OFF ]

ON Activates automatic closing

OFF Excludes automatic closing

- 3 Steps (3 step) [ OFF ]

ON Enables 3-step logic. A Start impulse has the following eects:

door closed:..........................................................................................opens

on opening:................................stops and enters TCA (if congured)

door open:..............................................................................................closes

on closing:.....................................................................stops and reopens

OFF Enables 4-step logic. A Start impulse has the following eects:

door closed:...........................................................................................opens

on opening:................................stops and enters TCA (if congured)

door open:..............................................................................................closes

on closing:...................................stops and does not enter TCA (stop)

after stopping: .....................................................................................opens

- Impulse lock (ibl open) [ OFF ]

ON The Start impulse has no eect during the opening phase.

OFF The Start impulse becomes eective during the opening or

closing phase.

- Rapid closing (fast cls) [ OFF ]

ON Closes thegateafterphotocelldisengagement, beforewaitingfor

the end of the TCA set.

OFF Command not entered.

- Photocells on opening photc. open [ OFF ]

ON

In case of obscuring, this excludes photocell operation on opening.

During the closing phase, it immediately reverses the motion.

OFF In case of obscuring, the photocells are active both on opening

and on closing.When a photocell is obscured on closing, it reverses

the motion only after the photocell is disengaged.

- Photocell test (test phot) [ OFF ]

ON Activates photocell check

OFF Deactivates photocell check

If this setting is not activated (OFF), it inhibits the photocell che-

cking function, allowing connection of devices not provided with

additional checking contact.

- Gate-open or 2nd radio channel warning light (SCA 2ch) [ OFF ]

ON The output between terminals 25 and 26 is congured as Gate-

open warning light, in this case the 2nd radio channel controls

pedestrian opening.

OFF The output between terminals 25 and 26 is congured as 2nd

radio channel.

- Motors in operation (1 mot ON) [ OFF ]

ON Only motor 2 is in operation (terminals 1 and 2).

With this conguration, the pedestrian input is disabled.

OFF Both motors are in operation.

VIRGO - 19

D811415A_03

INSTALLATION MANUAL

ENGLISH

- Lock hold (bloc persist) [ OFF ]

ON To be used when opening and closing mechanical backstops

are tted.

This function activates leaf pressure on the backstop, without this

being considered as an obstacle by the ampere-stop sensor.

Then the leaf continues its stroke for another 0,5s, after intercep-

ting

the limit switches.Therefore the limit switches are triggered

slightly

in advance, and the leaves will stop perfectly on the end

stop plate.

OFF To be used when no mechanical backstops are tted.

Movement is exclusively stopped by the limit switches being trig-

gered; in this case it is necessary to set the opening and closing

limit switch triggering point with precision.

- Prealarm (preal) [ OFF ]

ON The blinker comes on about 3s before the motors start.

OFF The blinker comes on at the same time as the motors start

- Fixed code (fixed code) [ OFF ]

ON The receiver is congured for operation in xed-code mode, see

paragraph on“Radio Transmitter Cloning”.

OFF The receiver is congured for operation in rolling-code mode, see

paragraph on“Radio Transmitter Cloning”.

- Radio transmitter programming (radio prog) [ ON ]

ON This enables transmitter storage via radio:

1 – First press the hidden key (P1) and then the normal key (T1, T2,

T3 or T4) of a transmitter already memorised in standard mode

by means of the radio menu.

2 – Within 10s press the hidden key (P1) and the normal key (T1,

T2, T3 or T4) of a transmitter to be memorised.

The receiver exits the programming mode after 10s, other new

transmitters can be entered before the end of this time.

This mode does not require access to the control panel.

OFF This disables transmitter storage via radio.

The transmitters can only be memorised using the appropriate

Radio menu.

- Motor logic reversal (change mot.) [ OFF ]

ON Mot.1: it is the rst to start on opening and the last to start on clo-

sing.

Mot.2: it is the last to start on opening and the rst to start on clo-

sing.

