EKE-Electronics EKE-Trainnet MVB User manual

MVB (EMD) 4TE

Multifunction

Vehicle Bus Module

Technical Manual

EKE-Electronics LTD

Piispanportti 7, FIN-02240 Espoo, FINLAND

Tel. +358 9 6130 3308

Fax +358 9 6130 3300

e-mail: electronics@eke.fi

Marketing and sales:

e-mail: electronics@eke.fi

TMS implementations, passenger train functions,

IEC 61131-3 type application programming

e-mail: electronics@eke.fi

Reports, testing, problem analysis

e-mail: [email protected]

The most recent information on EKE products and services is available at www.eke.com

Under copyright law no part of this document may be copied, reproduced or transferred electrically or manually, not even

partly, without prior written permission of EKE-Electronics LTD. This document is subject to change without notice.

EKE-Trainnet®is a registered trademark of EKE-Electronics LTD.

Copyright © 2008 EKE-Electronics LTD. All rights reserved.

EKE-Trainnet®MVB (EMD) Multifunction Vehicle Bus Module Technical Manual, version 1.04.

Contents

1: General information ...................................................................................................... 1

1.1 About this manual ..................................................................................................... 1

1.2 Safety considerations ................................................................................................ 1

1.3 Correct handling of the module ................................................................................. 2

1.4 Warning symbols used in this manual ....................................................................... 2

2: Overview of the MVB module....................................................................................... 3

2.1 Selected specifications .............................................................................................. 3

2.2 Module identification ................................................................................................. 4

2.3 Functionality diagram ................................................................................................ 5

2.4 MVB features ............................................................................................................ 5

2.4.1 Duplicated line ................................................................................................... 5

2.4.2 Medium Attachment Unit.................................................................................... 6

3: Installing the MVB into a rack ...................................................................................... 7

3.1 Before you begin ....................................................................................................... 7

3.1.1 Warnings............................................................................................................ 7

3.1.2 Preparations....................................................................................................... 8

3.2 Installation procedure ................................................................................................ 8

3.2.1 Placing the module in the rack........................................................................... 8

3.2.2 Checking the module ......................................................................................... 9

3.3 Problems in installation ........................................................................................... 10

4: On-board troubleshooting.......................................................................................... 11

4.1 Before you begin ..................................................................................................... 11

4.1.1 Warnings.......................................................................................................... 11

4.1.2 Preparations..................................................................................................... 12

4.2 Normal situation ...................................................................................................... 12

4.3 Error situations ........................................................................................................ 12

4.3.1 Yellow LED blinking or on ................................................................................ 13

4.3.2 Red LED on ..................................................................................................... 19

4.3.3 Red LED blinking ............................................................................................. 19

4.3.4 No LEDs on or glowing very faintly .................................................................. 20

5: Troubleshooting with software .................................................................................. 21

5.1 Finding the command you need .............................................................................. 21

5.2 MVB Configuration .................................................................................................. 22

5.3 Firmware loading ..................................................................................................... 22

5.4 Getting started with troubleshooting ........................................................................ 22

5.4.1 Automatic self-tests.......................................................................................... 23

5.4.2 Automatic self-tests.......................................................................................... 23

5.4.3 Note on commands.......................................................................................... 24

5.4.4 Structure of command sections ....................................................................... 25

5.5 HELP command ...................................................................................................... 26

5.6 Debugging commands ............................................................................................ 26

5.6.1 BA - Bus Administrator..................................................................................... 26

5.6.2 CHECK_LINE .................................................................................................. 27

5.6.3 CTRL (D).......................................................................................................... 27

5.6.4 GET_STAT - Get status................................................................................... 28

5.6.5 IN ..................................................................................................................... 30

5.6.6 MSGR - Message read (D) .............................................................................. 33

5.6.7 MSGS - Message send (D).............................................................................. 34

5.6.8 OUT - Output (D) ............................................................................................. 35

5.6.9 QUIT (D) .......................................................................................................... 35

5.6.10 REC - Reconfigure (D)................................................................................... 36

5.6.11 START (D) ..................................................................................................... 36

5.7 Memory commands ................................................................................................. 37

5.7.1 ADDR - Addressing mode................................................................................ 37

5.7.2 MEM - Memory switch ..................................................................................... 39

5.7.3 RM - Read Memory.......................................................................................... 39

5.7.4 RP - Read logical Port data ............................................................................. 40

5.7.5 SM - Set Memory (D) ...................................................................................... 41

5.7.6 SP - Set logical Port data (D).......................................................................... 41

5.7.7 TEST_EEPROM (D) ........................................................................................ 42

5.8 Software development commands .......................................................................... 43

5.8.1 AS - Active Slave ............................................................................................. 43

5.8.2 CS - Create Slave ............................................................................................ 44

5.8.3 MVB_MODE - MVB access mode selection (D) .............................................. 44

5.8.4 LOP - List of ports ............................................................................................ 45

