Eighteeth MotorTurbo User manual

Dental low-voltage Electrical Motor

USER MANUAL

Changzhou Sifary Medical Technology Co., Ltd.

MotorTurbo

P/N: IFU- 6435004

Version: S01

Issued: Oct.15,2021

Size:87mm X 180mm

Page 3 / 30

Content

1. Scope of MotorTurbo............................................................................ 4

1.1 Parts Identification...........................................................................4

1.2 Components and Accessories...................................................... 4

2. Symbols used in the User Manual......................................................5

3. Before Use.............................................................................................. 6

3.1 Intended Use.................................................................................... 6

3.2 Contraindications.............................................................................6

4. Install and disassemble the MotorTurbo........................................... 8

4.1 Connect the host..............................................................................8

4.2 Installation and removal of motor................................................. 8

4.3 Installation and removal of handpiece.........................................9

5. Use Interface........................................................................................10

5.1 Host operation panel.................................................................... 10

5.2 Screen display............................................................................... 10

5.3 Terms and definition..................................................................... 11

6. Setting................................................................................................... 12

6.1 Set mode parameter.....................................................................12

7. Operation.............................................................................................. 14

8. Cleaning, Disinfection and Sterilization.......................................... 15

8.1 Foreword.........................................................................................15

8.2 General recommendations.......................................................... 15

8.3 Autoclavable Components...........................................................15

8.4 Disinfection Components.............................................................19

9. Error warnings..................................................................................... 20

10. Troubleshooting.................................................................................21

11. Technical Data...................................................................................22

12. EMC Tables....................................................................................... 23

13. Warranty............................................................................................. 29

14. Statement........................................................................................... 30

1 Scope of MotorTurbo

Page 4 / 30

1. Scope of MotorTurbo

1.1 Parts Identification

1

2

①Host

②Motor

③Power cable

④Adapter

⑤Motor disinfection front

plug

⑥Motor disinfection back

plug

346

5

Note: This product does not contain Contra-angle handpiece

1.2 Components and Accessories

Host (1pcs)

Motor (1pcs)

Power cable (1pcs)

Power Adapter

(1pcs)

Motor disinfection

front plug (1pcs)

Motor disinfection

back plug(1pcs)

O-ring (3pcs)

Warranty card

(1pcs)

USER MANUAL

(1pcs)

Certificate (1pcs)

/

/

2 Symbols used in the User Manual

Page 5 / 30

2. Symbols used in the User Manual

WAR NIN G

If the instructions are not followed properly,

operation may lead to hazards for the product

or the user/patient.

NOTE

Additional information, explanation of

operation and performance.

SN

Serial number

Catalogue number

Manufacturer

Date of manufacture

LOT

Batch number

Safety class II device

Type B applied part

Direct current

Dispose of in accordance with the WEEE

directive

Keep dry

Sterilizable in a steam sterilizer (autoclave) at

the temperature specified

-20℃

55℃

Temperature limitation

20%

8 0%

Relative humidity limitation

106kPa

70 k Pa

Atmospheric pressure limitation

Manufacturer's LOGO

Consult instructions for use

Washer-disinfector for thermal disinfection

3 Before Use

Page 6 / 30

3. Before Use

3.1 Intended Use

Use to provide the driving force for dental handpieces for dental

surgery.

This device must only be used in hospital environments, clinics

or dental offices by qualified dental personnel and not used in the

oxygen-rich environment.

3.2 Contraindications

The MotorTurbo is contraindicated in cases where patient/user

carry medical implants such as pace makers or cochlear implants

etc.

Do not use the device for implants or other non-endodontic

dental procedures.

Safety and effectiveness have not been established in pregnant

women and children.

WAR NIN G

Read the following warnings before use:

1. The device must not be placed in humid surroundings or

anywhere where it can come into contact with any type of liquids.

2. Do not expose the device to direct or indirect heat sources. The

device must be operated and stored in a safe environment.

3. Do not use the equipment in the presence of free oxygen,

anesthetic gas or combustible materials. The equipment must be

operated, used and stored in a safe environment.