OFF Mot.1: it is the last to start on opening and the rst to start on clo-

sing.

Mot.2: it is the rst to start on opening and the last to start on closing.

10.3) RADIO MENU (RADIO)

- Add

Allows you to add one key of a radio control device to the receiver

memory; after storage it displays a message showing the receiver

number in the memory location (from 01 to 64).

Add Start button (add start)

associates the required key to Start command

Add 2ch button (add 2ch)

associates the required key to 2nd radio channel

- Read (read)

Checks one key of a receiver; if stored it displays a message showing

the receiver number in the memory location (from 01 to 64), and the

key number (T1, T2, T3 or T4).

- Eliminate list (erease 64)

WARNING! Completely removes all memorised radio control devices

from the receiver memory.

- Receiver code reading (RX code)

This displays the code entered in the receiver.

Consult paragraphs 12-13-14-15 for further information concerning

the advanced functions of the Clonix incorporated receiver.

10.4) LANGUAGE MENU (language)

Allows you to set the language on the display programmer.

- ITALIAN (ITA)

- FRENCH (FRA)

- GERMAN (DEU)

- ENGLISH (ENG)

- SPANISH (ESP)

10.5) DEFAULT MENU (default)

Restores the preset default values on the control unit. After restoring, a

new autoset operation must be carried out.

10.6) DIAGNOSTICS AND MONITORING

The display on the LINX panel shows some useful information, both

during normal operation and in the case of malfunctions.

Diagnostics:

In the case of malfunctions, the display shows a message indicating

which device needs to be checked:

PED = PED input activation

STRT = START input activation

STOP = STOP input activation

PHOT = PHOT input activation

FLT = FAULT input activation for checked photocells

SWO1 = activation of Motor 1 opening limit switch input

SWC1 = activation of Motor 1 closing limit switch input

SWO2 = activation of Motor 2 opening limit switch input

SWC2 = activation of Motor 2 closing limit switch input

In the case where an obstacle is found, the LINX panel stops the door

and activates a reverse manoeuvre; at the same time the display shows

the“AMP”message.

Monitoring:

During the opening and closing phases, the display shows four digits

separated by a dot, for example 35.40. The digits are constantly updated

during the manoeuvre, and represent the maximum torque reached by

motor 1 (35) and motor 2 (40).

These values allow the torque setting to be corrected.

Ifthemaximumtorquevaluereachedduringthemanoeuvregetssensibly

close to the value set in the parameter menu, malfunctions may occur

in the future following wear or slight door deformation.

It is therefore advisable to check the maximum torque reached during

some of the manoeuvres carried out in the course of installation, and

if necessary set a value about 15-20 percent points higher in the para-

meter menu.

10.7) AUTOSET MENU (autoset)

Allows you to automatically set the Motor torque.

WARNING!!Theautosetoperationisonlytobecarriedoutafterchecking

the exact leaf (opening/closing) movement, and correct limit-switch

activation.

As soon as the OK pushbutton is pressed, the “.... ....” message is displa-

yed, and the control unit executes an opening manoeuvre followed by

a closing manoeuvre, during which the minimum torque value needed

for leaf movement is automatically set.

During this phase, it is important to avoid obscuring the photocells, as

well as using the START, STOP or PED commands and the display.

After this, if autosetting has been successfully completed, the control

unit displays the “OK” message and, after pressing any key, returns to

the Autoset menu.

If,onthe otherhand,the controlunitdisplaysthe“KO”message,itmeans

thattheautosetprocedurehasnotbeensuccessfullycompleted;itisthus

necessary tocheck thewear conditionof thegate andthe regularmove-

ment of the leaves before proceeding to a new autoset operation.

WARNING! During the autoset phase, the obstacle detection function is

notactive,thereforetheinstallermustcontroltheautomationmovement

and prevent persons and things from approaching or standing within

the automation working range.

In the case where buer batteries are used, autosetting must be carried

out with the control panel supplied by mains power voltage.

