EKE-Electronics EKE-Trainnet AIM2505A User manual

EKE-Trainnet®

AIM2505A

Analog Input Module

Technical Manual

虚拟输入模块

技术手册

EKE-Electronics Ltd.

Piispanportti 7, FIN-02240 Espoo, FINLAND

Tel. +358 9 6130 3308

Fax +358 9 6130 3300

Marketing and sales

TMS implementations, passenger train functions and

IEC 61131-3 type application programming

Technical support and maintenance requests

e-mail: support@eke.com

The most recent information on EKE Electronics’ products and services is available at www.eke.com.

Under copyright law no part of this document may be copied, reproduced or transferred electrically or

manually, not even partly, without prior written permission of EKE-Electronics Ltd. This document is subject

to change without notice.

The EKE-Trainnet® is a registered trademark of EKE-Electronics Ltd.

Copyright © 2016 EKE-Electronics Ltd. All rights reserved.

EKE-Trainnet® AIM2505A Analog Input Module Technical Manual ver. 2.03

1. General information ............................................................................................. 5

Symbols used in this manual......................................................................... 6

Safety considerations .................................................................................... 7

Correct handling of the module...................................................................... 7

2. Overview of the AIM module................................................................................ 8

Selected specifications.................................................................................. 9

Module identification.................................................................................... 10

Functionality diagram................................................................................... 11

AIM module features.................................................................................... 11

2.4.1 Voltage and current inputs....................................................................... 12

2.4.2 Frequency inputs ..................................................................................... 12

2.4.3 Voltage supply outputs............................................................................. 12

2.4.4 Module temperature and self tests........................................................... 12

3. Installing the AIM module into a rack ............................................................... 13

Before the installation.................................................................................. 13

3.1.1 Warnings.................................................................................................. 13

3.1.2 Preparations ............................................................................................ 14

Installation procedure .................................................................................. 14

3.2.1 Installing the AIM module into the rack.................................................... 14

3.2.2 Installing the I/O cable on the module...................................................... 15

Checkingthat the module works correctly.................................................... 15

3.3.1 Memory Self Test..................................................................................... 15

3.3.2 Status Indicator LEDs.............................................................................. 16

3.3.3 Using the Portable System Tester (PST) software................................... 16

Potential problems in the installation procedure.......................................... 17

4. AIM Features and operation .............................................................................. 18

I/O Bus......................................................................................................... 18

Node addresses .......................................................................................... 19

4.2.1 Rack types............................................................................................... 19

I/O Connector pins....................................................................................... 19

Frequencyinputs (group 1).......................................................................... 20

Currentand voltage Input channels(groups 2, 3 and 4)................................ 21

Heartbeat..................................................................................................... 23

Module temperature..................................................................................... 23

Memory self test .......................................................................................... 23

5. AIM Binary Tree .................................................................................................. 24

AIM Binary tree Register map...................................................................... 24

5.1.1 Registers in detail .................................................................................... 28

6. Troubleshooting................................................................................................. 32

Warnings ..................................................................................................... 32

Preparations................................................................................................ 33

Visual check ................................................................................................ 33

6.3.1 Circuit board ............................................................................................ 33

6.3.2 Cabling..................................................................................................... 33

Getting started with troubleshooting ............................................................ 33

Opening the Remote Terminal connection .................................................. 35

Contents

General information

AIM2505A Technical Manual V2.03 4

Remote terminal commands........................................................................ 37

6.6.1 Notes on commands................................................................................ 37

6.6.2 Command help - print available commands............................................. 37

6.6.3 Command ver - version check................................................................. 37

6.6.4 Command ser - serial link diagnostic counters ........................................ 38

6.6.5 Command freq –print status of Frequency Inputs................................... 38

6.6.6 Command in [num] - print input channel values....................................... 38

7. Firmware loading................................................................................................ 39

8. Technical Specifications.................................................................................... 40

Mechanical specifications............................................................................ 40

Connectorand pin order specifications........................................................ 40

8.2.1 X1, IO Connector..................................................................................... 40

8.2.2 X2, VME CONNECTOR........................................................................... 41

8.2.3 X4, DLOAD CONNECTOR...................................................................... 42

Electrical specifications................................................................................ 43

Reliability specifications............................................................................... 43

Non-metallic parts........................................................................................ 44

Compliance with standards.......................................................................... 44

Environmental and EMC test specifications................................................. 45

9. Cable recommendations.................................................................................... 46

10. Diagrams ................................................................................................ 48

11. Disposal of the module ......................................................................... 50

EKE-Electronics Ltd. pursues a policy of continual product development. Although

every effort is made to produce up-to-date product documentation this publication should

not be regarded as an infallible guide to current specifications. We reserve the right to

make changes without prior notice.