4. The device requires special precautions with regard to electrom-

agnetic compatibility (EMC) and must be installed and operated in

strict compliance with the EMC information. In particular, do not use

the device in the vicinity of fluorescent lamps, radio transmitters,

remote controls and do not use this system near the active Surgical

Equipment and the RF shielded room of an ME SYSTEM for

magnetic resonance imaging, where the intensity of EM

DISTURBANCES is high. Portable RF communications equipment

(including peripherals such as antenna cables and external

antennas) should be used no closer than 30 cm (12 inches) to any

part of the MotorTurbo, including cables specified by the

manufacturer. Otherwise, degradation of the performance of this

equipment could result.

5. Please do not use or store this equipment at high temp- erature.

Please pay attention to the use and storage conditions.

6. Never open or repair the device yourself , otherwise, void the

warranty.

3 Before Use

Page 7 / 30

7. If irregularities occur in the device during treatment, switch it off.

Contact the agency.

8. Please use the original power adapter.

9. Do not dismount the motor or contra angle during the operation of

the main engine, otherwise the contra angle and motor will be

damaged.

10. Turn off the power switch After each use.

11. Heavy hit, such as falling , will cause damage to the dental

low-voltage electric motor.

12. Do not use accessories from other companies, otherwise the

product may be damaged. Our company will not be responsible for

any problems with the use of accessories outside of our company.

4 Install and disassemble the MotorTurbo

Page 8 / 30

4. Install and disassemble the MotorTurbo

4.1 Connect the host

Open the package, please make sure if the product contains all

accessories according to the packing list, and place the host on a

stable surface.

Connect the Compressed air and water connector to the handpiece

four-hole connector of dental unit, and tighten the nut.

Connect the power adapter to the power connector, and connect the

power cable to power adapter, then connect the power cable plug

into a power source that meets the requirements (refer to

11.Technical Specifications).

4.2 Installation and removal of motor

Motor installation: align the motor tail wire nut with the motor, and

then tighten the motor tail wire nut.

Motor Motor tail wire nut

Motor removal: Unscrew and separate the motor tail line nut, and

gently disassemble the motor.

Compressed air and

water connector

Mot or tail wire

Power

connector

Power

switch

4Install and disassemble the MotorTurbo

Page 9 / 30

4.3 Installation and removal of handpiece

Handpiece

Motor connector

O-ring

Motor

Align the dental handpiece positioning block and the motor groove,

insert the motor connector directly into the handpiece, and can hear

a "click" sound, indicate a successful connection.

When remove the handpiece, pull the dental handpiece parallel from

the motor.

WAR NIN G

1. Before install the handpiece, make sure that the O-ring on the

motor connector is lubricated. If there is no lubricant, please spray

lubricant(special lubricant for the handpiece) to ensure that the

O-ring is lubricated.

2.If the O-ring is severely worn or damaged, please replace it with a

new one to prevent water and air leakage.

3.When assemble O-ring, first assemble the outer O-ring, and then

assemble the inner O-ring in sequence.

4.After connecting the handpiece to the motor, gently pull the

handpiece to ensure that it is firmly installed.

5 Use Interface

Page 10 / 30

5. Use Interface

5.1 Host operation panel

There are 6 touch buttons on the host operation panel , their functions

and uses are as follows:

①LED light button :shortly press to switch the motor LED light state

②Working mode button:Shortly press to switch working mode

(M1-M4)

③Handpiece transmission ratio button:long press for 2 to 3 seconds

to set the handpiece transmission ratio in each working mode

④Rotation direction button: short press to switch the motor

forward/reverse (the host will have a continuous and slow "di, di"

sound when reversing)

⑤Rotation speed increase button: increase the motor output speed,

short press for a single step, along press for rapid adjustment

⑥Speed reduction button: Reduce the motor output speed, short

press for a single step, along press for rapid adjustment

1

2

3

4

5

6

5.2 Screen display

The picture shows the host screen display interface, the meaning of

each symbol is as follows:

①working mode: There are four working modes for users to choose

2 3 4

7

6

5

1

5 Use Interface

Page 11 / 30

(M1, M2, M3, M4). Users can set four common working modes

according to their habits. The speed, handpiece transmission ratio,

rotation direction and LED status of each working mode can be set

individually. It can save automatically after each setting completed.

