EFO MFT4 User manual

- 1 -

MFT4 Multifunction Installation

Tester

- 2 -

User manual

Index

Safety information and explanation of symbols used..............................3

Features of the MFT4...................................................................................5

Special Polarity Test Function. ..................................................................6

Audible tones...............................................................................................7

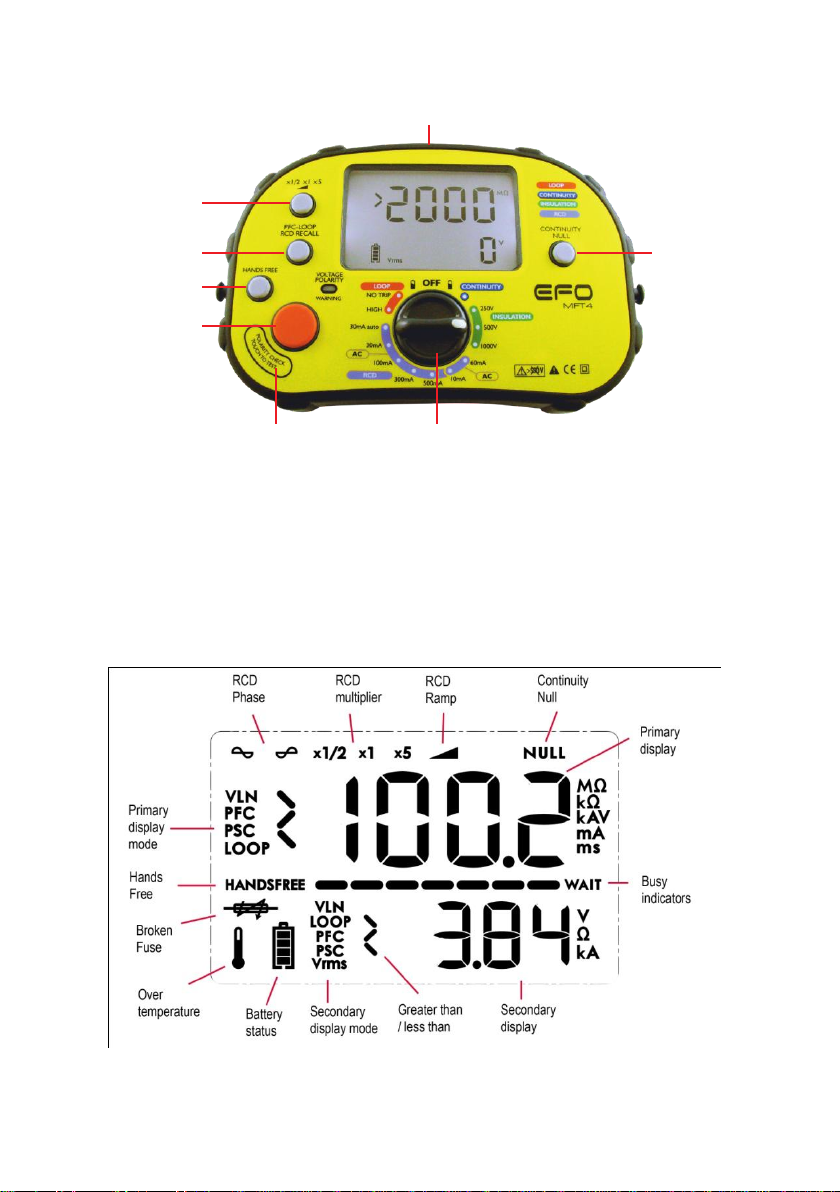

Overview of the switches and LCD .........................................................8

Test lead inputs............................................................................................9

Continuity Test Function...........................................................................10

Continuity Test Procedure.......................................................................10

Lead Nulling............................................................................................10

Hands Free Continuity Testing ................................................................11

Insulation Test Function............................................................................12

Insulation Test Procedure........................................................................12

Hands Free Insulation Testing.................................................................13

Loop Test functions...................................................................................14

High Current mode..................................................................................14

No Trip Mode...........................................................................................14

PFC/PSC.................................................................................................15

Test lead configuration............................................................................15

Lead configuration for No-Trip testing.....................................................16

