Eilon Engineering RON 2501 User manual

RON 2501 WIRELESS DYNAMOMETER

Eilon Engineering

5.2

Table of Contents

General Cautions and Warnings 3

Eilon Engineering Limited Warranty 6

1. General Description 7

2. Basic Operation 8

2.1 - General operation of the keyboard: 9

2.2 - Tare 9

2.3 - Max (a.k.a. Peak Hold) 10

2.4 - Overload Warnings 10

2.5 - Battery Care 11

3. Calibration 13

3.1 Best Practice for Calibration 13

3.2 Performing Calibration 14

Multi Point Calibration 14

4. Configuration 16

4.1 Backlight 16

4.2 Units, user selectable 17

4.3 Time - setting the real time clock 17

4.4 RS-232 Digital Output Communication Data (Optional, if included) 18

4.5 Totalizer (Optional, if included) 23

4.6 Manual Data Logger (Optional, if included) 24

4.7 Automatic Data Logger (Optional, if included) 25

4.8 Multiple Wire Rope Falls (Optional, if included) 26

4.9 Dampened Reading aka Averaging 27

4.10 Connector Cables 28

5 Pin Sealed Circular Connector: 28

4.11 Multiple Load Cells With Single Indicator 29

5. Troubleshooting 31

6. Error Table 33

7. Suitable Shackles 34

2

General Cautions and

Warnings

The following cautions and warnings, system

specifications, and user instruction sheets should be

read carefully before attempting to use this Eilon

Engineering product.

Products are supplied with the express understanding that the purchaser and/or user

are thoroughly familiar with their correct application and proper use. Eilon

Engineering will assume no responsibility for the misuse or misapplication of any of

its products.

In addition to these guidelines, the user must also comply with general safe operating

practices when using the system e.g. when weighing during lifting.

The load limit rating, a.k.a. capacity, indicates the maximum force or load a system can

carry under normal working conditions. Overloading or placing a load on the system

above its rated capacity is dangerous and is therefore STRICTLY PROHIBITED

except during the system's annual safety testing. This testing must be performed by

qualified personnel and allows the system to be overloaded up to 25% of its rated

capacity, no more than once per year.

Eilon Engineering will accept no liability for damage caused by the product being

used in excess of the working load limit or from abuse.

Opening, attempting to open, or any attempt to repair the system by unauthorized

personnel (without written authorization) will nullify the warranty as well as the

manufacturer's liability and could be dangerous. Refrain from doing so and contact an

Elion representative should any problem with the system arise.

When measuring loads using a shifted zero with the tare function, the actual load is

the value indicated on the readout plus that of the shifted zero or tare.

For best results, it is recommended to turn your system on 10 minutes prior to

measuring.

The system is designed for static loading. Eilon Engineering or other qualified

3

engineering personnel should be consulted before using the system to measure

dynamic loads.

Avoid bending, twisting, side loading and off-axis loading.

When connecting the load cell in order to measure forces or loads, special care should

be taken in choosing appropriate shackles or other connecting accessories that will

permit free movement and prevent bending moments and twisting in the load cell.

Always use shackles with a S.W.L. (Safe Working Load) equal to, or greater than the

system's rated capacity.

Check the system thoroughly before use, including the lifting accessories which are

included with some Ron systems. Do not use a damaged system.

We recommend that the system is checked occasionally by lifting a known weight.

Further, the system should be sent back to the manufacturer or to an authorized

service center for general examination once every year.

System calibration should at first be performed annually in an authorized laboratory

unless local laws, regulations, or other policies require alternative intervals. Once the

user becomes familiar with the particular needs of their system, the need for

calibration may vary.

Between calibrations, the user can verify whether the systems are still calibrated

correctly by using a known weight.

Calibration verification and adjustment must be performed with extreme care. An

erroneous calibration adjustment will result in false readings, which could be

dangerous.

If there is any doubt as to the reliability of the load indication, do not use the system

with an unknown load. To check its reliability, use a known load preferably with a

value of more than 50% and less than 100% of the system’s rated capacity. Never use

a weight that is more than the rated capacity.

The permitted temperature range appears in the Ron system specifications.

Do not allow the system to overheat or fall below the minimum permitted

temperature, as doing so may be dangerous and cause damage.

