EG4 WPOWER-16/280-AW User manual

© 2023 EG4 ELECTRONICS, LLC. ALL RIGHTS RESERVED.

VERSION 1.1 | INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE.

MODEL #: WPOWER-16/280-AW

USER MANUAL

LITHIUM BATTERY

POWERPRO WALLMOUNT

ALL-WEATHER BATTERY

SCAN FOR UPDATED

DOCUMENTS

TABLE OF CONTENTS

1. TECHNICAL SPECIFICATIONS SHEET............................................................................................................. 1

2. ABBREVIATIONS............................................................................................................................................... 3

3. SAFETY............................................................................................................................................................... 4

3.1 SAFETY INSTRUCTIONS............................................................................................................................... 4

3.2 IMPORTANT SAFETY NOTIFICATIONS...................................................................................................... 4

4. BRIEF INTRODUCTION .................................................................................................................................... 6

4.1 PRODUCT DESCRIPTION.............................................................................................................................. 6

5. PACKING LIST.....................................................................................................................................................7

6. BATTERY OVERVIEW....................................................................................................................................... 8

6.1 BATTERY DIAGRAM...................................................................................................................................... 9

7. LOCATION SELECTION AND INSTALLATION..............................................................................................10

7.1 POWERPRO CONDUIT BOX INSTALLATION............................................................................................ 11

7.2 INSTALLATION WITHOUT A CONDUIT BOX ........................................................................................... 14

7.3 INSTALLATION WITH A CONDUIT BOX ....................................................................................................15

7.4 WITH EG4 18KPV INVERTER..................................................................................................................17

8. GENERAL INSTALLATION ..............................................................................................................................21

8.1 BATTERY PARALLELING GUIDE.................................................................................................................21

8.2 BATTERY CABLE CONNECTIONS..........................................................................................................22

8.3 ADDITIONAL CONFIGURATIONS .......................................................................................................... 23

9. EMERGENCY STOP (RSD, ESS DISCONNECT)........................................................................................... 26

10. BATTERY COMMUNICATIONS ..................................................................................................................... 27

10.1 DIP SWITCH ID TABLE ............................................................................................................................ 27

10.2 LCD SCREEN .............................................................................................................................................28

10.3 COMMUNICATION PROTOCOL SELECTION........................................................................................29

11. OPERATION GUIDE..........................................................................................................................................31

11.1 BMS TOOLS INSTALLATION AND INTERFACING ...............................................................................31

12. BATTERY CHARGING .....................................................................................................................................34

12.1 BATTERY PERFORMANCE CURVES..................................................................................................... 35

13. TROUBLESHOOTING, MAINTENANCE & DISPOSAL................................................................................36

13.1 INTRODUCTION TO THE BMS............................................................................................................... 36

13.2 BMS PROTECTION .................................................................................................................................. 36

13.3 TROUBLESHOOTING............................................................................................................................... 37

13.4 BATTERY END OF LIFE........................................................................................................................... 39

14. EG4 10 YEAR LIMITED WARRANTY ............................................................................................................39

14.1 WARRANTY EXCLUSIONS ..................................................................................................................... 39

15. STORAGE..........................................................................................................................................................40

1

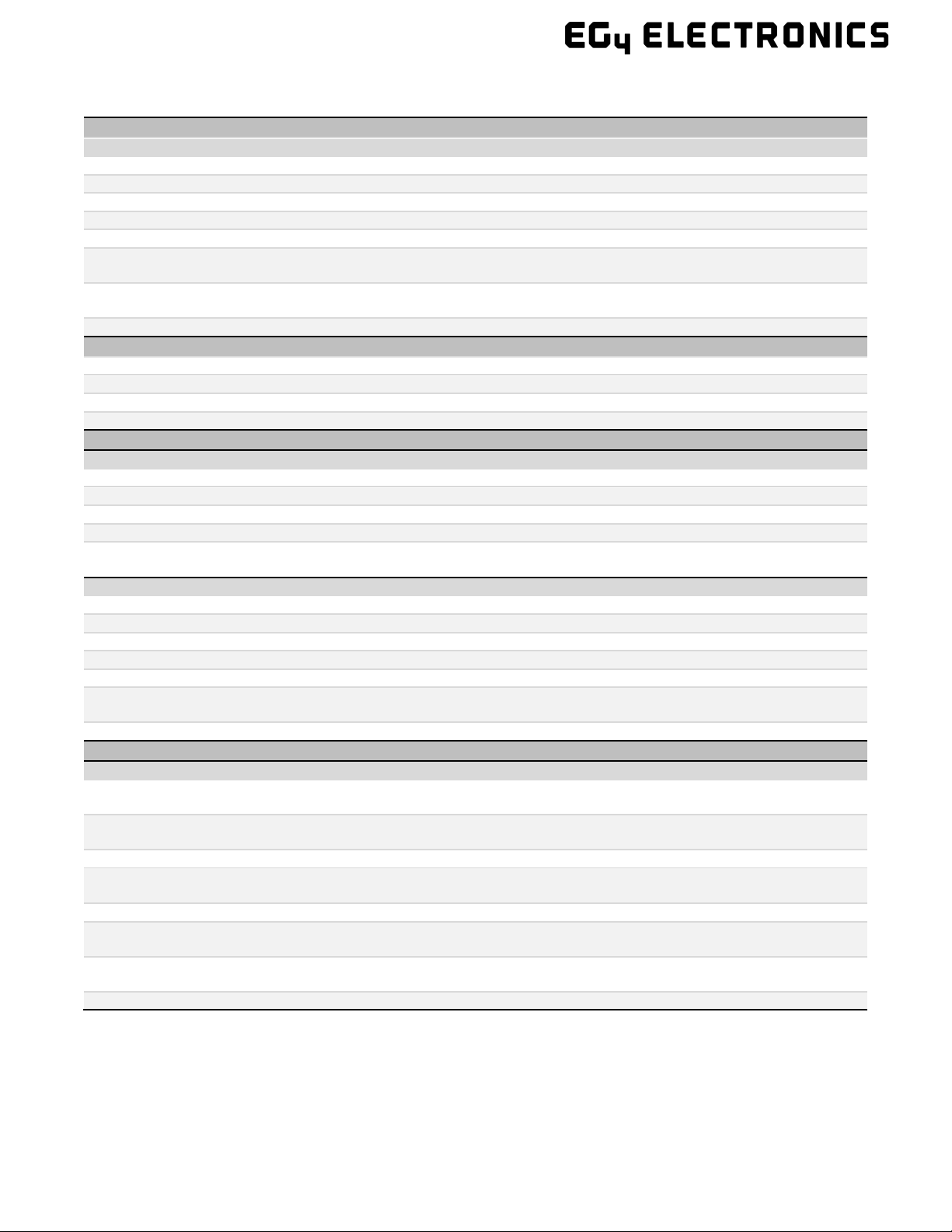

1. TECHNICAL SPECIFICATIONS SHEET

MODULE OPERATING PARAMETERS

Parameter

BMS

Recommended Charger Settings

Total Energy Capacity

14.3kWh @25C, 100% SOC

Voltage

51.2V

-

Capacity

280Ah ±2%

@25°C ±2°C @ 0.5C

Charging Voltage (Bulk/Absorb)

56.0V (±0.8V)

56.2V (±0.2V)

Float

-

54V (±0.2V)

Low DC Cuto 44.8V

47-45.6V

(start higher, lower as needed)

Charge Current

100/140/200A

Max. Continuous**

60 - 160A

Discharge Current

200A Max. Continuous

160A

ENVIRONMENTAL PARAMETERS

Charging Range

32° to ≈113°F (0°C to ≈45°C)

Discharging Range

-4°F to ≈122°F (-20°C to ≈50°C)

Storage Range

-4°F to ≈122°F (-20°C to ≈50°C)

