eisfink varithek acs 1100 d3 User manual

Issue: 2018-06-07

varithek®acs®1100 d3

varithek®acs®1500 d3

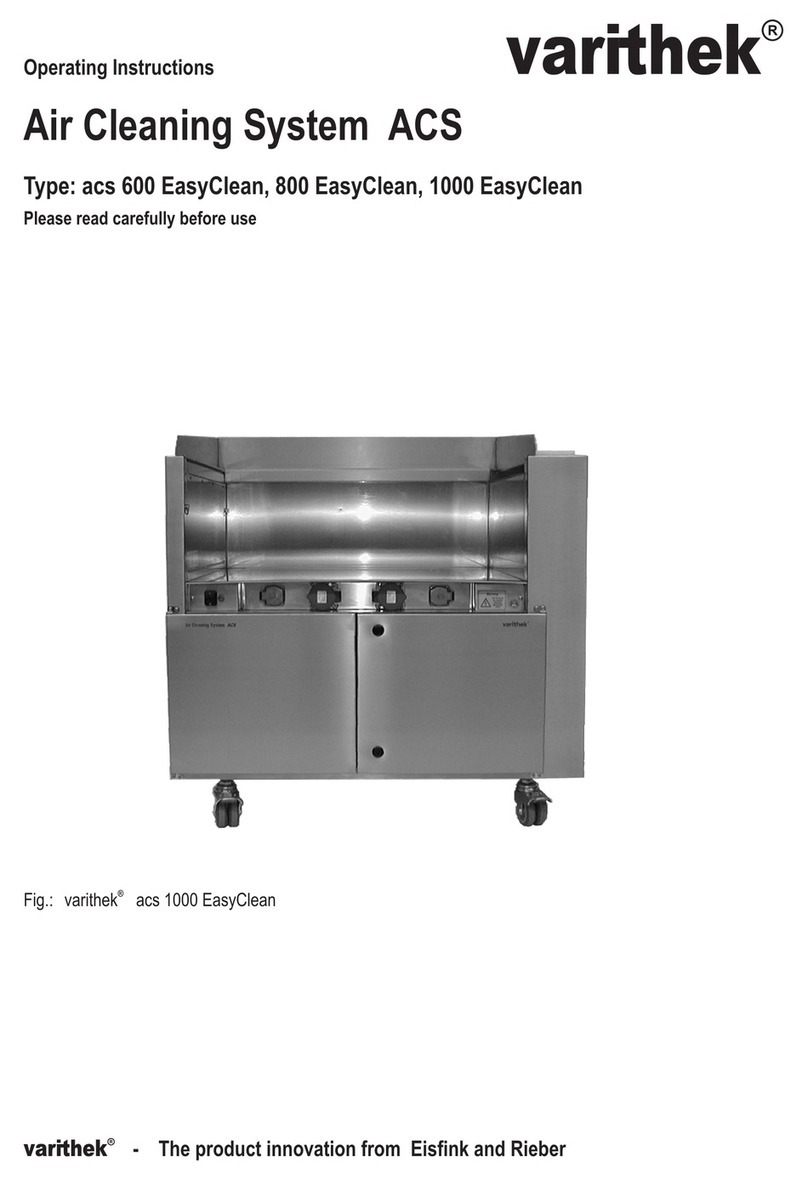

varithek®acs®600 ec

varithek®acs®1000 ec

varithek

air-cleaning-system acs®

With integrated side extraction and circulating-air cleaning for food delivery

With electronic fan control

The illustrations show configuration examples, which do not necessarily have to be included in the scope of delivery.

Observe the operating instructions

Translation of the Original Operating Instructions

DOWNLOAD: USER MANUAL

QR code on type plate

Contents

2

Eisfink Max Maier GmbH & Co. KG

Our solutions guarantee high quality, safety and, above all,

excellent energy efficiency and cost effectiveness.

The basic task of the patented air-cleaning-system acs®is to collect the vapour and steam that occur

during cooking at the point of origin, clean them in a sophisticated filter system and then pass them back

into the room free from odours.

Contents

1Revision Index ................................................................................................................................................. 3

2Important Information ..................................................................................................................................... 4

2.1 Use of this guide ................................................................................................................................................4

2.2 Reference to trademark rights granted for these appliances ..............................................................................5

2.3 Representation conventions in the text ..............................................................................................................5

2.4 Structure of safety instructions...........................................................................................................................5

3General Safety Instructions............................................................................................................................ 6

3.1 General behaviour .............................................................................................................................................6

3.2 On use of electrical appliances ..........................................................................................................................6

3.3 Operator's obligations ........................................................................................................................................7

3.4 Qualification of personnel...................................................................................................................................8

3.5 Provision of protective equipment for personnel.................................................................................................8

3.6 Appliance-specific safety instructions.................................................................................................................9

3.7 Information about regulations to be followed....................................................................................................13

3.8 Instructions on behaviour in an emergency......................................................................................................14

4Purpose .......................................................................................................................................................... 14

5Description of the Equipment ...................................................................................................................... 16

5.1 Designation......................................................................................................................................................16

5.2 Technical data..................................................................................................................................................19

6Before First Use............................................................................................................................................. 21

6.1 Transport .........................................................................................................................................................21

6.2 Observe when commissioning/recommissioning..............................................................................................23

