EGAmaster 79617 User manual

OPERATING INSTRUCTIONS

MANUEL D’INSTRUCTIONS

RECIPROCATING SAWS

SCIE PORTABLE PNEUMATIQUE

COD.79617

COD.79618

ENGLISH................................ 2

FRANÇAIS............................ 28

GUARANTEE / GARANTIE ... 56

2

TECHNICAL SPECIFICATION

Type COD. 79617 COD. 79618

Operating pressure 6 bar 6 bar

Motor output 1.1 kW 1.1 kW

Stroke number (under load) 330 1/min. 330 1/min.

Stroke of saw blade 60 mm 60 mm

Air consumption 1.45 m³/min. 1.45 m³/min.

Air connection R ¾” male R ¾” male

Operating pressure 6 bar 6 bar

Weight approx. 6.4 kg 10.65 kg

Cutting capacity for pipes Ø 530 mm Ø 530 mm

Cutting capacity for proles 290 mm 290 mm

Vibration level at free speed < 2.5 m/s² < 2.5 m/s²

Noise level at 1 m distance 84 dB (A) 84 dB (A)

ENGLISH

3

SAFETY INSTRUCTIONS

Any power tool can be dangerous.

Please follow these simple procedures.

They are for your protection.

Wear goggles ( chips – risk of injury)

Wear gloves (cutting damages by sharp edged work pieces)

Wear safety shoes

Wear protective clothing

Remove rings, watches, ties etc. that could be torn by the machine.

Dress properly. Do not wear loose clothing or jewellery, it can be caught in moving parts.

Follow the general current and appropriate Accident Prevention and Safety Procedures.

Never work under the inuence of alcohol, drugs or stronger medication.

Always make sure that you have a safe foothold.

Maintain a proper footing and balance at all time. Never work with the machine while standing

on a ladder or leaning against a scaffold.

Secure the working place well. Use clamps or a vice to x the work piece. This is safer than

using hands and clears both hands for operating the machine.

Hold the machine tight during operation.

Keep your working area clean and uncluttered.

Keep children away and avoid other persons to come into contact with the machine.

Switch off the machine if it stops - for any reason - to avoid the unexpected starting in

uncontrolled condition.

Do not operate the tool if it is damaged, improperly adjusted or not completely and correctly

assembled.

Check air hose for damage.

Work with oleiferous air only.

4

Avoid sparks in hazardous environment - created by the saw blade. Always ush material and

saw blade for cooling with sufcient water during working.

Do not employ machines by excessive force. Their performance is better and safer, if they work

at the prescribed speed.

Check damaged parts.

Before using the machine, damaged parts or protective devices should be carefully checked to

make sure they work soundly and full the designated function. Check alignment, connections

and attachment of moving parts. Also check if parts are broken. Parts or protective devices that are

damaged should, if nothing else is mentioned in these operating instructions, only be exchanged

or repaired by qualied personnel. The same applies to defective switches and valve triggers. If the

machine cannot be switched on or off with the valve trigger, it should not be used.

The use of other accessories, or other additional items than recommended in these operating

instructions, may include the risk of bodily injury.

Only operate the tool after a thorough training or under supervision of a trainer.

Never exceed the maximum operation pressure.

Follow the valid national provisions in the country of application.

ATTENTION! Never use the exible hose as a lifting handle!

USE

INTENDED USE

Skilled personnel only is allowed to operate the machine.

The machine (reciprocating saw) serves for cutting (shortening, cutting off to length) of different

materials and proles. Mainly the saw will be used xed in a clamping device that is

corresponding to the intended purpose.

But cutting without clamping device is also possible!

IMPROPER USE

Any use deviating from the intended use as described is considered to be improper use.

Working without personal protection equipment.