Lead configuration for High current 2-wire testing...................................16

Loop Test Procedures .............................................................................17

No Trip Loop test (Zs) .............................................................................17

High current test (Ze)..............................................................................18

Hands Free Loop testing.........................................................................18

RCD Test Function.....................................................................................19

Ramp test................................................................................................20

Sinusoidal polarity (the 0° or 180° test)...................................................20

RCD test procedure ................................................................................21

User selected test ...................................................................................21

30mAAutomatic test ...............................................................................22

Ramp test................................................................................................22

Specifications and tolerances..................................................................23

Continuity Test Range Accuracy..............................................................23

Insulation Test Range Accuracy ..............................................................23

Insulation Output Voltage........................................................................23

Loop Test Range Accuracy......................................................................23

RCD Test Range Accuracy......................................................................24

- 3 -

Safety information and explanation of symbols used

Because the MFT4 is a multi function tester used for testing both live and dead

circuits there are different safety issues that apply to the individual functions.

Before using your MFT4 please read these instructions paying particular

attention to the general safety warnings below and those at the start of each

section.

Before using the tester check the case and the test leads for damage.

If any damage is noticed the unit should be withdrawn from service and

returned to place of purchase for repair.

It is important for safety that only one set of leads can be fitted at a time. In the

unlikely event that the interlock cover is damaged the tester should be

withdrawn from service and returned to place of purchase for repair.

Caution read this manual for safety information

The Continuity and Insulation functions are rated at 500V Category III

The Loop and RCD functions are rated at 300V Category IV

When installing batteries observe correct polarity do not mix old and new

batteries - Dispose of used batteries in accordance with local regulations.

Never incinerate batteries.

Do not use this tester in a manner other than that described in this booklet.

To clean the tester wipe with a damp cloth with a mild soap solution taking care

not to allow water ingress into the input terminals. Do not use solvents and do

not immerse. Allow the tester to fully dry before use.

The MFT4 is fuse protected against damage by accidental connection to an

over-voltage supply. The fuse is located inside the battery compartment and

can be accessed by removing the two small battery cover retaining screws on

the back of the case. Always ensure that test leads are disconnected before

removing the battery cover.

- 4 -

The broken fuse indicator on the LCD will flag if the fuse has blown. It must be

replaced with the correct type:

Fuse type: F 500mA fast blow ceramic 600V.

The enclosure is double insulated

Protected against over voltage to 550V

For safety reasons the tester is shipped without batteries fitted. To install

batteries remove the two small crosshead screws on the back of the

instrument that retain the battery cover and fit four Alkaline batteries type

AA / LR6 in accordance with the polarity shown.

The MFT4 complies fully with the requirements of EN61010.

The following table details the operating ranges for the individual functions

compliant with the performance requirements of EN61557.

MEASUREMENT

RANGE

OPERATING

RANGE

PER EN61557

OTHER

CONTINUITY

0.00 Ω - 19.99 kΩ.

0.1 Ω - 9.99kΩ.

IN>200mA

Uq < 7V

INSULATION

0.00 MΩ - 1999 MΩ

.

0.1 MΩ - 1990 MΩ.

IN= 1mA

LOOP HI-I

0.01 Ω - 500 Ω

1.04 Ω - 500Ω.

230V

50Hz

LOOP NO-TRIP

0.01 Ω - 500 Ω.

1.04 Ω - 500Ω.

230V

50Hz

RCD TRIP TIME

5 ms –1999 ms

38 ms –1999ms.

- 5 -

Features of the MFT4

The MFT4 is packed with design features that maximise both convenience and

safety. These include:

Large display

To give the clearest results the MFT4 uses a large auto-backlit LCD which

makes reading the test results easy even when used in poorly lit areas.

Auto shut down

To preserve battery life when not in use the MFT4 incorporates an Auto-Off

function that powers the unit down after three minutes of inactivity. To resume

use after an Auto shut down a single press of any of the function buttons will

power up the unit.

Battery check

The first position either side of the off position of the rotary selector switch is a

battery check function.

Extended battery life

For simplicity the tester is powered by just four conventional AA(LR6) alkaline

batteries. The MFT4 has much lower power consumption than most testers

and therefore gives excellent battery life.