Ingress Protection

IP65

CHARGING/DISCHARGING PARAMETERS

Charge

Spec

Delay

Recovery

Cell Voltage Protection

3.8V

1 sec

3.45V

Module Voltage Protection

60V

1 sec

55.2V

Charge Over-Current 1

>205A

10 sec

-

Charge Over-Current 2

>225A

3 sec

-

Temperature Protection

<23°F or >158°F

<-5°C or >70°C

1 sec

>32°F or <140°F

>0°C or <60°C

Discharge

Spec

Delay

Recovery

Cell Voltage Protection

2.3V

1 sec

3.1V

Module Voltage Protection

44.8V

1 sec

48V

Discharge Over-Current 1

>205A

10 sec

60 sec

Discharge Over-Current 2

>300A

3 sec

60 sec

Short Circuit

2000A

0.1 ms

-

Temperature Protection

<-4°F or >167°F

<-20°C or >75°C

1 sec

>14°F or <149°F

>-10°C or <65°C

PCB Temperature Protection

>230°F (>110°C)

1 sec

@ <176°F (<80°C)

GENERAL SPECIFICATIONS

Parameter

Spec

Condition

Cell Balance 120mA Passive Balance Cell Voltage Dierence

>40mV

Temperature Accuracy 3% Cycle Measurement

Measure Range:

-40 – ≈212°F (-40 – ≈100°C)

Voltage Accuracy

0.5%

Cycle Measurement

Cells & Module

Current Accuracy 3% Cycle Measurement

Measure Range:

-200 – 200A

SOC

5%

Integral Calculation

Power Consumption

(Standby)

<300uA Standby/Storage

Power Consumption

(Operating)

<25mA Charging/Discharging

Communication Ports

RS485/CAN

Customizable

2

BATTERY HEATER SPECIFICATIONS

Parameter

Spec

Condition

Voltage

56V

-

Power Consumption

224W

-

Internal Battery Temperature

≤32°F (0°C) or ≥41°F (5°C)

Heat On/Heat O

PHYSICAL SPECIFICATIONS

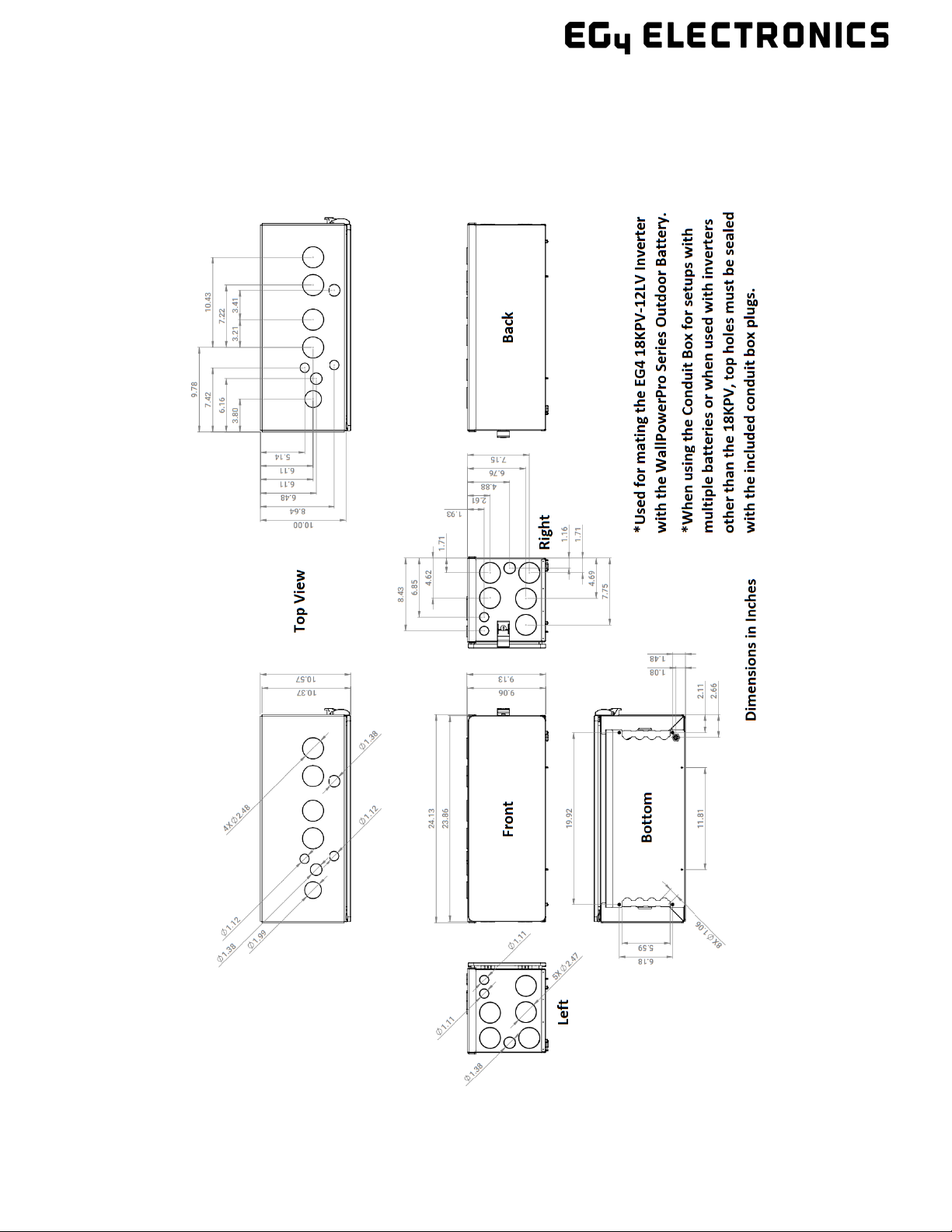

Dimensions (H × W × D)

34.6 × 22.3 × 9.1 in. (88 × 56.6 × 23.2cm)

Weight

308.6 lbs. (140 kg)

Design Life

>15 years

Cycle Life

>8000 Cycles @ 0.5C 80% DOD

Lifetime Production

82.6MWh*

*(51.2V×280Ah/1000×80%×8000 cycles/1000)90%=MWh

**Note: The default BMS in the module allows for 100A charging current maximum. To achieve higher charging currents,

please contact your distributor for optional firmware files, or navigate to https://eg4electronics.com/downloads/ for

the most up to date firmware.

3

2. ABBREVIATIONS

AWG – American Wire Gauge

A – Amp(s)

Ah – Amp hour(s)

AC – Alternating Current

AHJ – Authority Having Jurisdiction

ANSI – American National Standards Institute

BMS – Battery Management System

DC – Direct Current

DIP – Dual In-line Package

DOD – Depth of Discharge

EG – Equipment Ground

EGS – Equipment Grounding System

EPS – Emergency Power System

ESS – Energy Storage System

E-Stop NO – Emergency Stop Normally Open

GE – Grounding Electrode

GEC – Grounding Electrode Conductor

GES – Grounding Electrode System

Imp – Maximum Power Point Current

Isc – Short-Circuit Current

In. lbs. – Inch Pounds

kW – Kilowatt

kWh – Kilowatt-hour

LFP – Lithium Iron Phosphate or LiFePO4

mm – Millimeter(s)

ms – Millisecond(s)

mV – Millivolt(s)

NEC – National Electrical Code

NFPA – National Fire Prevention Association

Nm – Newton Meters

PC – Personal Computer

PCB – Printed Circuit Board

PE – Protective Earth (G or Ground)

PPE – Personal Protective Equipment

PV – Photovoltaic

RSD – Rapid Shut Down

SOC – State of Charge

STC – Standard Testing Conditions

V – Volt(s)

VOC – Open-Circuit Voltage

VMP – Voltage Maximum Power

4

3. SAFETY

3.1 SAFETY INSTRUCTIONS

International safety regulations have been strictly observed in the design and

testing of the inverter. Before beginning any work, carefully read all safety

instructions, and always observe them when working on or with the inverter. The

installation must follow all applicable national or local standards and regulations.

Incorrect installation may cause:

•injury or death to the installer, operator or third party

•damage to the inverter or other attached equipment

3.2 IMPORTANT SAFETY NOTIFICATIONS

There are various safety concerns that must be carefully observed before, during,

and after the installation, as well as during future operation and maintenance. The

following are important safety notifications for the installer and any end users of

this product under normal operating conditions.

1. Beware of high PV voltage. Please install an external DC disconnect switch or

breaker and ensure it is in the “o” or “open” position before installing or

working on the inverter. Use a voltmeter to confirm there is no DC voltage

present to avoid electric shock.