5

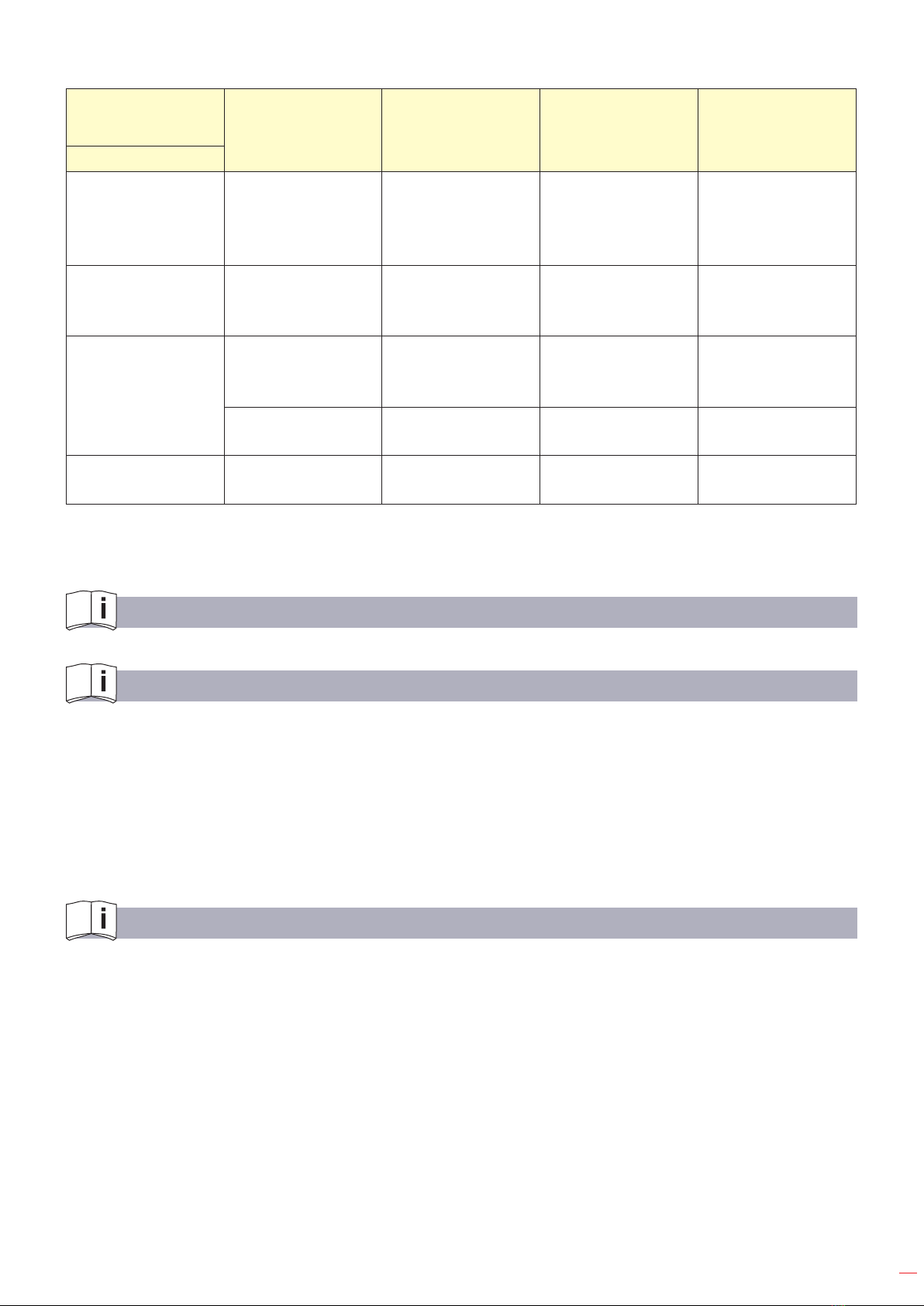

Danger Zones

Operational

condition Normal function Malfunction Improper use Expected use

Life phase

Transport

Transport of

the machine in

an inoperable

condition

Drop of the

machine

Transport of

the machine

in an operable

condition

unknown

Start-up

Operation

Operating the

machine with

designated device

unknown unknown Working without

device

Operation

Machine only

works with

actuated valve

Machine runs

without actuated

valve

Switch is blocked

in actuated

condition

unknown

Machine moves

the tool Tool blocks unknown unknown

Maintenance Operation at a

maintenance unit

Breakdown of the

machine unknown unknown

OPERATION INSTRUCTIONS

GENERAL

Our pneumatic saw is designed for a service pressure of 4 to 6 bar. The pneumatic reciprocating

saw is only used in conjunction with a clamping device. For this purpose the ground- in

receiving bolt of the clamping device is placed in the cross hole in gear casing cover and xed by

means of the locking device. Firmly clamped work-piece will yield a clean cut and will reduce saw

blade damage. The selection of the clamping device and of the saw blade depends on the type and

size of the work-piece. The saw blade must be cooled and/ or lubricated with lubricant or oil.

