EG&G ORTEC 426 Service manual

mi

n

Model

426

Linear

Gate

Operating

and

Service

Manual

Model

426

Linear

Gate

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

23"

on

rear

panel

Printed

in

U.S.A.

EG&G

ORTEC

Part

Number

733200

2740

1

.OC

0787

standard

Warranty

for

EG&G

ORTEC

Nuclear

Electronic

Instruments

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

two

yearsfrom

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

oruseof

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

pur

chase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obliga

tion

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEC

nuclear

electronic

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warrany

repair

and

as

a

source

of

statistical

information

for

design

improvements.

Repair

Service

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

AuthorizSlfon

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing,

by

telephone

((615)

482-4411

]

or

by

telex

(55-7450)

of

the

nature

of

the

fault

of

the

instrument

being

re

turned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

(In

the

case

where

the

instrument

did

not

function

upon

pur

chase,

EG&G

ORTEC

will

pay

shipment

costs

both

ways.)

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

Damage

in

Transit

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

Ill

CONTENTS

Page

WARRANTY

'i

PHOTOGRAPHS

iv

1.

DESCRIPTION

1

2.

SPECIFICATIONS

1

2.1

Performance

1

2.2

Controls

1

2.3

Inputs

1

2.4

Output

2

2.5

Electrical

and

Mechanical

2

2.6

Related

Equipment

2

3.

INSTALLATION

2

3.1

Connection

to

Power

2

3.2

Input

Signal

Connection

to

Linear

Gate

2

3.3

Logic

Input

to

the

Enable

Input

2

3.4

Logic

Inputs

to

the

DC

Inhibit

Input

3

3.5

Linear

Output

Signal

Connections

and

Terminating

Impedance

Considerations

3

4.

OPERATIONS

3

4.1

Front

Panel

Controls

3

4.2

Initial

Testing

and

Observation

of

Pulse

Waveforms

4

4.3

Connector

Data

4

4.4

Typical

Operating

Considerations

4

5.

CIRCUIT

DESCRIPTION

5

5.1

Linear

Gate

—

Etched

Board

426-0201

5

6.

MAINTENANCE

6

6.1

Testing

the

Performance

of

the

Linear

Gate

6

6.2

Adjustment

of

Linear

Gating

Duration

6.3

Adjustment

of

Linear

Gate

Pedestal

6.4

Tabulated

Test

Point

Voltages

6.5

Suggestions

for

Troubleshooting

6.6

Factory

Repair

Block

Diagram

and

Schematic

426-0200-B2

426-0000-S2

ILLUSTRATIONS

4

Fig.

4.2

Output

of

Linear

Gate

^

Fig.

4.1

Gating

Action

of

Linear

Gate.

IV

-

'■?'

'^'■1

""r---

-.

V

g^-M

i

"

-r

%,

.

iiSsiss#

O

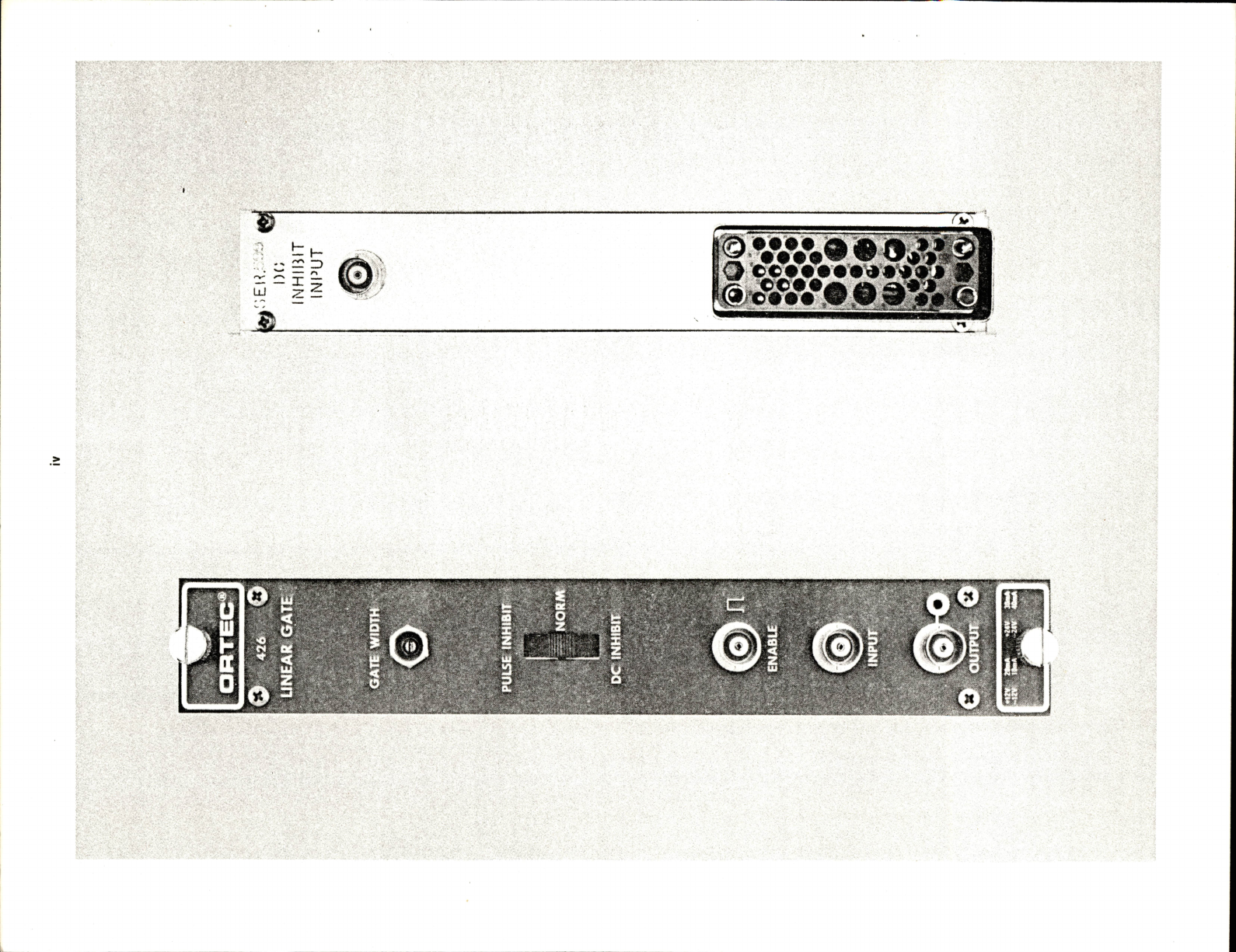

426

O

UNEAR

GATE

GATE

WIDTH

'H'f:,;

.