2. Beware of high grid voltage. Please ensure the AC switch and/or AC breaker are in

the “o” or “open” position before installing or working on the inverter. Use a

voltmeter to confirm there is no voltage present to avoid electric shock.

3. Beware of high battery current. Please ensure that the battery module breakers

and/or on/o switches are in the “open” or “o” position before installing or

working on the inverter. Use a voltmeter to confirm there is no DC voltage present

to avoid electric shock.

4. Do not open the inverter while it is operating to avoid electric shock and

damage from live voltage and current within the system.

5. Do not make any connections or disconnections (PV, battery, grid, communication, etc.)

while the inverter is operating.

6. An installer should make sure to be well protected by reasonable and

professional insulative equipment [e.g., personal protective equipment (PPE)].

7. Before installing, operating, or maintaining the system, it is important to

inspect all existing wiring to ensure that it meets the appropriate

specifications and conditions for use.

8. Ensure that the PV, battery, and grid connections to the inverter are secure

and proper to prevent damage or injuries caused by improper installation.

DANGER! Hazardous Voltage Circuits!

AVERTISSEMENT! Circuits à tension élevée!

5

All work on this product (system design, installation, operation, setting, configuration, and

maintenance) must be carried out by qualified personnel. To reduce the risk of electric

shock, do not perform any servicing other than those specified in the operating instructions

unless you are qualified to do so.

1. Read all instructions before installing. For electrical work, follow all local and national

wiring standards, regulations, and these installation instructions.

2. Make sure the inverter is properly grounded. All wiring should be in accordance with the

National Electrical Code (NEC), ANSI/NFPA 70.

3. The inverter and system can inter-connect with the utility grid only if the utility provider

permits. Consult with your local AHJ (Authority Having Jurisdiction) before installing this

product for any additional regulations and requirements for your area.

4. All warning labels and nameplates on this inverter should be clearly visible and must not be

removed or covered.

5. The installer should consider the safety of future users when choosing the inverter’s correct

position and location as specified in this manual.

6. Please keep children away from touching or misusing the inverter and relevant systems.

7. Beware! The inverter and some parts of the system can be hot when in use, please do not

touch the inverter’s surface or most of the parts when they are operating. During operation,

only the LCD and buttons should be touched.

DISCLAIMER

EG4 reserves the right to make changes to the material herein at any time without notice.

Please refer to www.eg4electronics.com for the most updated version of our manuals/spec sheets.

WARNING: To reduce the risk of injury, read all instructions

6

4. BRIEF INTRODUCTION

Battery Features

•Constant rated output current of 200A

•IP65 all-weather rated, integrated self-heating during low ambient temperatures.

•Smart balancing of cells enhancing the battery consistency and the lifespan up to 15 years of

life with over 8000 cycles at 80% DOD at 0.5C

•Built-in intelligent BMS with battery voltage, current, temperature, and health management

to reduce electrical risks and overheating

•Internal busbars rated to 600 Amps for paralleling multiple batteries and feeding multiple

inverters

•Real time monitoring and LCD screen to display battery voltage, current, temperature, SOC in

detail

•Integrated E-stop circuit supports emergency stop function with remote Rapid Shutdown

Initiator (RSD) or Energy Storage Systems (ESS) disconnect or by inverter’s RSD or ESS

terminals

•Communicate with inverter using CAN or RS485. Firmware update using RS485

•Plug-and-play cable installation with the use of the 250A weather-tight quick connectors

•Stable, reliable, and maintenance-free battery pack

•Comprehensive safety UL9540A, UL1973 on cell and module level with enhanced onboard

fire-extinguishing modules.

4.1 PRODUCT DESCRIPTION

The EG4® 48V PowerPro WallMount All Weather 280Ah batteries are ideal for low-voltage

residential outdoor energy storage system (ESS) applications. These batteries use lithium iron

phosphate (LiFePO4 or LFP) cells with the highest safety performance and an intelligent Battery

Management System (BMS) that can monitor and record the voltage of each cell, along with the

current, voltage, and temperature of the module in real-time. The BMS also contains a passive

balance function and an advanced battery control method, both of which improve the

performance of the battery pack. For enhanced security, the battery has two onboard fire-

extinguishing modules. With a design life of more than 15 years, the WallMount is designed to last

over 8000 cycles at 80% DOD at 0.5C°.

7

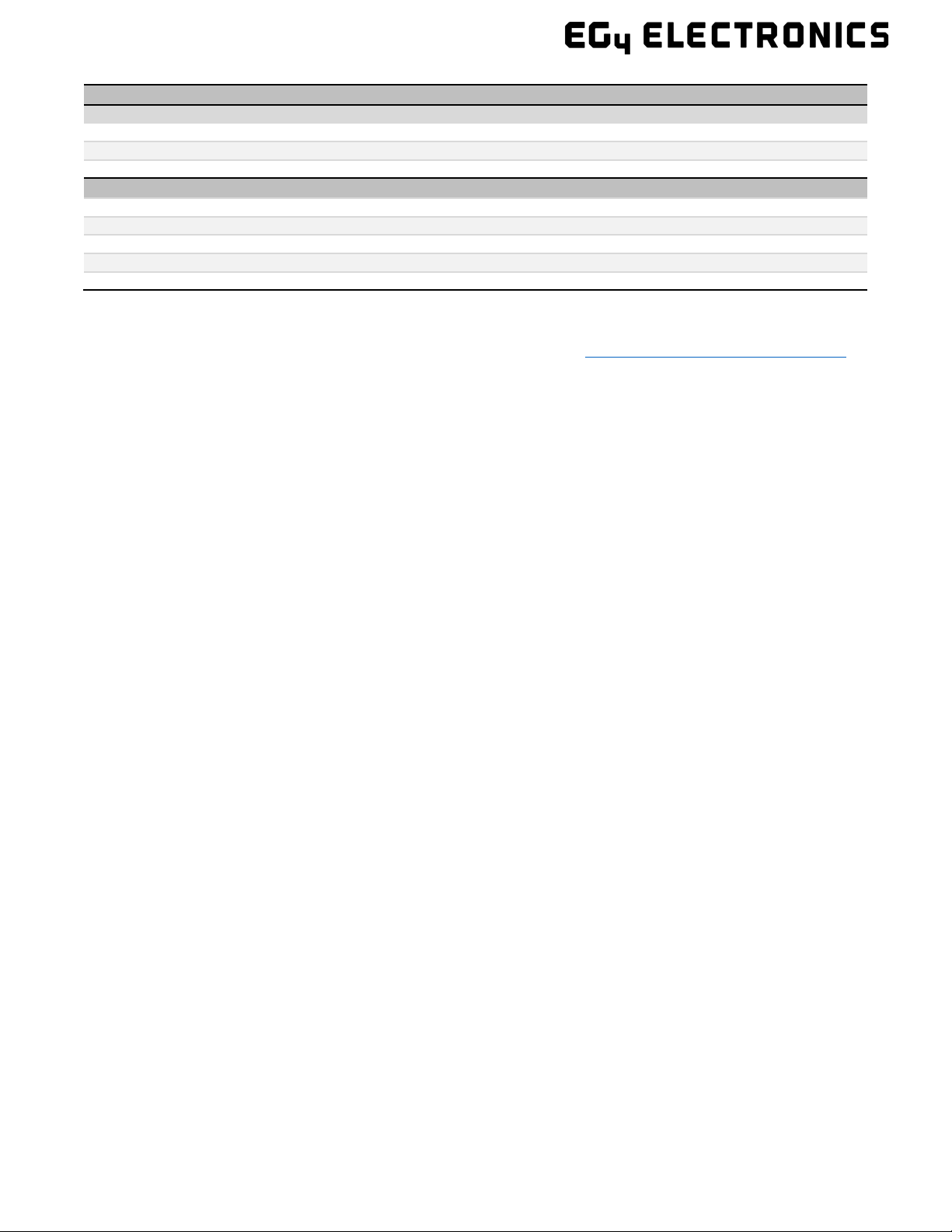

5. PACKING LIST

The items listed below are included with the purchase:

280Ah Battery

(Qty 1)

X-Bracket

(used for EG4-18kPV)

Concrete

expansion bolts

M8×70 (Qty 6)

Mounting

bracket (Qty 1)