CUTTING

- Check oil level and ll up oiler, if neccessary.

- Equip saw with the appropriate saw blade. For this loosen two nuts, take away the pressure

plate and put in the saw blade. Mount the pressure plate and x it to the saw blade by tightening

the nuts.

6

- Connect pneumatic hose. (Before connecting, it is recommended to blow out the hose and thus

remove impurities).

- Actuate valve and press sensor button. (Only after pressing the sensor button, the channel is

opened. When the valve is closed, the sensor shuts as well. When the valve is opened again, the

sensor button has to be pressed again as well.)

- Start cutting.

- Ensure appropriate cooling (water) of tool and working piece.

AFTER FINISHING THE SAWING WORK

- Shut valve

- Shut compresse air supply and disconnect air hose.

- Take saw out of the device.

- Clean saw and retainer seat.

- Check oiler

MAINTENANCE INSTRUCTIONS

Our pneumatic motors are designed for an operation pressure of 4 -6 bar (65-90 PSI).

Service life and performance of the machines are decisively determined by:

a) The air purity

Blow the air hose clear before connecting it to the machine. Install dirt and water separator

upstream of the machine, if it is not possible to prevent the formation of rust and water

condensation in the air distribution lines.

b) The lubrication conditions and maintenance

see “Maintenance of pneumatic tools“

The proper quantity of grease is very important from the point of good lubrication and low heat

generation. The grease quantities listened in the following table must be complied with:

Grease Quantity in grams

In the crank casing 100

In the bevel gears 40

In the spur gears 30

7

MAINTENANCE OF PNEUMATIC TOOLS

Only proper maintenance can ensure constant performance, reduction in wear and thus, a

decrease in operating costs and an increase in service life.

Our pneumatic tools are equipped for an operating pressure of 6 bar. A regulator setting for an

operating pressure of 4 bar is possible as well as expedient for grinding machines with a built-in

regulator so as to take full advantage of the speed prescribed for the corresponding grinding wheels.

Pneumatic tools should not run empty, because this results in heat and higher wear. The

compressed air should be clean and dry.

This is guaranteed by a proper pneumatic system.

Blow through the pneumatic hose before connecting it.

For the economical use of pneumatic tools. The prescribed air quantities are necessary, i. e. , the

line, armatures and hoses must have the required cross sections so that the ow pressure remains

constant.

Proper lubrication is a must; for this reason, our pneumatic tools usually have built-in oilers.

Which are located between the inlet valve and the motor, and which function in any position. In

smaller and lighter hand tools, these oilers must often be left out, because the machines would then

be too heavy and not easy to manage. In such cases, lubrication must be carried out by service

units or by manual hose oilers. We recommend service units for permanently installed workplaces

(see accessories list). However, where longer hose lines are necessary.

Line oilers built into the hose lines are more effective. The distance between the tool and oiler

should not be more than 5 m.

Most of pneumatic tools have located at the connection a lined-up screen, which is to be

regularly checked and cleaned.

After ending a working task, the machines are to be ushed with a thin oil, or protected some

other way against corrosion.

Visible grease nipples ar provided for regular lubrication of the gears with a grease gun. Note the

following for grease lubrication: Every 60 hours of operation check striking mechanism, friction

bearings and antifriction bearings; if necessary, grease them. Every 300 hours of operation grease

the gears and antifriction bearings anew. In the case of impact wrenches, use a grease gun to

grease the anvil guide before beginning daily work or every 6 to 8 hours. All inner parts must be

lubricated before storing for longer periods of time in order to prevent rusting. It is recommended

to check the vanes and bearings at regular intervals. Store pneumatic tools in dry rooms only.

Lubricating oils to be used:

Generally SAE 5 W to SAE 10

For gearless impact wrenches and small grinders, only SAE 5 W.

For damp compressed air, oils are to be used that take up water ( without losing the lubricating

effect) and that contain anticorrosive additives. At lower temperatures (especially for work

outside) it may be necessary to use an antifreeze lubricant (e.g. Kilfrost, BP Energol AX 10,

Kompranol N 74).

For saw-chain lubrication on chain saws:

Machine oil with adhesive additive, viscosity c ST 49-55’ (6.5-7.5 E)/ 50°C

8

Greases ( free of resins and

acids)

Multi-purpose greases for

antifriction and friction

bearings

Special greases for high-speed

miter gears

Designation in accordance

with DIN 51502 Consistency

class (DIN 51818)

Saponication type Dripping

point Worked penetration

Temperature range

K L 2 k

2

Lithium

185 °C

265 to 295

-25°C to + 125°C

G 000 h

00

Sodium

145°C

400 to 410

-25°C to + 100°C

Before starting: Check correct oiler setting!