^

,»»^e

--

<v,-^

W9iBxMSIs§MliSSM

'

'

'■

-

•

1

s«®Slafai

:->El^;

DC

INHIIilT

INPUT

.'»

^

'

-

'..

.

-1

-

'

'J..

•

■

■;

"-U^"

'

Ut

sJ^sSsftpfsPiH

iili^M

'•.

'

i

111

j

lii

'■

^5

r:W;^-3

/■:

j

'

i

:'

.

ORTEC

426

LINEAR

GATE

1.

DESCRIPTION

The

ORTEC

426

is

a

modular

Linear

Gate

that

provides

a

variable

gate

duration

whose

width

is

control

led

by

a

single-

turn

front-panel-mounted

potentiometer.

The

nominal

gate

duration

range

is

from

0.3

to

4

fisec.

Operation

of

the

Linear

Gate

is

controlled

by

the

application

of

a

positive

Enable

pulse.

The

Linear

Gate

is

useful

in

appl

ications

that

require

inhibiting

a

linear

signal

according

to

chosen

coincidence

or

timing

requirements,

e.g.,

reducing

the

counting

rate

in

sub

sequent

l

inear

analysis

equipment.

The

426

is

designed

to

meet

the

recommended

interchange-

abil

ity

standards

of

USAEC

Report

TID-20893

(Rev.)

.

An

ORTEC

401/402

Series

Bin

and

Power

Supply

provides

all

necessary

power

through

the

rear

module

power

connector.

All

signal

levels

and

impedances

are

compatible

with

other

modules

in

the

ORTEC

400

Series.

The

basic

function

of

the

426

is

to

accept

al

l

pulse

shapes

existing

in

the

ORTEC

400

Series

l

inear

function

modules.

If

the

input

signal

is

bipolar,

the

negative

portion

wi

l l

not

be

passed

through

the

Linear

Gate.

The

input

impedance

is

greater

than

5000^2,

and

the

input

is

normal

ly

sent

from

the

factory

ac-coupled.

The

input

can

be

operated

dc-coupled

if

desired

(refer

to

Section

4.4).

A

dc-restoration

network

at

the

input

reduces

basel

ine

shift

at

high

counting

rates.

The

restoration

network

works

on

both

unipolar

and

bipolar

in

put

pulse

shapes.

The

Linear

Gate

proper

consists

of

a

series-

paral

lel

saturated

transistor

switch.

This

switch

network

incorporates

an

adjustment

that

allows

the

Linear

Gate

to

operate

with

no

pedestal.

The

series-parallel

transistor

switch

is

activated

by

a

transistor-pair

current

switch.

This

latter

switch

is

activated

by

,the

gate

control

pulse

which

is

generated

with

the

appl

ication

of

an

externally

generated

Enable

pulse.

The

output

of

the

Linear

Gate

circuit

is

fed

into

a

cascode

emitter-fol

lower

cable

driver.

The

ORTEC

426

has

two

operating

modes:

normally

blocks

all

input

signals

not

accompanied

by

an

Enable

pulse

and

normal

ly

passes

all

signals

unless

accompanied

by

an

Inhibit

signal.

The

Inhibit

signal

can

be

fed

into

the

front

panel

Enable

connector

for

Pulse

Inhibit

operation

or

into

the

DC

Inhibit

Input

connector

for

dc

or

continuous

inhibit

opera

tion.

2.

SPECIFICATIONS

2.1.

PERFORMANCE

Gain

Unity.

Integral

Nonlinearity

<0.15%

from

0.2

to

10

V.

Pulse

Feedthrough

<10

mV

with

a

lO-V

input

pulse.

Temperature

Stability

<0.015%/°C,

0

to

50°C.

Counting

Rate

The

gain

shift

of

a

4-V

reference

pulse

is

<0.25%

with

the

application

of

an

additional

count

rate

of

65,000

counts/sec

of

6.0-V

random

pulses.

furnished

through

the

Enable

input

connector,

which

is

on

the

front

panel,

or

the

DC

Inhibit

Input

connector

on

the

rear

panel:

Norm

Input

pulse

wi

ll

be

gated

through

to

the

output

during

a

gate

width

interval

fol

lowing

the

leading

edge

of

each

Enable

input

pulse.

Pulse

Inhibit

Input

pulses

wil

l

be

inhibited

from

passing

through

the

output

during

a

gate

width

interval

following

each

Bnable

input

pulse.

DC

Inhibit

Input

pulses

wi

l l

be

inhibited

from

passing

through

the

output

during

intervals

of

pulses

or

dc

levels

through

the

DC

Inhibit

Input

connector

on

the

rear

panel.

2.2.

CONTROLS

Gate

Width

Continuously

variable

from

0.3

to

4

fjsec.

Output

Pedestal

Adjustable

to

<1

mV.

Pulse

Inhibit/Norm/DC

Inhibit

3-position

mode

switch

that

permits

selection

of

the

function

of

any

pulse

or

dc

level

2.3.

INPUTS

Input

Unipolar

or

bipolar

with

positive

portion

leading.

Rated

range

0.2

to

10

V,

12

V

maximum.

Input

impedance

>5000T2.

BNC

connector

on

front

panel

.

Enable

(or

Inhibit)

Any

positive

input

>2

V,

maximum

in

put

20

V.

Enable

impedance

1000^2,

dc-coupled;

Inhibit

impedance

65012,

dc-coupled.

Front

panel

BNC

connector

for

each.

DC

Inhibit

Rear

panel

BNC

connector;

inhibits

input

pulses

from

passing

through

the

output

during

intervals

of

pulses

or

dc

levels;

impedance

65012,

dc-coupled.

Weight

(Shipping)

4.0

lb

(1.82

kg).

Weight

(Net)

2.1

lb

(0.96

kg).

Dimensions

Single-width

module

(1.35

by

8.714

in.)

per

TID-20893

(Rev.).

2.4.

OUTPUT

Rated

output

range

0.2

to

10

V

positive;

12

V

maximum.

Output

impedance

~212,

short-circuit

protected.

BNC

con

nector.

2.5.

ELECTRICAL

AND

MECHANICAL

Power

Requirements

-1-24

V,

30

mA;

-H2

V,

16

mA;

.

-24

V,

49

mA;

-12

V,

4.9

mA.

2.6.

