Ekinex EK-BH1-TP-485 User manual

Pag. 1

Gateway Modbus master RTU RS485 –

KNX TP

Code: EK-BH1-TP-485

Data sheet STEKBH1TP485_EN

V1.3 – 01 2019

KNX device with gateway function (protocol conversion)

between a serial RS485 Modbus RTU network (Master

function) and a KNX TP network over a twisted pair

communicaton cable. Ideal application in integration of

Modbus devices over a RS485 serial network in a KNX-

based automation system for homes and buildings.

Description

The Modbus master RTU RS485 ekinex® EK-BH1-TP-

485 gateway is a KNX modular unit for panel mounting.

It allows you to exchange informations with one or more

slave devices over a RS485 differential serial network

through Modbus RTU (Remote Terminal Unit) protocol.

The ekinex gateway acts as Modbus Master. The

informations exchanged over the Modbus network are

updated over the KNX network by means of a twisted

pair (TP) communication cable.

The device manages a two-way data stream: the

Modbus registers can be cyclically read and their value

sent as a communication object over the KNX TP

network through a multicast communication to

configured group addresses. The data update over the

KNX network can be done cyclically and/or on event of

change of the data acquired by the Modbus network.

Likewise, the ekinex gateway can make requests to

cyclically readings KNX communication objects or

acquire their values during data exchange over the bus.

Cyclically or on event of change of the communication

objects, data are written on the Modbus registers of one

or more configured devices.

The ekinex gateway supports the entire Modbus RTU

master protocol with the possibility of reading and writing

single and multiple 1-bit registers (Coil and Status) as

well as 16-bit registers (Holding and Input). It is also

possible to read and write multiple registers containing

32-bit floating point values (IEEE 754 format).

As for KNX communication, 1-bit, 1-byte, 2-byte and 4-

byte communication objects can be acquired: internal

conversion functions allow you to convert the

informations from and to 16-bit floating point values (DPT

9.xxx) starting from integer Modbus registers.

Configuration is performed through a PC application

software which communicates through the integrated

Ethernet port. The application software

CGEKBH1TP485 is available for download at

www.ekinex.com.