5.8.5 LOS - List of Slaves ......................................................................................... 46

5.8.6 LPORT - Modify the logical port of an active slave .......................................... 46

5.8.7 RESET (D) ....................................................................................................... 47

5.8.8 VER.................................................................................................................. 47

Appendix A: Technical Specifications .......................................................................... 49

Appendix B: Diagrams .................................................................................................... 57

1

1: General information

This chapter includes general information about this manual (MVB EMD Multifunction

Vehicle Bus Module Technical Manual).

The following topics are covered in this chapter:

About this manual

Safety considerations

Correct handling of this module

Warning symbols used in this manual

1.1 About this manual

This is the technical manual for the EKE-Trainnet®MVB Multifunction Vehicle Bus

module.

In this manual, the abbreviation MVB always refers to the module, not to

the MVB bus. The module is referred to as “the MVB module” or "MVB".

When talking about the Multifunction Vehicle Bus, the entire name is used.

This manual includes instructions for the following tasks:

Installing the MVB into a rack

Troubleshooting the MVB on board

Troubleshooting the MVB with software

Note that this manual does not include instructions for the installation or maintenance

of the rack or its components. For these instructions, refer to the manual provided by

the rack manufacturer.

Also, this manual does not include information on other EKE-Trainnet®products. If you

need to check other modules than the MVB during troubleshooting, refer to the manual

of the corresponding module.

1.2 Safety considerations

The MVB is a low voltage device. In a normal situation, it presents no safety risk to the

user. However, in case of a severe train malfunction or wiring errors, there is a risk of

an electric shock through the bus cables.

General information

2

When you remove and handle a module, always hold it by the sides. Do not touch the

components.

Never disconnect the MVB from, or connect it to, a rack with active power, as this can

damage the MVB module or other modules in the system.

1.3 Correct handling of the module

Electrostatic discharge (ESD) can damage electronic circuits. EKE products are

protected against ESD. However, you run the risk of delivering electrostatic discharges

to the module whenever you handle it or any of its components. To avoid this risk, only

handle the MVB at a static-free workstation. If this is not possible, you must ground

yourself using a wrist strap and a resistive connection cord.

Remember to handle the module according to these instructions even

when you are removing a defective module and sending it to maintenance.

1.4 Warning symbols used in this manual

In this manual, situations that require caution (as specified above) are marked with

special warning symbols. The warning symbols appear in the beginning of the

appropriate chapter. The following symbols are used.

Figure 1.1: Electric shock warning symbol

Figure 1.2: General caution symbol

Figure 1.3: ESD warning symbol

Figure 1.4: Note symbol

3

2: Overview of the MVB

module

This chapter lists selected specifications of the EKE-Trainnet®MVB module and

highlights some of its features.

The following topics are covered in this chapter:

Selected specifications

Module identification

Functionality diagram

MVB features

2.1 Selected specifications

The EKE-Trainnet®MVB module is designed for train data transmission. It is an

interface between the VME Bus and devices attached to the Multifunction Vehicle Bus.

This section lists some technical specifications of the MVB module. For complete

technical specifications, see Appendix A.

Table 2.1: Selected specifications of the MVB module

Size of the printed circuit board 100 mm * 160 mm (Euro 1)