RELATED

EQUIPMENT

The

input

to

the

linear

gate

of

the

426

can

be

from

any

of

the

linear

circuitry

in

theORTEC

NIM-standard

modules.

In

typical

applications

the

output

of

the

linear

gate

feeds

a

multichannel

analyzer

directly.

The

output

is

also

compatible

with

any

of

the

linear

modular

circuitry

in

the

ORTEC

NIM-

standard

modules.

3.

INSTALLATION

The

ORTEC

426

contains

no

internal

power,

but

is

used

in

conjunction

with

an

ORTEC

401

/402

Series

Bin

and

Power

Supply,

which

is

intended

for

rack

mounting.

Therefore

if

vacuum

tube

equipment

is

operated

in

the

same

rack

with

the

426,

there

must

be

sufficient

cooling

air

circulating

to

prevent

any

localized

heating

of

the

all-transistor

circuitry

used

throughout

the

426.

The

temperature

of

equipment

mounted

in

racks

can

easily

exceed

120°F

(50°C)

unless

precautions

are

taken.

The

426

should

not

be

subjected

to

temperatures

in

excess

of

120°F

(50

C).

3.1.

CONNECTION

TO

POWER

Turn

off

the

Bin

power

supply

when

inserting

or

removing

modules.

The

ORTEC

400

Series

is

designed

so

that

it

is

not

possible

to

overload

the

Bin

power

supply

with

a

full

complement

of

modules

in

the

Bin.

Since,

however,

this

may

not

be

the

case

when

the

Bin

contains

modules

of

other

than

ORTEC

design,

the

Power

Supply

voltages

should

be

checked

after

the

modules

are

inserted.

The

401/402

has

test

points

on

the

Power

Supply

control

panel

to

monitor

the

dc

voltages.

When

using

the

ORTEC

426

outside

the

Bin

and

Power

Supply,

take

care

to

ensure

that

the

power

jumper

cable

used

properly

accounts

for

the

Power

Supply

grounding

circuits

provided

in

the

recommended

standards

of

AEC

TID-20893

(Rev.).

Both

clean

and

dirty

ground

connections

are

provided

to

ensure

proper

reference

voltage

feedback

into

the

Power

Supply,

and

these

must

be

preserved

in

remote

cable

installations.

Be

careful

to

avoid

ground

loops

when

the

module

is

operated

outside

the

Bin.

3.2.

INPUT

SIGNAL

CONNECTION

TO

LINEAR

GATE

The

linear

input

to

the

ORTEC

426

is

on

the

front

panel

BNC

connector

and

is

directly

compatible

with

the

output

of

all

linear

amplifiers,

biased

amplifiers,

pulse

stretchers,

and

delay

amplifiers

and

with

all

linear

circuitry

found

in

the

ORTEC

400

Series.

The

Linear

Gate

passes

only

positive

uni

polar

signals

and/or

the

positive

portion

of

bipolar

signals.

This

must

be

kept

in

mind

when

putting

in

linear

signals

from

other

than

ORTEC

products.

The

linear

input

to

the

426

is

ac-coupled

as

normally

supplied,

but

may

be

dc-

coupled

if

desired.

If

the

linear

input

to

the

426

is

driven

from

a

low

driving

impedance,

such

as

the

output

from

an

ORTEC

410

Linear

Amplifier,

the

426

linear

input

should

be

terminated

in

the

characteristic

impedance

of

the

connecting

coaxial

cable.

3.3.

LOGIC

INPUT

TO

THE

ENABLE

INPUT

The

input

pulses

to

the

Enable

input

may

come

from

any

source

of

logic

pulses.

The

input

impedance

of

the

Enable

input

is

100012,

dc-coupled,

and

some

care

must

be

given

to

ensure

that

reflections

do

not

occur

in

the

driving

trans

mission

cable.

This

probably

can

best

be

avoided

by

termi

nating

the

driving

cable

at

the

Enable

input

with

the

characteristic

impedance

of

the

driving

cable.

The

amplitude

and

width

of

the

Enable

input

signal

are

specified

in

Section

2.

The

maximum

width

of

the

Enable

input

is

not

specified

in

Section

2

and

indeed

may

be

any

width

since

the

Enable

signal

is

regenerated

to

al

low

gate

width

duration

to

be

independent

of

the

pulse

shape

of

the

Enable

input.

The

minimum

recommended

width

of

the

Enable

Input

is

50

nsec

measured

at

50%

amplitude,

although

narrower

pulses

with

larger

amplitude

will

trigger

the

Enable

circuitry.

3.4.

LOGIC

INPUTS

TO

THE

DC

INHIBIT

INPUT

The

same

considerations

of

Section

3.3

apply

to

input

pulses

to

the

DC

Inhibit

Input

connector.

This

input

provides

the

faci

lity

to

block

the

passage

of

signals

through

the

Linear

Gate

by

the

application

of

a

dc

voltage

either

in

the

basic

form

of

a

battery

and

switch

contact

or

by

the

application

of

a

pulse

waveform

between

dc

voltage

levels.

The

input

is

dc-coupled

and

has

an

impedance

of

approximately

650J2.

A

maximum

dc

voltage

of

20

V

is

allowed

on

this

input.

A

DC

Inhibit

control

is

not

regenerated

internal

ly,

but

exists

throughout

the

duration

of

the

inhibiting

signal

.

3.5.

LINEAR

OUTPUT

SIGNAL

CONNECTIONS

AND

TERMINATING

IMPEDANCE

CONSIDERATIONS

The

source

impedance

of

the

0-

to

10-V

standard

linear

out

puts

of

most

400

Series

modules

is

approximately

1J2.

Interconnection

of

l

inear

signals

is

thus

noncritical,

since

the

input

impedance

of

circuits

to

be

driven

is

not

important

in

determining

the

actual

signal

span,

e.g.,

0-10

V,

delivered

to

the

following

circuit.

Paral

leling

several

loads

on

a

single

out

put

is

therefore

permissible

while

preserving

the

0-

to

10-V

signal

span.

Short

lengths

of

interconnecting

coaxial

cable

(up

to

approximately

4

ft)

need

not

be

terminated.

If,

however,

a

cable

longer

than

approximately

4

ft

is

necessary

on

a

l

inear

output,

it

should

be

terminated

in

a

resistive

load

equal

to

the

cable

impedance.

Since

the

output

imped

ance

is

not

purely

resistive

and

is

slightly

different

for

each

individual

module,

when

a

certain

given

length

of

coaxial

cable

is

connected

and

is

not

terminated

in

the

characteristic

impedance

of

the

cable,

oscillations

wi

l l

generally

be

observed.