Take particular care not to expose the system to ionizing radiation.

4

Local environmental conditions such as extreme temperatures (those that exceed the

stated temperature range in the system specifications), chemical materials, radio

transmissions or other magnetic radiation may interfere with the system's reliability

causing a false reading which could prove dangerous. Avoid using the system under

such conditions.

The system is not explosion-proof and should not be used in hazardous areas.

Unless otherwise specified, Eilon Engineering products are not legal for trade.

Each system consists of a load cell with its own indicator (excluding 1000 & 4000

models).

Important: If you own several systems, make sure that each load cell is used with its

original indicator. Load cells and indicators are calibrated as matched pairs and are

non-interchangeable.

Important:

At all times, it is the responsibility of the user of this equipment to ensure that normal

safety precautions are observed. No amount of safety features and engineering can be

a substitute for common sense and a desire to work safely.

The Ron 2501 relies on wireless communication. Like all wireless devices it is

susceptible to interference and other reception issues.

The system will display TR.ERR during such communication problems. When

TR.ERR is displayed the system will be unable to detect overloads. We recommend

that a prolonged TR.ERR be handled as if an overload was occurring.

Take extra care when TR.ERR is displayed.

Ron systems are prohibited by the manufacturer and/or seller to be used in any

nuclear or similar site wherenuclear and/or radioactivity and/or ionizing radiation

(henceforth radiation) exists. Ron systems may not function well in any space

whereradiation exists. If despite this warning the user uses the system in radiation,

he/she is waiving any right of claim against the manufacturer and/or seller concerning

direct or consequential damages or loss resulting from the use of Ron systems in

violation of the above restrictions, and theuser assumes full responsibility and liability

to waive any subrogation claim rights by the insurer to such claim against the

manufacturer and/or seller. This restriction does not apply to areas that are deemed

safe for people to work in.

5

Eilon Engineering Limited Warranty

Eilon Engineering Ltd. load meters and overload detectors are built in

accordance with listed specifications. Eilon Engineering Ltd. also

guarantees that all its products are thoroughly inspected and

performance tested prior to shipment.

If any appropriately maintained part proves to have been originally defective in

materials or workmanship within the Warranty Period explicitly stated in the Eilon

Engineering Ltd. literature that accompanies the product, Eilon Engineering Ltd. will

replace or repair the part at no charge at the sole discretion of Eilon Engineering Ltd.

This warranty specifically excludes shipping costs.

The warranty shall be null and void if any repair or modification is performed on the

system, or if any attempt has been made to open any part of the system by any parties

other than those specifically authorized by Eilon Engineering Ltd.

Batteries are not covered by this warranty.

The system supplied comes factory calibrated and is accompanied by the relevant

certification. All Eilon systems are built to enable user adjustment and calibration. As

such, our accountability for the state of calibration is limited to the time when the

system is received by the user, thus excluding calibration from this warranty.

Eilon Engineering Ltd. reserves the right to change materials or designs without

notice when in its opinion such changes will improve its product.

These warranties exclude all other warranties, express or implied.

Eilon Engineering Ltd. will not, in any event, be liable for incidental or consequential

damages.

The distributor is solely responsible for ensuring that this warranty is delivered to his

sub-distributors and to their ultimate customers or users.