Width 4 TE

Height 3 U

Required free space in front of the module 75 mm

VME interface A24/D16, slave

MVB bus connectors Subminiature D9

Operating temperature –40 — +70 °C

Reliability (MBTF) greater than 1200 000 h

estimated from field data at 40 °C

ambient temperature

Overview of the MVB module

4

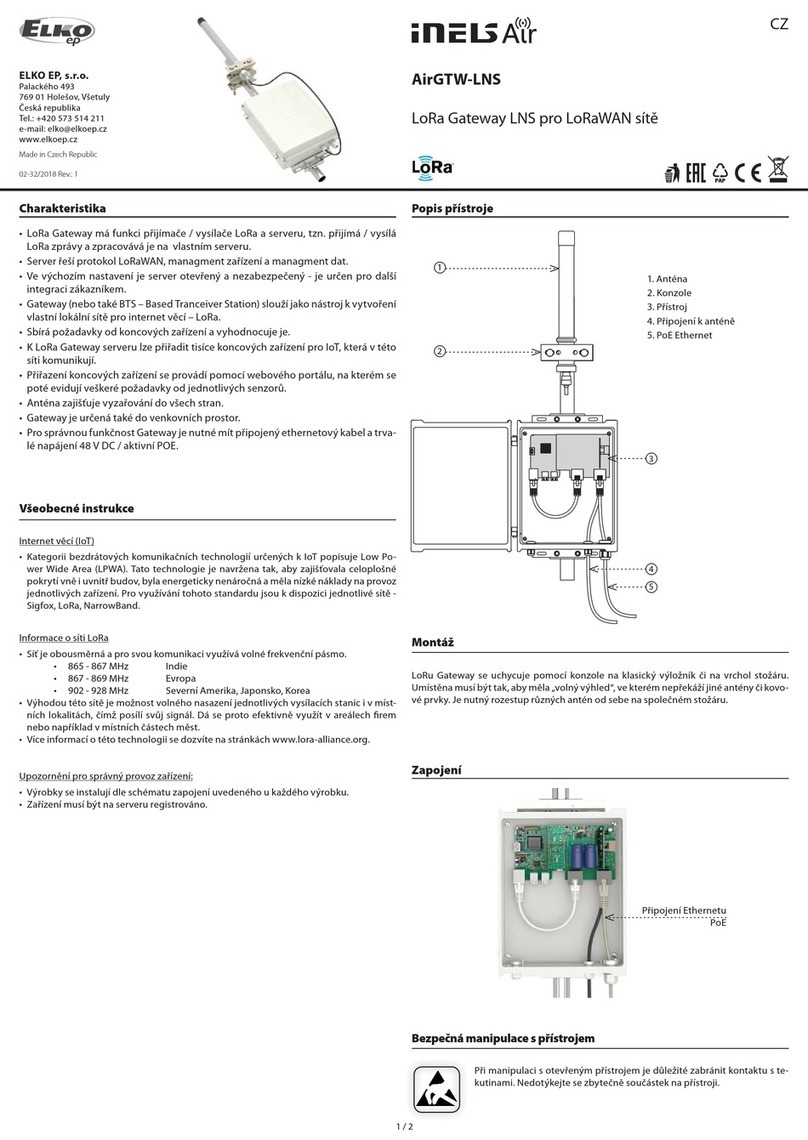

2.2 Module identification

Version and modification information appears on the board. The following pictures

show you where to find this information.

Figure 2.1: Location of version and modification information

The modification label shows the module modification. It is located above the back

connector of the module. The label includes letters, and the modification is indicated by

crossing out one. If nothing is crossed out, the modification is 00. If the letter A is

crossed out, the modification is A, and so on. This label gives the modification level of

the entire module, and the circuit board may have a different modification level,

indicated by numbers printed on the board’s modification field.

Overview of the MVB module

5

The board test label indicates that the board has gone through the required testing

cycle.

The serial number identifies the module. It is found on the back side of the front panel.

This is the serial number of the entire module, and the board has its own serial number.

The Module ID, located on the front panel handle, indicates an ID for this module. Again

note that the board has its own Board ID.

2.3 Functionality diagram

The following figure presents a general diagram of the MVB module functionality. For

a more detailed block diagram, see Appendix B.

Figure 2.1: General functionality diagram

2.4 MVB features

The MVB module is designed to ensure reliable data transmission on board a train. The

following sections present some MVB features intended for this purpose.

2.4.1 Duplicated line

To ensure uninterrupted functionality of the Multifunction Vehicle Bus, the bus is

duplicated: there are two lines (A and B) through which devices transmit data. In case

one of the lines is temporarily out of order, the other line can take over, and full

redundancy is ensured. This way, the flow of important data can continue without

interruption even in case of potential problems.

MVB MAU

VME bus

MVB

Configuration

MVB

Manager

(Z180)

PST Interface

Trainnet® Download

VME bus

Slave Logic

MVB line A

MVB line B

MVB MODULE

Overview of the MVB module

6

2.4.2 Medium Attachment Unit

The module has a fully IEC 61375-1 compliant redundant Multifunction Vehicle Bus

interface with EMD (Electrical Middle Distance) media, isolated by transformers.

The implementation of redundancy is based on MVBC01 ASIC and is subject to its

limitations.

EKE-Electronics LTD also manufactures versions of the MVB module, which support

OGF (Optical Glass Fibre) or ESD (Electrical Short Distance) media.