COPYRIGHT EKE-ELECTRONICS LTD. 2016

General information

5AIM2505A Technical Manual V2.03

1. General information

This is the Technical Manual for the EKE-Trainnet® AIM2505A Analog Input Module.

This manual is for system user and for designers.

This manual contains following chapters:

Chapter 1: General information

Chapter 2: Overview of the AIM module

Chapter 3: Installing the AIM module into the rack

Chapter 4: AIM features and operation

Chapter 5: AIM Binary tree

Chapter 6: Troubleshooting

Chapter 7: Firmware loading

Chapter 8: Technical specifications

Chapter 9: Cable recommendations

Chapter 10: Diagrams

This manual does not include information on other EKE-Trainnet®

products than the AIM module. If you need information about other

EKE-Trainnet® products (e.g. modules, racks or accessories), refer to

the manual of the product in question.

This chapter includes general information about this manual. The following topics are

covered in this chapter:

About this manual

Symbols used in this manual

Safety considerations

Correct handling of the module

基本信息

AIM 模块的概述

AIM 模块安装到机架中

AIM 功能与操作

AIM 二进制树

故障排除

固件加载

技术规格

电缆推荐

图表

General information

AIM2505A Technical Manual V2.03 6

Symbols used in this manual

In this manual, situations that require caution are marked with special warning symbols.

The warning symbols appear in the beginning of the appropriate chapter. The following

symbols are used.

Figure 1.1 Electric shock warning symbol

Figure 1.2 ESD warning symbol

Figure 1.3 General caution symbol

Figure 1.4 Note symbol

Figure 1.5 Separate collection for Waste Electrical and Electronic Equipment according to

Directive 2002/96/EC (WEEE)

General information

7AIM2505A Technical Manual V2.03

Safety considerations

The AIM module is a low voltage device. In a normal situation, it presents no safety risk

to the user.

When the AIM module is in use, it will contain a charge from 8V to

36V, depending on the current loop voltage used. Never disconnect

the AIM module from the rack with active power. When you remove

an AIM module that has been in use, always turn off the rack power

first.

In case of a severe train malfunction or wiring errors, there is a risk of

an electric shock through the bus cables.

The rack and modules can contain sharp edges. Use protective

clothing (gloves etc.).

The protection components on the module are intended to protect

module only from external surges and transients. They do not provide

protection against incorrect wiring or connection.

Correct handling of the module

Electrostatic discharge (ESD) can damage electronic circuits. EKE products are

protected against ESD. However, you run the risk of delivering electrostatic discharges

to the module whenever you handle it or any of its components.

To avoid this risk, only handle the AIM module at a static-free workstation. If this is not

possible, you must ground yourself using a wrist strap and a resistive connection cord.

Remember to handle the module according to these instructions even when you are

removing a defective module and sending it to maintenance.

Remember to handle the module according to these instructions even

when you are removing a defective module and sending it to

maintenance.

静电放电会损坏电子线路。保护EKE产品免受静电放电。无论怎样,每当你处理模块或其任何组件时,都会有向模块发送静电的风

险。

为了避免这种风险,可以在防静电工作台上处理模块。如果还不能奏效,你必须带手环和接地线进行连接。即使在拿出有缺陷的模块

进行维护时也要按照这个指令操作。

Overview of the AIM module

AIM2505A Technical Manual V2.03 8

2. Overview of the AIM

module

This chapter lists selected specifications of the AIM module and highlights some of

its features.