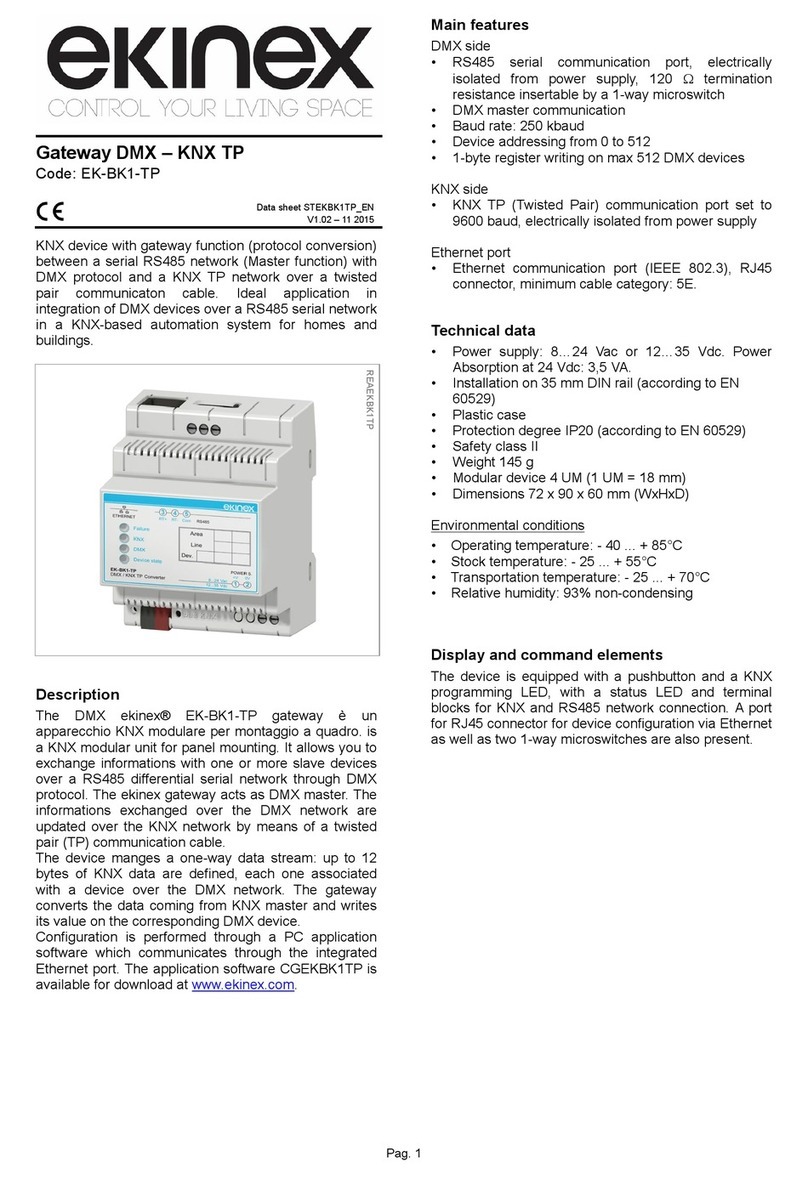

Main features

Modbus side

•RS485 serial communication port, electrically

isolated from power supply, 120 termination

resistance insertable by a 1-way microswitch

•Modbus master RTU (Remote Terminal Unit)

communication

•Selectable baud rate from 1200 to 115200 baud

•Device addressing from 0 to 250

•Coil, Input, Holding Register e Input Register data

exchange

•Single and multiple register reading/writing

•1440-byte volatile support “Modbus image” memory

buffer

KNX side

•KNX TP (Twisted Pair) communication port set to

9600 baud, electrically isolated from power supply

•1440-byte volatile support “KNX image” memory

buffer

Ethernet port

•Ethernet communication port (IEEE 802.3), RJ45

connector, minimum cable category: 5E.

Technical data

•Power supply: 8…24 Vac or 12…35 Vdc. Power

Absorption at 24 Vdc: 3,5 VA.

•Installation on 35 mm DIN rail (according to EN

60529)

•Plastic case

•Protection degree IP20 (according to EN 60529)

•Safety class II

•Weight 145 g

•Modular device 4 UM (1 UM = 18 mm)

•Dimensions 72 x 90 x 60 mm (WxHxD)

Environmental conditions

• Operating temperature: - 40 ... + 85°C

• Stock temperature: - 25 ... + 55°C

• Transportation temperature: - 25 ... + 70°C

• Relative humidity: 93% non-condensing

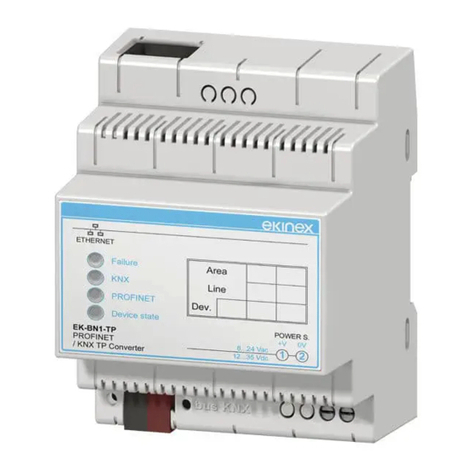

Display and command elements

The device is equipped with a pushbutton and a KNX

programming LED, with a status LED and terminal blocks

for KNX and RS485 network connection. A port for RJ45

connector for device configuration via Ethernet as well

as two 1-way microswitches are also present.