6

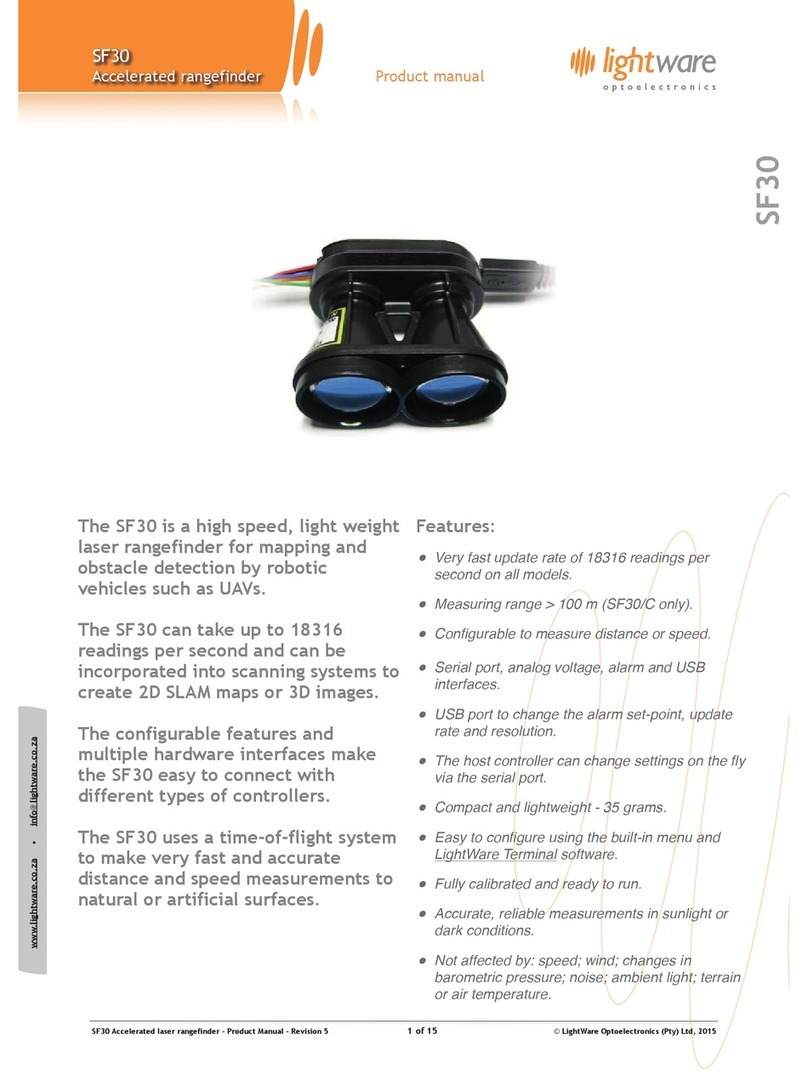

1. General Description

Ron Crane Scale and Dynamometer basic information.

The Ron 2501 is available either as a Shackle or Hook Type. The system consists of a

Load Cell and an indicator.

The indicator includes a 6 digit 0.5" (12 mm) LCD display and front panel standard

with a nine button keypad.

The system includes 2 AA disposable 1.5V alkaline batteries. Continuous operation of

the system while using batteries rated 3AH will result in at least 2000 hours of battery

life (more than two months). Occasional use will extend the battery life up to several

years.

The following are available options:

●Rechargeable batteries (instead of disposable) with a charger.

●A specially fitted carrying case.

●Digital RS-232 or RS-485 output for communication with computers, printers

or data acquisition devices.

●Additional 1" (25mm), 2" (50mm) and 5" (125mm) displays.

●Totalizer: stores/displays a total of selected loads.

●Automatic/Manual Data Logger: Records measurement to indicator memory

for later download to PC. (Up to 50,000 measurements)

●Rope falls multiplier, user selectable

●Wireless communication to additional display or PC

7

2. Basic Operation

Basic operation of Ron systems and helpful tips and tricks

Before operation, be sure the shackles you intend to use are appropriate for the

system (see shackle specification table). Press the key to turn the system on. The

display will read BATT, then the percentage of remaining battery life of the indicator

and then the load cell, followed by the unit of measurement.

M. TON (Metric Tons)

S. TON (Short Tons, American tons, 2000 Lbs)

LBS

K.NTON (Kilo Newton)

DECA.N (Deca Newton)

N.WTON (Newton)

KG

The current weight value will then be displayed.

Before loading the system, press until ZERO is displayed.

The system should then read GROSS then 0.

Once use of the system has been completed, press the key to power down.

Return both the load cell and indicator to their carrying case or another appropriate

safe place of storage.

2.1 - General operation of the keyboard:

When pressing a key, the system responds with a short audio signal (a beep) followed by

a change to the display. For example, if one presses the key, MAX will be displayed.

The key should be pressed continuously until the beep is heard. Exceptions are turning

the system on or off which does not require a long press. Also, when several keys are

pressed in sequence as part of a code during calibration, the visual signal will only appear

8

upon completion of the code, but the beep will still follow each valid key press. If the

passcode is not accepted, the display will read COD.E.R. In this case, a new attempt

should be made. (See Calibration for more.)