Oiler types used on or with our tools

Oiler to mount on the machine or connect in

the hose line

Setting the oiler: The adjustment screw item 2

is visible after removing the screw plug item

3. Theoil supply is decreased by tightening

the screw, and by loosening the screw, more

oil gets into the machine. In most cases it is

sufcient to tighten or loosen the screw by ¼

or ½ of a turn. When plugged, clean borehole

(dia. 2 mm) with wire.

Correct setting; When under pressure and with

the ller screw (item 4) open, the oil must

bubble slightly. The llint lasts for approx. 8

operating hours.

Line oiler

For stationary pneumatic machines and motors,

the lubrication is carried out by lined-up oilers

for horizontal or vertical installation.

Setting of oilers: Shut off air supply. Open plug

item 3. Loosen visible lock nut item 5 with a

socket wrench. Using a screw driver turn back

the tightened screw plug item 4 by ¼ to ½ of

a turn and then lock again. No oil is to get into

the borehole “a” when lling. Close plug item 3

and open the air supply.

Correct setting: A piece of paper held for a short

time in front of the outlet must be coated with

oil without drops forming.

9

Transparent oiler

For installing in permanently equipped

workplaces (especially for type using service

units – see accessories list)

The transparent supply containers allow for

good checking as well as for good setting

possibility by means of a screw driver via a set

screw with visible dripping. (The set screw is

above the lateral thread connection – turning

to the right for less oil; turning to the left for

more oil) The setting (2 to 5 drops per m³/min

air consumption) is to be carried out when air

is owing through, i.e., when the machine is

running.

SPARE PARTS AND ACCESSORIES

Only original spare parts may be used. There is no warranty for damages and liability is

disclaimed, if non-original spare parts and accessories are used.

The repairing of the machine is allowed authorized expert companies only.

The accessories applicable with our machine are listed in our brochure.

TROUBLES HOOTING

Problem Cause Remedy

aMachine does not start Air not connected Connect and open air line

bMachine rotates too

slowly

Operating pressure too

low

Increase operating

pressure (on the machine

) to 6 bar

cGearbox makes strong

noise

Contact authorized expert

company

dOther problems Contact authorized expert

company

REPAIR INSTRUCTION

Disassembly and re-assembly

Dismantling and assembly should only be carried out using the sectional drawing.

Gearbox

Loosen the 2 cap nuts item 94 and 2 screws item 97 and pull out the motor with sealing disc

item 16, bearing item 43 and drive block item 35 from the gear housing item 30. Disconnect the

10

drive block from the rotor and disassemble (watch out for the compensating ring item 47).

Loosen the screws item 88 and 89, remove the gear box cover item 70 and connecting rod item 77.

Remove the screws item 65, pull out the crankshaft item 51 with bearing plate item 62.

Pay attention to compensating ring item 49.

Motor

Unscrew the governor casing item 25 with complete valve. Extract the rotary sleeve item 18

from motor housing.

Motor components as end plate item 7, cylinder bushing item 4, rotor item 11 and end plate

item 13 are pressed forwards out of the motor housing und unscrew the weight clip item 19 from

rear rotor pivot (left-hand thread) and disassemble motor. Check all parts for wear and damage and

replace, if necessary.

Assembly

Assembly is carried out essentially using the reverse procedure. The correct distancing of the

motor must be observed. The axial play between rotor and the end plates should be approx.

0.04mm in both sides. Screws items 79 and hexagonal nuts item 87 for fastening of connecting rod

item 78 must be tightened with 15 Nm and connected with Loctite 242. Tighten cap nuts item

94 with 4 Nm.