The following topics are covered in this chapter:

Selected specifications

Module identification

Functionality diagram

AIM module features

选择规格

模块识别

功能图

AIM模块特征

Overview of the AIM module

9AIM2505A Technical Manual V2.03

Selected specifications

The EKE-Trainnet® AIM module is designed for receiving control information from

devices on board a train to the EKE-Trainnet® CPU.

This section lists some technical specifications of the AIM module.

Table 2.1 Selected specifications

Parameter

Value

Size of the AIM module printed circuit board

100x160 mm (Euro 1)

Width

4 TE

Height

3 U

Weight

160g

Required free space in front of the module

75 mm

Operating voltage

5 VDC (4.75…5.25 VDC)

Operating temperature

- 40...+70 °C

Analog inputs

Number of voltage inputs

10

Number of current inputs

10

Voltage input range

-10...10 V

Current input range

-20...+20 mA

Accuracy

±0.4% of full scale (12 bit)

Frequency inputs

Number of frequency inputs

4

Input range

0…16 kHz

Input resolution

0...16 kHz

Input accuracy

0.25 Hz

Input voltage

± 0.1%

Input positive going threshold

8 V

Input negative going threshold

7 V

Reliability, MTBF, greater than (FIT data at +40°C ambient)

250 000 h

AIM 模块是从列车上的设备接收控制信息给CPU模块。

AIM电路板模块的尺寸

宽

长

重量

模块前所需空间。·

工作电压

工作温度

模拟输入

频率输入

电压输入值

电流输入值

电压输入范围

电流输入范围

准确率

频率输入值

输入范围

输入分辨率

输入精确值

输入电压

输入正向极值

输入负向极值

可靠工作时间

Overview of the AIM module

AIM2505A Technical Manual V2.03 10

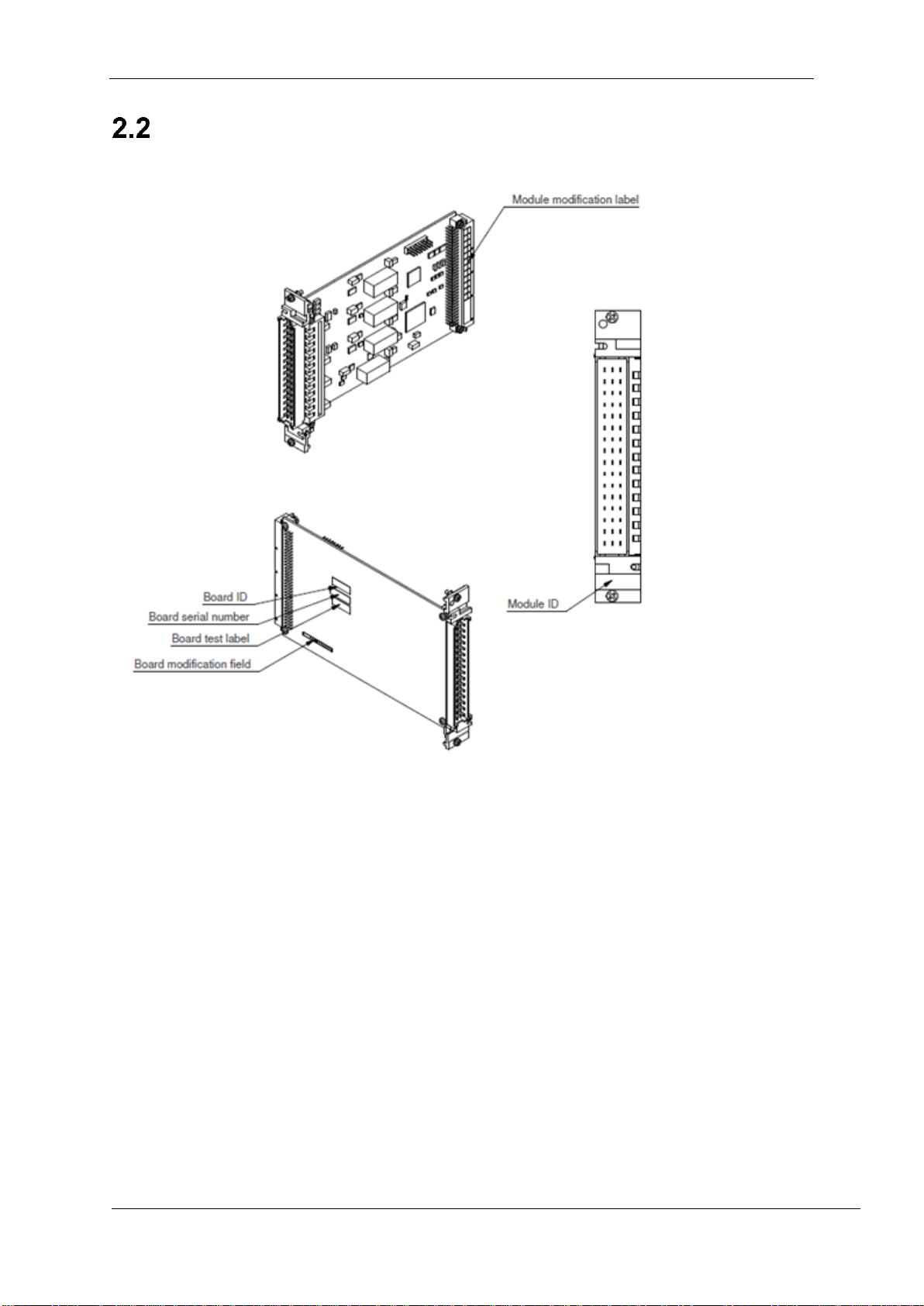

Module identification

The following figure shows where to find the version and the modification

information.

Figure 2.1 The location of version and modification information

A modification label shows the module modification. It is located on the back

connector. The label includes letters, and the modification is indicated by crossing

out one. If letter A is crossed out, the modification is A, and so on. This modification

field is for the entire module.

The circuit board may have a different modification level, indicated by numbers,