In addition to the battery status indicator that shows on the LCD, when the

battery power is becoming very low the Red warning LED will light to show that

imminent replacement is necessary. Always use Alkaline rather than zinc

carbon batteries.

Easy to locate

The test lead inputs are located on the top of the case allowing the tester to

stand vertically or be laid flat. Alternatively the unit can be carried by the

supplied neck strap.

Hands Free

Most of the test functions can utilise the Hands-Free mode in which the tester

is primed to automatically start the test as soon as the probes are connected to

a circuit, thereby leaving your hands free to hold the test probes.

Socket wiring check

To protect both the user and the instrument against harm caused by accidental

connection to an incorrectly wired supply the tester will automatically check the

polarity upon connection to a live supply. If the wiring has been incorrectly

connected testing will be inhibited an alarm will sound with flashing LED.

- 6 -

Special polarity test function.

It is a little known fact that a system can be reverse wired with Line (Phase) to

earth/neutral and earth/neutral to Line (Phase). The sockets will all work and

conventional loop testers will show and test that everything is correct despite

this very dangerous wiring condition.

Although extremely rare, this miss wire condition can exist so if your test

shows this fault do not proceed –if in any doubt advise your customer to

contact their supply company immediately.

Correct Polarity

Reversed Polarity

- 7 -

Audible tones

A simple selection of audible tones is used to supplement the visual display.

These help the user by providing intuitive feedback during testing. In addition

to warning about dangerous or unstable supply conditions they provide a very

quick confirmation that the measurement process is taking place and, upon

completion of the test, a warning if the results are likely to be regarded as a

failure.

The meaning of the tone for each individual function is covered in detail in the

relevant section. Generally however there are five types of tone emitted.

Danger

A rising siren type

alarm

In the event of a potentially dangerous situation

such as connecting to a live supply when

configured for insulation testing. Will be

accompanied by the Red Voltage/Polarity warning

LED flashing.

Warning

A continuous 2 tone

alarm

An unsuitable supply configuration such as a

mains supply with incorrect polarity or having the

leads connected wrongly will be accompanied by

the Red Voltage/Polarity warning LED flashing.

Wait-Test in progress

A steady beeping

sound

Emitted whilst a measurement is in progress. The

same tone is sounded when used in Hands free

mode to indicate that continual measurement is

being made

Test completed

A single beep

Sounded upon completion of a measurement to

indicate that the result is being displayed

Alert

A short 2 tone alarm

Sounded when a test returns a result that is likely

to be regarded as a failure e.g.An insulation test

that gives a result of less than 2 MΩ

- 8 -

Test lead inputs

RCD

Muliplier

PFC-PSC /

RCD Recall

Polarity test

touch pad area

Hands free

Button

Test

Button

Function Selector

Continuity

Null Button

Overview of the switches and LCD

The Primary display of the large LCD shows the result of the test being

conducted. At the same time a secondary display area shows supporting

information e.g. for an insulation test the main display shows the resistance of

the insulation whilst the secondary display confirms the test voltage applied.

- 9 -

Test lead inputs

The test lead input/ output terminals are separated into two groups by the clear

sliding interlock cover.

When slid to the left (figure 1) the interlock cover exposes only the Black

terminal (marked -) and the Red terminal (marked +). These are used for the

Continuity and Insulation test functions.

For both of these functions two of the test leads from the TL-RGB set are used.

The Red 4mm Plug should be connected to the Red socket (+) and the Black

4mm plug connected to the Black socket (-)