11

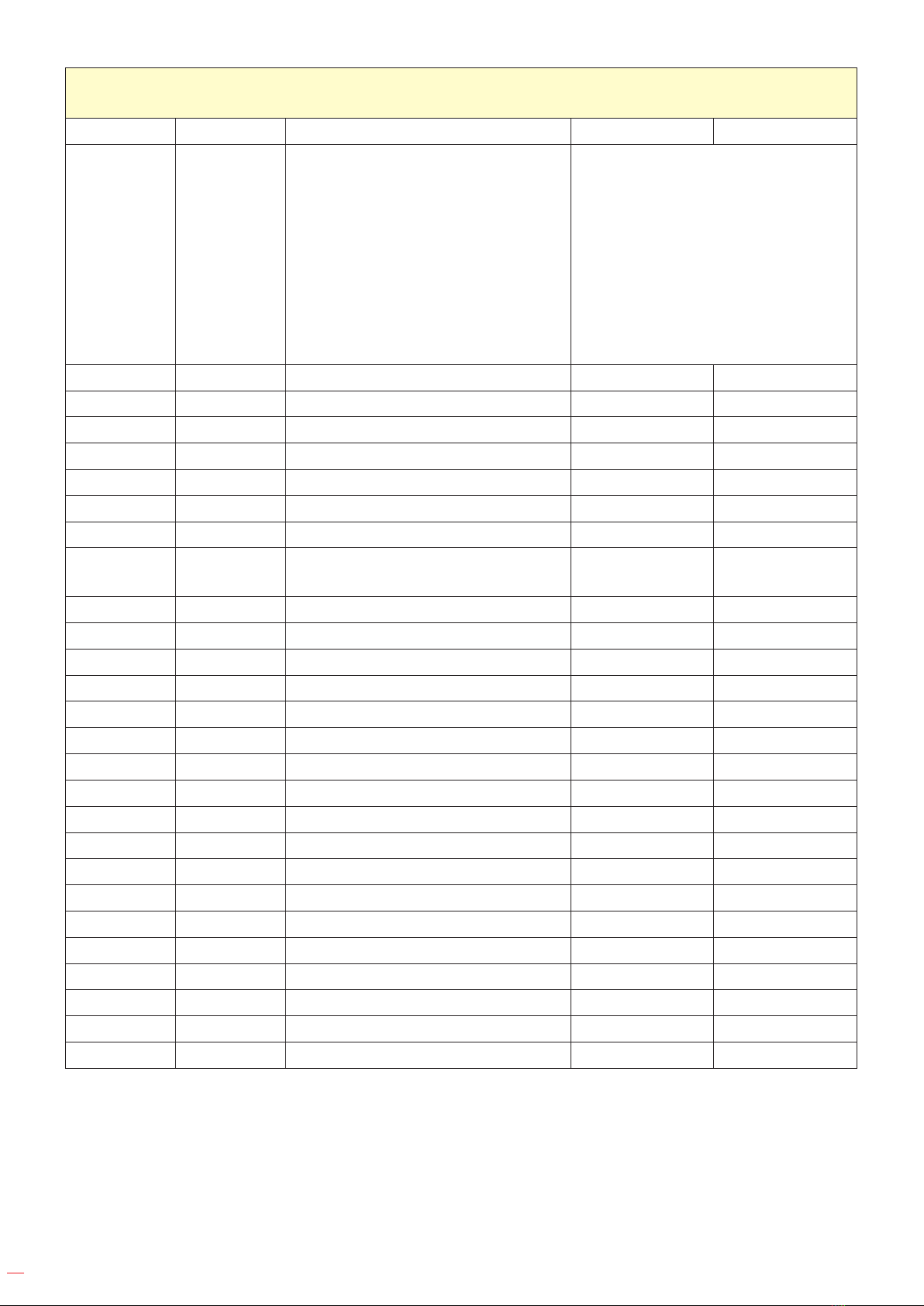

SPARE PARTS

Only original spare parts may be used. There is no warranty for damages and liability is

disclaimed, if non-original spare parts and accessories are used.

Pneumatic Reciprocating Saw. COD. 79617 / COD. 79618

Qty. Description

1 Motor, Assy.

1Gearbox head, Assy.

Motor, Assy. COD. 79617

Item Qty. Remarks

1 1

2 1 *

3 1 *

4 1

5 2

1 * With ítem 7-10

7 1 *

8 1

9 1

10 1 *

11 1

12 4 *

13 1 *

14 1 *

15 1

16 1

17 1 *

18 1

19 1

20 10

21 2

22 1

23 1

24 1

25 1

26 1

26 1

27 4

28 1

320 1 See extra list

* Wear and tear parts to be stored in case of continuous use.

12

13

Twist valve

Item Qty. Description Remarks

301 1 Valve housing, Assy. with item 312

302 1 Twist valve

303 1 Steel ball

304 1 Steel ball

305 1 Sealing *

306 1 Pressure spring

307 2 O-Ring *

308 1 Connecting nipple

311 1 Locking screw

312 1 Adjusting screw

313 1 Sealing *

314 1 Locking screw

315 1 Sealing *

* Wear and tear parts to be stored in case of continuous use.