7Use.................................................................................................................................................................. 24

7.1 Only equip the appliances with suitable accessories........................................................................................25

7.2 Ensure undisturbed extraction of steam and vapours ......................................................................................27

7.3 Freshly prepare food on the cutting board........................................................................................................28

7.4 Switch appliance on and off electrically............................................................................................................28

7.5 Electronic fan control (option)...........................................................................................................................29

7.6 Clean the appliance after use ..........................................................................................................................32

Contents

Eisfink Max Maier GmbH & Co. KG

3

8Cleaning, Maintenance and Care ................................................................................................................. 33

8.1 Safety information relating to cleaning, maintenance and care ........................................................................33

8.2 Cleaning agents for stainless steel...................................................................................................................34

8.3 Overview of maintenance measures and intervals ...........................................................................................35

8.4 Choose the correct cleaning method................................................................................................................36

8.5 Clean and service stainless steel parts ............................................................................................................36

8.6 Clean casters ...................................................................................................................................................37

8.7 Clean and service plastic parts ........................................................................................................................37

8.8 Appliance type ‘ec’ ..........................................................................................................................................38

8.9 Clean cooking area and splash guard ..............................................................................................................40

8.10 Clean high-performance grease separator, grease drip trays … ......................................................................43

8.11 Inspect technical compartment; clean if necessary ..........................................................................................48

8.12 Disinfect the appliance as required ..................................................................................................................52

8.13 Keep ready for next use in dry condition ..........................................................................................................52

8.14 Ensure preservation of the product identification..............................................................................................52

9Troubleshooting............................................................................................................................................ 52

9.1 Notes on troubleshooting .................................................................................................................................52

9.2 Disposing of your product.................................................................................................................................54

10 Warranty and Liability................................................................................................................................... 55

11 Excerpt from EC Declarations of Conformity ............................................................................................. 55

12 Index............................................................................................................................................................... 56

13 Contact address ............................................................................................................................................ 56

1 Revision Index

Revision

Change

2013-10-01

New edition

2013-11-19

Potential equalisation system, damaged supply line

2014-04-11

Index

2015-06-15

General modification, adaptation to acs 1600 O3, ISO 82079,

VDE requirement, electronic fan control

2016-08-05

New Eisfink active carbon filter, plus electronic control

2018-06-07

Entfall 800 ec; Absaugung

Important Information

4

Eisfink Max Maier GmbH & Co. KG

2 Important Information

2.1 Use of this guide

This guide contains important information about how you can use the appliance safely and correctly.

►It is essential that you read the user guide before using the product for the first

time.

►Keep this guide in a safe place and pass it onto the next owner should you

wish to part with the product.

Our customers often express the wish to have one compact guide instead of a number of different

guides for these product variants, which have similar functions.

If there are any shortcomings in your opinion, please do not hesitate to let us know. With your help, we

will try to become even better.

Please add your notes here

Important Information

Eisfink Max Maier GmbH & Co. KG

5

2.2 Reference to trademark rights granted for these appliances

DE –Design patent no. 202 05 642.2 and no. 201 17 490.1

International patent application no. PCT/EP01/04469/ (WO 01/81831 A 1)

European Patent no. 1 194 721

2.3 Representation conventions in the text

Lists are represented in this way.

Instructions on certain actions are represented in this way.

See ‘. . . ’ cross-references are represented in this way

Notes

ATTENTION

indicates potential damage to property without any personal injury.

Failure to follow these instructions may cause damage to property.

User tip

►Useful information or tip

2.4 Structure of safety instructions

The signal words DANGER - WARNING - CAUTION classify the degree of risk of bodily injury in an actual

situation. You can avoid injury by complying with the behavioural rules provided.

The warning triangle symbol indicates a "General Danger".

DANGER

indicates imminent danger.

Failure to follow these warning instructions will result in serious bodily injury or even

death.

WARNING

indicates a potentially hazardous situation.

Failure to follow these warning instructions may cause serious bodily injury or even

death.

CAUTION

indicates a potentially harmful situation.

Failure to follow these warnings may cause minor bodily injury.

General Safety Instructions

6

Eisfink Max Maier GmbH & Co. KG

3 General Safety Instructions

This section covers residual risks and hazards associated with the intended use of the appliance. We have

provided a list of all generally valid safety instructions which must be followed.

In the following section, safety information relating to a particular operation or situation is placed before the

appropriate operation step or description of the situation.

The information provided here such as ‘Basic rules of conduct’, ‘Operator's obligations’ etc. only refers to the

legally required observance of requirements such as the Workplaces Ordinance (ArbStättV) according to

German law.

3.1 General behaviour

This appliance meets the current state of the art and complies with all acknowledged technical safety-

related regulations. Nevertheless hazards may still arise.

Only use this appliance when it is in fault-free condition and according to the instructions in this

user guide.

During all phases of the appliance's life please ensure that the appliance is safely integrated into

its environment.

Do not make any conversions or modifications to the appliance.

3.2 On use of electrical appliances

Safety instructions according to EN 60745-1:

Work area

Keep your work area clean and tidy. A messy or unlit work area can cause accidents.

Keep children and other persons at a distance when using the product.