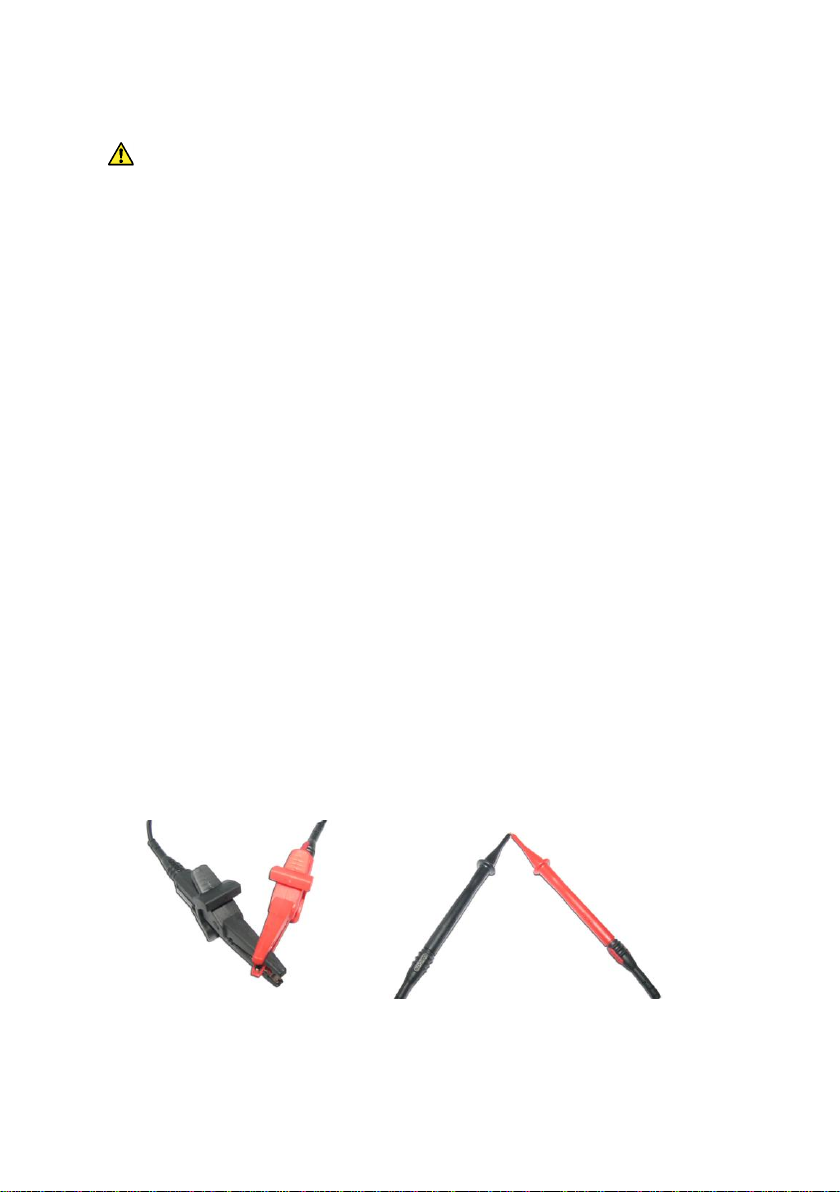

Fig.1 Interlock in position for Continuity and Insulation testing

Moving the interlock cover to the right (figure 2) blanks off these inputs and

exposes the Black (Neutral), Green (Earth) and Red (Line) inputs that are used

for Loop and RCD testing. This allows for connection of either the 10Amains

lead (TL-3P) or the 3-pole test lead set TL-RGB for the live testing functions.

When using these lead sets the Red 4mm plug is connected to the Red socket

(L), The Black 4mm plug to the Black socket (N) and the Green 4mm plug to

the Green socket (E).

Fig.2 Interlock in position for RCD & Loop testing

- 10 -

Continuity Test Function

Caution

If accidentally connected to a live circuit the Red warning LED will flash, a rising siren type

alarm will sound and testing will be inhibited. If this happens disconnect the probes from the

circuit and isolate the circuit it before continuing.

The tester is protected against being damaged by accidental connection to a live circuit but

for personal safety it is essential to ensure that the circuit is dead before working on it.

Continuity Test Procedure

Fit the Red test lead from the TL-RGB set into the Red (+) input terminal and

the Black lead into the Black (-) input terminal. Fit either the test prod or

crocodile clip to the other end of the test lead.

Select the Continuity test function by rotating the selection switch to the

‘CONTINUITY’ setting.

Lead Nulling

The purpose of continuity testing is to establish the resistance of the circuit

under test. However the continuity test function will measure the overall

resistance of the circuit between the two input terminals on the tester, this will

include the resistance of the test leads, an element that is not wanted in the

final result. Traditionally this would mean that the resistance of the test leads

would have to be measured and manually deducted from each subsequent

reading. The MFT4 has a handy feature known as lead nulling that does this

calculation for you.