2.2 - Tare

Switching between Gross and Net modes

The system features a Tare function that enables the user to ensure the display reads 0

even though there may be weight on the system such as from a sling, shackles or a

container. This capability makes the system easy to use as it eliminates the need for

the operator to subtract the weight of the container, etc. when only the net amount of

the load is required.

To use the tare mode, load the system with the desired container and then press .

The screen will display NET, then the value of 0. The system is now in Net mode. To

exit out of Net mode, press again. GROSS will appear indicating that the

system is back in Gross mode. The system will show NET on the screen about once

every minute as a reminder that it is in Net mode. Note that switching between Gross

and Net modes will clear the MAX (see MAX section).

CAUTION:

When measuring loads using a shifted zero applied and/or with the tare function

applied, the real load is the value indicated on the readout plus that of the shifted zero

or tare. Take this into account to avoid accidental overloads.

2.3 - Max (a.k.a. Peak Hold)

Checking the maximum registered load value

The system features a MAX (aka PEAK HOLD) function. MAX will store the

maximum weight that the system has detected since it was last powered on or since

the Gross/Net mode was changed.

Press the key until the display shows :M:AX. It will then display the current

maximum load the system has registered since the last time the MAX was reset. The

weight will be displayed for approximately two seconds with colons in between the

digits. These simply serve as a visual indicator that the displayed value is the stored

9

max and not the current weight. The system will go back to the current value then a

beep will sound indicating that the system is ready for a new operation.

The MAX memory is cleared every time the system is powered down or the mode is

changed between Net and Gross or Zero is applied. The MAX will also be reset if the

unit of measurement is changed (see UNITS section).

2.4 - Overload Warnings

Two level visual overload warning

The system features a two level visual overload warning. When loaded to 100% of its

maximum capacity and up, the displayed weight will flash on and off continuously.

Should this occur, the lift should be terminated immediately and the current load set

down.

Should the system be drastically overloaded (130% of max capacity), DANGER

(short for danger) will appear on the display. Only when the system is completely

unloaded and the measured value reduced to zero will the DANGER message

disappear.

Should this occur, it is critical that the Ron system and all accompanying rigging

accessories are checked by an authorized inspector before being used again.

The system will display TR.ERR during communication problems. When TR.ERR is

displayed the system will be unable to detect overloads. We recommend that a

prolonged TR.ERR be handled as if an overload was occurring.

Take extra care when TR.ERR is displayed.

Please note that both overload warnings remain functional at the same levels (100% &

130% of full capacity) whether the system is in Gross or Net mode. This means that

when TARE is used, you may see an overload warning at a displayed value that is less

than 100% of capacity.

All overloads are dangerous to personnel and should be avoided at all costs.

Overloading the system can also result in costly damage to the system itself.

10

2.5 - Battery Care

Maintenance of Ron 2501 batteries for top performance

The standard system is powered by two AA 1.5V disposable alkaline batteries in bothe

the indicator and load cell.

Batteries rated 3AH will result in at least 2000 hours of battery life (more than two

months of continuous use). Occasional use will extend the battery life up to several

years. Optional extended battery life: 4000 hours.

The display will show LO:BAT when the batteries need to be replaced. Once

LO:BAT is displayed, you still have several hours of operation left. If the battery level

gets too low, the system will automatically power down in order to avoid damage from

low voltage.

When the system is turned on, the batteries' energy level is displayed as a percentage

e.g 100%. Battery level can also be checked from the menu.

Replacing the batteries

Indicator:

Use a screwdriver to remove the back cover of the indicator. Gently remove the

battery holder from the indicator being careful not to damage the wiring. Replace the

batteries with two fresh AA 1.5V disposable alkaline high quality high energy batteries.

Load Cell:

Use a screwdriver or your thumbs to loosen the screws of the panel on the back of the

load cell.

Accessing the battery compartments

11

2.5.1 - Rechargeable Batteries

Though we recommend standard alkaline AA batteries, rechargeable batteries are

offered. This option includes 2 AA NiMH 2700 mA rechargeable batteries. The

system is supplied with a external wall charger.

The batteries should be charged:

1. Prior to using the unit for the first time.

2. Before use, if more than two months have passed since the last charge.

3. When LO:BAT (low battery) is displayed on the screen.

A full charge will take 10-14 hours.