These

osci

llations

can

be

suppressed

for

any

length

of

cable

by

properly

terminating

the

cable

either

in

series

at

the

sending

end

or

in

shunt

at

the

receiving

end

of

the

line.

To

properly

terminate

the

cable

at

the

receiving

end,

it

may

be

necessary

to

consider

the

input

impedance

of

the

driven

circuit,

choosing

an

additional

parallel

resistor

to

make

the

combination

produce

the

desired

termination

resistance.

Series

terminating

the

cable

at

the

sending

end

may

be

preferable

in

some

cases

where

receiving-end

terminating

is

not

desirable

or

possible.

When

series-

terminating

at

the

sending

end,

full

signal

span,

i.e.,

amp

litude,

is

obtained

at

the

receiving

end

only

when

it

is

essentially

unloaded

or

loaded

with

an

impedance

many

times

that

of

the

cable.

This

may

be

accomplished

by

insert

ing

a

series

resistor

equal

to

the

characteristic

impedance

of

the

cable

internal

ly

in

the

module

between

the

actual

amplifier

output

on

the

etched

board

and

the

output

con

nector.

Remember

that

this

impedance

is

in

series

with

the

input

impedance

of

the

load

being

driven,

and

in

the

case

where

the

driven

load

is

900J2

a

decrease

in

the

signal

span

of

approximately

10%

wi

ll

occur

for

a

93J2

transmission

line.

A

more

serious

loss

occurs

when

the

driven

load

is

93n

and

the

transmission

system

is

93K2;

in

this

case,

a

50%

loss

will

occur.

BNC

connectors

with

internal

terminators

are

available

from

a

number

of

connector

manufacturers

in

nominal

values

of

50,

100,

and

100012.

ORTEC

stocks

in

limited

quantity

both

the

50

and

10012

BNC

terminators.

The

BNC

terminators

are

quite

convenient

to

use

in

conjunction

with

a

BNC

tee.

4.

OPERATION

4.1.

FRONT

PANEL

CONTROLS

Gate

Width

A

single-turn

potentiometer

provided

to

adjust

the

gate

width

to

the

desired

value

within

the

nominal

range

of

0.3

to

4

jusec.

This

control

is

recess-mounted

and

as

such

is

a

screwdriver

adjustment,

but

it

may

be

panel-mounted

so

that

a

knob

may

be

added

to

the

potentiometer

shaft

to

allow

finger-thumb

adjustment

if

this

seems

desirable.

Mode

Switch

A

3-position

switch

used

to

set

the

Linear

Gate

into

one

of

the

fol

lowing

operation

modes:

Normal

In

this

mode

the

Linear

Gate

normally

blocks

al

l

input

signals

unless

the

Enable

signal

sets

the

Linear

Gate

to

pass

signals

for

a

selected

duration

(as

set

by

the

Pulse

Width

control)

after

receiving

an

Enable

pulse.

Pulse

Inhibit

The

reciprocal

of

the

Normal

mode

is

available

with

the

switch

in

this

position,

i.e.,

the

Linear

Gate

passes

all

signals

except

when

a

pulse

isapplied

to

the

Enable

input.

The

pulse

on

the

Enable

input

causes

the

gate

to

block

the

passage

of

signals

through

the

Linear

Gate

for

a

duration

set

by

the

Pulse

Width

adjustment.

DC

Inhibit

This

mode

is

identical

to

the

Pulse

Inhibit

mode

except

that

the

application

of

an

inhibit

or

block

input

must

be

made

on

the

rear

panel

BNC

connector,

and

the

Linear

Gate

wil

l

remain

blocked

for

the

duration

that

the

dc

signal

is

applied

to

the

DC

Inhibit

Input

connector.

For

applications

where

the

Linear

Gate

is

desired

to

be

switched

for

Normal,

i

.e.,

selectively

passing,

to

a

condition

of

passing

al

l

signals,

the

switch

should

be

operated

between

Normal

and

DC

Inhibit

position

and

there

should

be

no

connection

on

the

DC

Inhibit

Input

rear

panel

connector.

4.2.

INITIAL

TESTING

AND

OBSERVATION

OF

PULSE

WAVEFORMS

See

Sections

6.1

and

6.2

for

test

performance

data.

4.3.

CONNECTOR

DATA

CN1

Input,

BNC

Connector

AC-coupled

linear

gate

input;

input

impedance

>50000:

input

rated

voltage

range

0.2

to

10

V;

maximum

input

12

V.

To

minimize

reflections

when

driving

from

low

impedance

sources

into

this

connector,

a

terminator

equal

to

the

characteristic

impedance

of

the

driving

cable

should

be

shunted

from

this

connector

to

ground.

CN2

Linear

Gate

Output,

BNC

Connector

DC-coupled

out

put;

output

impedance

<20,;

positive

output

signals

only

with

rated

range

of

0.2

to

10

V;

maximum

output

12

V.

TP2

Linear

Gate

Output

Test

Point

Osci

l

loscope

test

point

for

monitoring

signal

on

l

inear

gate

output

BNC

connector

CN2.

This

test

point

has

470J2

series

resistor

connecting

it

toCN2.

CN3

Enable

Input,

BNC

Connector

DC-coupled;

input

impedance

100012;

requires

a

positive

2-V

pulse;

maximum

input

20

V.

CN4

DC

Inhibit

Input,

BNC

Connector

DC-coupled;

input

impedance

65012;

requires

a

positive

4-V

pulse

or

dc

level;

maximum

input

20

V.

4.4.

TYPICAL

OPERATING

CONSIDERATIONS

In

the

Normal

mode

the

Linear

Gate

is

opened,

i

.e.,

passes

input

signals,

with

the

appl

ication

of

a

positive

pulse

on

the

Enable

input.

The

duration

that

the

Linear

Gate

wi

ll

remain

open

is

normally

continuously

variable

from

0.3

to

4

jusec

with

the

front

panel

control.

For

other

pulse

widths

refer

to

Section

6.2.

