-2-

Contents

SERVICE MANUAL ................................................... 1

Contents ........................................................................ 2

Safety Instructions......................................................... 3

Safety Precautions ..........................................................3

Product Safety Notice .....................................................3

Service Personnel Warning.............................................3

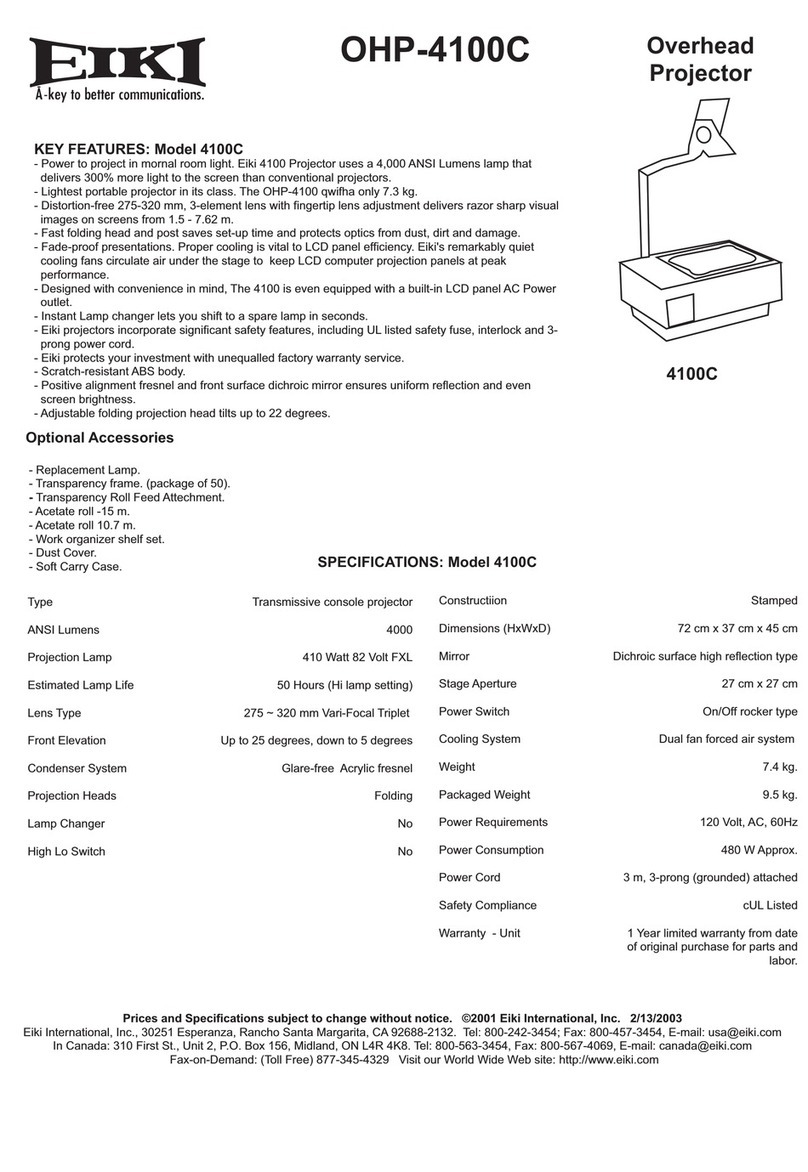

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Fuse.................................................................................5

Thermostats (SW903, SW904) .......................................5

Mechanical sensor switches (SW902, SW6581) ............6

Temperature sensors, wind sensors ...............................7

Power failure and fan lock detection ...............................8

Maintenance.................................................................. 9

Filter Instructions.............................................................9