Electrical safety

The plug on the unit must fit in the socket. Do not modify the plug in any way. Never use

an adapter in combination with earthed appliances. Using an unmodified plug and a

suitable socket will reduce the risk of an electric shock.

Keep the appliance away from rain or damp. Allowing water to get into an electric

appliance will increase the risk of electric shock.

Do not misuse the cable by using it to remove the plug from the socket. Always remove

whilst holding onto the plug. Keep the cable away from heat, oil, sharp edges or the

moving parts of other appliances. Using damaged or tangled cables increases the risk of

electric shock.

Potential risk of fire due to heat build-up. Unwind the cable from the spool to prevent any

heat build-up or cable fire. The coupling must have splash protection, must be made of

rubber or be rubber-coated.

Safety guidelines for persons

Be attentive and pay attention to what you are doing, act rationally when working with an

electrical appliance. Do not use the appliance when tired or under the influence of drugs,

alcohol or medication.

Just one moment of inattention whilst using the appliance can result in serious injury.

Make sure the appliance cannot be switched on unintentionally. Double check that the

main switch is in the "OFF" position before inserting the plug in the socket. Connecting

the appliance to the power supply while it is switched on can cause an accident.

General Safety Instructions

Eisfink Max Maier GmbH & Co. KG

7

Careful handling and use of electrical appliances

Never use an electrical appliance with a faulty switch. An electrical appliance which can

no longer be switched on or off is dangerous and must be repaired.

Keep unused electrical appliances in places where children are not able to reach them.

Do not allow the appliance to be used by persons who are not familiar with it or persons

who are not familiar with this user guide. Electrical appliances are dangerous when in the

hands of inexperienced persons.

Treat the device with care. Check that moving parts are functioning properly and do not

block; check whether parts are broken or damaged and impairing the functioning of the

device. Have any damaged parts repaired before using the appliance. Many accidents

are caused by poorly-maintained electrical appliances.

Use electrical appliances, accessories etc. in accordance with these guidelines and in a

manner that is specified for this particular appliance type. When using the appliance,

please take into account the working conditions and the work being carried out. Using

electrical appliances for other uses than that intended can lead to hazardous situations.

Service

Only have the device repaired by qualified and authorised staff. Only use original spare

parts. In this way you can ensure that the appliance remains safe.

3.3 Operator's obligations

Operator

The operator is the person who operates the appliance for commercial or economic purposes either

himself/herself or lets others use it and bears the legal appliance responsibility for protection of the

user, staff or any third parties during operation.

Operator's obligations

The appliance is used in commercial applications. For this reason, the operator of the appliance must

meet all legal duties relating to work safety.

In addition to the safety instructions in this guide, the safety, accident prevention and environmental

protection regulation applying to the application of the appliance must be complied with.

In particular, the following shall apply:

The operator must be familiar with the applicable work safety regulations and identify, by

carrying out a risk analysis, any additional hazards which are due to the place where the

appliance is used. These hazards must be addressed in the form of operating instructions

governing the operation of the appliance.

During the whole service life of the appliance, the operator must verify if the operator's

operating instructions reflect the current versions of the applicable regulations. If necessary,

the operator must update the operating instructions accordingly.

The operator must define and assign the responsibilities for installation, operation, repair,

maintenance and cleaning clearly.

The operator must make sure that all personnel working with the appliance have read and

understood this guide. In addition, the operator must train the personnel and inform them of

the hazards involved at regular intervals.

The operator must provide the personnel with the necessary protective equipment and

make sure that they wear it.

General Safety Instructions

8

Eisfink Max Maier GmbH & Co. KG

In addition, the operator must ensure that the appliance is always in a perfect technical condition. For

this reason, the following shall apply:

The operator must ensure that the maintenance intervals defined in this guide are obeyed.

The operator must have all safety equipment checked regularly for completeness and

proper function.

The operator must ensure that the required media connections are available.

The operator must ensure that all safety-relevant measures required on site are taken.

3.4 Qualification of personnel

Safe operation requires certain technical skills and personal qualification of each person.

The responsibility for organization lies with the ‘Designated Representative’ (operator).

According to EN 50110-1, the Designated Representative is a 'person assigned the direct

responsibility for the performance of the work. If necessary, this responsibility can be

assigned partly to other persons. [...] The designated representative must instruct all

persons involved in the work on all hazards which may not be obvious for them’.

The work may only be performed by ‘instructed persons’ who have been trained

accordingly. Training, instructions must be repeated, proper understanding must be verified

(ideally by way of an appropriate test).

Only ‘Qualified Staff’ are allowed to carry out repair work.

IEC 60204-1 defines qualified personnel as "persons who, on account of their training and

relevant experience are in the position to recognise risks and avoid potentially dangerous

situations."

Electrical work may only be carried out by trained and experienced electricians.

Electro-technically instructed persons may only work under the supervision of a qualified

electrician.

Any repairs and/or overhaul during the warranty period may only be carried out by the

manufacturer´s service department.

Chapter ‘Warranty and Liability’, page 55

3.5 Provision of protective equipment for personnel

Ensure that the personnel wear the personal protective equipment appropriate to the relevant

situation.

Wear safety shoes to prevent injuries when transporting or moving the appliance.

Wear protective gloves to prevent burns to hands and arms when using the cooking accessories.