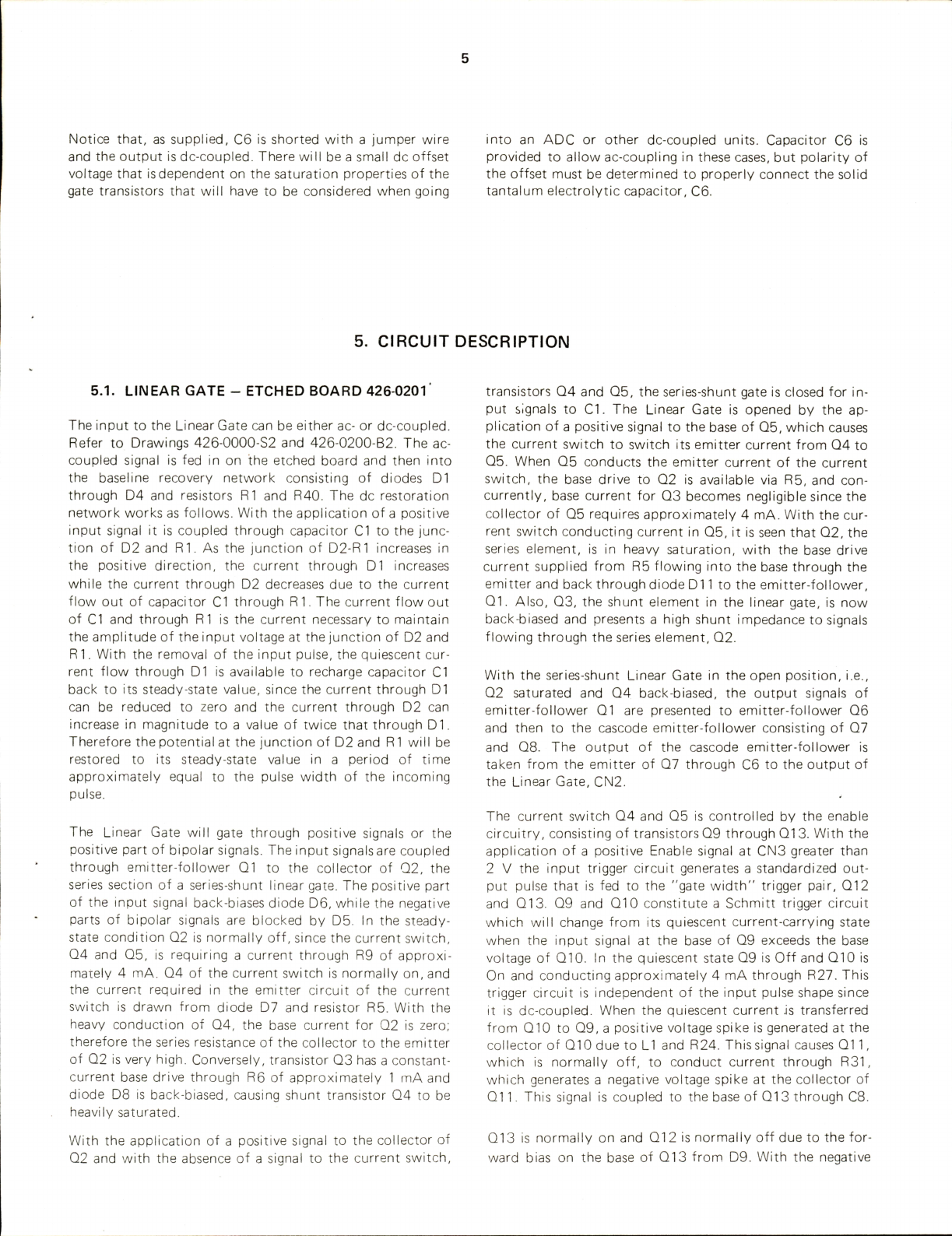

Figure

4.1

illustrates

the

gating

action

of

the

Linear

Gate.

Notice

that

only

the

positive

portion

of

the

input

signal

is

passed

through

the

Linear

Gate.

The

Linear

Gate

has

an

internal

pedestal

adjustment

that

al

lows

the

pedestal

to

be

reduced

to

a

negligible

value

(refer

to

Section

6.2

for

adjustment

procedure).

Figure

4.2

shows

the

output

of

the

Linear

Gate

with

the

pedestal

properly

adjusted

and

improperly

adjusted.

The

Linear

Gate

is

usual

ly

operated

in

the

normal

ly

closed

mode

with

both

input

and

output

ac-coupled.

Two

variants

of

this

mode

are

possible;

gate

operating

normal

ly

open,

i

.e.,

normally

passes

al

l

input

signals

except

when

accompanied

by

an

enable

or

inhibit

pulse,

and

gate

dc-coupled

operating

either

normally

closed

or

normally

open.

Operation

in

the

second

mode

requires

modification

to

the

actual

etched

circuit

board.

For

dc

operation

the

input

and

output

capacitors

C1

and

C6

must

be

replaced

with

jumper

wires

HH

I

•H+f

-H-

"Input"

1-H

Output

ff-

Fig.

4.1.

Gating

Action

of

Linear

Gate.

-Hi-H

1'

11

1

L

1

1

1 1

1

If

IJ

Ji

l

l

1 1

n

Sea

1 1

1 1

'

e;

IOC

50C

Mi

l

mV/c

nsec/

-ntr

m

:m

(a)

Pedestal

Properly

Adjusted.

f

ill

1

1

I

1

1 1 1

1

1

1

1

1

1

I I I

1

1 1

I I

I

!

t

i l

l

1

1

1 1

1

1

1 1

Mi

l

Sea

le:

Id

5d

D

mV/

D

nsec/

:m

cm

(b)

Pedestal

Improperly

Adjusted.

Fig.

4.2.

Output

of

Linear

Gate.

for

a

dc

connection.

With

this

arrangement

a

small

dc

offset

voltage

from

input

to

output

wil

l

be

observed,

approximately

160

mV,

and

must

be

considered

in

the

connection

of

the

gate

to

the

input

and

output

equipment.

For

operation

in

the

Inhibit

mode,

al

l

input

signals

wil

l

be

passed

except

when

an

inhibit

signal

is

applied

to

either

the

Enable

input

or

to

the

DC

Inhibit

Input.

The

particular.in

put

depends

on

the

position

of

the

mode

switch.

Enable

in

put

for

Pulse

Inhibit

position

and

DC

Inhibit

Input

for

the

DC

Inhibit

position

(refer

to

Section

4.1).

With

the

mode

switch

set

to

DC

Inhibit

and

no

input

to

the

DC

Inhibit

In

put

connector,

the

linear

gate

wil

l

pass

all

input

signals.

This

can

be

a

very

useful

mode

for

setting

up

experiments

since

the

proper

timing

of

the

input

signal

to

the

Enable

input

is

not

necessary

to

get

an

output

signal

.

A

sl

ight

difference

in

the

pedestal

magnitude

may

be

noticed

when

changing

modes

from

Normal

to

DC

Inhibit.