WARNING: Check that the impact force value measured at the

points established by the EN 12445 standard is lower than that

specied in the EN 12453 standard.

Incorrect sensitivity setting can cause injuries to persons or

animals, or damage to things.

11) STATISTICS

Having connected the Universal palmtop programmer to the control

unit,enterthe CONTROL UNIT/STATISTICSmenuandscrollthescreenful

showing the statistical parameters:

- Board microprocessor software version.

- Number of cycles carried out. If motors are replaced, count the

number of manoeuvres carried out up to that time.

- Number of cycles carried out from the latest maintenance opera-

tion.

It is automatically set to zero after each self-diagnosis or parameter

writing.

20 - VIRGO

D811415A_03

INSTALLATION MANUAL ENGLISH

- Date of latest maintenance operation.To be updated manually from

the appropriate menu“Update maintenance date”.

- Installation description. 16 characters can be entered for installation

identication.

12) INTEGRATED RECEIVER TECHNICAL SPECIFICATION

Receiver output channels:

- output channel 1, if activated, controls a START command.

- output channel 2, if activated, controls the excitation of the 2nd radio

channel relay for 1s.

Transmitter versions which can be used:

all Rolling Code transmitters compatible with .

ANTENNA INSTALLATION

Use an antenna tuned to 433MHz.

For Antenna-Receiver connection, use RG8 coaxial cable.

The presence of metallic masses next to the antenna can interfere with

radioreception.Incaseofinsucienttransmitterrange,movethean-

tenna to a more suitable position.

13) RECEIVER CONFIGURATION

Theon-boardreceivercombinescharacteristicsofutmostsafetyincopy-

ing variable code (rolling code) coding with the convenience of carrying

out transmitter“cloning”operations thanks to an exclusive system.

Cloning a transmitter means creating a transmitter which can be au-

tomatically included within the list of the transmitters memorised in

the receiver, either as an addition or as a replacement of a particular

transmitter.

Cloning by replacement is used to create a new transmitter which takes

the place of the one previously memorised in the receiver; in this way

a specic transmitter can be removed from the memory and will no

longer be usable.

Thereforeit willbepossibletoremotelyprogramalargenumberofadditional

transmitters or, for example, replacement transmitters for those which have

been lost, without making changes directly to the receiver.

When coding safety is not a decisive factor, the on-board receiver allows

you to carry out xed-code additional cloning which, although abando-

ningthe variable code, providesahigh number ofcodingcombinations,

therefore keeping it possible to“copy”any transmitter which has already

been programmed.

PROGRAMMING

Transmitterstoragecanbecarriedoutinmanualmodeorbymeansofthe

Universal palmtop programmer which allows the complete installation

database to be managed through the Eedbase software.

In this second case, receiver programming takes place through the con-

nection of Universal palmtop programmer to the LINX control panel,

using the UNIFLAT and UNIDA accessories as indicated in Fig. 18.

14) MANUAL PROGRAMMING

In the case of standard installations where advanced functions are not

required, youcanproceedtomanualstorageof thetransmitters,making

reference to g. B for basic programming.

- If you wish the transmitter to activate output 1 (START) by means of

key1, key2, key3 or key4, enter the transmitter in menu“Start key”, as

in g. B.

- If you wish the transmitter to activate output 2 (2nd radio channel

relay) by means of key1, key2, key3 or key4, enter the transmitter in

menu“2nd ch. key”, as in g. B.

Note:HiddenkeyP1appearsdierentlydependingonthetransmitter

model.

For transmitters with hidden key, press hidden key P1 (g. B1). For

transmitters without hidden key, the key P1 function corresponds

to simultaneously pressing the 4 transmitter keys or, after opening

the battery compartment, bridging the two P1 points by means of

a screwdriver (g. B2).

IMPORTANT NOTE:ATTACHTHEADH ESIVEKEYLABELTOTHE FIRST

MEMORISED TRANSMITTER (MASTER).