To use the lead nulling feature hold the tips of the test prods very firmly

together (or clip the jaws of the crocodile clips together) and press the

‘CONTINUITY NULL’ button on the tester. This will start a measurement of the

resistance of the pair of test leads and display the result.

Nulling Crocodile clips and prods. Note: The two lower static jaws of the crocodile clips should contact

each other when nulling. Prods should be held very firmly together.

- 11 -

The word ‘NULL’ will now appear in the display and all subsequent continuity

tests conducted by pressing the Orange test button will automatically deduct

this value before displaying the result. To confirm that this is working press the

Orange test button with the prod tips still connected together and the display

should show zero resistance.

You can now use the Orange test button to measure the resistance of a circuit

in either manual or Hands Free mode and the result shown will be that of the

circuit tested and not include the resistance of the test leads.

This will continue as long as the ‘NULL’ indicator appears lit in the LCD, which

will be until the tester is switched off either manually or as a result of the Auto

off feature. If the instrument is powered off by either method it will be

necessary to null the leads again before further testing.

Hands Free continuity testing

To enable the hands free feature simply press the HANDS FREE button once,

The ‘HANDSFREE’ annunciator will appear flashing on the LCD and will

continue to do so until canceled by a further press of the HANDS FREE button

or by changing the function selector switch.

When the HANDSFREE annunciator is flashing a single press of the Orange

test button will toggle continuous testing on and off.

Once started a steady beeping tone will be emitted to indicate that

measurement is being taken.

After a second or two the test result will be displayed in the primary display

area and an audible tone will indicate either by a single beep that the result is a

value under 20 KΩor by a short 2-tone alarm that the result is a value over

19.99 KΩ. The secondary display area will show the terminal voltage being

applied.

The tester will continue to take measurement and any further change to the

resistance of the circuit will be indicated by an audible tone as described above

and a change of result on the display.

A further single press of the test button will suspend measurement.

- 12 -

Insulation Test Function

Caution

Do not touch the metal jaws of the crocodile clips (or prod tips) when using the Insulation test

function in either manual or hands free mode as they will be energised during testing.

The Insulation function is for use on dead circuits only. If accidentally connected to a live

circuit the Red warning LED will flash, a rising siren type alarm will sound and testing will be

inhibited.

The tester is protected against being damaged by accidental connection to a live circuit but

for personal safety it is essential to ensure that the circuit is dead before working on it

All equipment and appliances should be disconnected from the circuit under test. Attached

equipment may be damaged by the higher voltages applied during testing and may return an

artificially low test result.

There may be capacitance on the circuit being tested (a longer than normal test time will

indicate this condition). Your tester will automatically discharge this but do not disconnect the

test leads until this auto discharge has completed.

Insulation test procedure

Fit the Red test lead from the TL-RGB set into the Red (+) input terminal and

the Black lead into the Black (-) input terminal. Fit either the test prod or

crocodile clip to the other end of the test lead.

Select the voltage range that you wish to test at by turning the function

selection switch to the 250V, 500V or 1000V setting within the Insulation test

range.

Connect the Red test probe to the phase conductor and the Black probe to the

other conductor being tested and press the Orange test button.

During Insulation testing the MFT4 will audibly indicate that measurement is

being made by emitting a steady beeping sound.

The Red Voltage/Polarity LED will flash to warn that there is a voltage potential

at the probe tips/crocodile clips and the primary display will show only the

dashes chasing across the LCD that also indicate that measurement is being

made. The secondary display will show the voltage being applied during the

test.

Once the test is complete the result will be shown in the LCD primary display

area whilst the secondary display will revert to 0V to confirm that there is no

longer any voltage between the test probes. A single beep will indicate that the

result of the test is resistance above 2 MΩwhilst a short 2-tone alarm will

sound if the result is below 2 MΩ

- 13 -

Hands Free Insulation testing

To enable the hands free feature simply press the HANDS FREE button once,

The ‘HANDSFREE’ annunciator will appear flashing on the LCD and will

continue to do so until cancelled by a further press of the HANDS FREE button

or by changing the function selector switch.

When the HANDSFREE annunciator is flashing a single press of the Orange

test button will toggle continuous testing on and off.