REAEKBH1TP485

Pag. 2

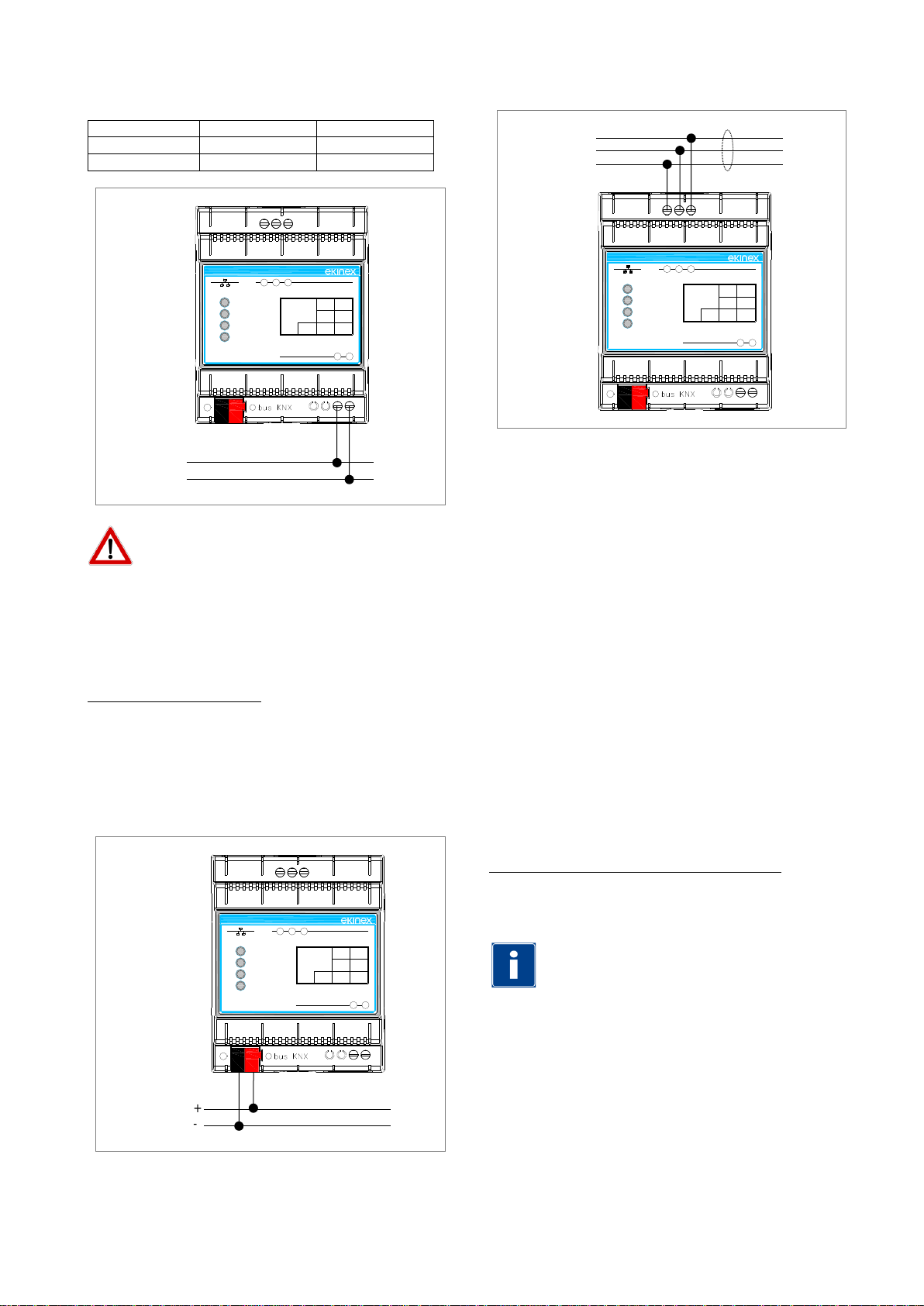

1) KNX bus line terminal blocks

2) KNX programming pushbutton

3) KNX programming LED

4) Power supply terminal blocks

5) 1-way microswitch A

6) Ethernet port

7) Ethernet port LED

8) Device satus LED

9) Modbus communication LED

10) KNX communication LED

11) Device error LED

12) RS485 serial line terminal blocks (3 Com, 4 RT-, 5 RT+)

13) 1-way microswitch B

Command elements

•Pushbutton that switches between normal mode and

KNX physical address programming.

1-way microswitches

•A - OFF: normal mode active. ON: Boot mode active

•B - OFF: open. ON: RS485 line termination inserted

(120 termination resistance in parallel between

RT+ and RT-)

Display elements

The device can run according to two operating modes:

Normal mode (configuration loaded, Modbus and KNX

communication running) and Boot mode (no

configuration or configuration still loading).

•Green LED (8) – Device status. Normal mode: Slow

blinking (~1 Hz). Boot mode: ON= device on; OFF=

device off.

•Yellow LED (9) – Modbus communication. Normal

mode: blinks when a frame is received on the RS485

port. Boot mode: if fast blinking: no configuration, if

very slow blinking (~0,5 Hz): loading configuration.

•Yellow LED (10) – KNX communication. Normal

mode: blinks when a frame is received. Boot mode: if

fast blinking: no configuration, if very slow blinking

(~0,5 Hz): loading configuration.

•Yellow LED (11) – Device error. Normal mode: ON=

at least one Modbus request did not get a correct

answer; OFF= no error. Boot mode: if fast blinking:

no configuration, if very slow blinking (~0,5 Hz):

loading configuration.

•Green LED (7) – Ethernet port. Normal mode: ON=

Ethernet connector plugged; OFF= Ethernet

connector unplugged. Boot mode: ON= Ethernet

connector plugged; OFF= Ethernet connector

unplugged.

•Red LED (3) – KNX programming. Normal mode:

ON= physical address programming mode on; OFF=

physical address programming mode off. Boot mode:

if fast blinking: no configuration, if very slow blinking

(~0,5 Hz): loading configuration.