In the case of manual programming, the rst transmitter assigns the

key code to the receiver; this code is necessary in order to carry out

subsequent cloning of the radio transmitters.

15) RADIO-TRANSMITTER CLONING

Rolling-code cloning / Fixed-code cloning

Make reference to the Universal palmtop programmer Instructions and

the CLONIX Programming Guide.

15.1) ADVANCED PROGRAMMING: COLLECTIVE RECEIVERS

Make reference to the Universal palmtop programmer Instructions and

the CLONIX Programming Guide.

16) LIMIT SWITCH ADJUSTMENT (Fig.12)

• Identifytheopeningandclosinglimitswitches(FC1andFC2)taking

into account that:

FC1 corresponds the CLOSING limit switch

FC2 corresponds the OPENING limit switch.

• Withthegatecompletelyclosedoropened,rotatethecorresponding

cam until the relevant limit microswitch is heard being tripped, then

lock the cam into position by means of the appropriate screws.

• Checkthatthelimitswitchesaretriggeredcorrectly,byinitiatinga

few complete motor-driven opening and closing cycles.

• Ifthe“lockhold”logicissettoONintheLINXpanel,theleafcontinues

itsstrokeforabout0,5seconds,inordertoensurestabilityandperfect

leaf stopping against the end-of-stroke backstops.

17) EMERGENCY MANOEUVRE (Fig.19)

In the case where the power supply is o, or any faults are present, the

manual emergency manoeuvre can be carried out by operating the

external release lever (Fig.1 ref.”S”).

1) Insert the release key and turn it clockwise (Fig.19 ref.”1”).

2) Move lever“S” until the lock is released (Fig.19 ref.”2”).

3) Keep the lever in the release position by turning the key clockwise

(Fig.19 ref.”3”).

4) Push the leaf slowly to open or close the gate.

To reactivate motor-driven operation, turn the key clockwise to free the

lever from its released position, then return it to its initial position for

normal operation.

18) MANUAL WIRE RELEASE DEVICE (Fig.13)

The manual emergency release can be operated by a wire device:

- Take all the metal cable out of the sheath and insert it into the release

lever.

- Lock the sheath and suitably adjust its position by means of the

appropriate screw.

- The cover is provided with a section to be torn o for the sheath to

go through.

- Forfurtherinformation,refertothespecicinstructionsfortherelease

device.

19) VIRGO BAT KIT INSTALLATION

- Fix the SBS board on the back of the panel box by means of a screw,

as indicated in Fig.14.

- Fix the board protection box (Fig.14 - “C”) supplied with the kit.

-

Position the two batteries on the supports, as indicated in Fig.14 (“A”).

- Secure the batteries using the bracket and screws supplied.

- Proceed to wire the SBS board with reference to the diagram in

Fig.14.

20) AUTOMATION CHECK

Before allowing the automation to be used normally, carry out the

following procedure very carefully:

• Check the correctfunctioning of all safety devices (limit micro-

switches, photocells, sensitive edges etc.).

• Checkthatthethrust(anti-squash)forceoftheleafiswithinthelimits

set by current regulations.

• Checkthemanualopeningcommand.

• Checktheopeningandclosingoperationswiththecontroldevices

in use.

• Checkthestandardandcustomisedelectronicfunctioninglogic.

21) AUTOMATION OPERATION

Since the automation can be remote-controlled by means of a remote

control device or a start button, and so out of sight, the good working

order of all the safety devices should be checked regularly. In the event

of any anomalous functioning of the safety devices, consult a speciali-

sed technician immediately. Keep children at a safe distance from the

automation operation area.

VIRGO - 21

D811415A_03

22) CONTROL

Theautomationisusedforthepower-operatedopeningandclosingofthe

gate.Thecontrolcanbeofanumberoftypes(manual,remote-controlled,

magnetic badge access control, etc.) depending on requirements and

the characteristics of the installation. See the specic instructions for

the various control systems. Users of the automation must be instructed

about its control and operation.