which are printed on the board’s modification field. This is found on the back side of

the circuit board on the lower left section.

The Board test label indicates that the module has gone through the required testing

cycle. It is located above the board modification field.

The Board serial number identifies the module. It is located above the board test

label.

The Board ID above the Board serial number indicates an ID for the circuit board.

The Module ID located just below the front connector indicates an ID for this entire

module.

下图显示在哪里找到版本和修改信息。

模块修正标签

模块ID号

板卡ID号

板卡序列号

板卡测试标签

板卡修正区域

修正标签展示模块的修正版本,它位于背面的连接处。标签包含字母和修改表示被划掉的一个部分。如果字母A被划掉,修改的就是A,等等。

这个修改区域是对整个模块的。

电路板可以有不同的修改级别,用数字表示,在板的修改字段上打印。这个

位于电路板的左下角。

板卡测试标签证明了模块通过了要求的测试周期。它位于板

卡修改区域上方。

板卡序列号用于证明模块,它位于板卡测试标签的上方。

板卡ID号位于板卡序列号的上方,证明电路板的ID号。

位于前连接器下方的模块ID指示此模块的ID号。

Overview of the AIM module

11 AIM2505A Technical Manual V2.03

Functionality diagram

The following figure (Fig. 2.2) presents a general diagram of the AIM module

functionality. Channels are divided into four isolated groups which are galvanically

isolated from each other and from control electronics.

Group 1 has four frequency inputs and two voltage output pins for external sensor or

current loop.

Group 2 has two voltage and current inputs.

Groups 3 and 4 are identical and they have four voltage and current inputs and one

voltage output pin for external sensors or current loops.

Figure 2.2 Functionality diagram of the SIU module, SIU3449A represented.

AIM module features

The AIM module is an intelligent analog input interface module that can be located in

the Coach Computer or distributed within the coach. The module has its own 32-bit

embedded processor and a serial bus interface for communication with the Coach

Computer’s (EKE-Trainnet® Gateway) CPU.

第1组有四个频率输入和两个电压输出引脚在外部传感器或电流环。

第二组有两个电压和电流输入。

第三组和第四组是相同的,它们有四个电压和电流输

入,还有一个电压输出针脚在外部传感器或电流环。

AIM模块是一个智能模拟输入接口模块,可以位于车厢计算机或分布在旅

客车厢内。该模块拥有自己的32位嵌入式处理器和一个与车厢计算机CPU

通信的串行总线接口(EKE trainnet®网关).