14

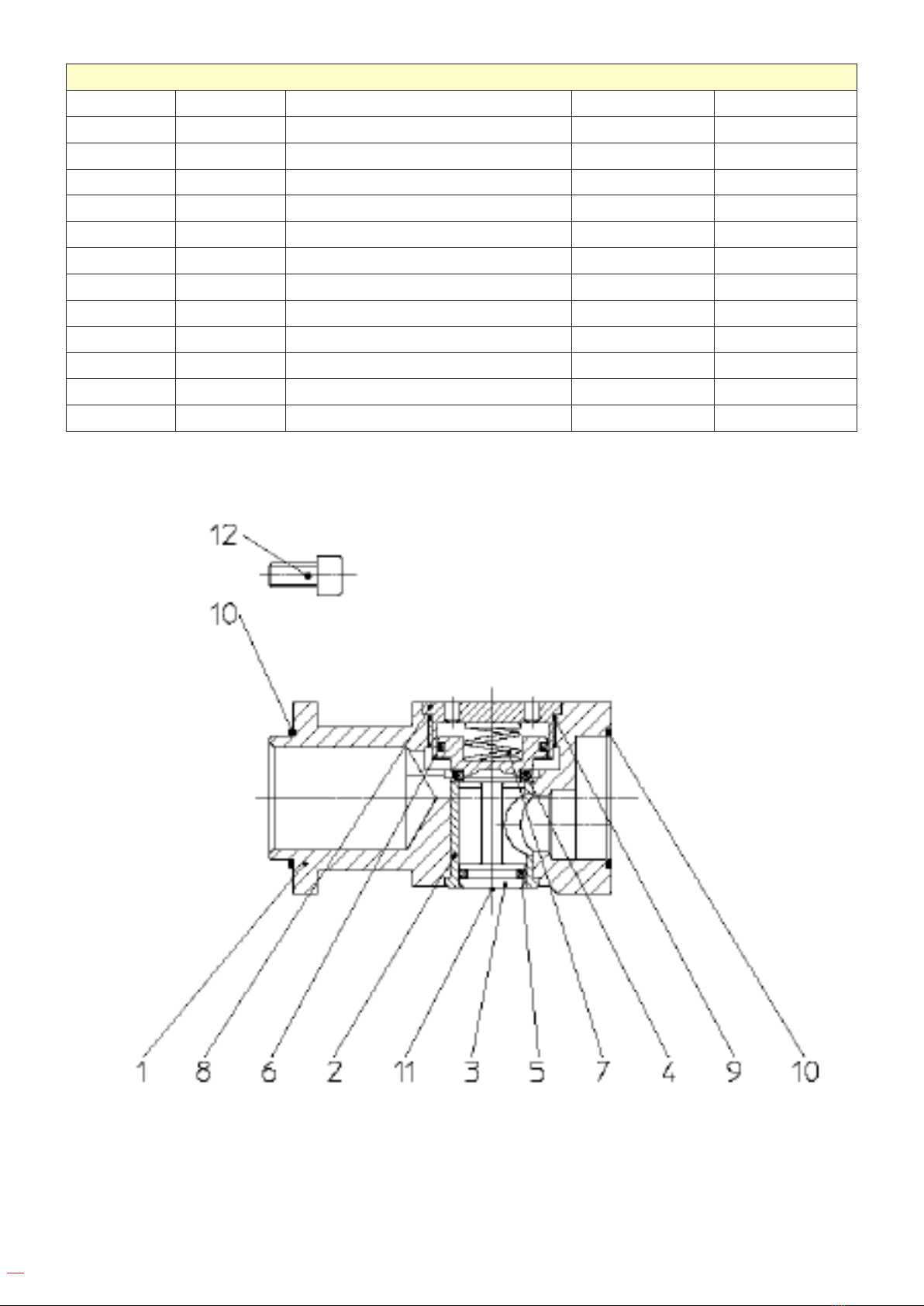

Sensor Block

Item Qty. Description Remarks

1 1 Sensor housing, Assy.

2 1 Control bushing

3 1 Differential piston,Assy.