And when open the machine next time, the working mode will be set

as last shutdown.

②LED state:There are three states: off, half-light, and high-light. The

state of the LED light will be displayed as the high-light state by

default each time it is turned on;

③Fault light: when the fault light is on, it indicates that the machine is

malfunctioning. At this time, you need to check the status of the

machine. The fault light is off under normal conditions.

④Motor forward: indicates that the motor is rotating forward in the

current working mode;

⑤Motor reversal: indicates the motor is reversing in the current

working mode;

⑥Dental handpiece output speed: indicates the current output speed

of the dental handpiece. The range of rotation speeds that can be set

for dental handpiece with different transmission ratios is different.

⑦Handpiece transmission ratio: indicates the gear transmission ratio

of the currently driven dental handpiece. There are four kinds

handpiece transmission ratios (1:5, 1:1, 16:1, 20:1), please select the

corresponding parameters according to the handpiece transmission

ratio (make sure that the handpiece transmission ratio is consistent

with the set handpiece transmission ratio), to avoid damaging the

dental handpiece

5.3 Terms and definition

Fwd/Fw

Forward (Clockwise rotation)

Rev/Rv

Reverse (Counter clockwise rotation)

RPM

Revolutions Per minute

Working mode

Such as M1-M4

Handpiece

transmission ratio

The gear transmission ratio of the handpiece,

such as: 1:5 for increasing speed, 1:1 for

constant speed, 16:1 for deceleration, and

20:1 for deceleration.

6 Setting

Page 12 / 30

6. Setting

6.1 Set mode parameter

M1 mode parameter setting (connected to a handpiece with a

transmission ratio of 1:5)

Set the working mode M1

Set the transmission ratio 1:5

Set rotation direction FWD

Set LED light status highlighted

Set rotation 200000RPM

(rotation range: 10000RPM -

200000RPM,

step value is 5000RPM)

M2 mode parameter setting (connected to a handpiece with a

transmission ratio of 1:1)

Set the working mode M2

Set the transmission ratio 1:5

Set rotation direction FWD

Set LED light status highlighted

Set rotation 2000RPM

(rotation range:

2000RPM - 40000RPM,

step value is 1000RPM)

M3 mode parameter setting (connected to a handpiece with a

transmission ratio of 16:1)

6 Setting

Page 13 / 30

Set the working mode M3

Set the transmission ratio 16:1

Set rotation direction REV

Set LED light status OFF

Set rotation 600RPM

(rotation range:

100RPM - 2500RPM,

step value is 100RPM)

M4 mode parameter setting (connected to a handpiece with a

transmission ratio of 20:1)

Set the working mode M4

Set the transmission ratio 20:1

Set rotation direction FWD

Set LED light status highlighted

Set rotation 100RPM

(rotation range:

100RPM - 2000RPM,

step value is 100RPM)

Note: The above is only an example of setting the parameters of

each working mode. Users can set the transmission ratio, rotation

direction, LED light status, speed under each working mode

according to their own needs. The steps are the same as above.

7 Operation

Page 14 / 30

7.Operation

Install the product correctly

according to the product

installation steps;

Turn on the power switch on the

back of the host and enter the

standby state;

In the standby state, electing a

working mode and setting the

parameters, start the dental

low-voltage electric motor by

stepping on the foot switch of

dental treatment machine.

WAR NIN G

1. Before using the device for the first time, make sure that foot switch

of dental treatment machine calibration has been carried out.

2. Before using it for treatment, please try it outside the oral cavity to

make sure that there is no problem with the function of the device.

3. Before starting the equipment, please confirm that the transmission

ratio of the handpiece is the same as the transmission ratio of

selected working mode , otherwise the handpiece may be damaged.

4. Check the handpiece if it spray normally. If the spray is abnormal,

stop using it.

5. Do not press the button of the back cover of the handpiece during

treatment, otherwise the equipment will be damaged, and even bur

flying, which may hurt the patient.

8 Maintenance

Page 15 / 30

8.Cleaning, Disinfection and Sterilization

8.1 Foreword

For hygiene and sanitary safety purpose, the components (motor,

Motor disinfection front plug and Motor disinfection back plug) must

be cleaned, disinfected and sterilized before each usage to prevent

any contamination. This concerns the first use as well as the

subsequent uses. Comply with your national guidelines, standards

and requirements for cleaning, disinfection and sterilization.