Battery to Inverter

communication cable

(Qty 1)

Red power cable 2/0 AWG

39.4 in (to inverter

positive terminal) (Qty 2)

Black power cable 2/0

AWG 39.4 in (to inverter

negative terminal) (Qty 2)

Black battery

parallel cable 53.1 in

(Qty 1)

Parallel

communication

cable 59.1 in (Qty 1)

Red battery parallel

cable 53.1 in (Qty 1)

The following items are included in the optional

Battery Paralleling kit

•Red positive battery parallel cable 53.1 in. (Qty 1)

•Black negative battery parallel cable 53.1 in. (Qty 1)

•Parallel Communication cable 59.1 in. (Qty 1)

PowerPro Conduit

Box (Qty 1)

Conduit box

plugs (Qty 9)

Rubber / plastic

grommets between

battery and conduit

box (Qty 9)

Cable glands for

conduit box (Qty 16)

The following Items are included in

the optional conduit box kit

•Conduit box (Qty 1)

•Conduit box plugs (Qty 9)

•Rubber/plastic grommets

between battery and conduit box

(Qty 9)

•Cable glands for conduit box 1, 1.5

and 2.5in knockouts (Qty 16)

Figure 1 – Packing List

Figure 2 – Conduit Box Packing List

Figure 3 – Parallel Kit Packing List

8

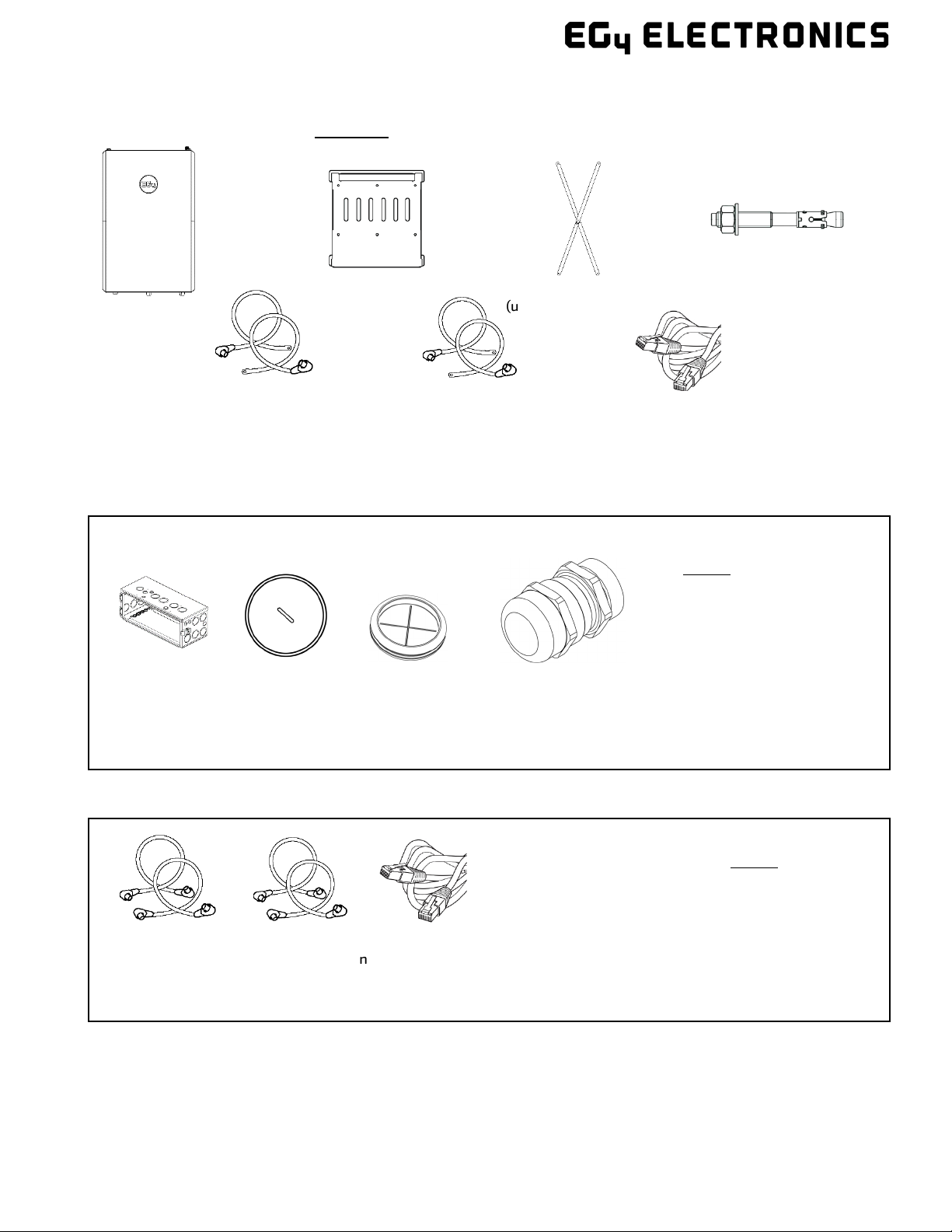

6. BATTERY OVERVIEW

When installing or removing battery, ensure battery is in the o position, and use a voltmeter to

confirm there is no voltage present. This will prevent users from encountering live (powered)

terminals by accident.

Failure to do so can result in severe injury and/or death.

Figure 4 – Battery Cross-Sectional View

DANGER

9

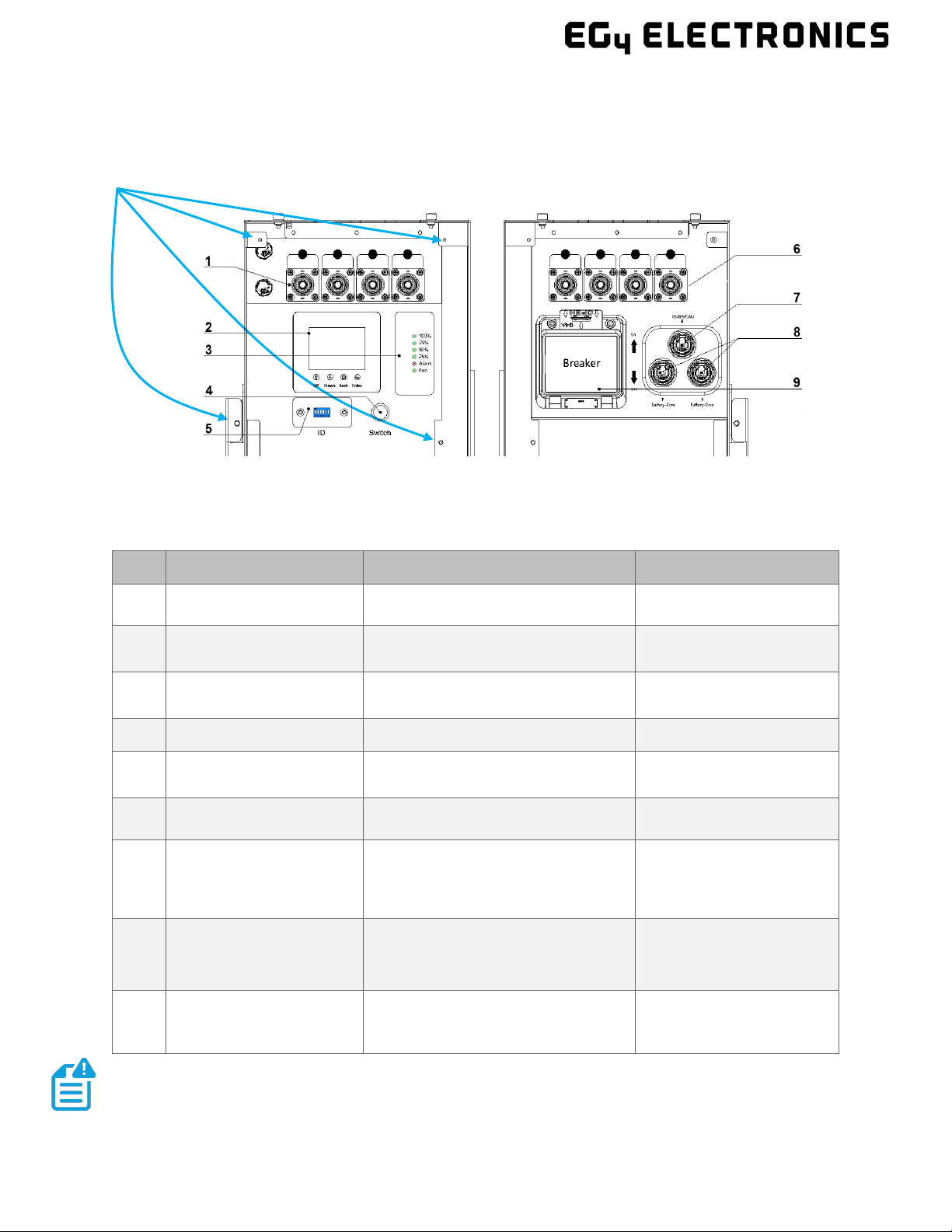

6.1 BATTERY DIAGRAM

It is highly recommended to install the battery with at least 12-inch clearance on each side ofthe battery

(back and front sides excluded) to easily access the side panel.