Overview of the AIM module

AIM2505A Technical Manual V2.03 12

2.4.1Voltage and current inputs

Each of the 10 voltage and current channels have similar measurement range.

Voltage inputs

The nominal input voltage range is -10...+10V. All the parameters are specified over

this range. Actual measurement range which is -12...+12V exceeds the nominal input

range and allows overrange detection. Measurement resolution is 13 bits and the

step size in the input register is 10 mV.

Current inputs

The current input is compatible with the industry standard 4...20mA current loops (2-

wire receiver according to the standard ANSI/ISA-50.1-1982 (R1992)). The nominal

input range is extended to -20...+20mA. All the parameters are specified over this

range. Actual measurement range which is -25...+25mA exceeds nominal input

range and allows overrange detection. Measurement resolution is 13 bits and the

step size in the input register is 10µA.

2.4.2Frequency inputs

The frequency inputs can be used to measure frequency, pulse width ratio and pulse

count. The input frequency range is 0...16 kHz. The frequency accuracy is better

than 1000 ppm which is 16 Hz at full range. Frequency measurement resolution is

0.25 Hz.

2.4.3Voltage supply outputs

Groups 1, 3 and 4 have output voltage supply pins that can be used to supply

voltage to external sensors or used to supply loop voltage to the current loops.

Output supply voltage is 15V nominal and it can supply 100mA current per group.

2.4.4Module temperature and self tests

The module has a sensor that measures the temperature of the module continually

with 3 ºC (Celsius) accuracy, and informs the Coach Computer CPU about it.

When the module is installed in a rack and the power turned on, the module

performs memory tests on itself to make sure it is functioning correctly.

电压和电流的10个频道中的每一个都有相似的测量范围。

普通的电压输入范围是-10V到10V之间。所有参数都在此范围内指定。实际测

量范围是在-12V到12V的超标普通输入范围和允许的超标的区域。测量分辨率

为13位,在输入寄存器的步长为10毫伏。

频率输入可用于测量频率,脉冲宽度比和脉冲计数.输入频率的范围是0到16kHz。频率精度优于1000 ppm的16 Hz全量

程。频率测量分辨率为0.25赫兹。

组1,3和4有输出电压引脚,可用于供应电压外部传感器或用于提供回路电压的电流回路。输出电压一般是15V,它提供100mA电流

每组。

该模块具有一个传感器测量模块的温度持续3ºC(摄氏度)的精度,并通知给有关车厢电脑CPU。

当模块安装到机架上,电源打开,该模块对自己进行内存测试,以确保它的功能正确。

Installing the AIM module into a rack

13 AIM2505A Technical Manual V2.03

3. Installing the AIM module

into a rack

This chapter includes instructions on how to install the EKE-Trainnet® AIM module

into a rack.

The following topics are covered in this chapter:

Before the installation

Installation procedure

Potential problems in installation procedure

Before the installation

3.1.1Warnings

This section contains warnings you need to consider before and during the AIM

module installation.

Do not turn on the rack power before you have finished the

installation of the rack.

Never remove the AIM module from a rack. Always turn OFF the rack

power first BEFORE removing the rack.

Electrostatic discharge can damage electronic circuits. Always handle

the module at a static free workstation. If this is not possible, ground

yourself using a wrist strap and a resistive connection cord.

The module and also the rack can contain sharp edges. Use

protective clothing (gloves etc.).

Do not drop the module.

Make sure that the module or any of the components on it do not get

wet.

When handling the module, only touch the front panel. Do not touch

the board or any of the components on it. Even when you are

removing a defective module and sending it to maintenance, handle

the module according to these instructions.

Installing the AIM module into a rack

AIM2505A Technical Manual V2.03 14

3.1.2Preparations

Before you start installing the AIM module to a rack, make the following preparations.

Make sure you have a Pozidrive Pz0 or Pz1 screwdriver to tighten the front

panel fastening screws on the module.

Check the shipping container to see that it is not damaged.

Take the module out of its shipping container carefully. The module is always

shipped in an ESD protective wrapping.

Check the module, especially the connectors, for any visible signs of damage

that may have occurred during shipment.