7

3: Installing the MVB into a

rack

This chapter includes instructions on how to install the EKE-Trainnet®MVB

Multifunction Vehicle Bus module into a rack.

The following topics are covered in this chapter:

Before you begin

Installation procedure

Potential problems

3.1 Before you begin

Read the following sections carefully before you start installing the MVB module.

3.1.1 Warnings

This section contains warnings you need to consider before and during the MVB

installation.

Do not turn on the rack power before you have finished the

installation.

Never connect the MVB to, or disconnect it from, a rack with active

power, as this can damage the MVB module or other modules in the

system. Always turn off the rack power first.

Electrostatic discharge can damage electronic circuits. When not handling

the module at a static free workstation, ground yourself using a wrist strap

and a resistive connection cord.

Installing the MVB into a rack

8

When handling the module, only touch the front panel. Do not touch the

board or any of the components on it.

Do not drop the module.

Make sure that the module or any of the components on it do not get wet.

Even when you are removing a defective module and sending it to

maintenance, handle the module according to these instructions.

3.1.2 Preparations

Before you start installing the MVB module to a rack, make the following preparations.

Make sure you have a Pozidrive Pz0 or Pz1 screwdriver to tighten the screws on

the module.

Check the shipping container to see that it is not damaged.

Take the module out of its shipping container carefully. The module is always

shipped in an ESD protective wrapping.

Check the module, especially the connector on the back, for any visible signs of

damage that may have occurred during shipment.

3.2 Installation procedure

The following sections include instructions for installing the MVB module into a rack.

3.2.1 Placing the module in the rack

The first step in the MVB installation is placing it in the rack. Do the following:

1Hold the module by the front plate.

2Place the module on the rails of the rack.

3Slide the module towards the back plane of the rack until it clicks into its place. Do

not use force.

4Tighten the two screws (slotted head collar screws) on the front panel.

5If there are other modules in the rack, make sure that the front plate of the MVB

module is at the same level with the other modules.

If the module does not fit into its place in the rack, see section 3.3 on page 10.