The

pedestal

is

normal

ly

adjusted

for

minimum

in

the

Normal

mode,

but

may

be

adjusted

to

suit

the

experiment

in

any

mode

desired.

Notice

that,

as

suppl

ied,

C6

is

shorted

with

a

jumper

wire

and

the

output

is

dc-coupled.

There

will

be

a

small

dc

offset

voltage

that

is

dependent

on

the

saturation

properties

of

the

gate

transistors

that

will

have

to

be

considered

when

going

into

an

ADC

or

other

dc-coupled

units.

Capacitor

C6

is

provided

to

allow

ac-coupling

in

these

cases,

but

polarity

of

the

offset

must

be

determined

to

properly

connect

the

solid

tantalum

electrolytic

capacitor,

C6.

5.

CIRCUIT

DESCRIPTION

5.1.

LINEAR

GATE

-

ETCHED

BOARD

426-0201

The

input

to

the

Linear

Gate

can

be

either

ac-

or

dc-coupled.

Refer

to

Drawings

426-0000-S2

and

426-0200-82.

The

ac-

coupled

signal

is

fed

in

on

the

etched

board

and

then

into

the

basel

ine

recovery

network

consisting

of

diodes

D1

through

D4

and

resistors

R1

and

R40.

The

dc

restoration

network

works

as

fol

lows.

With

the

appl

ication

of

a

positive

input

signal

it

is

coupled

through

capacitor

C1

to

the

junc

tion

of

D2

and

R1.

As

the

junction

of

D2-R1

increases

in

the

positive

direction,

the

current

through

D1

increases

while

the

current

through

D2

decreases

due

to

the

current

flow

out

of

capacitor

C1

through

R1.

The

current

flow

out

of

C1

and

through

R1

Is

the

current

necessary

to

maintain

the

amplitude

of

the

input

voltage

at

the

junction

of

D2

and

R1

.

With

the

removal

of

the

input

pulse,

the

quiescent

cur

rent

flow

through

D1

is

available

to

recharge

capacitor

C1

back

to

its

steady-state

value,

since

the

current

through

D1

can

be

reduced

to

zero

and

the

current

through

D2

can

increase

in

magnitude

to

a

value

of

twice

that

through

D1.

Therefore

the

potential

at

the

junction

of

D2

and

R1

will

be

restored

to

its

steady-state

value

in

a

period

of

time

approximately

equal

to

the

pulse

width

of

the

incoming

pulse.

The

Linear

Gate

will

gate

through

positive

signals

or

the

positive

part

of

bipolar

signals.

The

input

signals

are

coupled

through

emitter-follower

Q1

to

the

col

lector

of

Q2,

the

series

section

of

a

series-shunt

linear

gate.

The

positive

part

of

the

input

signal

back-biases

diode

D6,

whi

le

the

negative

parts

of

bipolar

signals

are

blocked

by

D5.

In

the

steady-

state

condition

Q2

is

normal

ly

off,

since

the

current

switch,

Q4

and

Q5,

is

requiring

a

current

through

R9

of

approxi

mately

4

mA.

Q4

of

the

current

switch

is

normally

on,

and

the

current

required

in

the

emitter

circuit

of

the

current

switch

is

drawn

from

diode

D7

and

resistor

R5.

With

the

heavy

conduction

of

Q4,

the

base

current

for

Q2

is

zero;

therefore

the

series

resistance

of

the

col

lector

to

the

emitter

of

Q2

is

very

high.

Conversely,

transistor

Q3

has

a

constant-

current

base

drive

through

R6

of

approximately

1

mA

and

diode

D8

is

back-biased,

causing

shunt

transistor

Q4

to

be

heavily

saturated.

With

the

application

of

a

positive

signal

to

the

col

lector

of

Q2

and

with

the

absence

of

a

signal

to

the

current

switch.

transistors

Q4

and

Q5,

the

series-shunt

gate

is

closed

for

in

put

signals

to

C1.

The

Linear

Gate

is

opened

by

the

ap

plication

of

a

positive

signal

to

the

base

of

Q5,

which

causes

the

current

switch

to

switch

its

emitter

current

from

Q4

to

Q5.

When

Q5

conducts

the

emitter

current

of

the

current

switch,

the

base

drive

to

Q2

is

avai

lable

via

R5,

and

con

currently,

base

current

for

Q3

becomes

negligible

since

the

col

lector

of

Q5

requires

approximately

4

mA.

With

the

cur

rent

switch

conducting

current

in

Q5,

it

is

seen

that

Q2,

the

series

element,

is

in

heavy

saturation,

with

the

base

drive

current

supplied

from

R5

flowing

into

the

base

through

the

emitter

and

back

through

diode

D11

to

the

emitter-fol

lovyer,

Ql.

Also,

Q3,

the

shunt

element

in

the

linear

gate,

is

now

back-biased

and

presents

a

high

shunt

impedance

to

signals

flowing

through

the

series

element,

Q2.

With

the

series-shunt

Linear

Gate

in

the

open

position,

i.e.,

Q2

saturated

and

Q4

back-biased,

the

output

signals

of

emitter-follower

Ql

are

presented

to

emitter-follower

06

and

then

to

the

cascode

emitter-follower

consisting

of

07

and

08.

The

output

of

the

cascode

emitter-fol

lower

is

taken

from

the

emitter

of

07

through

C6

to

the

output

of

the

Linear

Gate,

CN2.

The

current

switch

04

and

05

is

controlled

by

the

enable

circuitry,

consisting

of

transistors

09

through

013.

With

the

application

of

a

positive

Enable

signal

at

CN3

greater

than

2

V

the

input

trigger

circuit

generates

a

standardized

out

put

pulse

that

is

fed

to

the

"gate

width"

trigger

pair,

012

and

013.

09

and

010

constitute

a

Schmitt

trigger

circuit

which

wi

l

l

change

from

its

quiescent

current-carrying

state

when

the

input

signal

at

the

base

of

09

exceeds

the

base

voltage

of

O10.

In

the

quiescent

state

09

is

Off

and

O10

is

On

and

conducting

approximately

4

mA

through

R27.

This

trigger

circuit

is

independent

of

the

input

pulse

shape

since

it

is

dc-coupled.

When

the

quiescent

current

.is

transferred

from

O10

to

09,

a

positive

voltage

spike

is

generated

at

the

col

lector

of

O10

due

to

LI

and

R24.

This

signal

causes

011,

which

is

normally

off,

to

conduct

current

through

R31,

which

generates

a

negative

voltage

spike

at

the

col

lector

of

011.

This

signal

is

coupled

to

the

base

of

013

through

C8.