NO. ITEM DESCRIPTION REMARKS

1 Negative Terminals

Connects to negative terminal of

Inverter and/or paralleled battery

2 LCD Screen Shows battery information

3 SOC Display State of Charge LED

4 Power Switch Turns BMS on/o

5 ID/DIP Switch DIP Switch board for BMS

6 Positive Terminal Connects to positive terminal of

Inverter and/or paralleled battery

7 RS485/CAN Port RS485/CAN Communication

Interface

Pin 1 & Pin 8 ‒RS485_B

Pin 2 & Pin 7 – RS485_A

Pin 4 – CAN_H

Pin 5 – CAN_L

8 Battery-Comm Parallel battery Communication

Port

Pin 1 & Pin 8 ‒RS485_B

Pin 2 & Pin 7 – RS485_A

Pin 3 & Pin 6 ‒E-Stop NO

9 Battery Disconnect

Breaker Turns power supply on/o

Double Pole Single Throw

125 Frame size

125A Rating

*

NOTE: Additional hardware may be required to remove the side terminal covers. EG4 recommends a

3mm width, 90mm length #2 Phillips head screwdriver

Figure 5 – Battery (side view)

Side Panel Screws

Side A

Side B

*NOTE: The battery disconnect breaker is 2 single pole breakers with a singular

switch, paralleled together to reach a 250A Rating.

10

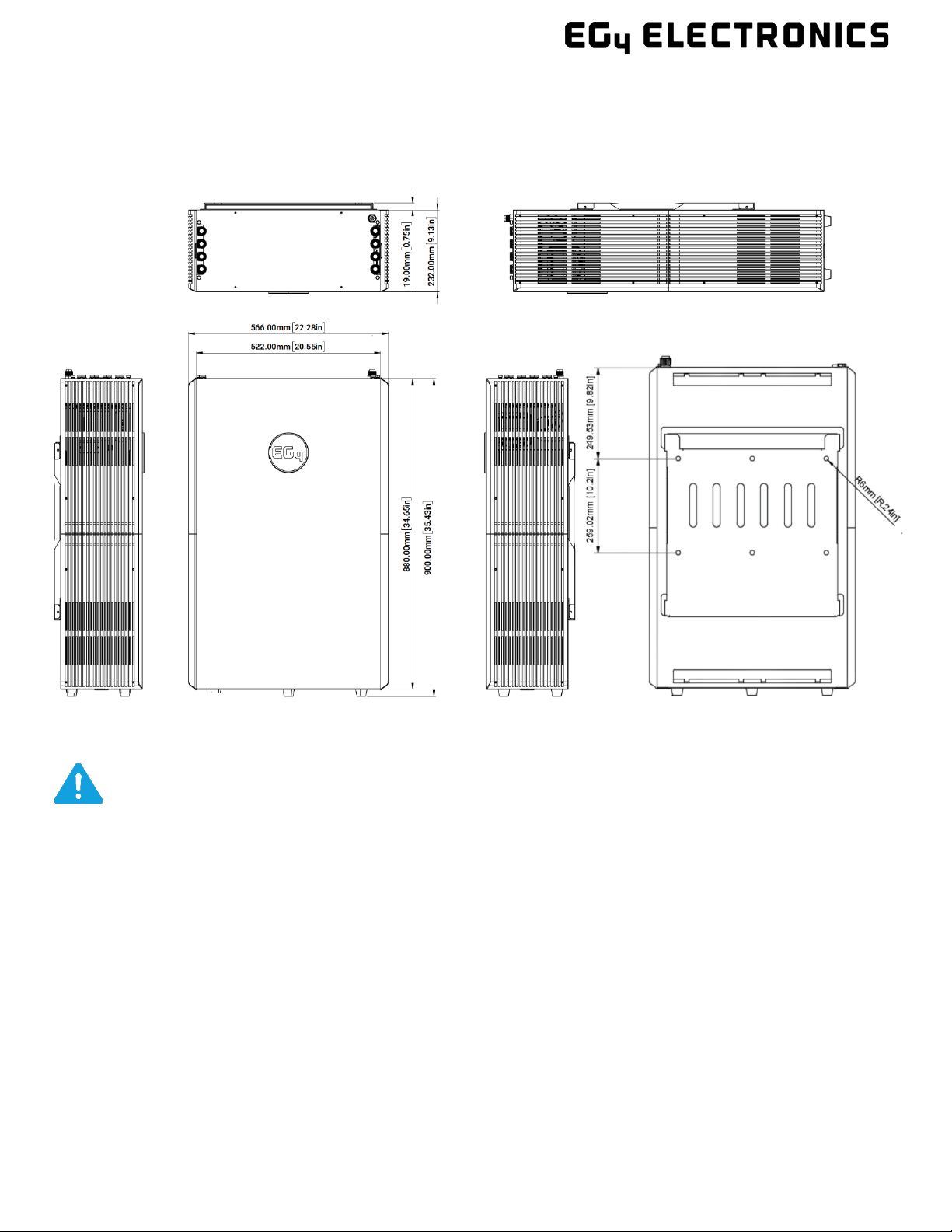

7. LOCATION SELECTION AND INSTALLATION

•Do not put EG4 48V batteries in series. The BMS and internal components are not designed to

handle this setup, which could cause the modules to fail.

•Do NOT mix EG4 WallMount 280Ah batteries with any non-280Ah lithium batteries. This will

void your warranty.

•The WallMount is heavy. Use a lift or other equipment to lift and carry the unit

•The WallMount can be installed on either flat ground or on the wall. If installed on flat ground,

ensure there is proper drainage on the ground surrounding the battery to maintain integrity of

the module over time. If installing on the wall, ensure at least a 12 in. gap on each side of the

unit for adequate airflow and operations.

•Install the WallMount in a location that prevents damage from flooding

•Always mount the battery in an upright position.