23) MAINTENANCE

Disconnect the power supply when carrying out any maintenance

operations.

• LubricatetheVIRGOs of the manoeuvring arm regularly.

• Cleanthelensesofthephotocellseverysooften.

• Haveaqualiedperson(installer)checkcorrectmotortorqueset-

ting.

• Intheeventofanyanomalousfunctioningwhichcannotberesolved,

disconnect the power supply and contact a specialised technician

(installer). Whilst the automation is out of order, activate the manual

release to allow manual opening and closing.

24) SCRAPPING

WARNING! This operation should only be carried out by qualied

personnel.

Materials must be disposed of in conformity with the current regula-

tions.

In case of scrapping, the automation devices do not entail any particular

risksordanger.Incaseofmaterialsto berecycled,theseshouldbe sorted

out by type (electrical components, copper, aluminium, plastic etc.).

25) DISMANTLING

WARNING! This operation should only be carried out by qualied

personnel.

When the automation system is disassembled to be reassembled on

another site, proceed as follows:

• Disconnectthepowersupplyandtheentireexternalelectricalin-

stallation.

• Inthecasewheresomeofthecomponentscannotberemovedor

are damaged, they must be replaced.

WARNINGS

Correct controller operation is only ensured when the data contai-

ned in the present manual are observed. The Company is not to

be held responsible for any damage resulting from failure to

observetheinstallation standardsandtheinstructionscontained

in the present manual.

The descriptions and illustrations contained in the present manual

are not binding.The Company reserves the right to make any alte-

rations deemed appropriate for the technical, manufacturing and

commercialimprovementoftheproduct,whileleavingtheessential

product features unchanged, at any time and without undertaking

to update the present publication.

INSTALLATION MANUAL

ENGLISH

22 - VIRGO

D811415A_03

+

OK

Fig. A

OK

Press the OK key

BFT

LINX 1.0

0000

0000

00

PARAM

LOGIC.

OK

+/-

+/-

OK

ACCESS TO MENUS

FOLLOWING MENUS

FIG. B

OK

8888

-

+

-

+

Control unit software version

No.total manoeuvres

(in thousands)

No.manoeuvres since latest

maintenance(in thousands)

No.radio control devices

memorised

LEGENDA

[ 00 ] Preset value

Parameter increment/reduction

or ON/OFF commutation

Menu scrolling

(+ = preceding - = following)

Press OK key (Enter/confirm)

Message: Programming in progress

PRG

OK

+/-

-

+

/ON

/OFF

Message: KO! (value or function error)

Simultaneously press the + and - keys.

Simultaneous pressure of the + and – keys allows

youtoexittheactivemenuandreturntothe

preceding menu;if this takes place at the main

menu level, programming is exited and the display

switched off.

The modifications made are only confirmed if the

OK key is subsequently pressed.

+/-

END

+/-

END

Message:“Wait” (enter value or function)

-+

-+

-+

-+

-+

-+

-+

-+

-+

-+

-+

-+

OK

TCA

ON

OFF

[oFF]

OK

PRG

OK

3 step ON

OFF

[off]

OK

PRG

OK

ibl open ON

OFF

[off]

OK

PRG

OK

fast cls ON

OFF

[off]

OK

PRG

OK

Fotoc. open

ON

OFF

[off]

OK

PRG

OK

TEST PHOT

ON

OFF

[off]

OK

PRG

OK

SCA 2ch ON

OFF

[off]

OK

PRG

OK

i Mot ON

ON

OFF

[off]

OK

PRG

OK

BLOC persist

ON

OFF

[off]

OK

PRG

OK

Preal

ON

OFF

[off]

OK

PRG

OK

radio prog

ON

OFF

[on]

OK

PRG

OK

fixed code

ON

OFF

[off]

OK

PRG

OK OK

TCA [0010]

PRG

-+

OK

change mot

ON

OFF

[off]

OK

PRG

-+

-+

-+

-+

-+

-+

OK OK

[0050]