General Safety Instructions

Eisfink Max Maier GmbH & Co. KG

9

3.6 Appliance-specific safety instructions

This chapter describes general, appliance-specific safety instructions. In the following section, additional safety

information relating to a particular operation or situation is placed before the appropriate operation step or

description of the situation.

3.6.1 Risks due to cooking accessories

All kinds of risks may occur if the wrong cooking accessories are selected.

User tip

The cooking modules in the Rieber varithek®range are recommended. Baking, grilling, cooking,

wok cooking and frying.

Observe the instructions in the relevant operating manuals.

# Deep-fryer

For the deep-fryer, use an insertion mask that prevents slipping into the system carrier.

3.6.2 Risks due to ventilation, circulating-air cleaning

The unit's extraction and circulating-air cleaning is not a replacement for an air-conditioning system.

Always ensure an adequate supply of fresh air.

Risks due to human error when using the Eisfink active carbon filter for odour and

contaminant absorption and odour elimination using plasma technology

WARNING

Breathing difficulties, lacrimal irritation, mucosal irritations in throat, neck and lungs,

headache, strong tickle in the throat, cannot be excluded in the case of human error.

►Only use with Eisfink active carbon filters, which are correctly mounted.

►Do not interfere with the extraction and circulating-air cleaning: Do not place any

objects on the Eisfink active carbon filter in the technical compartment. Only operate

with a dry Eisfink active carbon filter.

Fire risks

Risk of fire

Risk of fire due to missing or incorrectly mounted filter components.

►Only use with original filter components and grease drip trays, which are correctly

fitted.

►Clean filter area daily.

Chapter ‘Cleaning, Maintenance and Care’, page 33 ff.

General Safety Instructions

10

Eisfink Max Maier GmbH & Co. KG

3.6.3 Risks due to opened technical compartment

The technical compartment contains a rotating fan wheel. Keep the technical compartment closed. Use

a suitable tool to open and close the technical compartment.

Before opening the technical compartment

Switch off the ‘ON/OFF pushbutton with indicator light’ and

Switch off the electrical power to the unit by unplugging the main plug.

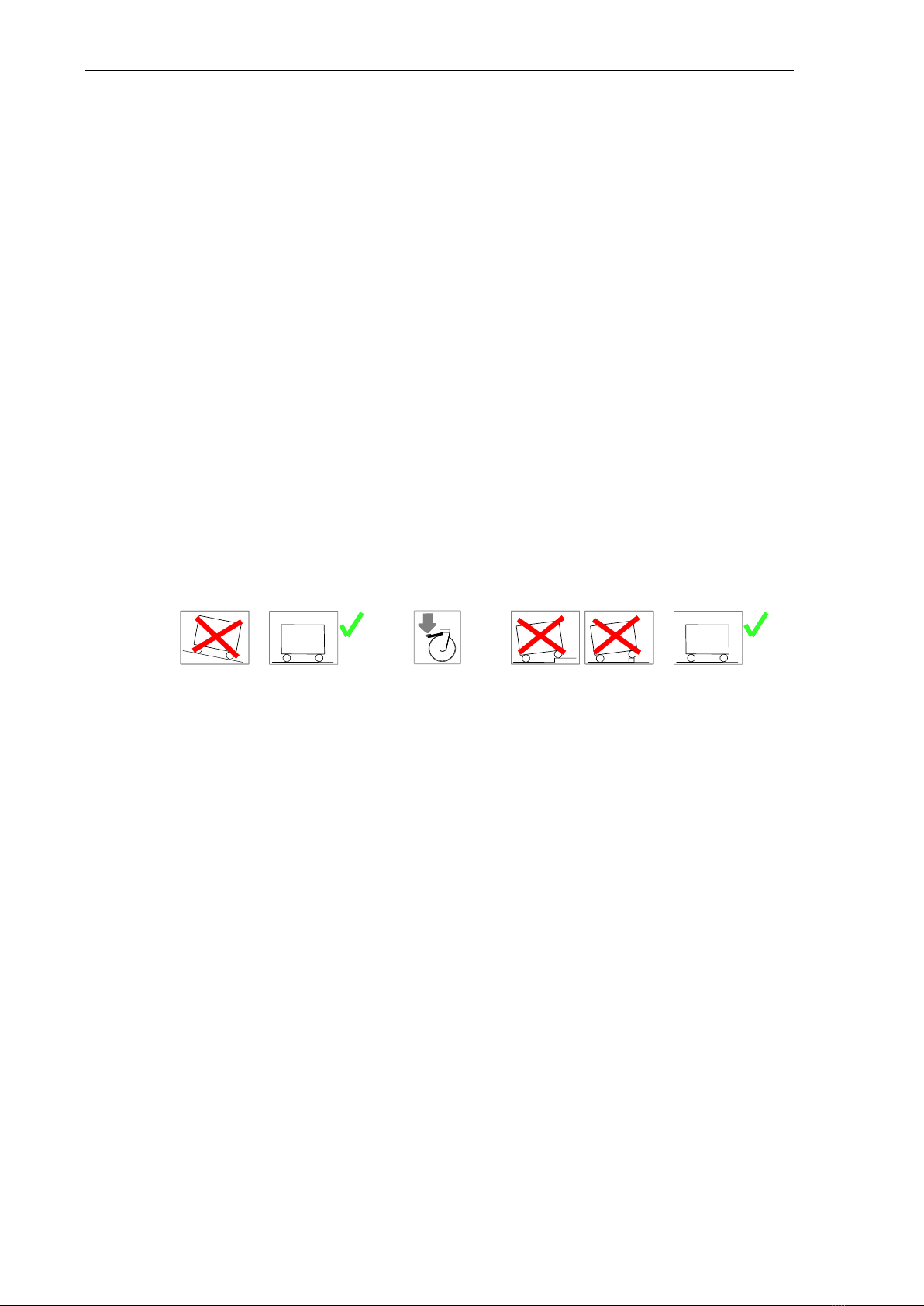

3.6.4 Risks due to transport of mobile appliance

Numerous hazards such as crushing can arise when transporting this heavy product 110 to 160 kg.