Installation procedure

The following sections include instructions for installing the AIM module into a rack.

3.2.1Installing the AIM module into the rack

1. Check that the coding pins are installed according to the project specifications

2. Hold the module by the front connector.

3. Place the module on the rails of the rack.

4. Slide the module towards the back plane of the rack until it clicks into its

place. Do not use force.

5. Tighten the two screws (Pozidriv head collar screws) on the front panel.

6. If there are other modules in the rack, make sure that the front connector of

the AIM module is at the same level with the other modules.

If the module does not fit into its place in the rack refer to section 3.4 “Potential

problems in the installation procedure” on page 17.

检查编码引脚是否按照项目规范安装。

Installing the AIM module into a rack

15 AIM2505A Technical Manual V2.03

The following picture shows a sample rack with modules successfully installed. The

modules in the picture are just an example, and the picture is intended as illustration

only.

Figure 3.1 Modules installed in a rack

3.2.2Installing the I/O cable on the module

1. Check that the coding pins on the cable connectors are installed according to

the project specifications.

2. Check that the installed I/O cable fulfils the cable requirements described in

the Cable Recommendations chapter.

3. Connect the cable to the module I/O interface without using force.

4. Tighten the two (2) attachment screws of the cable connector.

Checking that the module works correctly

3.3.1Memory Self Test

When the module is installed in a rack and the power turned on, the module

performs memory self test to verify correct operation.In case the module does not

pass the self tests an error will occur and the red LED located on the circuit board

will light on (refer to Table 3.2).

AIM module

Installing the AIM module into a rack

AIM2505A Technical Manual V2.03 16

3.3.2Status Indicator LEDs

There are three status indicator LEDs (green and red) on the circuit board, which can

be seen if there are no other modules next to it in the rack (refer to “Module

identification” on page 10).

Table 3.1 Indicator LEDs and their functions

Colour

Reference

designator

Name

Meaning when

Off

On

Blinking

Red

H1

System error

(SE)

System OK

System error

occurred,

module in

reset

Self-tests failed

Green

H2

Status

(ST)

If SE (red) led

is also off, no

power

System OK

System OK,

communication

with host CPU

Green

H3

FPGADONE

FPGA Not

initialized,

module in

reset

System OK,

FPGA

initialized

Module in “reset-

loop”

If all leds are off, there is no power provided to the module.

3.3.3Using the Portable System Tester (PST) software

The EKE-Trainnet Portable System Tester (PST) software can be used to examine

the AIM module’s operation through the Coach Computer. For further details and

instructions refer to the PST User’s Manual.

Installing the AIM module into a rack

17 AIM2505A Technical Manual V2.03

Potential problems in the installation procedure

The following table lists some potential problems that can occur during the AIM

module installation, as well as their causes, and actions you can take to solve the

problem.

Table 3.2 Potential problems in the installation procedure

Problem

Potential cause

Action

The module does not fit into

the rack.

The connector pins of the

module are damaged.

Replace the module with a

spare one.

Connector pins are OK, but

the module does not fit into

the rack.

The back plane of the rack

is damaged.

Refer to the documentation

provided by the rack

manufacturer.

The module is installed

correctly into the rack, but it

is not working.

The module is damaged.

Replace the module with a

spare one.

The installed module is not

working and the red LED is

on or blinking on the circuit

board (refer to “Indicator

LEDs and their functions”

on page 16).

System error

Replace the module with a

spare one.

AIM Features and operation

AIM2505A Technical Manual V2.03 18

4. AIM Features and

operation

This chapter includes a brief description about the AIM firmware.

The following topics are covered in this chapter:

I/O-bus

Node address

Input channels

Other AIM module feature

I/O Bus

The AIM module is compatible with EKE-Trainnet® Common I/O-bus (later referred

to as I/O-bus). The I/O-bus is available in several EKE-Trainnet® Coach Computer

central processing units like CPU, CPG, CPR etc. In this document all these units

are referred to as CPU.

The following figure shows the principal connection between the AIM module and the

CPU.