Installing the MVB into a rack

9

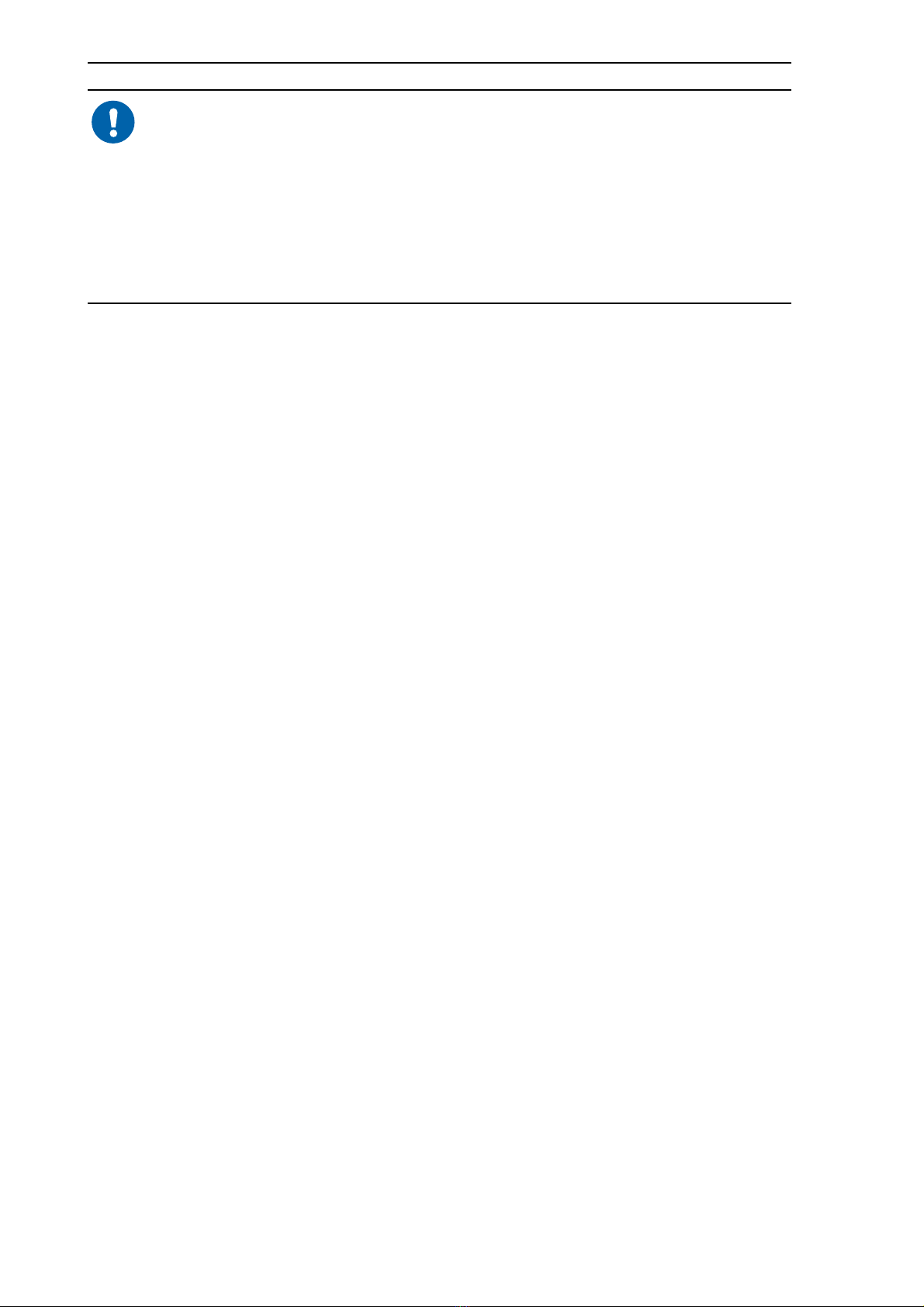

The following picture shows a sample rack with modules successfully installed. The

modules in the picture are just an example, and the picture is intended as illustration

only.