Remove accessories and transport them separately.

Disconnect the connection cable.

Only transport unit on a straight surface. Do no transport on a sloping surface.

Carry out transport with an adequate number of people, at least two.

Transport only permissible using the casters.

Secure the appliance against inadvertently rolling away with the ‘parking brake’.

Wear safety shoes to prevent injuries.

ATTENTION

Observe the permissible step height of maximum 4 mm, otherwise the ‘casters with parking brake’

could be damaged.

Do not push or pull the appliance over sharp edges; Otherwise the casters could sustain damage.

Do not use this appliance with poor floor conditions.

We are not able to rule out the possibility of marks appearing on the floor due to friction with

casters or the formation of scratches due to split cracks in the casters, for example.

We are not able to rule out the possibility that the casters may be damaged or become unusable

due to swelling or sharp edges on the floor.

Mobile appliances may only be moved manually. Machine-aided transport, e.g. using fork lift trucks

or lift trucks, is not permissible. Risk of injury and risk of damaging the appliance.

General Safety Instructions

Eisfink Max Maier GmbH & Co. KG

11

3.6.5 Dangers due to electricity

Before each use, inspect the product, the connecting plug and electric cable for any visible signs

of damage.

The cable must be routed so that it cannot be squeezed or overheated.

The socket outlet must be easily accessible so that the unit can be disconnected from the power

supply at any time.

Compare the connection data on the type plate with the data of the electrical network before

connecting (voltage and frequency, power rating).

3.6.6 Risks due to power interruption possible

Possibility of malfunction after power interruption.

Disconnect the unit from the mains completely after a power failure.

Then switch back on.

3.6.7 Warnings concerning the use of the appliance by children

This appliance may be used by children over 12 and by persons with limited physical,

sensory and intellectual abilities or a lack of experience and/or knowledge if they are

supervised or if they were instructed in the safe use of the appliance and have understood

the resulting dangers.

When using the appliance with ‘accessories’, other risks may arise.

Children may not play with the appliance.

Cleaning and user maintenance may not be carried out by children without supervision.

3.6.8 Safety and monitoring devices

High-performance grease separator (100% flame propagation proof) with Cyclone®blade

profile (separation efficiency approx. 95%)

In addition to protection against electric shock and in order to ensure that the frames of

electrical equipment and any external conductive components are at an equal (or practically

equal) potential, the appliance must be connected to the potential equalisation system.

The connection of all conductive bodies (housing) of electrical equipment to an earthed

protective conductor and the main earthing bar is the basic principle for protection against

electric shock.

For variant with odour elimination using plasma technology:

Pressure sensor monitors the pressure conditions in the technical compartment; in the

event of a fault the plasma generator is switched off

General Safety Instructions

12

Eisfink Max Maier GmbH & Co. KG

3.6.9 Product identification

Product identification at the housing, outside

The type plate bears the legally required product data.

The technical compartment is identified.

High-performance grease separators are marked with raised points. These markings can

also be found on the counterpart or frame.

‘Clean filter area daily’.

Equipotential bonding on the underside of the appliance. Note the symbol.

Product identification, especially 600 ec, 1000 ec, 1100 d3

(Variant with 16 A)

Only connect varithek®appliances with the same voltage, i.e. 400 V or 230 V.

Product identification in technical compartment for all appliance types

‘WARNING

Unplug mains plug before removing the fan device.’

General Safety Instructions

Eisfink Max Maier GmbH & Co. KG

13

Product identification in technical compartment for variant with Eisfink active carbon

filter for odour and contaminant absorption and odour elimination using plasma technology

WARNING

Health risks, respiratory disorders

►Only use Eisfink active carbon filter, install correctly.

►Do not place any objects on the

Eisfink active carbon filter.

►All interference with the plasma generator is forbidden.

Product identification in technical compartment for appliance type ‘ec’‘Setting mark’

In the technical compartment, the bottom opening on the left in the floor of the technical compartment

set by the manufacturer is to be left as is.

3.7 Information about regulations to be followed

In addition to this user guide there are a range of health and safety and other regulationsthat are

relevant for the operation of this cooking station; these include HACCP food hygiene regulations for

example.

# Fulfillment of standards and guidelines

VDI directive 2052 Air-conditioning systems. The unit's extraction system is not a

replacement for an air-conditioning system.

Purpose

14

Eisfink Max Maier GmbH & Co. KG

3.8 Instructions on behaviour in an emergency

In an emergency always interrupt the power connection immediately, by disconnecting the

electrical connector.