Once started a steady beeping tone will be emitted to indicate that

measurement is being taken.

After a second or two the test result will be displayed in the primary display

area and an audible tone will indicate either by a single beep that the result is a

value above 2MΩor by a short 2-tone alarm that the result is a value under

2MΩ. The secondary display area will show the terminal voltage being applied.

The tester will continue to take measurements and any further change to the

resistance of the circuit will be indicated by an audible tone as described above

and a change of result on the display.

Whilst testing in hands free mode continues the Red warning LED will flash to

warn of the voltage between the prod tips/crocodile clips.

A further single press of the test button will suspend measurement.

- 14 -

Loop test functions

Caution

Although fully protected against over voltage to 440V this tester should only be used on a

240V 50Hz supply

Important note for calibration check box users: The smart loop test system used by the MFT4

is immune to sudden high value changes such as voltage spikes. As a result when changing

calibration or check box loop values the tester or the supply must be switched off between

changes

Over temperature. If this symbol shows in the display the temperature of the unit has

reached a point where the performance accuracy could not be guaranteed. Allow the tester

to cool down before proceeding

The MFT4 Loop test function has 2 modes for Loop testing that allow the user

to conduct the most accurate test possible whether or not the circuit under test

is protected by an RCD.

High Current mode

For Ze testing at the distribution board or at any point upstream of RCD

protection there is a traditional fast high current test mode. The high current

mode is a 2-wire test that enables the user to test the true impedance of both

the Line-Neutral Loop and the Line–Earth Loop and therefore to establish both

the PSC (prospective short circuit current) and the PFC (prospective fault

current) for the installation.

Unlike most testers that only measure the resistance of the Loop, the high

current mode of the MFT4 will measure the true Impedance of the Loop which

includes an element of reactance. This can be significant where the distribution

board is close to the mains supply transformer and is therefore much more

accurate than older Loop testing techniques.

You should be aware that because of this there may well be variations in

readings compared to ordinary loop testers or to the no-trip function of this

tester, particularly when the measurement is made near to the mains supply

transformer.

No Trip Mode

For Zs testing where the circuit being tested is protected by an RCD there is

the new NTL (No Trip Loop) mode. In this mode testing can be made at

sockets on the final circuit without fear of tripping the RCD.

This is achieved by testing at a current that is too low to trip an RCD on an

otherwise healthy circuit.* The No Trip test is a 3-wire test that also checks the

Live, Neutral / Earth conductors are correctly connected before running the

loop test.

- 15 -

Whilst No-Trip testing at points on the final circuit will normally function with a

high level of accuracy, it should be noted that the low current measurement

technique used is more likely to be adversely affected by external factors.

Circumstances such as testing at seldom used socket outlets with tarnished

contacts or testing a circuit with a lot of background noise from electronic

apparatus can result in the occasional erroneous reading.

For this reason it is recommended that multiple measurements are made when

using the No-trip mode and any isolated odd results are ignored. When taking

multiple readings the tester should be disconnected from the supply between

consecutive tests

For safety reasons the No-Trip mode is recommended for all measurements

made on TT systems.

* Where practical all other equipment powered by the same circuit should be

switched off before testing. This will reduce the chances of the RCD tripping as

a result of combined leakages.

PFC/PSC

In both Loop test modes the MFT4 will also display the supply voltage and at

the touch of the PFC button the PFC/PSC will be displayed.

Test lead configuration

The MFT4 Loop test function can be used with 2 different types of connecting

lead. It is important to understand and use the correct lead configuration for

each test mode or you may not obtain the correct results.

Lead options

1 Ref: TL-3P The mains lead with 3 x 4mm plug to 10A plug

2 Ref: TL-RGB The 3-Pole distribution board test lead set that can be fitted

with either prod tips or crocodile clips as required.

The lead is an integral part of the tester set-up and should accompany the

tester when being returned for re-calibration or service. Do not use any other

type of mains lead or test lead set.

- 16 -

Lead configuration for No-Trip testing

In No-trip mode the tester can be used with the mains lead TL-3P when testing

at 10A socket outlets, or the distribution board lead set TL-RGB for testing at

other points in the circuit. In No-trip mode the 3 colour coded prods/crocodile

clips of the test lead should be connected to the corresponding Line, Neutral

and Earth terminals.