Figure 3.1: Modules installed in a rack, an example only

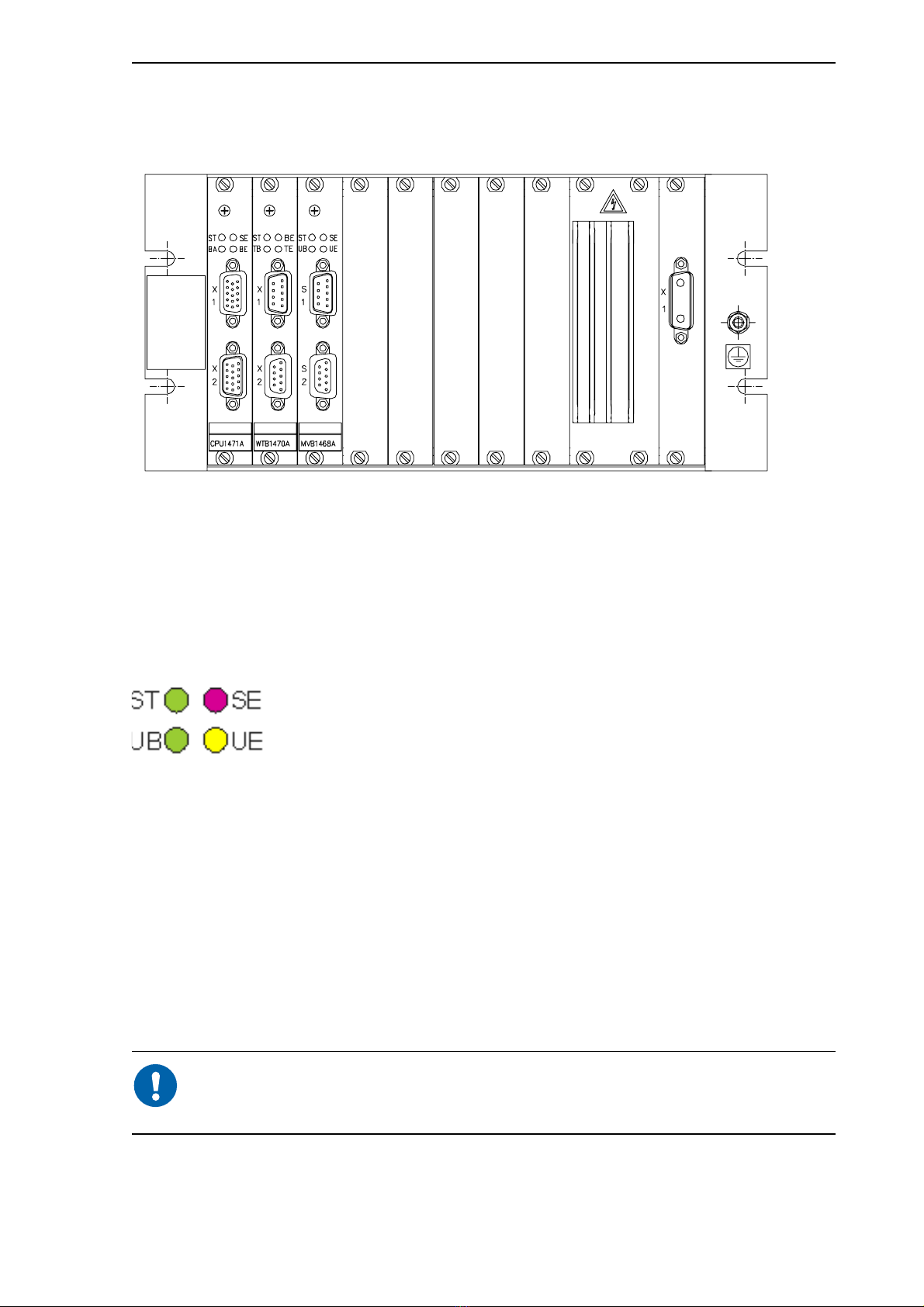

3.2.2 Checking the module

When you have successfully installed the module in the rack, the next step is to check

that the module works. You can do this by observing the LEDs. The following picture

shows the four LEDs on the module and their names.

Figure 3.2: MVB LEDs

To check the module, do the following:

1Turn on the rack power.

2Check that the green ST LED is on. Also, check that the red SE LED and yellow UE

LED are not on. This means that the module is OK.

3If the red SE LED and yellow UE LED are constantly on, the module is not OK. In

such a case, make sure you have placed the MVB module properly in the rack. If

these LEDs still remain on, turn off the rack power, loosen the screws on the module

front panel and pull the module carefully out of the rack.

During module start-up, the red and yellow LEDs are on for a moment and

then go off. This is part of the normal start-up procedure and does not

indicate an error.

If the module was not OK, see the following section.