Figure 4.1 AIM-CPU connection

On the CPU side, an I/O-bus master called CIAO manages all communication

between the AIM module and the CPU. The CIAO transfers all data coming from the

AIM module into Binary tree registers. An ISaGRAF application can read this data

from the Binary tree. In the same manner, if the ISaGRAF application wants to send

something to the AIM module, it writes the data to the Binary tree.

The CIAO transfers all data from the Binary tree registers to the AIM module. The

Binary tree register addresses and the contents of each register are explained in

Chapter 5: AIM Binary Tree.

AIM Features and operation

19 AIM2505A Technical Manual V2.03

Node addresses

There can be several I/O modules connected to one I/O-bus. To be able to separate

all I/O modules from each other, they must have a unique node address. A unique

node address is assigned to each I/O module depending on their slot position in a

rack. At power-up, every I/O module reads a physical address that is coded to the

rack backplane. Based on this physical address, the I/O module selects a node

address. Different rack type backplanes are coded differently. The I/O-bus node

address is thus dependent on both in what slot and in which rack type the module is

in.

4.2.1Rack types

Please refer to corresponding rack manual for information about

racks and IO bus slot addresses.

I/O Connector pins

The following table show each channel and its related pins on connector X1.

Table 4.1 AIM IO Connector pinout

Connector X1

Pin

Signal

Pin

Signal

Pin

Signal

z32

GROUP4VSSI

b32

CURR10

d32

VOLT10

z30

GROUP4VSSI

b30

CURR9

d30

VOLT9

z28

GROUP4VSSI

b28

CURR8

d28

VOLT8

z26

GROUP4VSSI

b26

CURR7

d26

VOLT7

z24

PE

b24

PE

d24

GROUP4VOUT

z22

GROUP3VSSI

b22

CURR6

d22

VOLT6

z20

GROUP3VSSI

b20

CURR5

d20

VOLT5

z18

GROUP3VSSI

b18

CURR4

d18

VOLT4

z16

GROUP3VSSI

b16

CURR3

d16

VOLT3

z14

PE

b14

PE

d14

GROUP3VOUT

z12

GROUP2VSSI

b12

CURR2

d12

VOLT2

z10

GROUP2VSSI

b10

CURR1

d10

VOLT1

z8

PE

b8

GROUP1VOUT

d8

PE

z6

GROUP1VSSI

b6

GROUP1VOUT

d6

FREQ3

z4

GROUP1VSSI

b4

GROUP1VSSI

d4

FREQ2

z2

GROUP1VSSI

b2

FREQ4

d2

FREQ1

FREQ = Frequency/pulse count

CURR = Current Input

VOLT = Voltage Input

PE = Protection Earth

GROUPxVSSI = Group ground (return, wire)

GROUPxVOUT = Group voltage supply output

AIM Features and operation

AIM2505A Technical Manual V2.03 20

Frequency inputs (group 1)

AIMmodulehasfourfrequencyinputs that can be used for measuringinput frequency,

input pulse count and input pulse width ratio.

They can also be used as plain digital inputs.

Figure 4.2 Frequency input block

Additionally, inputs FREQ1 and FREQ2 (see table 4.5) can be paired to measure

phase direction between two signals of the same frequency that are phase shifted in

respect to each other. Another pair can be made from FREQ3 and FREQ4. This

enables applications such as measurement of train travel distance to be aware of

travel direction, which then can be used (with pulse counting) to estimate train

location on track.

Figure 4.3 Example of direction sensing capable tachometer

Frequency inputs have fixed positive going threshold level of 8V and negative going

threshold level of 7V. Input voltage range is specified up to 36V.

The GROUP1VSSI pins (refer to Table 4) on all channels are internally connected

together and therefore no voltage difference between GROUP1VSSI pins are

allowed.

Table of contents

Other EKE-Electronics Control Unit manuals

Popular Control Unit manuals by other brands

CALEFFI

CALEFFI SATK Series Installation, operation and maintenance manual

Ferroli

Ferroli CONNECT manual

Samsung

Samsung SPC-6000 Quick setup guide

Genebre

Genebre 2406 Installation, operation and maintenance manual

Emerson

Emerson KTM 2-WAY Installation, operation and maintenance instructions

PIKO

PIKO 35260 installation instructions