First aid in the case of burns and scalding or electric shock:

Inform yourself on this before commissioning the appliance.

Store the emergency equipment, including the relevant instructions, at a readily accessible place

near the place of use.

User tip

►Inform yourself in details by reading the in-house operating instructions.

►We recommend that half-yearly emergency training sessions should be carried out.

First aid in the case of unaccountable irritations of the mucous membranes, strong urge to

cough when using appliances with additional odour elimination using plasma technology

WARNING

Breathing difficulties, lacrimal irritation, mucosal irritations in throat, neck and lungs,

headache, strong tickle in the throat, cannot be excluded in the case of human error.

►Only use with Eisfink active carbon filters, which are correctly mounted. Replace active

carbon filters after at least 500 operating hours.

►Do not interfere with the extraction and circulating-air cleaning. Do not place any

objects on the active carbon filter in the technical compartment, for example. Only

operate with a dry Eisfink active carbon filter.

►Seek medical treatment if necessary. Ozone-containing air can trigger complaints.

4 Purpose

This chapter describes the intended use and contains warnings against misuse, for your safety.

Generally, the following are intended uses for the product:

For mobile service in the catering, hotel, and food processing industry; also suitable for the

care and school catering sectors.

Use correctly sized cooking units, like the cooking modules in the Rieber varithek® range.

Baking, grilling, cooking, wok cooking and frying. The relevant operating instructions must

be observed.

The patented air-cleaning-system®(acs®) collects the vapour and steam that occur during

cooking at the point of origin, cleans them in a sophisticated filter system and then passes

them back into the room free from odours.

To prevent persons from burning themselves on hot surfaces, use of the product in

public/for self-service should only be allowed under constant supervision.

Purpose

Eisfink Max Maier GmbH & Co. KG

15

The variant with Eisfink active carbon filter for odour and contaminant absorption and odour

elimination using plasma technology is intended for applications requiring a high level of

odour neutralisation.

The intended use includes compliance with the technical data. Note the information on the

rating plate as well as the product identification.

Equipotential bonding must be carried out by a qualified electrician.

For use only by appropriately trained and suitable operating personnel.

Prevent any potential misuse in advance:

Only use with original filter components, which are correctly mounted.

Only Use correctly sized cooking units, such as the cooking modules in the Rieber varithek®

range.

Provide the unit with electrical fuse connection on site.

The integrated air-cleaning-system acs®ensures that the extracted air is passed back into

the room odour-free. This is not a replacement for an air-conditioning system.

For variants with Eisfink active carbon filter and odour elimination using plasma technology:

Any inference in the ‘plasma generator’ is forbidden.

In appliance type ‘ec’: in the technical compartment, do not adjust the bottom opening

which has been correctly set by the manufacturer. Can be recognised by product

identification with ‘Setting mark’.

Only use one deep-fryer per the appliance, as otherwise the extraction and circulating air

cleaning system may be overloaded and odours may develop.

Do not use gas cooking units, as this can be dangerous.

Do not flambé, as this can be dangerous.

Never operate the appliance unsupervised. To prevent persons from burning themselves on

hot surfaces, use of the product in public, e.g. for self-service, should only be allowed under

supervision.

Front cooking is only admissible with the sneeze guard that can be closed on four sides.

Observe the Food Hygiene Regulations under German law.

Not intended for private use at home.

Do not lean against or sit on the appliance.

Incorrect cleaning can substantially and irreparably damage the stainless steel surfaces.

Do not push or pull the appliance over sharp edges; Otherwise the casters could sustain

damage.

Do not use this appliance with poor floor conditions.

We are not able to rule out the possibility of marks appearing on the floor due to friction with

casters or the formation of scratches due to split cracks in the casters, for example.

We are not able to rule out the possibility that the casters may be damaged or become

unusable due to swelling or sharp edges on the floor.

Mobile appliances may only be moved manually. Machine-aided transport, e.g. using fork

lift trucks or lift trucks, is not permissible. There is a risk of injury and substantial damage to

the appliance.

Description of the Equipment

16

Eisfink Max Maier GmbH & Co. KG

5 Description of the Equipment

This chapter provides useful information on the structure and function of the equipment.

5.1 Designation

The illustration shows a configuration example which does not necessarily have to be included in the scope of

delivery.