Installing the MVB into a rack

10

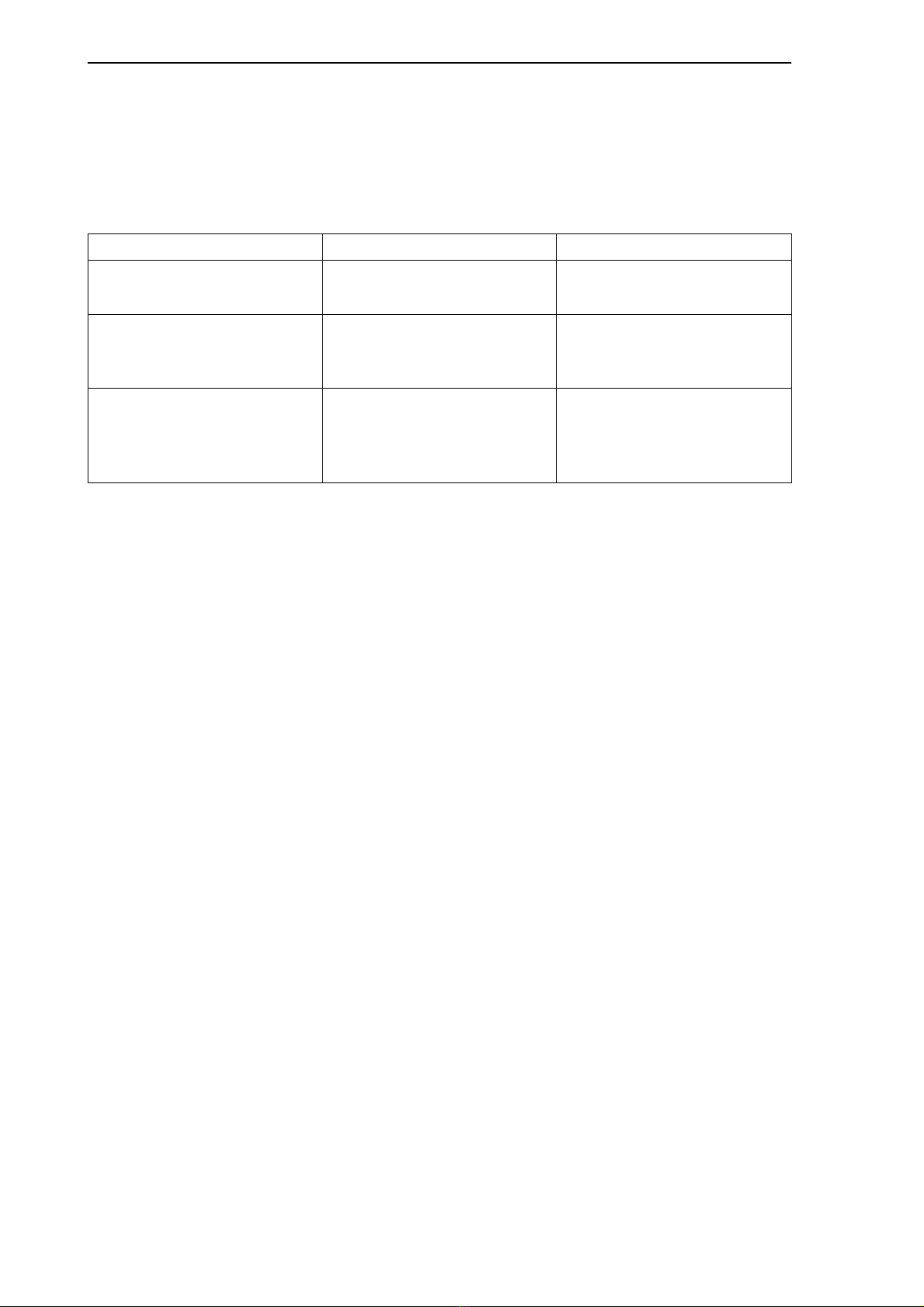

3.3 Problems in installation

The following table lists some potential problems that can occur during the MVB

installation, as well as their causes, and actions you can take to solve the problem.

Table 3.1: Potential problems in the installation procedure

Problem Potential cause Action

The module does not fit into

the rack.

The connector pins of the

module are be damaged.

Replace the module with a

spare one.

Connector pins are OK, but

the module does not fit into

the rack.

The back plane of the rack is

damaged.

Refer to the documentation

provided by the rack

manufacturer.

You have installed the

module into the rack, but it is

not working: the red SE LED

and yellow UE LED are on.

The module is damaged. Replace the module with a

spare one.

11

4: On-board troubleshooting

This chapter includes instructions for troubleshooting the EKE-Trainnet®MVB module

on board a train.

The following topics are covered in this chapter:

Before you begin

—Warnings

—Preparations

Normal situation

Error situations

—Yellow LED blinking or on

—Red LED on

—Red LED blinking

—No LEDs on or glowing very faintly

4.1 Before you begin

Read the following sections carefully before you start troubleshooting the MVB module.

4.1.1 Warnings

This section contains warnings you need to consider before and during the

troubleshooting of the MVB.

Never disconnect the MVB from a rack with active power, as this can

damage the MVB module or other modules in the system.

Electrostatic discharge can damage electronic circuits. Always handle the

module at a static free workstation. If this is not possible, ground yourself

using a wrist strap and a resistive connection cord.

When you remove and handle the module, always hold it by the front panel

or sides. Do not touch the board or any of the components on it.

Remember to handle the module with care even when you are removing a

defective module and sending it to maintenance.

On-board troubleshooting

12

4.1.2 Preparations

You may need the following tools and devices:

A Pozidrive Pz0 or Pz1 screwdriver to loosen the screws on the module.

An oscilloscope

A multimeter

4.2 Normal situation

The front panel of the MVB contains four LEDs: two green, one red and one yellow.

You can detect the status of the MVB module by looking at the LEDs in the front panel.

The following picture shows the four LEDs on the module and their names.

Figure 4.1: MVB LEDs

When the LEDs are on, it means the following:

In a normal situation, the green ST LED is on and the green UB LED is blinking. If the

red SE LED or the yellow UE LED is on, there is an error situation. For troubleshooting,

see page 13 (Yellow LED blinking) and page 19 or page 19 (Red LED on/blinking).

During the module start-up, the red SE LED and yellow UE LED are on for

a moment and then go off. This is part of the normal start-up procedure and

does not indicate an error.

4.3 Error situations

If the Multifunction Vehicle Bus does not function normally, the problem can be either

in the MVB module or in the bus itself. If the problem is with the bus, you can only

troubleshoot it on board the train. If the problem is with the module, you need to remove

ST (green):

STATUS

Module hardware has started.

UB (green):

UNIT BUS

Principal activity of the module is OK; the module is transmitting data.

UE (yellow):

UNIT ERROR

Problems with the principal activity of the MVB module. This means that the

module has detected a network bus related error or a data transmission

error.

SE (red):

SYSTEM

ERROR

No principal activity in the MVB module. This means that the module is not

able to provide any kind of bus service.

On-board troubleshooting

13

the module from the rack, replace it with a spare one and send the defective module to

maintenance.