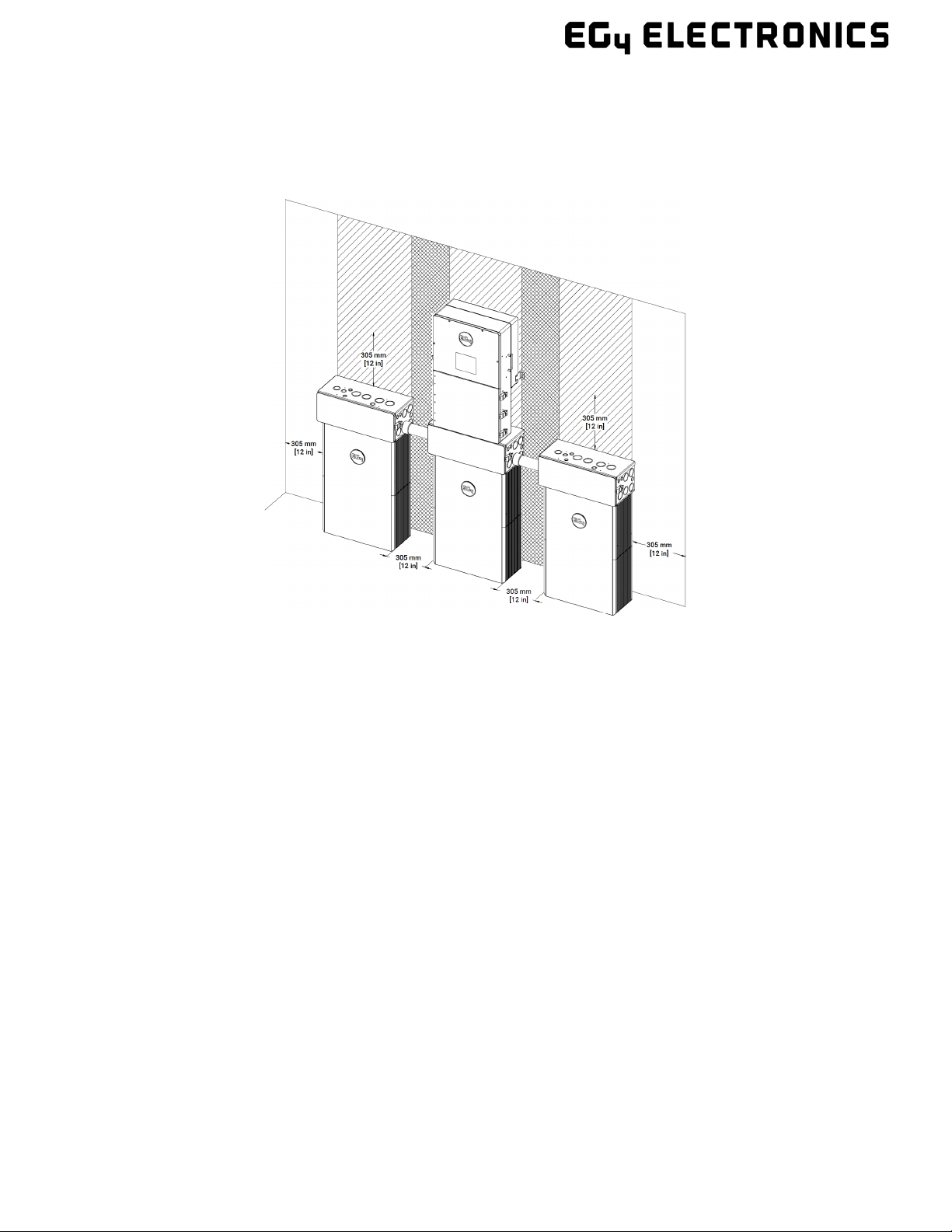

•WallMount must be installed with clearance at the left, right, top, bottom, and front of the

product for easy installation and safe operation of the unit as shown in the above picture.

Back View

Temporary Lifting

Handles

Figure 6 – Battery Lifting Handles

WARNING

NOTE: The battery will be shipped with temporary lifting handles for removing the

battery from its packaging. See image below for location. EG4 recommends removing

the handles before connecting any wiring to the battery.

11

•Ensure at least 12 in. between multiple WallMount batteries and other devices, unless it is

installed as a part of PowerPro WallMount ESS that includes EG4-18kPV with the conduit box.

In a PowerPro WallMount ESS installation, the conduit box is attached directly to both battery

and inverter.

•Please follow NEC and other local codes while installing the product.

The battery can be installed in multiple dierent configurations:

1. Installation without a conduit box (Sec 7.2)

2. Installation with a conduit box (Sec 7.3)

3. Installation with EG4 18kPV inverter (Sec 7.4)

Refer to Section 7.3 for multiple battery installations with multiple EG4-18kPV units.

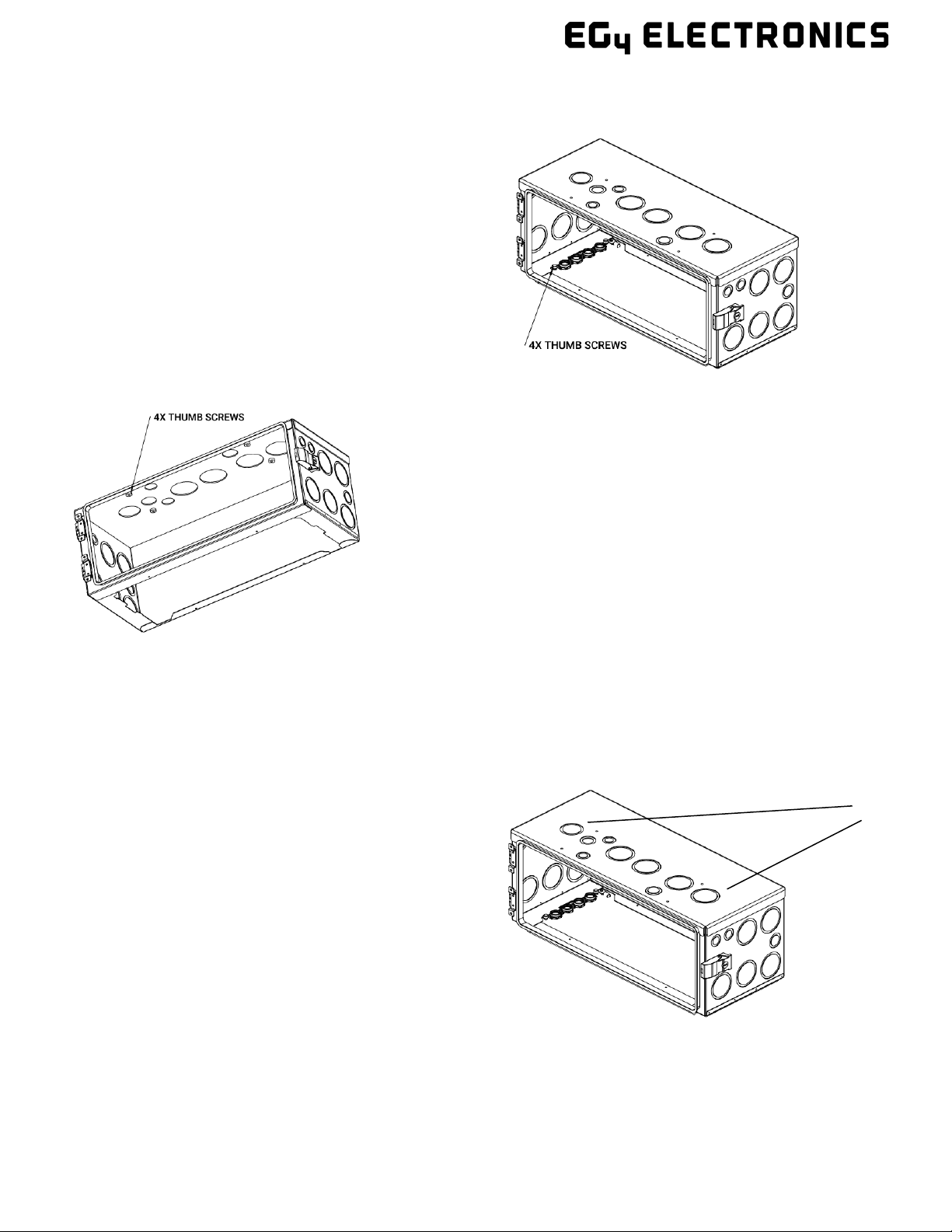

7.1 POWERPRO CONDUIT BOX INSTALLATION

The conduit box is a highly recommended accessory for the battery to retain all the cables inside an

enclosure for added protection and safety. The conduit box holds both the conduits and wires that are

running between the inverter and the battery.

Each Conduit box comes with 8 thumb screws that can be used to attach the inverter and the battery.

Figure

7 – Clearance Diagram

12

Figure 8 – Conduit Box Schematics

13

Step 1: Identify the four screw locations that attach to the battery (Figure 9). Place the conduit box on

top of the battery and use the provided thumb screws to tighten the conduit box to the battery.

Step 2: If you are installing the WallMount along with the 18kPV

inverter (Sec 7.4), please use the remaining 4 thumb screws on

the top side of the conduit box to secure it to the inverter, as

shown in Figure 10.

If you are installing the WallMount as an additional battery or along with non-EG4 18kPV inverter

(Section 7.3), please use the plugs to cover the top holes on the conduit box. Refer to Figure 11.

