TEN INNOVA 3000 User manual

TEN

TEN Automotive Equipment Ltd. ©Page 1 Version 5.0 November 2010

User Manual

INNOVA 3000

The contents of this manual and INNOVA 3000 software are the property of Test Equipment Nederland BV (Herein thereafter referred to as

TEN). Copying the manual or parts of the manual and software is strictly prohibited. For additional copies of the manual or software please

contact TEN.

The information contained in this manual is believed to be correct but does not purport to be all inclusive and should only be used as a guide.

TEN shall not be liable for errors contained herein or for any incidental or consequential damage, loss or injury arising from use of this guide or

their equipment.

The INNOVA 3000 is manufactured by TEN and conforms to requirements of, and in accordance with the EMC directive 89/336/EC.

TEN

TEN Automotive Equipment Ltd. ©Page 2 Version 5.0 November 2010

Table of contents

1 Introduction .................................................................................................................................................................3

2 Front Screen and Connection Panel...........................................................................................................................4

3 Specifications of the INNOVA 3000............................................................................................................................6

4 Principle and operation...............................................................................................................................................7

5 User information..........................................................................................................................................................8

6 Using the INNOVA 3000.......................................................................................................................................... 10

7 Periodic Checks....................................................................................................................................................... 11

8 Messages................................................................................................................................................................. 12

9 Program of the INNOVA 3000 ................................................................................................................................. 17

11 Official (MOT) test.................................................................................................................................................. 21

12 Standard test (MID)................................................................................................................................................ 22

13 System purge......................................................................................................................................................... 25

14 System diagnosis................................................................................................................................................... 26

15 User menu ............................................................................................................................................................. 30

16 Maintenance .......................................................................................................................................................... 33

17 Troubleshooting..................................................................................................................................................... 34

TEN

TEN Automotive Equipment Ltd. ©Page 3 Version 5.0 November 2010

1 Introduction

Thank you for choosing to purchase the INNOVA 3000 Exhaust Emissions Analyser manufactured by TEN

Automotive. Please take a few minutes to read this User Manual carefully!

The INNOVA 3000 is designed to comply with the highest technical and accuracy requirements of modern day,

mandatory vehicle testing, worldwide. The flexibility and smart design of the INNOVA 3000 facilitates a wide range

of options for testing and measuring exhaust emissions of vehicles with Petrol, Diesel, LPG and CNG engines.

The INNOVA 3000 boasts the achievement of gaining MID Type Approval, meeting the demands and technical

specification required for Government vehicle testing throughout Europe. The non dispersive, fully digital infrared

gas bench incorporates the component quality and technology required for high accuracy emissions testing, with

the minimum of maintenance. The gas processing system is protected from moisture and contamination by the

combined automatic drain and filtration system.

The heart of the INNOVA 3000 comprises of a powerful personal computer controlling the software processes and

program routines resulting in a clear, high resolution visual display presentation on the full colour flat panel monitor.

With data entry and software program control via the QWERTY keyboard and mouse, the INNOVA 3000 performs

easy, step by step test routines, with the minimum of effort. Test results can be stored on PC as well as printed on

the A4 colour printer.

For quick and comprehensive diagnosis the INNOVA 3000 is fitted with RPM and OIL/Engine Temperature

measurement capability with a range of accessories and adaptors to keep up with advances in motor vehicle

technology. These range from inductive RPM Clamps, Pulse Sensors and Oil Temperature Transducers to

“Bluetooth connectivity” Data interface devices such as OUBT, CobraScan and EDA2 “Compact” portable

smokemeter. Please contact your supplier for further information and available options.

Contact information:

TEN Automotive Equipment Ltd

Lubeck Road

North Lynn Industrial Estate

King’s Lynn

Norfolk

PE30 2JE

Tel: +44(0)1553 764900

Fax: +44(0)1553 770002

E-mail: info@ten-automotive.co.uk

TEN

TEN Automotive Equipment Ltd. ©Page 4 Version 5.0 November 2010

2 Front Screen and Connection Panel

Figure 1: Front Screen of the INNOVA 3000

1: LED indication power on/off.