Reprocessing procedures have only limited implications to this

dental device. The limitation of the numbers of reprocessing

procedures is therefore determined by the function / wear of the

device. From the processing side there is no maximum number of

allowable reprocessing. The device should no longer be reused in

case of signs of material degradation.

In case of damage the device should be reprocessed before

sending back to the manufacturer for repair.

8.2 General recommendations

● The user is responsible for the sterility of the product for the first

cycle and each further usage as well as for the usage of damaged or

dirty instruments, where applicable after sterility.

● For your own safety, please wear personal protective equipment

(gloves, safety glasses, etc.).

● Use only a disinfecting solution which is approved for its efficacy

(VAH/DGHM-listing, CE marking, and FDA approval) and in

accordance with the DFU of the disinfecting solution manufacturer.

● The water quality has to be convenient to the local regulations

especially for the last rinsing step or with a washer-disinfector.

● Thoroughly clean and wash the components before autoclaving.

● Do not lubricate the motor.

● Do not clean the contra angle with an ultrasonic cleaning device.

● Do not use bleach or chloride disinfectant materials.

8.3 Autoclavable Components

Autoclavable Components

Motor

Front plug

Back plug

8 Maintenance

Page 16 / 30

WAR NIN G

1. Only the components above can be autoclaved.

2. Before first use and after each use, sterilize the above components.

Reprocessing Instructions

Preparation at the Point of Use: Disconnect the motor from the host.

Refer to "Chapter 4-Installation and removal of motor" of this manual

for disassembly instructions. Remove gross contaminations from the

motor surface with a cloth, which dipped in cold water (<40°C)

immediately after use. Don’t use a fixating detergent or hot water

(>40°C) as this can cause the fixation of residuals which may

influence the result of the reprocessing process.

WAR NIN G

Do not submerge the motor or wipe it with any of the following

functional water (acidic electrolyzed water, strong alkaline solution, or

ozone water), medical agents (glutaral, etc.), or any other special

types of water or commercial cleaning liquids. Such liquids may result

in metal corrosion and adhesion of the residual medical agents to the

components.

Do not rinse the motor with water, to prevent water from entering the

motor

Transportation:

Safe storage and transportation to the reprocess- sing area to avoid

any damage and contaminate on to the environment.

Pre-Cleaning:

Wipe the motor surface with cloth dipped in clean water

Do a manual pre-cleaning, until the components are visually clean.

Cleaning:

To prevent water from entering the motor, manual cleaning is

recommended.

More than 5 times wipe the motor surface with a soft cloth, that is

dipped in clean water

WAR NIN G

1. Do not rinse the motor with water, to prevent water from entering

the motor

2.Do not submerge motor with any liquid.

Disinfection:

Automated Thermal Disinfection in disinfector under consideration of

national requirements in regards to A0 value (see EN ISO 15883).

8 Maintenance

Page 17 / 30

A disinfection cycle of 5 min disinfection at 93°C has been validated

for the device to achieve an A0 value of 3000.

After manual cleaning, the instruments should be automated

disinfected of sterilized immediately. A manual disinfection is not

recommended.

Drying:

Automated Drying:

Drying of outside of instrument through drying cycle of

washer/disinfector. If needed, additional manual drying can be

performed through lint free towel. Insufflate cavities of instruments by

using sterile compressed air.

Disinfection plug installation:

To prevent the steam from entering the motor, please screw the

disinfection front and back plug to motor two side before sterilization.

Refer to the figure below:

Completed state

WAR NIN G

1. Be sure to screw the plug to the motor before sterilization, or it will

reduce the life of motor

Packaging:

Pack the instruments in an appropriate packaging material for

sterilization.

WAR NIN G

1. Check the validity period of pouch given by the manufacturer to

determine the shelf life.

2. Use pouches which resist to a temperature up to 141℃ and in

accordance with EN ISO 11607.

3.Do not lubricate the motor.

4.Check the disinfection plugs are screwed before packaging.