013

is

normal

ly

on

and

012

is

normally

off

due

to

the

for

ward

bias

on

the

base

of

013

from

D9.

With

the

negative

signal

from

the

collector

of

Q11

,

Q13

turns

off

and

Q12

conducts

the

quiescent

current

through

R33,

the

common-

emitter

resistor.

The

current

through

Q12

wil

l

flow

unti

l

capacitor

C8

charges

enough

to

cause

the

base

of

Q13

to

equal

the

base

voltage

of

Q12.

At

this

time

Q13

wi

l l

return

to

its

stable

state,

conducting

the

quiescent

current

through

R33.

The

duration

that

Q12

conducts

is

controlled

by

the

time

constant

of

R34

and

R35

and

C8.

The

gate

width

is

then

seen

to

be

controlled

by

the

setting

of

R35.

The

positive

pulse

generated

at

the

collector

of

Q13

is

fed

to

the

current

switch

Q4

and

Q5

to

switch

the

current

flowing

in

R9

through

Q5

during

the

gating

period.

The

above

circuit

description

assumes

the

mode

switch

to

be

in

the

Normal

position.

With

the

switch

in

Pulse

Inhibit

position

the

base

of

Q5

is

held

at

ground

whi

le

the

base

of

Q4

is

held

at

—0.6

V.

Therefore

the

current

switch

wi

l

l

have

the

current

through

R9

flowing

in

Q5,

and

Q4

will

be

cut

off.

With

the

current

switch

in

this

condition

Q2

is

saturated

and

Q3

is

cut

off,

thereby

passing

all

input

signals

to

the

base

of

Q6.

With

the

appl

ication

of

an

Enable

input

pulse

a

positive

signal

is

applied

to

Q4

base

through

capacitor

C2,

and

the

transistors

Q2

and

Q3

change

state

and

thereby

block

passage

of

signals

from

the

input

to

the

base

of

Q6.

Conse

quently,

there

is

no

output

from

the

linear

gate.

In

the

DC

Inhibit

position

the

same

conditions

apply

to

the

current

switch

Q4

and

Q5,

and

the

current

switch

can

change

state

only

with

the

application

of

a

positive

input

on

the

DC

Inhibit

Input

CN4.

Notice

that

in

the

DC

Inhibit

position

the

current

switch

is

dc-coupled

to

the

connector

CN4

and

therefore

absolute

control

of

the

Linear

Gate

is

avai

lable

on

connector

CN4.

6.

MAIIMTENAIMCE

6.1.

TESTING

THE

PERFORMANCE

OF

THE

LINEAR

GATE

Use

the

fol

lowing

procedure

to

check

the

performance

of

the

426:

The

fol

lowing

paragraphs

are

intended

as

an

aid

in

the

installation

and

checkout

of

the

ORTEC

426.

These

instructions

present

information

on

front

panel

controls,

waveforms

at

test

points

and

output

connectors.

It

wil

l

be

helpful

to

refer

to

the

schematic

and

block

diagram

at

the

end

of

this

manual.

1

.

Feed

the

419

Pulse

Generator

output

into

the

410

Linear

Amplifier.

Feed

the

Bipolar

Output

of

the

410

into

the

407.

Crossover

Pickoff.

Feed

the

Output

from

the

407

into

the

Enable

input

of

the

426.

Set

the

410

pulse

shaping

mode

to

Double

RC

(DRC),

i

.e.

.

Integrator,

First

Differentiator,

and

Second

Differentiator

to

0.2

jdsec.

The

following,

or

equivalent,

test

equipment

is

needed:

ORTEC

419

Pulse

Generator

Tektronix

Model

580

Series

Osci

l

loscope

1000

BNC

Terminators

Vacuum

Tube

Voltmeter

ORTEC

410

Linear

Amplifier

ORTEC

427

Delay

Amplifier

ORTEC

407

Crossover

Pickoff

The

fol

lowing

prel

iminary

procedures

should

be

observed:

1.

Visual

ly

check

module

for

possible

damage

due

to

shipment.

2.

Plug

module

into

Bin

and

check

for

proper

mechanical

alignment.

3.

Connect

ac

power

to

ORTEC

401/402

Bin

and

Power

Supply.

4.

Switch

ac

power

on

and

check

the

dc

power

supply

voltages

at

the

test

points

on

the

Power

Supply

control

panel

on

the

401

.

2.

Also

feed

the

Bipolar

Output

of

the

410

into

the

ORTEC

427

Delay

Amplifier.

The

output

of

the

427

should

be

approximately

0.5

V.

3.

Observe

the

output

of

the

426.

Adjust

the

trim

potenti

ometer

at

the

top

of

the

board

for

a

minimum

pedestal

.

4.

The

ampl

itude

of

both

the

initial

and

final

transient

negative

spikes

should

not

exceed

300

mV.

5.

Feed

the

Output

of

the

427

into

the

l

inear

Input

of

the

426.

Measure

the

input

and

output

of

the

426.

The

input

should

not

differ

from

the

output

by

more

than

80

mV.

6.

Adjust

the410

gain

controlsto

give

a

-t-8-V

pulse

into

the

linear

Input

of

the

426.

The

Linear

Gate

Output

should

be

8

±

0.4

V.

Load

the

426

Output

with

lOOil.

The

output

pulse

amplitude

should

not

decrease

more

than

0.15

V.

7.

Adjust

the

410

Linear

Amplifier

gain

controls

to

give

a

-r11

V

pulse

into

the

Input

of

the

Linear

Gate.

The

Linear

Gate

Output

should

saturate

at

greater

than

20

V.

8.

Remove

the

All

Output

from

the

linear

Input

on

the

426.

Rotate

the

Gate

Width

control

over

its

entire

range

and

measure

the

resultant

gating

period.

The'

minimum

should

be

0.3

jjsec

or

less

and

the

maximum

should

be

4

jusec

or

greater.

6.2.

ADJUSTMENT

OF

LINEAR

GATING

DURATION

The

linear

gating

period

is

continuously

variable

from

approximately

0.3

jusec

to

4

ixsec.

The

pulse

width

is

controlled

by

capacitor

C8

and

resistors

R34

and

R35.

To

change

the

gating

duration,

simply

adjust

the

control

R35,

which

is

recess-mounted

on

the

front

panel.

In

the

event

that

gating

durations

different

from

0.3

to

4

jusec

are

desirable,

the

capacitor

C8

may

be

replaced

with

a

capacitor

of

different

value

to

change

the

range

of

gating

duration.