TEN

TEN Automotive Equipment Ltd. ©Page 5 Version 5.0 November 2010

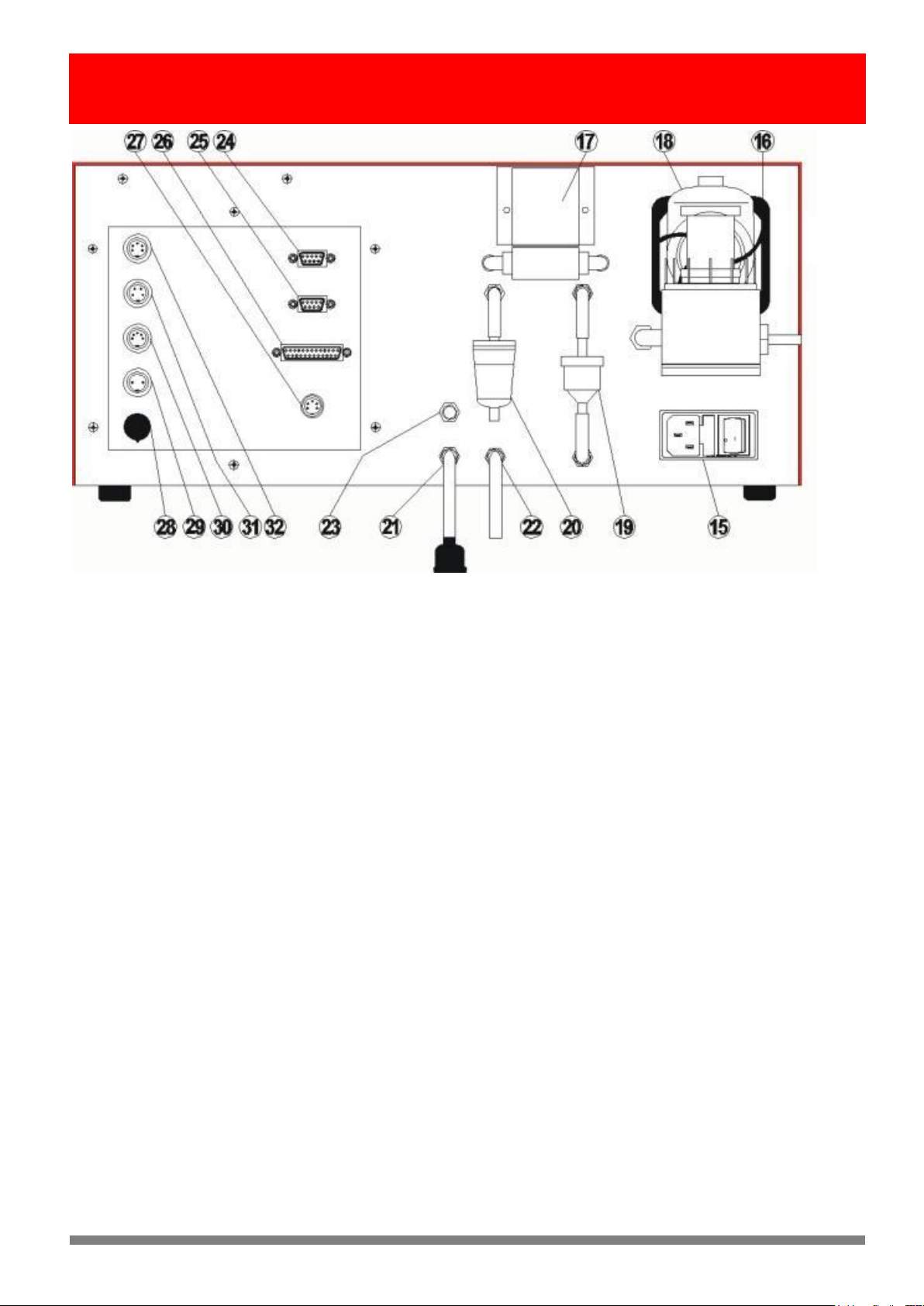

Figure 2. Connection Panel of the INNOVA 3000

15. Mains voltage input with main switch and fuses (2x2AT).

16. Fan.

17. Oxygen Sensor.

18. Drain separator with integrated pre-filter, fine filter and connection for sample probe

19. Inline filter (water drain system).

20. Carbon filter.

21. Gas outlet with leak check adapter.

22. Water outlet, (water drain system).

23. Calibration gas inlet.

24. COM 1, RS 232 communication port INNOVA 3000 to smoke meter

25. COM 2, RS 232 communication port INNOVA 3000 to PC.

26. Not used.

27. Not used.

28. Not used.

29. Connection for the inductive RPM clamp.

30. Connection for the Piëzo or optional RPM Pulse adapter.

31. Connection for the Oil temperature probe.

32. Connection for the Multi meter cable

Table of contents

Other TEN Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started