4sE c t i O n 2 — iM p O r t a n t En g i n E sa f E Op E r a t i O n pr a c t i c E s

Never fuel equipment indoors because flammablel.

vapors will accumulate in the area.

Extinguish all cigarettes, cigars, pipes, and otherm.

sources of ignition.

Check fuel line, tank, cap, and fittings frequently forn.

cracks or leaks. Replace if necessary.

Operation

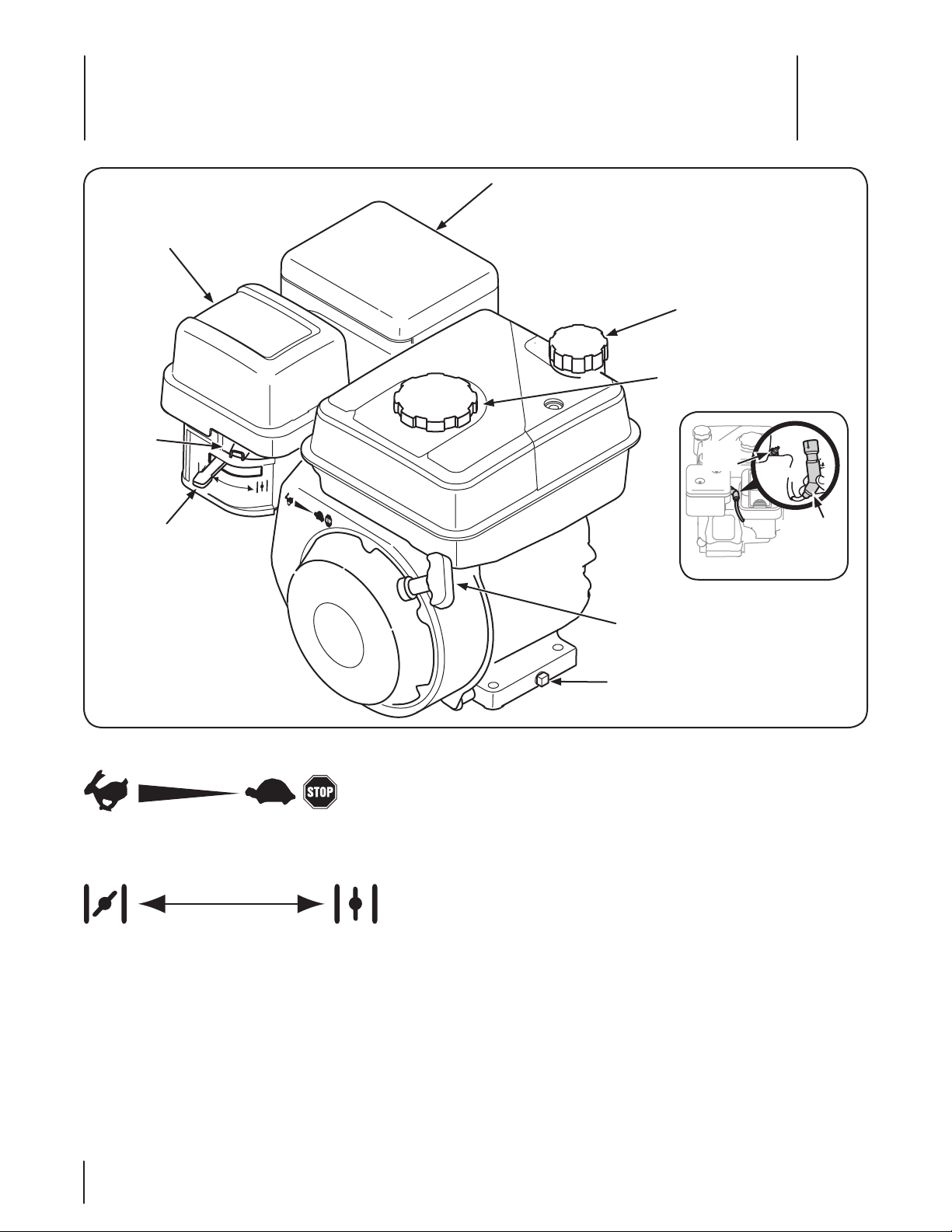

When starting the engine, make sure spark plug, muffler,1.

and fuel cap are in place.

Do not crank engine with spark plug removed.2.

If fuel spills, wait until it evaporates before starting engine.3.

Allow muffler, engine cylinder, and fins to cool before4.

touching.

Keep children away from hot or running engines. They can 5.

suffer burns from a hot muffler.

Remove accumulated combustibles from muffler and6.

cylinder area.

Operate equipment with all guards in place.7.

Keep hands and feet away from rotating parts.8.

Tie up long hair and remove jewelry.9.

Do not wear loose-fitting clothing, dangling drawstrings or10.

items that could become caught.

When starting the engine, pull cord slowly until resistance11.

is felt, then pull rapidly.

Remove all external equipment/engine loads before12.

starting engine.

Direct coupled equipment components such as, but not13.

limited to blades, impellers, pulleys, sprockets, etc., must

be securely attached.

WARNING! Your Responsibility — Restrict the use of the engine to persons who read, understand, and follow the

warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

Maintenance & Storage

Keep the engine in safe working order1.

Allow the engine to cool at least five minutes before2.

storing. Never tamper with safety devices. Check their

proper operation regularly.

Check bolts and screws for proper tightness at frequent3.

intervals to keep the engine in safe working condition.

Visually inspect the engine for any damage.

Before cleaning, repairing or inspecting; stop the4.

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire and ground it against the

engine to prevent unintended starting.

Do not change the engine governor settings or over-speed5.

the engine. The governor controls the maximum safe

operating speed of the engine.

Maintain and replace safety and instruction labels as6.

neccessary.

Always refer to the operator’s manual for important details7.

if the machine is to be stored for an exended period of

time.

If the fuel tank has to be drained, do this outdoors.8.

Observe proper disposal laws and requlations for gas, oil,9.

etc. to protect the environment.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

Spark Arrestor

WARNING! This machine is equipped with an

internal combustion engine and should not be used

on or near any unimproved forest-covered, brush

covered or grass-covered land unless the engine’s

exhaust system is equipped with a spark arrester

meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrester for the muffler is available through your nearest

engine authorized service dealer .