Plugs

Figure 9 – Conduit Box Thumb Screws

Figure 10 – Conduit Box Thumb Screws

Figure 11 – Conduit Box Plug Location

14

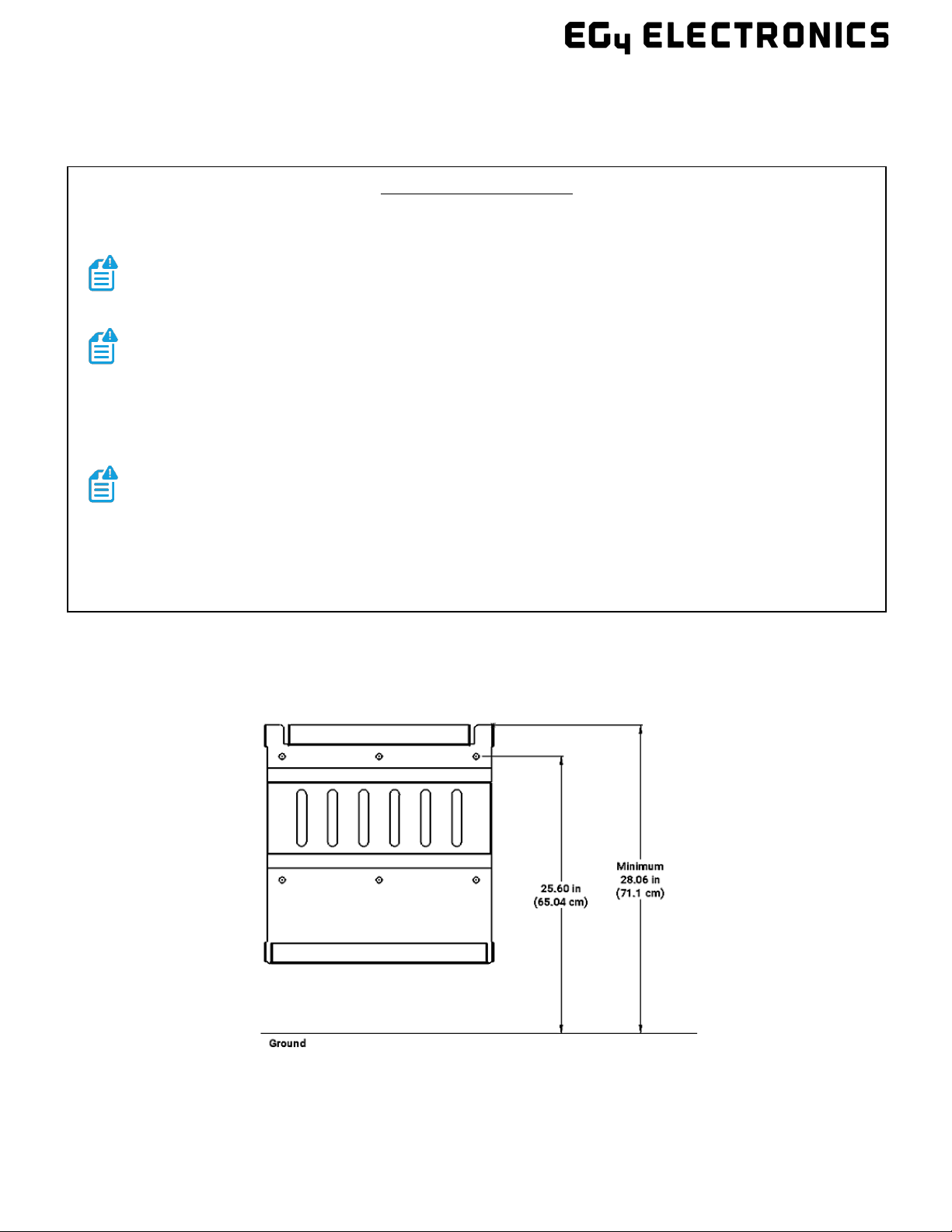

7.2 INSTALLATION WITHOUT A CONDUIT BOX

Mounting Instructions

1. Place mounting bracket on wall at proper mounting height (Min. 28.0625 in) from the ground; use a

Level to make sure the bracket is straight, and mark mounting hole locations. Drill holes to

accommodate mounting hardware being used.

Note: The mounting bracket at 28.065in from the ground makes the battery sit on the ground.

2. Secure mounting bracket to the wall using the included expansion bolts (concrete/brick walls) or

appropriate hardware required for the mounting surface.

Note: If not mounting into concrete or brick using the included expansion bolts, ensure bolts are

mounted into both studs or other supportive material. The battery is 300lbs, please ensure full

mounting support.

3. Attach the WallMount battery pack to the mounting bracket. To accomplish this, lift the battery up

and hook the flange on the back of the battery into the flange on the front of the mounting bracket.

Secure the battery to the mounting bracket with the 4 included side screws (see Figure 12)

Note: The battery is very heavy. Please use the team lift technique to prevent damage to personnel

and/or equipment

4. Finally, properly ground the battery, attaching a grounding conductor to the M6 grounding screw on

top of the battery to the Equipment Grounding System.

Steps 1 & 2

Completed Install

Step 3

Figure 12 – WallMount Installation without Conduit Box

Secure Points

15

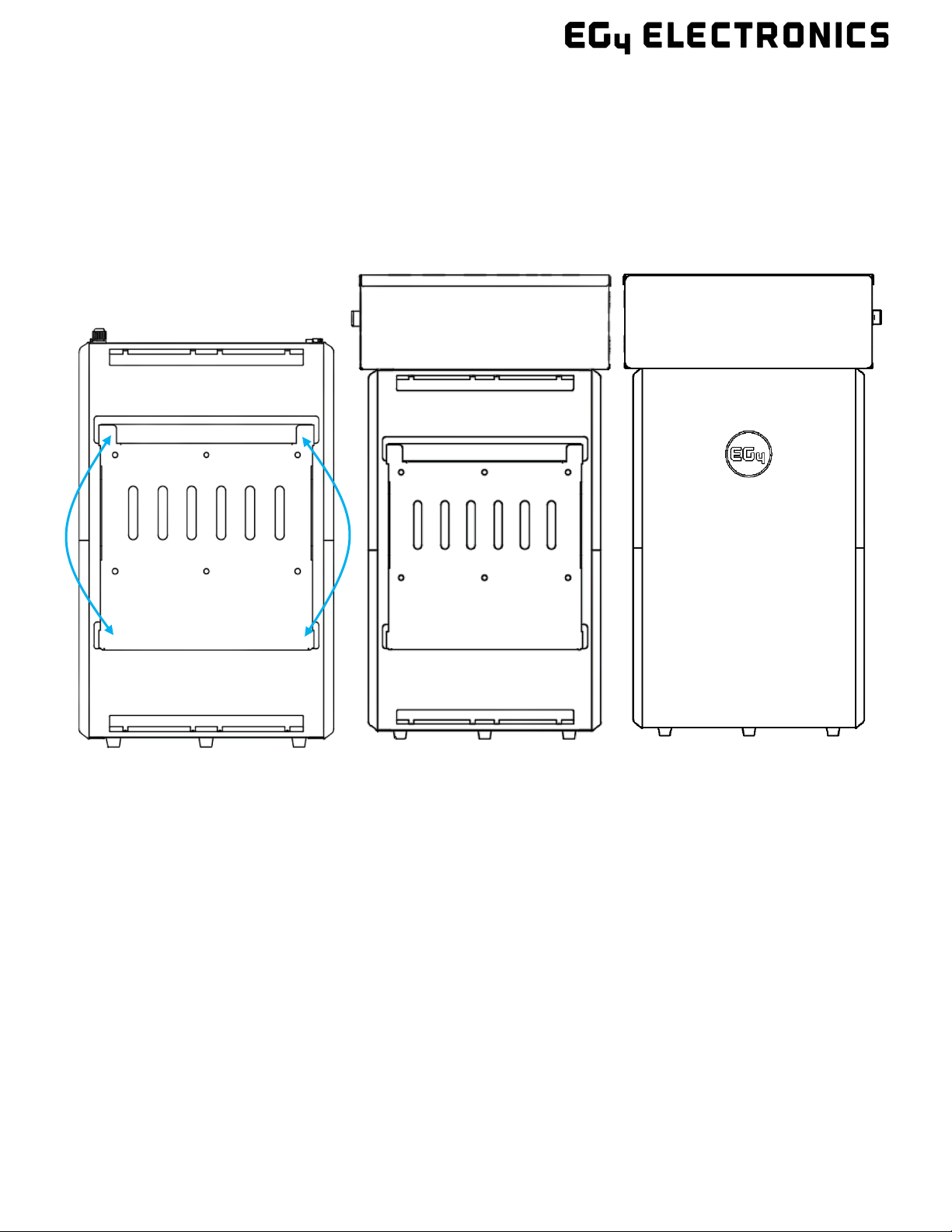

7.3 INSTALLATION WITH A CONDUIT BOX

Attach the conduit box (sold separately) to the top of the WallMount battery using the included

hardware. Refer to Section 7.1 for the conduit box installation instructions.