Replacing the Filter Cartridge ....................................... 10

Resetting the Filter Counter .......................................... 11

Resetting the Scroll Counter ......................................... 11

Lamp Management ....................................................... 12

Lamp Replacement ....................................................... 13

Checking the projector used time and lamp used time. 14

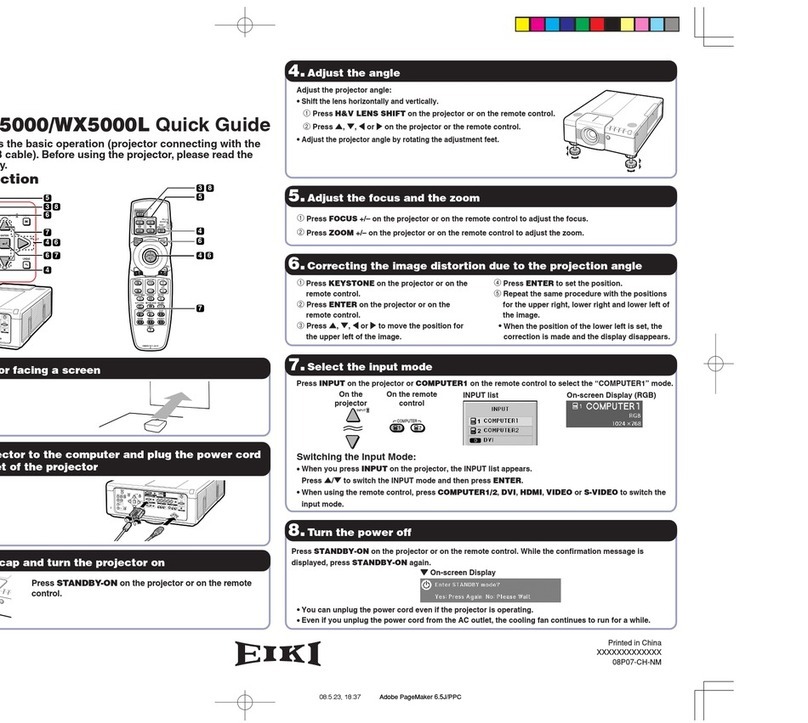

Quick Maintenance ....................................................... 15

Cleaning the optical parts.............................................. 16

Cleaning the Projection Lens ........................................ 16

Cleaning the Projector Cabinet ..................................... 16

Security Function Notice ............................................. 17

Lens Mounting............................................................. 18

Mechanical Disassembly............................................. 22

Mechanical disassembly flow chart...............................22

Mechanical disassembly ...............................................23

Optical Parts Disassembly .......................................... 39

Adjustments................................................................. 51

Adjustments after Parts Replacement........................... 51

Note on Main Board Replacement ................................ 51

Optical Adjustments .................................................... 52

Optical adjustment location...........................................52

Before Adjustment.........................................................53

1. Optical Center adjustment.........................................55

2. PBS adjustment.........................................................59

3. Contrast adjustment ..................................................60

4. Back focus adjustment ..............................................61

5. Convergence adjustment ..........................................62

Adjustment ....................................................................65

Electrical Adjustments................................................. 66

Service Adjustment Menu Operation ............................66

Circuit Adjustments .......................................................67

Test Points and Locations .............................................71

Service Adjustment Data Table.....................................72

Chassis Description .................................................. 147

Chassis over view........................................................ 147

Boards Connection...................................................... 148

Troubleshooting......................................................... 149

No Picture.................................................................... 149

No Power..................................................................... 153

Power Supplies to Boards ...........................................154

Power (AC) ..................................................................155

Power (DC) .................................................................155

Power (PFC)................................................................ 156

Power Supply and Power Fail Detection ..................... 157

Power Drive and Power Failure Signals ......................160

Fan Control.................................................................. 161

Temperature Abnormality ............................................ 162

Power Lens and Shutter System and Abnormality...... 163

Lamp Abnormality ....................................................... 164

Power failure detection system ...................................165

Error information table................................................. 165

Error History Log ......................................................... 166

Diagnosis of Power Failure with RS-232C port ........... 167

Diagnosis procedure ................................................... 167

Indicators and Projector Condition.............................. 168

Serial Control............................................................. 171

Serial Control Interface ............................................... 171

Control Port Functions............................................... 173

IC Block Diagrams..................................................... 176

Parts Location Diagrams........................................... 182

Mechanical Parts List ................................................ 196

Electrical Parts List.................................................... 198

Diagrams & Drawings.................................................. A1

Parts description and reading in schematic diagram ..A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams................................. A17

Pin description of diode, transistor and IC ................A27

Note on Soldering......................................................A28