Translation of the original instructions

1 About this document

This document describes the use of the above-mentioned product.

Certain aspects of use are described in other documents and must be observed

è 1.1 Further applicable documents.

1.1 Further applicable documents

Document Table of contents

Description of automation system CPX-E

(CPX-E-SYS)

Detailed description of automation system CPX-E

Instruction manual for use of automation system

CPX-E (CPX-E-SYS)

Instruction manual and important information on

assembly, electrical installation and mainten-

ance tasks for an automation system CPX-E

Description of counter module CPX-E-1CI

(CPX-E-1CI)

Detailed description of product function and

parameterisation options

Documentation of the components in an automa-

tion system CPX-E and the connected peripherals

Information on using the components

Documentation for the higher-order controller

and the additional participants in the network

Information on commissioning and paramet-

erisation of the components

Tab. 1 Further applicable documents

All available documents for the product èwww.festo.com/pk.

1.2 Product version

This document refers to the following product versions:

Product Version

CPX-E-1CI Counter module CPX-E-1CI, revision1 or later

Tab. 2 Product version

The product version can be identified from the product labelling or with the help

of appropriate software from Festo.

Appropriate software for determining the product version can be found in the

Festo Support Portal èwww.festo.com/sp.

Information on using the software can be found in the integrated Help function.

There may be an updated version of this document for these or later product ver-

sions.

• Check whether a corresponding version of this document is available on the

Festo Support Portal èwww.festo.com/sp.

1.3 Product labelling

The product labelling is located on the left-hand side of the module. Scanning the

printed Data Matrix Code with an appropriate device opens the Festo Support

Portal, with the information appropriate for the product. Alternatively, the Product

Key (11-digit alphanumeric code on the product labelling) can be entered in the

search field of the Support Portal.

You can find detailed information on the product labelling in the description of the

module è 1.1 Further applicable documents.

1.4 Specified standards

Version status

EN60529:2013-10 IEC60204-1:2014-10

EN61000-6-2:2005-08 IEC61131-2:2015-05

EN61000-6-4:2007-01 –

Tab. 3 Standards specified in the document

2 Safety

2.1 Safety instructions

– Take into consideration the legal regulations for the respective destination.

– Use the product only within the defined values è 13 Technical data.

– Observe labelling on the product.

– Observe further applicable documents.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

– Before working on the product: switch off the power supply and secure it

against being switched on again.

– Comply with the handling specifications for electrostatically sensitive devices.

2.2 Intended use

The product described in this document is intended only for use in automation

systems CPX-E.

Use the product only as follows:

– Use only in an industrial environment. Outside of industrial environments,

e.g. in commercial and mixed-residential areas, it may be necessary to take

measures to suppress interference.

– Use only in combination with modules and components that are permissible

for the respective product variant èwww.festo.com/catalogue.

– Only use the product if it is in perfect technical condition.

– Only use the product in original status without unauthorised modifications.

Only the conversions or modifications described in this and the further applic-

able documents are permitted.

2.3 Training of skilled personnel

Installation, commissioning, maintenance and disassembly should only be con-

ducted by qualified personnel.

The qualified personnel must be familiar with installation of electrical control sys-

tems.

3 Additional information

– Accessories èwww.festo.com/catalogue.

– Spare parts èwww.festo.com/spareparts.

4 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

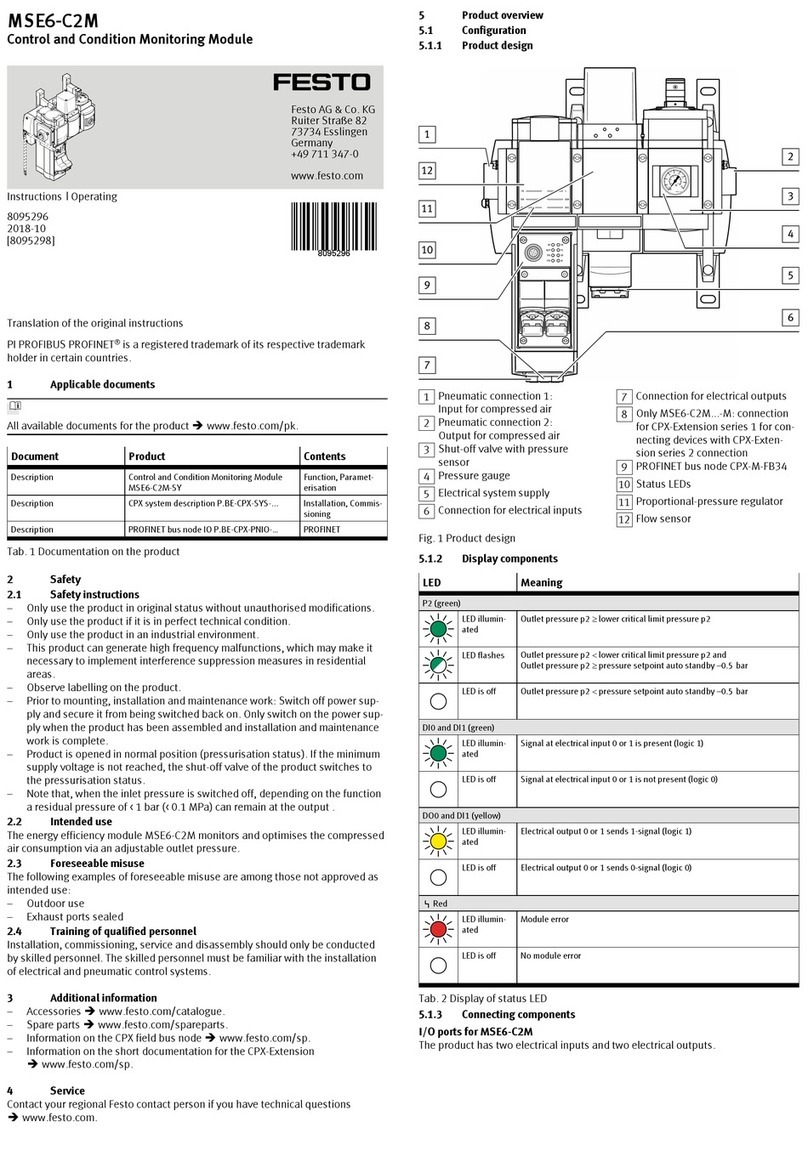

5 Product overview

5.1 Function

In an automation system CPX-E, the module offers the option of connecting an

encoder for detecting pulses. The encoder supply has an electronic fuse for pro-

tection against short circuit or overload. After the elimination of a short circuit or

overload, the encoder supply is switched on again automatically.

The module provides the following functions:

– Setting the counter

– Blocking the counter

– Latching

– Speed measurement

The module also provides 4digital inputs (I0...I3), each of which can be used to

trigger a particular function:

– Input I0: trigger latching

– Input I1: block latching

– Input I2: set counter

– Input I3: block counter

The debounce time of inputs I0...I3 and the module response can be set using

module parameters.

The following encoder types can be used with the module:

– Encoder 24VDC (singleended)

– Encoder 5VDC (differential or singleended)

You can find detailed information on the types of encoder that can be used in the

description of the module è 1.1 Further applicable documents.

8071179

Counter module

CPX-E-1CI

8071179

2018-02

[8071181]

Instructions|Use

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com