Lead configuration for High current 2-wire testing

The high current test mode requires the use of the distribution board lead set

TL-RGB configured in 2-wire mode.

To arrange the test leads in 2-wire mode pull the black prod or crocodile clip off

the black test lead and plug the black probe into the back of the Green 4mm

connector as shown below. You will now have the Earth and Neutral leads

connected together ready for connection to the Earth or Neutral conductor to

be tested.

Fig 3. Prods in 2 wire testing configuration

Fig 4. Crocodile clips in 2 wire testing configuration

- 17 -

Mains supply wiring and voltage test

When first connected to a mains supply the MFT4 will automatically conduct a

safety test to ensure that the Live, Neutral and Earth conductors are all

connected correctly and that the supply voltage is in the acceptable range

( 207-264V ).

If all is well the VOLTAGE/POLARITY warning LED will light Green and the

supply voltage will be displayed in the primary display area.

In the event of a problem with either the mains voltage supply or reversed

connections the VOLTAGE/POLARITY warning LED will light Red, a warning

tone will be sounded and testing will be inhibited.

Loop Test Procedures

No Trip Loop test (Zs)

Rotate the function selector switch to ‘NO TRIP’.

Connect the test lead to the socket/circuit under test.

Providing that the connections are correct and the supply voltage is within the

correct range the VOLTAGE/POLARITY LED will light Green, the MFT4 will

start taking some background measurements and will display the Line-Neutral

supply voltage.

Touch the touch-pad area next to the test button. There should be no change

in the indication given. If the Voltage/Polarity LED flashes Red and a warning

tone is emitted when the touch-pad is touched a potentially dangerous polarity

reversal exists see page 7 for example. Do not proceed. If in any doubt advise

the customer to contact the electricity supply company immediately.

Press the test button to start the loop test. While measurement is being taken

the primary display will go blank whilst the secondary display will continue to

show the supply voltage accompanied by a steady beeping tone.

The result of the test will be shown in the primary display.

A single press of the PFC- Loop button will toggle the display so that the PFC

is shown in the primary display and the impedance in the secondary display. A

further press will toggle the results between the primary and secondary

displays.

- 18 -

High current test (Ze)

The high current should only be conducted with the distribution board test lead

set TL-RGB configured in 2 wire mode. Do not use this function with the TL-3P

mains lead or the distribution lead set in 3-wire configuration.

Rotate the function selector to the HIGH position.

Connect the test lead probes to the circuit under test and press the test button.

The result will be shown in the primary display and the mains voltage will be

shown in the secondary display.

Press the PFC-LOOP button to show the PFC/PSC in the primary display and

the impedance in the secondary display area.

Note: The reading described here as PFC/PSC will be the prospective fault current for

the circuit being immediately tested. This is known as PSC in the case of a test between

Live and Neutral or PFC for a test between Live and Earth conductors.

Hands Free Loop testing

The hands free feature can be used in either No Trip or high current test

modes.

To enable the hands free feature simply press the HANDS FREE button once,

The ‘HANDSFREE’ annunciator will appear flashing on the LCD and will

continue to do so until cancelled by a further press of the HANDS FREE button

or by changing the function selector switch.

When the HANDSFREE annunciator is flashing all you need to do is connect

the test lead to a mains supply and the test will be automatically carried out.

- 19 -

RCD Test Function

Caution

Although fully protected against over voltage to 440V this tester should only be used on a

240V supply

The MFT4 will test RCD standard (AC) types across the full range of tests

required.

Test requirements

Each RCD should be tested to ensure that:

It operates with a maximum disconnection time indicated in the table when a

fault at its rated current is introduced. This is referred to as the x1 test.

Residual Tripping

Current

Maximum Tripping

Time

10mA

40mS

30mA or Other

300mS

Recommended Additional Tests For 30mA RCD’s

It is not prone to ‘nuisance’ tripping and does not trip when a fault of

half its rated current is introduced. This is referred to as the x½ test

In the case of an RCD rated at 30mA it should operate with a

maximum disconnection time of 40ms when a fault of five times its

rated current is introduced. This is referred to as the x5 test.