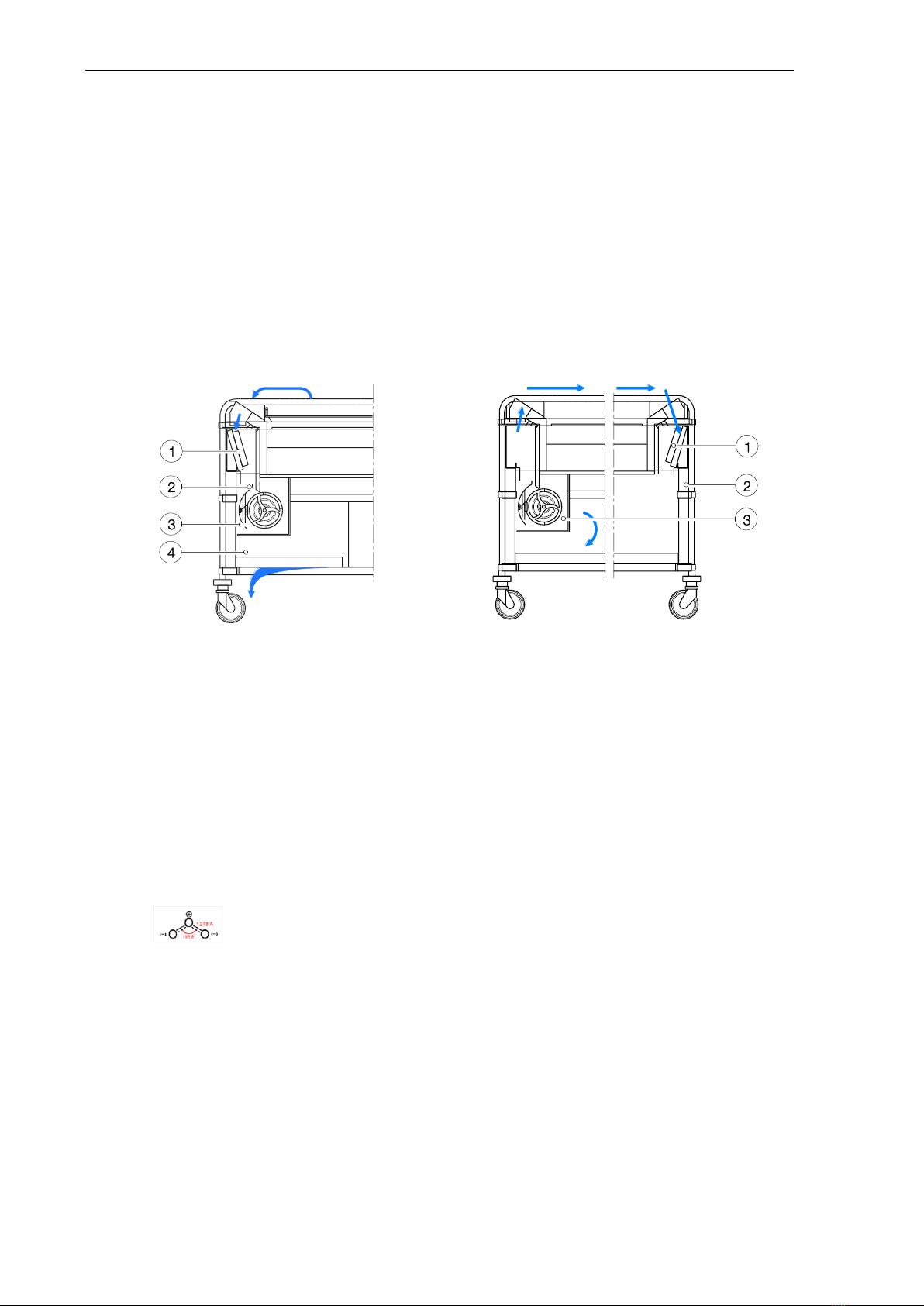

5.1.1 Appliance type ‘d3’

Appliance type ‘d3’ means three- sided extraction Extraction of steam and vapour.

Extraction at front left / right or on both sides and at the back.

Example

1500 d3

1 4 swivel casters, including 2 ‘swivel casters with parking brakes’ on the operator side

→ Always secure the position of the appliance with the parking brakes.

2 Technical compartment

3 Power connections for cooking units

4 Extraction areas →three-sided extraction of steam and vapour

5 Splash guard; removable for cleaning → option

6 Sneeze guard attachment, including shelf for serving food → option

7 Operating elements, power connections for cooking units

The electrical connection with cable and plug is located at the back of the product.

Description of the Equipment

Eisfink Max Maier GmbH & Co. KG

17

Appliance type ‘ec’

Appliance type ‘ec’ means ‘EasyClean’, German ‘Einfach reinigen, one- sided extraction of steam

and vapour. The extraction system (push & pull system) is designed in such a way that the vapour

created when cooking and roasting is collected by a transversally running air stream and is extracted

into the side flank.

Example

600 ec

1 4 swivel casters, including 2 ‘swivel casters with parking brakes’ on the operator side

→Always secure the position of the appliance with the parking brakes.

2 Technical compartment

3 Operating elements, power connections for cooking units

4 sided extraction of vapour and steam

4.1 Air supply area →from radial fan

4.2 Extraction area →one-sided extraction of steam and vapour

5 Splash guard; removable for cleaning

6 Cutting board →fresh preparation of food on the cutting board.

The electrical connection with cable and plug is located at the back of the product.

5.1.2 Cooking units

User tip

Only use correctly sized cooking units.

►Use cooking modules from the Rieber varithek®range. Baking, grilling, cooking, wok

cooking and frying.

Description of the Equipment

18

Eisfink Max Maier GmbH & Co. KG

5.1.3 Extraction and circulating-air cleaning

Appliance type ‘d3’: The acs®side extraction systems in appliance type ‘d3’ are designed in such a

way that the generated steam is extracted on three sides; Extraction at front left / right or on both sides

and at the back.

The variant "Eisfink active carbon filter for odour and contaminant absorption and odour elimination

using plasma technology" is intended for applications requiring a high level of odour neutralisation.

Appliance type ‘ec’: In appliance type ´ ec´, the extraction system (push & pull system) is designed in

such a way that the vapour created when cooking and roasting is collected by a transversally running

air stream and extracted into the side flank.