Store bought rechargeable batteries may be used. Choose NiMH AA size 1.2V

rechargeable batteries (minimum 1800mAH or higher) and a standard charger.

Due to the difference in battery voltage, rechargeable batteries will display a biased

energy level. For example, fully charged NiMH batteries will only show an energy

level of 80% rather than 100% and will normally show a value about 20% less than

the actual level.

WARNING

It is dangerous to charge disposable batteries and may result in the batteries

exploding. If you are using disposable batteries in a system sold with

rechargeable ones, please remove the charger from the system's carrying case

or place of storage in order to prevent potential accidents.

12

3. Calibration

Performing additional calibration and adjustment to the system

Note

It is recommended that calibration be performed by authorized and skilled

personnel only! It should be performed using an accurate known weight or in a

laboratory.

Unless otherwise required by local laws, it is recommended that the system be

calibrated annually. The weight used in the calibration must not exceed the system's

capacity.

3.1 Best Practice for Calibration

It is recommended that calibration and adjustment are performed using a known weight that

is 80% of the system's maximum capacity. This will give the best and most accurate results.

A known weight between 80% – 100% of capacity may be used but never a weight greater

than the capacity.

It is recommended that the system be turned on for at least 10 minutes prior to calibration.

If the system includes a dampened display/averaging, the dampening should be shut

off before calibrating (see Dampened Readings section). The system is protected by

two different codes to prevent calibration by unauthorized personnel.

3.2 Performing Calibration

Access the Menu:

Press and hold the Menu/OK button.

Using the arrow keys scroll to CALIBR. and press OK

The system will display CODE?

Press ESC + OK simultaneously until you hear the beep.

The system will display CODE?

Press TARE.

The display will show the current units in use e.g. Lbs,M. TONS etc. and will then

display LOAD.0. At this point all weight/force must be removed from the system.

13

Once the system is unloaded, press OK. The display will flash WAIT for a few

seconds and then L.VALU (load value). This means that the load of a known weight

intended for calibration is ready to be applied.

Once the known weight has been applied (lifted), press OK. The display will show

APPLY followed by the max capacity of the system. Using the arrow keys ▲▼, set

the load value you intend to use for the calibration. If no key is pressed for 8 seconds,

the system will exit out of calibration mode and you will have to start again from the

beginning. Once the load value on the display matches that of the known weight

currently loaded, press OK. The display will flash WAIT and then OK. This means

the system has successfully been adjusted and the display will return to the standard

measuring screen.

At any time, you may press ◀ESC to exit out of the calibration process. The display

will read OK and then revert back to the main measuring screen.

Multi Point Calibration:

Access the Menu:

Press and hold the Menu/OK button until a beep is heard

Using the arrow keys ▲▼ scroll to CALIBR. and press OK

The system will display SEL. ID (Select ID) and then will display ID. X (X will be the

ID of the load cell to be calibrated)

Using the▲▼ arrows will allow you to change the ID

Press Menu/OK

The system will display CODE?

Press ESC + Menu/OK simultaneously until you hear the beep.

The system will display CODE?

Quickly press TARE.

The display will show the current units in use e.g. Lbs,M. TONS etc. and will then

display LOAD.0.

At this point all weight/force must be removed from the system.

Once the system is unloaded, press OK.

The display will flash WAIT for a few seconds and then L.VALU (load value).

14

This means that the load of a known weight intended for calibration is ready to be

applied.

Important Note: Known weight must be at least 80% of the load cells capacity. (e.g

for a 1000 kg capacity system at least 800 kg must be used)

Once the known weight has been applied (lifted), press OK. The display will show

APPLY followed by the max capacity of the system.

Using the arrow keys ▲▼, set the load value you intend to use for the calibration.

If no key is pressed for 8 seconds, the system will exit out of calibration mode and

you will have to start again from the beginning.

Once the load value on the display matches that of the known weight currently

loaded, press OK.

The display will flash WAIT and then OK.

This means the load cell has successfully been adjusted and the display will return to

the standard measuring screen.

Repeat the procedure above for each load cell.

At any time, you may press ESC to exit out of the calibration process. The display will

read OK and then revert back to the main measuring screen.

15

4. Configuration

Using the various available features and options for the Ron 2501

Settings can be accessed through the Menu.