R35

will

provide

continuously

adjustable

pulse

width

within

the

new

range.

6.3.

ADJUSTMENT

OF

LINEAR

GATE

PEDESTAL

The

Linear

Gate

has

a

trim

potentiometer,

R11,

to

al

low

the

pedestal

on

the

Linear

Gate

Output

to

be

reduced

to

a

negligible

value,

typically

1

mV.

R11

is

located

near

the

top

of

the

etched

circuit

board.

To

adjust

the

pedestal

it

is

necessary

to

open

the

Linear

Gate,

with

no

input

signal

feeding

into

the

Linear

Gate

input

CN1

while

observing

with

an

oscil

loscope

the

output

of

the

Linear

Gate.

Observing

the

Linear

Gate

output,

adjust

the

pedestal

trim

potentiometer

until

the

pedestal

is

reduced

to

a

negl

igible

amount.

6.4.

TABULATED

TEST

POINT

VOLTAGES

The

following

voltages

are

intended

to

indicate

the

typical

dc

voltages

measured

on

the

etched

circuit

board.

In

some

cases

the

circuit

wil

l

perform

satisfactorily

even

though,

due

to

component

variations,

some

voltages

may

measure

out

side

the

given

limits.

Therefore

the

voltages

given

should

not

be

taken

as

absolute

values,

but

rather

as

an

aid

in

troubleshooting.

6.5.

SUGGESTIONS

FOR

TROUBLESHOOTING

In

situations

where

the

426

is

suspected

of

malfunction,

it

Table

6.1.

Pin

No.

Test

Point

Voltage

(V)

1

Q7e

-1-

0.2

2

Q4b

-

0.61

3

Q5b

-

1.7

4

Q9c

-r

10.9

5

Q12c

-f-

11

.4

6

Q13B

+

0.6

Note:

All

voltages

were

measured

from

ground

with

vtvm

having

input

impedance

of

10

mf2

or

greater.

Voltages

are

dc

values

with

no

input

pulses.

is

essential

to

verify

such

malfunction

in

terms

of

simple

pulse

generator

impulses

at

the

input

and

output.

In

consideration

of

this,

the

426

must

be

disconnected

from

its

position

in

any

system,

and

routine

diagnostic

analysis

performed

with

a

test

pulse

generator

and

osci

lloscope.

It

is

imperative

that

testing

not

be

performed

with

a

source

and

detector

until

the

ampl

ifier-Linear

Gate

system

and

the

logic

system

perform

satisfactorily

with

the

test

pulse

generator.

The

testing

instructions

in

Section

6.1

of

this

manual

and

the

circuit

descriptions

in

Section

5

should

provide

assist

ance

in

locating

the

region

of

trouble

and

repairing

the

malfunction.

The

guide

plate

and

shield

cover

can

be

completely

removed

from

the

module

to

enable

oscillo

scope

and

voltmeter

observations

with

a

minimal

chance

of

accidental

ly

short

circuiting

portions

of

the

etched

board.

6.6.

FACTORY

REPAIR

This

instrument

can

be

returned

to

the

ORTEC

factory

for

service

and

repair

at

a

nominal

cost.

Our

standard

proce

dure

for

repair

ensures

the

same

quality

control

and

check

out

that

are

used

for

a

new

instrument.

Always

contact

Customer

Services

at

ORTEC,

(615)

482-4411,

before

send

ing

in

an

instrument

for

repair

to

obtain

shipping

instruc

tions

and

so

that

the

required

Return

Authorization

Num

ber

can

be

assigned

to

the

unit.

Write

this

number

on

the

address

label

and

on

the

package

to

ensure

prompt

atten

tion

when

it

reaches

the

ORTEC

factory.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

(Rev

4)

(adopted

by

DOE)

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

-3

volts

24

Reserved

3

Spare

Bus

25

Reserved

4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

♦28

+24

volts

7

Coaxial

♦29

-24

volts

8

200

volts

do

30

Spare

Bus

9

Spare

31

Spare

*10

+6

volts

32

Spare

♦11

-6

volts

♦33

117

volts

ac

(Hot)

12

Reserved

Bus

♦34

Power

Return

Ground

13

Spare

♦♦35

Reset

(Sealer)

14

Spare

♦♦38

Gate

15

Reserved

♦♦37

Reset

(Auxiliary)

♦18

+12

volts

38

Coaxial

♦17

-12

volts

39

Coaxial

18

Spare

Bus

40

Coaxial

19

Reserved

Bus

♦41

117

volts

ac

(Neut.)

20

Spare

♦42

High

Quality

Ground

21

Spare

G

Ground

Guide

Pin

22

Reserved

Pins

marked

(')

are

Installed

and

wired

in

EG&G

ORTEC's

4001

A,

4001B,

4001C,

401A,

and

4018

Modular

System

Bins.

Pins

marked

(')

and

(**)

are

installed

in

EG&G

ORTEC-HEP

M250/N

and

M350/N

NIMBINS.

4eC'0^oo-^

QG

en

i

Tree.

POLL

O

Q7

Ot/TPUT

El^iTT£.f^

FOLLO^SK.

EFtlTTER.

Llf\/£F^

G^7

GAT

iAJRUT

<24

QS

ccje&EAJT

sShtt

TCH

BAS€L>M£

££COV£ISY

TJeYSvo^

en

/OOSL,

B£J?

PiDJ.

a

9

Q/O

SCeM/TT

re/GG£e

Q/z

a/3

T/e/sae'/s

p>Afia

a

/-?

IHHiSiT

AoL%e

1

NOKM

iNPOT

o

c

//V'T/B/r

'Z4V

//vPt/r

AJote'

/Gef&r^ncE

drc-i^'in^

4^C'

Jtk,

/V

4^6

'

3

m^utt

D

W

ie-3i>-66

OAK

RIDGE

TECHNICAL

ENTERPRISES

CORP.

OAK

RIDOe.

TENN.

L/NEAR

G/^re:

BLOCR

D/RGRAM

RESP.

ENGR.

R.

Scroggs.

SCALE

DRAWING

NO.

AEG-0300-62

(?

II

HI*

♦

Hr5I

-cnx

CZED?!

-EH>

-dH}-

426-0201

©

P

'g>f-

-iHZIh-

in

WcHH

Q

c:-sZZ)

Cf

Wd35>~

-{HZIr-

-■i

:i

o

fO

o

<

tn

Z

g

in

&

et

UNLESS

OTHERWISE

SPECIFIED

DIMENSIONS

IN

INCHES

ORTEC

(vo/V

OAK

RIDGE

TECHNICAL