Mounting Instructions

1. Place mounting bracket on wall at proper mounting height (minimum 28.0625 in) from the ground;

use a Level to make sure the bracket is straight, and mark mounting hole locations. Drill holes to

accommodate mounting hardware being used.

Note: The mounting bracket at 28.065in from the ground makes the battery sit on the ground.

2. Secure mounting bracket to the wall using the included expansion bolts (concrete/brick walls) or

appropriate hardware required for the mounting surface.

Note: If not mounting into concrete or brick using the included expansion bolts, ensure bolts are

mounted into both studs or other supportive material. The battery is 300lb, please ensure full

mounting support.

3. Attach the WallMount battery pack to the mounting bracket. To accomplish this, lift the battery up

and hook the flange on the back of the battery into the flange on the front of the mounting bracket.

Secure the battery to the mounting bracket with the 4 included side screws (see Figure 14)

Note: The battery is very heavy. Please use the team lift technique to prevent damage to

personnel and/or equipment

4. Attach the conduit box (sold separately) to the top of the WallMount battery using the included

hardware.

5. Finally, properly ground the battery, attaching a grounding conductor to the M6 grounding screw

on top of the battery to the Equipment Grounding System.

Steps 1 & 2

Figure 13 – WallMount Installation with Conduit Box Steps 1 & 2

16

Step 4

Final-Front View

Step 3

Secure Points

Figure 14 – WallMount Installation with Conduit Box Steps 3, 4 & 5

17

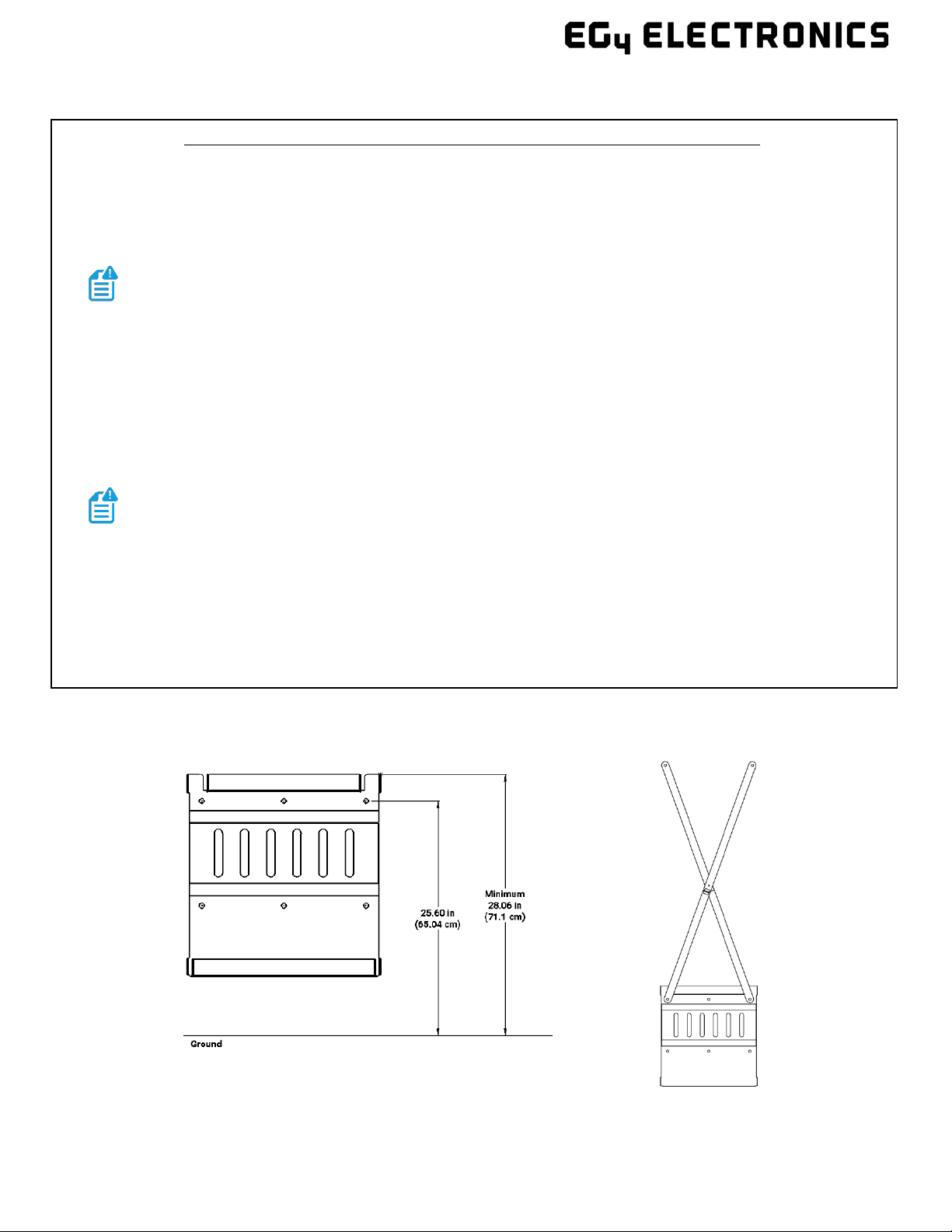

7.4 WITH EG4 18KPV INVERTER

Step 2 (back view)

Mounting Instructions with EG4 18kPV (See diagrams on following pages)

Note: If not mounting into concrete or brick using the included expansion bolts, ensure bolts are mounted

into both studs or other supportive material. The battery is 300lb, please ensure full mounting support.

1. Place mounting bracket on wall at proper mounting height (Min. 28.0625 in) from the ground; use a

Level to make sure the bracket is straight, and mark mounting hole locations. Drill holes to

accommodate mounting hardware being used.

Note: The mounting bracket at 28.065in from the ground makes the battery sit on the ground.

2. Align the provided X-bracket with the holes on the mounting bracket and secure both to the wall,

using the included expansion bolts (concrete/brick walls) or appropriate hardware required for the

mounting surface. The X-bracket will be behind the mounting plate, against the wall.

3. Using the X-bracket as a guide, attach the EG4 18kPV mounting bracket using the appropriate

hardware required for the mounting surface.

4. Attach the WallMount battery pack to the mounting bracket. To accomplish this, lift the battery up

and hook the flange on the back of the battery into the flange on the front of the mounting bracket.

Secure the battery to the mounting bracket with the 4 included side screws (see Figure 16).

Note: The battery is very heavy. Please use the team lift technique to prevent damage to personnel

and/or equipment

5. Attach the conduit box (sold separately) to the top of the WallMount battery using the included

hardware.

6. Attach the 18kPV to the inverter mounting bracket making sure that the holes of the inverter align

with the conduit box and secure to each other with the included hardware.

7. Finally, properly ground the battery, attaching a grounding conductor to the M6 grounding screw on

top of the battery to the Equipment Grounding System.

Step 1 (front view)

Figure 15 – WallMount Installation with Conduit Box & 18kPV Steps 1 & 2

Table of contents

Other EG4 Batteries Pack manuals

Popular Batteries Pack manuals by other brands

Husqvarna

Husqvarna BLi100 Workshop manual

Sony

Sony VAIO VGP-BPSC24 operating instructions

Power works

Power works LB60A00PW owner's manual

Bosch

Bosch PowerPack Frame 800 Original operating instructions

Inventus Power

Inventus Power PROTRXion S-24V80-TRX quick start guide

Panasonic

Panasonic CF-VZSU0PW operating instructions