Sterilization:

Sterilization of instruments by applying a fractionated pre-vacuum

Front plug

Back plug

8 Maintenance

Page 18 / 30

steam sterilization process (according to EN 285/EN 13060/EN ISO

17665) under consideration of the respective country requirements.

Minimum requirements: 3 min at 134 °C (in EU: 5 min at 134 °C)

Maximum sterilization temperature: 137°C

Flash sterilization is not allowed on lumen instruments!

WAR NIN G

1. Use only approved autoclave devices according to EN 13060 or EN

285.

2. Use a validated sterilization procedure according to EN ISO 17665.

3. Respect the maintenance procedure of the autoclave device given

by the manufacturer.

4. Use only this recommended sterilization procedure.

5. Control the efficiency (packaging integrity, no humidity, color

change of sterilization indicators, physicochemical integrators,

digital records of cycles parameters).

6. Wait for cooling before touching.

Storage:

Storage of sterilized instruments in a dry, clean and dust free

environment at modest temperatures, refer to label and instructions

for use.

WAR NIN G

1. Sterility cannot be guaranteed if packaging is open, damaged or

wet.

2. Check the packaging and the contra angle before using it

(packaging integrity, no humidity and validity period).

NOTE

The instructions provided above have been validated by the

manufacturer of the medical device as being capable of preparing a

medical device for use. It remains the responsibility of the processor

to ensure that the processing, as actually performed using equipment,

materials and personnel in the processing facility, achieves the

desired result. This requires verification and/or validation and routine

monitoring of the process. Likewise, any deviation by the processor

from the instructions provided should be properly evaluated for

effectiveness and potential adverse consequences.

8 Maintenance

Page 19 / 30

8.4 Disinfection Components

Disinfection components

Host

Power cable

Adapter

Wipe all the surfaces with a cloth lightly moistened with Ethanol for

Disinfection (Ethanol 70 to 80vol%) at least 2min, repeat for 5 times.

NOTE

1. Do not use disinfectants other than alcohol for disinfection.

2. Do not use excessive alcohol to prevent alcohol from seeping

Into the parts and damaging the internal parts.

3. Disinfect before and after each use.

9 Error Warnings

Page 20 / 30

9.Error warnings

When the When input air source

pressure more than 0.5MPa, the

fault light will highlight. At this

time, though operate the control

foot switch, the host will not work.

Adjust the input pressure to the

range of 0.25-0.5MPa. If the fault

light is still on, please contact

your local dealer.

When the motor drive fails, the

fault light will be on, please

contact your local dealer for

repair, do not disassemble the

machine to repair it yourself.

Table of contents

Popular Engine manuals by other brands

Great Power Engine

Great Power Engine GP-123 owner's manual

Simu

Simu T5 Hz.02 manual

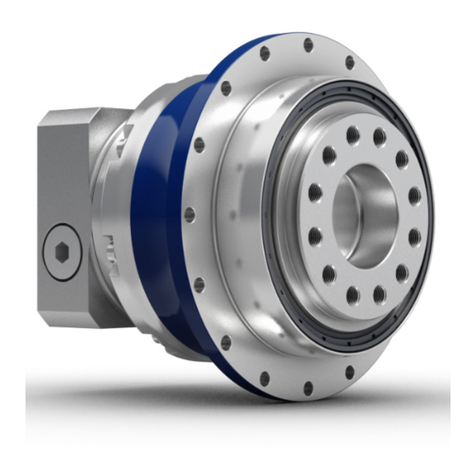

brevini

brevini Dana K Series Installation and maintenance manual

Wittenstein Alpha

Wittenstein Alpha Advanced TP+ Series operating manual

Bosch

Bosch rexroth MBT operating instructions

Lenze

Lenze G7 Series Mounting and switch-on instructions

Briggs & Stratton

Briggs & Stratton Intek 200000 Operating & maintenance instructions

Briggs & Stratton

Briggs & Stratton VANGUARD Series Operating & maintenance instructions

Canaline Engines

Canaline Engines Canaline 30 Operator's handbook

VOLTRIUM

VOLTRIUM Rogue Dual Motor Series owner's manual

MTD

MTD 170-TOA Operator's manual

MTU

MTU 12 V 4000 T95 x operating instructions