4 1 O-Ring *

5 1 O-Ring *

6 1 O-Ring *

7 1 Pressure spring

8 1 Guide bushing

9 1 O-Ring *

10 2 O-Ring *

11 1 Marking

12 4 Fillister-head screw

* Wear and tear parts to be stored in case of continuous use.

15

Gear head, Assy.

Item Qty. Description Remarks

30 1 Gear housing, Assy. with item 31

31 1 Sliding bearing

34 1 Grooved ball bearing *

35 1 Planet carrier

36 2 Bearing bolt

37 2 Planetary wheel

38 2 Needle cage *

41 1 Rim of the gear

42 2 Slotted llister-head screw

43 1 Grooved ball bearing *

44 1 Feather key

45 1 Snap ring

1 Bevel gear, Assy. item 46+48

47 1 Compensating ring

47 1 Compensating ring

49 1 Compensating ring

49 1 Compensating ring

50 1 Feather key

1 Crankshaft, Assy. item 51-56

51 1 Crankshaft

52 1 Bolt

53 1 Bearing, Assy. *

55 1 Washer

56 1 Snap ring

58 1 Grooved ball bearing *

59 1 Hexagonal nut

62 1 Bearing plate

63 1 Snap ring

64 2 Grooved pin

65 4 Fillister-head screw

66 4 Locking plate

68 1 Washer

69 2 Grooved pin

70 1 Gearbox cover, Assy. with item

71+72

71 1 Bearing bushing

72 1 Locking device, Assy.

1 Connecting rod, Assy. item 77-87

77 1 Connecting rod

78 1 Rocker arm

79 2 Fillister-head screw

80 1 Half length taper grooved pin

16

81 2 Threaded pin

82 1 Pressure plate

83 2 Hexagonal nut

84 4 Washer

85 2 Adapter sleeve

86 2 Spring washer

87 2 Hexagonal nut

88 1 Fillister-head screw

89 8 Fillister-head screw

90 4 Sliding bearing

91 2 Scraper

92 1 Felt packing

93 2 Stud bolt

94 2 Cap nut

95 13 Locking plate

96 1 Handle, Assy. item 96.1-96.2-

6.4+96.5

96.1 1 Crank handle

96.2 1 Frame

96.4 1 Hexagonal screw

96.5 1 Hexagonal nut

97 2 Fillister-head screw

98 2 Fillister-head screw

* Wear and tear parts to be stored in case of continuous use.

17

18

Motor, Assy. COD. 79617

Item Qty. Description Remarks

1 1 Motor housing, Assy.

2 1 O-Ring *

3 1 O-Ring *

4 1 Cylinder bushing

5 1 Spiral pin

1 End plate, Assy. * Mit Pos. 7-10

7 1 End plate *

8 1 Grooved ball bearing

9 1 Snap ring

10 1 Spacer ring *

11 1 Rotor

12 4 Vane *

13 1 End plate *

14 1 Grooved ball bearing *

15 1 Snap ring

16 1 Sealing disc

17 1 Felt stripe *

18 1 Rotary sleeve

19 1 Weight clip

20 10 Governor weight

21 2 Cylinder pin

22 1 Pressure spring

23 1 Governor sleeve

24 1 Governor nut

25 1 Governor casing, Assy.

26 1 O-Ring *

27 4 Fillister-head screw

28 1 Safety lever valve, Assy. see extra list

29 Compensating ring

29 Compensating ring

* Wear and tear parts to be stored in case of continuous use.

19

20

Safety lever valve

R ¾“ - with oiler

Item Qty. Description Remarks

101 1 Valve housing, Assy. item102-104+109,122,123+128

102 1 Ring

103 1 Valve bushing

104 1 Control bushing

105 1 Pin

106 1 O-Ring *

107 1 Plastic ball

108 1 Pressure spring

109 1 Nipple, Assy. with screen +

ring

110 1 O-Ring *

111 1 Valve latch

112 1 Rivet pin

114 1 Differential piston, Assy. with item 115

115 1 O-Ring *

116 1 O-Ring *

117 1 O-Ring *

118 1 Pressure spring

119 1 Guide bushing

120 1 O-Ring *

121 1 Sign

122 1 Lubricator pipe

123 1 Adjusting screw

124 1 Gasket *

125 1 Locking screw

126 1 Gasket *

127 1 Locking screw

128 1 O-Ring *

* Wear and tear parts to be stored in case of continuous use.

This manual suits for next models

1

Table of contents

Languages:

Other EGAmaster Saw manuals