Schematic

diagrams

↑ Appliance type ‘d3’

↑ Appliance type ‘ec’

1 High-performance grease separator

2 Grease drip trays, removable

3 Radial fan

4 # Model type A:Eisfink active carbon filter

# Model type B: Eisfink active carbon filter for odour and contaminant absorption and odour

elimination using plasma technology

The plasma generator converts odorous substances into odourless substances.

Germs and odour-causing bacteria are also killed in the process.

Active carbon filter. Adsorbed substances accumulate in the carbon. Substances to

be filtered are physically absorbed by means of the active carbon filter. When the

capacity is exhausted, the filter must be replaced.

A wet active carbon filter is unusable. Never dry a wet Eisfink active carbon filter in the

oven or dryer, as there is a risk of fire. Let the active carbon filter dry in dry ambient air.

Description of the Equipment

Eisfink Max Maier GmbH & Co. KG

19

5.1.4 Sneeze guard attachment /Option

Standard:

3-sided splash guard made of stainless steel.

Option:

Sneeze guard attachment, including storage space for food delivery made of composite

safety glass and lighting.

Option

5.2 Technical data

5.2.1 Generally applicable data

Rated voltage / mains

frequency

3N AC 400V 50/60Hz,

Equipotential bonding on the underside of the appliance. This protective

measure serves for additional safety. Standard-compliant

implementation with subsequent inspection of the system is carried out

by a qualified electrician.

IEC 60364-5-54:2011;

for Germany DIN VDE 0100:540:2012-06

Protection class

IPX4 according to DIN EN 60529

→Unit offers protection against water splashes on all sides.

→Only use unit inside buildings. Protection against penetrating

moisture is required.

Ambient temperature

+5 °C to +40 °C

3-sided splash guard

Detachable splash guard made of chromium-nickel steel

CNS 1810 (WN 1.4301). Laminated safety glass optional

Rustproof casters

In accordance with DIN 18867, Part 8. 4 height-adjustable swivel

casters made from chromium-nickel steel CNS 1810 (WN 1.4301),

wheel diameter 80 mm.

Including 2 ‘swivel casters with parking brakes’ on the operator side;

Option: 4 stands, height-adjustable

Material

Stainless steel CNS 18/10, WN 1.4301

Circulating air cleaning

Radial fan,

High-performance grease separator (100% flame propagation proof)

with Cyclone ®blade profile (separation efficiency approx. 95%),

Grease drip trays. In addition

Version A: Eisfink active carbon filter

Model type B: Eisfink active carbon filter for odour and contaminant

absorption and odour elimination using plasma technology

Description of the Equipment

20

Eisfink Max Maier GmbH & Co. KG

5.2.2 Concerning appliance type ‘d3’

varithek®acs®1100 d3

varithek®acs®1500 d3

Power consumption

Maximum 11 kW / 22 kW

maximum 22 kW

Electrical fuse

Connect the unit on site to a socket with a series-connected residual

current operated device (RCD) with a tripping current of 30 mA.

16 A: Only connect appliances that have the same voltage, i.e.

400 V or 230 V.

32 A: Automatic circuit breaker for integrated power outlets in the

device, right installation compartment.

Permissible loading

maximum 80 kg

maximum 120 kg

Air capacity in accordance with

DIN 61591

Circulating air 1150 m3per hour

Circulating air 1250 m3per hour

External dimensions

(L x W x H) approx.

1100 x 722 x 900 (1100) mm

1500 x 770 x 900 (1100) mm

Placement niche (L x W x H)

approx.

805 x 615 x 260 mm

1205 x 660 x 260 mm

Weight approx.

115 kg

155 kg

Emitted sound pressure level

Lpa ≤70 dB(A)

Lpa ≤70 dB(A)

Electrical connection

Approx. 3 m cable / CEE plug 3x 16 / 32 A / L1 / L2 / L3 / N / PE

5.2.3 Relating to appliance type ‘ec’

varithek® acs® 600 ec

varithek®acs®1000 ec

Power consumption

Maximum 11 kW

Maximum 11 kW

Electrical fuse

16 A. Connect the unit on site to a socket with a series-connected

residual current operated device (RCD) with a tripping current of 30 mA.

Only connect appliances that have the same voltage, i.e. 400 V or 230 V.

Permissible loading

maximum 40 kg

maximum 80 kg

Air capacity in accordance

with DIN 61591

Circulating air 750 m3per hour

External dimensions

(L x W x H) approx.

600 x 720 x

900 (1000 1) mm

1000 x 720 x

900 (1000 1) mm

Placement niche

(L x W x H) approx.

405 x 690 x 260 mm

805 x 690 x 260 mm

Weight approx.

110 kg

140 kg

Emitted sound pressure

level

Lpa ≤70 dB(A)

Connected load

3N AC 230 V / 400 V, 50 Hz, 16 A, maximum 11 kW

Electrical connection

Approx. 3 m cable / CEE plug 3x 16 A / L1 / L2 / L3 / N / PE

For detailed information on dimensions, order number, accessories, circuit diagrams, spare and

wearing parts:

see type plate, catalogue, brochure

1

Complete with splash guard

This manual suits for next models

3

Table of contents

Other eisfink Air Cleaner manuals