PRG

m1 t

OK OK

[0050]

PRG

m2 t

OK OK

[0045]

PRG

m1 t slow

-+

-+

OK OK

[0045]

PRG

m2 t slow

OK OK

[0010]

PRG

open delay time

OK OK

cls delay

time

[0010]

PRG

OK OK

m1 fast time

[0050]

PRG

OK OK

[0050]

PRG

OK OK

slow speed [0000]

PRG

m2 fast time

VIRGO - 23

D811415A_03

Fig. B

DEFAULT

T1

T2

T1

T2

T3

T4

12 3

T1 T2 T1 T2

T3 T4

RADIO

AUTOSET MENU

It automatically sets the motor torque.

WARNING! During the autoset phase, the obstacle

detection function is not active, therefore the installer

must control the automation movement and prevent

persons and things from approaching or standing

within the automation working range.

PRECEDING MENUS

FIG. A

OK OK

-

+

-

+

-

+

-

+

+/-

END

+/-

END

OK

+/-

. . . . . .

OK

AUTOset

+/-

END

language

ITA

FRA

DEU

ENG

esp

OK OK

OK

OK

OK

OK

+/-

END

-

+

-

+

-

+

-

+

OK

OK

PRG

Press P1 (pushbutton) on radio

control device

Press the required T (key) on

radio control device – see Fig. B3

Press the required T (key) on

radio control device – see Fig. B3

Release P1 on radio

control device

ADD start

hidden button release

desired button

01

PRG.

READ

OK

OK

OK

ERASE 64

-

+

-

+

Press P1 (pushbutton) on radio

control device

Press the required T (key) on

radio control device – see Fig. B3

Release P1 on radio

control device

ADD 2ch hidden button release

desired button

01

OK

-

+

01 t1

COD RX

OK

1A9C

OK

22FD

OK

01

OK

-

+

+/-

RADIO MENU

ADD - Allows you to add one key of a radio control

device to the receiver memory; after storage it displays

a message showing the receiver number in the

memory location (from 01 to 64).

Add Start button

– associates the required key to

Start command

Add 2ch button

– associates the required key to 2nd

radio channel

READ - Checks one key on a receiver, if stored it

displays a message showing the receiver number in

the memory location (from 01 to 64), and the key

number (T1, T2, T3 or T4).

ERASE 64

WARNING! Completely removes all memorised radio

control devices from the receiver memory.

COD RX

Displays the receiver code.

Make reference to paragraph 11.

P1P1

P1

24 - VIRGO

D811415A_03

Fig. 1

Fig. 3

Fig. 2

Fig. 5

Fig. 6

SX

300 MIN

30

123

180

215

635

230

Fig. 4

SX

300 MIN

135123

63

63

335 120

90˚

390

230

120˚

390 230

120˚

90˚

Max. 210

335

VIRGO - 57

D811415A_03

Fig. 11

Fig. 8

Fig. 10

Fig. 9

Fig. 7

S

S

S

58 - VIRGO

D811415A_03

Fig. 12

A

C

VIRGO BAT

SBS

VIRGO - 59

D811415A_03

Fig. 15

Fig. 16 Fig. 17

LINX

JP1

(+)*

(-)*

60 - VIRGO

D811415A_03

Fig. 4Fig. 18

Fig. 19

LINX

UNIDA

UNIFLAT

8888

S

1

32

Conector programador palmar.

VIRGO - 61

D811415A_03

Other manuals for Virgo

1

Table of contents

Other Eelink Gate Opener manuals

Popular Gate Opener manuals by other brands

CAME

CAME TOP Series instructions

Motorline professional

Motorline professional KVM205 User& installer's manual

King gates

King gates STAR OPEN Installation and use instructions and warnings

Nice

Nice SlideSmart CNX 15 Installation and programming manual

Dea

Dea ghost 200 operating instructions

Nice

Nice hyke HK7024 Instructions and warnings for installation and use