For the reasons explained below all of the above tests have to be conducted at

both 0° and 180°.

The user friendly design of the MFT4 simplifies the test process by enabling

you to do any of these tests by making just two function selections.

Automatic test

For the most commonly encountered 30mA RCD the test process is even

simpler. Just turn the rotary selector to the ‘30mA AUTO’ setting and the MFT4

will conduct all six (1/2x, 1x, 5x at both 0oand 180o) tests at the single touch of

a button.

Pass or Fail result

- 20 -

In addition to displaying the time taken for the RCD to trip the MFT4 will also

indicate whether it has passed or failed the RCD test requirements.

Ramp test

The MFT4 also includes a diagnostic Ramp test feature. In this mode rather

than applying a steady fault current and measuring the time taken for the RCD

to trip, the MFT4 gradually increases the fault current and identifies the level of

additional leakage at which the RCD trips.

This is particularly useful in diagnostic testing of circuits where nuisance

tripping is a problem and helps to identify the difference between an over

sensitive RCD and excessive leakage from poor insulation or equipment with

high leakage.

Sinusoidal polarity (the 0° or 180° test)

RCD’s often operate with different reaction times depending upon whether the

fault is introduced during the positive or negative half cycle of the AC

waveform. Therefore to accurately determine the maximum response time of

an RCD it is necessary to test it twice at each given fault current, firstly with the

fault introduced during the positive half cycle and secondly during the negative

half cycle.

The MFT4 takes care of this for you by alternating the start point of

consecutive tests at any given setting. If for example you have selected a test

at the rated trip current (x1) of a 100mA RCD, the first press of the test button

will apply a 100mA fault current starting on the positive half cycle (0°)

and display the result.A further press of the test button will carry out another

test at the same current but starting on the negative half cycle

(180°).

Test leads

Where testing is to be conducted at a point on the circuit other than a socket

outlet the distribution board test lead set TL-RGB is used in 3-wire mode as

described in the previous chapter. The probes can be fitted with either prod tips

or crocodile clips as required.

Mains supply wiring and voltage test

When first connected to a mains supply the MFT4 will automatically conduct a

safety test to ensure that the Live, Neutral / Earth conductors are correctly

connected and that the supply voltage is in the acceptable range of 207-264V

.

If all is well the VOLTAGE/POLARITY warning LED will light Green and the

supply voltage will be displayed in the primary display area.

Table of contents

Popular Test Equipment manuals by other brands

Dwyer Instruments

Dwyer Instruments UHH2 Installation and operating instructions

Coretec

Coretec Trainer 1000 SE user manual

Agilent Technologies

Agilent Technologies 54610B User's and service guide

VOLTCRAFT

VOLTCRAFT MS-228 operating instructions

Agilent Technologies

Agilent Technologies 85056D User's and service guide

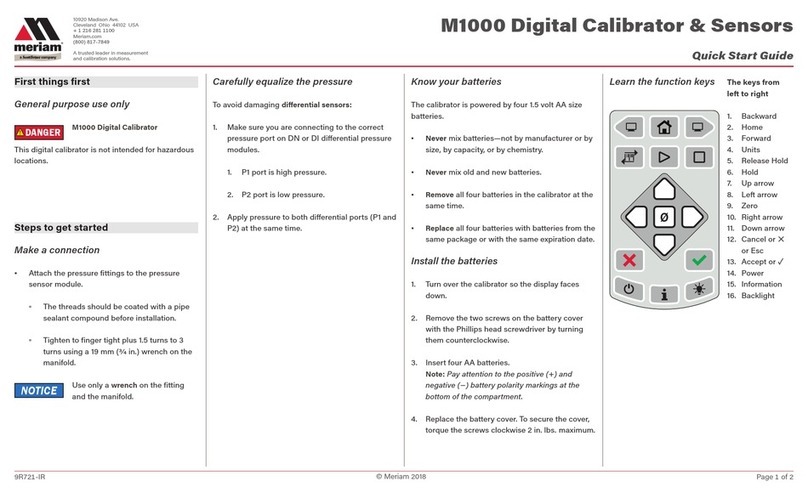

Meriam

Meriam M1000 quick start guide