To access the Menu press and hold

Once you see the first function displayed you may use the up arrow ▲ or down arrow

▼ keys to scroll through all of the available option on the system.

To enter into the calibration procedure, you will be required to enter an additional

code (see CALIBRATION section 3.0).

At any time you may press ◀ESC to exit a menu.

4.1 Backlight

The Ron 2501 is equipped with a backlight for use in low light environments.

The backlight is activated using the button.

Use of the backlightgreatly reduces the battery life.

To change the backlight settings, access the menu and use the ▲▼ keys scroll to

BACKL. Press OK.

There are two setting than can be configured:

● TIME - Configure how long the backlight will remain on after the

backlight button is pressed. If set to ALWAYS the backlight button will

toggle the backlight on and off.

● BRIGHT - Set the brightness of the backlight. The higher the brightness

the shorter the battery life will be when using the backlight.

16

4.2 Units, user selectable

Press and hold Menu/OK

Use the arrow keys ▲▼ to scroll through the available options until you see UNITS

and press OK.

The current unit in use will be displayed. Use the arrow keys again and scroll to the

desired unit of measurement.

The available units are:

Lbs K.NTON (Kilo Newtons)

DECA.N (Deca Newtons) N.WTON (Newtons)

KG M. TON (Metric tons)

S. TON (Short tons)

When the desired unit appears on the screen, press OK.

The display will flash OK, show the select unit, and then revert back to options menu.

You may select another option or press ◀ESC in order to exit from the options menu.

4.3 Time - setting the real time clock

Enter into the options menu by following the instructions in section 4. Use the arrow

keys ↑↓ to scroll through the available option until you see TIME and press OK.

The display will read YEAR. Press OK again and you will see 20:00 (meaning the

year 2000) with the rightmost two digits blinking. Use the arrow keys ↑↓ to select the

current year and press OK.

The screen will read OK and then MONTH. Press OK and the display will show four

digits with the two leftmost digits blinking. This is the month. Use the arrow keys

again to select the month and press OK.

Continue with this process again for the day, hour, and minute. Press ◀ESC to finish

setting the clock and exit back to the options menu. You may select another option or

press ◀ESC again in order to exit from the options menu.

17

4.4 RS-232 Digital Output Communication Data

(Optional, if included)

Possible baud rates: 9,600 - 19,200 - 38,400 - 115,200.

Length: 8 bits

Stop bits: 1 bit

Paring bit: none

Data output modes:

The RS-232 output on Ron systems has two modes of data output that are selectable

by the user: on demand and continuous stream.

The first will send a signal at a rate of about once per second when in use. The

second will send data only when there is a change in value detected by the indicator.

Mode Selection

Press and hold the Menu/OK button until a beep is heard

Use the arrow keys▲▼ to select RS232 from the options menu and press OK.

Use the arrow keys again and select the desired output mode:

D. MAND (on demand)

CONT. (continuous stream)

CHNGS. (upon value change)

Press OK. The display will show OK and revert back to the options menu. Press ESC

again to exit the options menu.

On demand mode:

To output data to a PC/printer when the RS-232 is set to on demand mode, simply

press OK/Menu while a load measurement is displayed.

Continuous mode:

There are two continuous modes. Each system is factory set to one or the other.

1. Continuous - unconditional constant flow(default): the displayed value will be

output at a rate of about once per second.

2. Changes - upon value change: the displayed value will only be output when there is

a change in the reading. If there is a steady change in value, a reading will be output at

18

a rate of about once per second. If there is no change to the load value, no data will

be output.

When the system is first turned on, it will output a lead section of six lines. The first

five of these are the system's owner identification info and must be factory set. If no

instructions were given at the time of ordering, these lines will be blank. Each line

includes up to 60 characters.

A printed data record line includes the following:

1. The load (up to 5 digits)

2. The unit of measurement

3. TARE mode: NET or GROSS

4. Function: LOAD = reading taking directly from indicator.

MAX (PEAK HOLD) = max value reading

TOT. # = reading from totalizer memory. Value and number of

loads

D.L. 1 = reading #1 from Data Logger memory

D.L. 2 = reading #2 from Data Logger memory

D.L. etc.