The following sections give you hints on analysing error situations and finding out

whether the problem is with the module or with the bus. The sections are arranged by

symptoms, in other words, by the problems you observe when checking the module or

browsing the Coach Computer.

The following table lists symptoms that are covered in this chapter.

Table 4.1: Symptoms for potential problems with the MVB module and the Multifunction

Vehicle Bus

4.3.1 Yellow LED blinking or on

If the yellow UE LED of the MVB module is blinking, there are sporadic transmission

errors in the Multifunction Vehicle Bus or the MVB has not received its configuration

from the Gateway CPU. If the yellow LED remains constantly on, there is a continuous

problem with one or more of the lines. You need to rule out the following causes for the

error situation:

Missing configuration

Defective module

Wrong connection or a loop connection or missing termination

Missing or defective device

Physical defect in connectors

Low signal level or missing signal

Defective termination

The following sections provide you with tips and instructions for solving these error

situations.

Missing configuration

This situation is most likely to occur if the system has been reset for some reason, and

the MVB has not re-received its configuration from the Gateway CPU. In this case, the

green ST LED is on, and the yellow UE LED is blinking. You should try resetting the

Coach Computer again. If the situation does not alter, there may be a fault with the

Gateway CPU or with the VME backplane.

Symptom To find out potential causes, see page

Yellow LED blinking or on 13

Red LED on 19

Red LED blinking 19

No LEDs on or LEDs glowing very faintly 20

On-board troubleshooting

14

Defective module

A transmission error can be caused by a defective module. All EKE-®modules have

passed a production test procedure and are thus guaranteed to function properly.

However, a module may be damaged during shipment or handling.

To find out whether the transmission error is caused by a defective module, do the

following:

1Disconnect connectors M1 and M2 from the MVB module and connect the

terminators in their place. The module is no longer connected to the bus.

2Check the green UB LED. It should be dimly lit when the terminators are connected.

(The yellow UE LED, too, remains on.)

3If the green ST LED is not lit or blinks only very dimly, the module is defective.

Remove the module from the rack and replace it with a spare one.

If the module was not defective, try resetting the Coach Computer - the problem could

be with the application software of some other module.

If the problem persists, continue with the troubleshooting tips presented in the following

sections.

Physical defect in connectors

A transmission error can be caused by a physical defect, such as oxidation, in the MVB

connectors or in the bus cable.

To find out whether the transmission error is caused by a physical error in connectors,

check the connectors visually. Also, if the terminators are in their place and the green

UB LED is not on, the cable connector is more than likely defective.

If there is no physical error in connectors, continue with the troubleshooting tips

presented in the following sections.

Wrong connection or a loop connection or missing termination

In this situation the yellow UE LED is on, and the green UB LED is blinking faintly. The

transmission error may result from a wrong connection or a loop connection. The

terminator modules might be missing, or in the wrong places, or the Multifunction

Vehicle Bus might have been connected into a loop. Visually check all connections and

terminations.

Missing or defective device

In this situation the yellow UE LED is on, and the green UB LED is either on or blinking

very rapidly. The module is not getting a response from all the ports in its configuration.

The MVB configuration may not match with the connected slave devices, or the slave

devices may be defective. Check all connections, terminations and devices, or

troubleshoot the devices according to their manuals. Try resetting the Coach

Computer.

On-board troubleshooting

15

Low signal level or missing signal

A transmission error can be caused by a low signal level. One possible cause for a low

signal level is that the other half of the differential signal is missing. Also, the entire

signal can be missing. You can measure the signal levels with an oscilloscope.

It is not recommended to use a multimeter, as it does not properly indicate

the status of the transmission line.

To find out whether the transmission error is caused by a low signal level or a missing

signal, do the following:

1Set the vertical amplification of the oscilloscope to 2v/div or 5v/div and the time

scale to 1µs/div or 500 ns/div.

2If you need to measure line A, connect oscilloscope channel 1 to pin 1 and channel

2 to pin 2 of connector M1. If you need to measure line B, connect oscilloscope

channel 1 to pin 4 and channel 2 to pin 5.

3Connect the ground of the oscilloscope channels to PE (module front panel).

4Set the oscilloscope for a differential measurement (channel 1 - channel 2) and

determine the cause of the problem by the resulting waveform.

The following figure shows a normal waveform that indicates no transmission errors.

Figure 4.1: No transmission errors

On-board troubleshooting

16

The following figure shows a waveform that indicates a low signal level.

Figure 4.2: Low signal level

The following figure indicates a missing half in a differential signal.

Figure 4.3: Missing half of the differential signal

Table of contents