5. DATE & TIME

Baud Rate Selection

Press and hold the Menu/OK button until a beep is heard

Use the arrow keys▲▼ to select RS232 from the options menu and press OK.

Use the arrow keys▲▼ to select BAUD.R, and press OK

The display will show the current baud rate in use. Use the arrow keys again to scroll

through the available rates:

115,200 – 38,400 – 19,200 – 9,600

Press Menu/OK. The display will show OK, the selected baud rate, and then revert

back to the options menu. Press ESC to exit the options menu.

19

Other manuals for RON 2501

1

Table of contents

Other Eilon Engineering Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Challenger Optics

Challenger Optics CO-OLS-MPO12U operating manual

Axio MET

Axio MET AX-355 instruction manual

B.M. Tecnologie Industriali

B.M. Tecnologie Industriali TTFM100-NG Series instruction manual

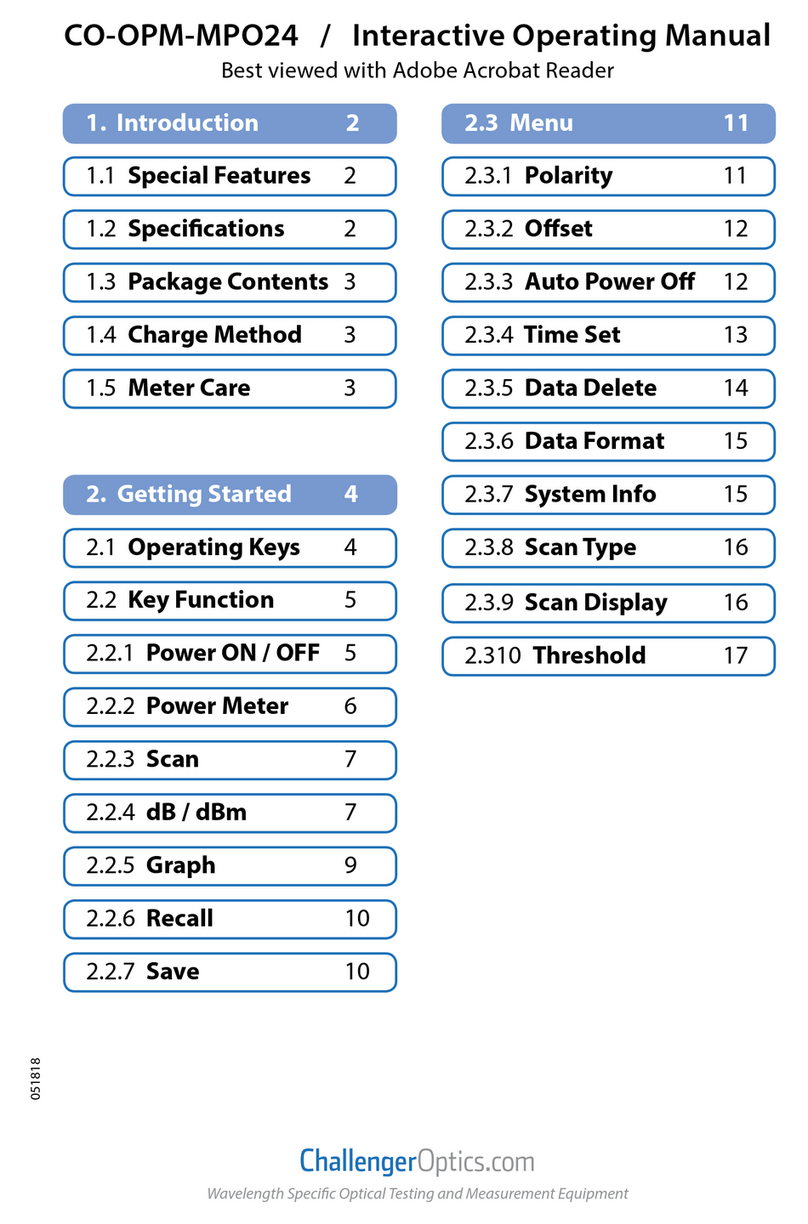

Challenger Optics

Challenger Optics CO-OPM-MPO24 Interactive operating manual

TAS

TAS VLRF 600 user manual

Bin Master

Bin Master SMARTBOB TS1 Installation and operating instructions