Installation

The device has IP20 protection degree and is therefore

suitable for dry indoor environments. The case is suitable

for mouting on a DIN rail (according to EN 60715) inside

eletrical distribution cabinets. The proper installation

involves the bus terminal blocks to be in the lower side.

For installation proceed as follows:

•with the aid of a tool bring the locking device in

completely lowered position (1);

•place the device on the upper edge of the DIN rail

(2);

•rotate the device towards the DIN rail (3);

•push the locking device up untili il stops (4).

1

2

3

4

To unmount the device, make sure to unplug the network

connection and the bus terminal from its housing. Use a

screwdriver to slide down the lock and remove the device

from the rail.

Note. It is recommended to install the device so to

always guarantee full frontal accessibility, in order to

properly display the status LEDs.

Power supply connection

The device supports a very wide range of supply

1

2

5

4

12

6

7

8

9

10

11

13

3

Failure

KNX

Modbus

Device state

EK-BH1-TP-485

Modbus Master RS485 RTU

/ KNX TP Converter 1 2

8...24 Vac +V 0V

POWER S.

12...35 Vdc

3 4 5 RS485ETHERNET

Dev.

Line

Area

ON

ON

RT-Com RT+

DCEKBH1TP485

Pag. 3

voltages, both DC and AC.

Vmin

Vmax

Vac

8

24

Vdc

12

35

Important! In case of DC power supply, DO NOT

reverse the terminal blocks polarity!

KNX connection

Connection to KNX bus is made via the supplied KNX

terminal block. The terminal block must be inserted into

the slot located on the lower front side of the device.

KNX terminal block features

•Conductors’ spring clamping

•4 conductors’ location for each polarity

•Suitable for KNX bus cables with single-wire

conductors (diameter between 0.6 and 0.8 mm)

•Recommended wire stripping: 5 mm

•Color code: red = bus conductor + (positive), black =

bus conductor – (negative)

RS485 Modbus connection

In order to terminate the RS485 network and balance the

line impedance, you must enter the terminating resistor

(120 Ω), by setting ON the 1-way microswitch B.

The maximum extension of the RS485 network is 1200

m.

Below are some recommended cable codes for wiring

the RS485 line:

•Belden code 8132. 2x 28AWG twisted pairs of

conductors + foil shielding + shielding mesh;

•Belden code 82842. 2x 24AWG twisted pairs of

conductors + foil shielding + shielding mesh;

•Tasker code C521. 1x 24AWG twisted wire pair + foil

shielding + shielding mesh;

•Tasker code C522. 2x 24AWG twisted pairs of

conductors + foil shielding + shielding mesh.

Configuration and commissioning

Configuration and commissioning of the ekinex®

gateway must be performed using the application

program CGEKBH1TP485, available for download at

www.ekinex.com.

System requirements for configuration software

•Desktop o laptop PC with Ethernet IEEE 802.3 port.

•32/64 bit operating system, Microsoft Windows® XP,

7, 8.0, 8.1 e 10.

Note. .NET Framework 4.0 system library installation is

required.

The ekinex® configuration software CG-EK-BH1-TP-485

allows you to perform the following operations:

•Selection of physical parameters of the RS485 serial

communication;

•Selection of physical address of the device over the

KNX TP network;

•Selection of Ethernet parameters (for configuration

download only);

•KNX network: communication objects definition and

relative group addresses to be acquired;

communication objects definition and relative group

addresses to be sent over the KNX network;

+

-

Alimentazione

Failure

KNX

Modbus

Device state

EK-BH1-TP-485

Modbus Master RS485 RTU

/ KNX TP Converter 1 2

8...24 Vac +V 0V

POWER S.

12...35 Vdc

3 4 5

RT-Com RS485ETHERNET

Dev.

Line

Area

RT+

+

-

Bus

KNX

Failure

KNX

Modbus

Device state

EK-BH1-TP-485

Modbus Master RS485 RTU

/ KNX TP Converter 1 2

8...24 Vac +V 0V

POWER S.

12...35 Vdc

3 4 5

RT-Com RS485ETHERNET

Dev.

Line

Area

RT+

RT+

RT-

Com

Failure

KNX

Modbus

Device state

EK-BH1-TP-485

Modbus Master RS485 RTU

/ KNX TP Converter 1 2

8...24 Vac +V 0V

POWER S.

12...35 Vdc

3 4 5

RT-Com RS485ETHERNET

Dev.

Line

Area

RT+

EL1EKBH1TP485

EL3EKBH1TP485

EL2EKBH1TP485

Pag. 4

•Modbus network: definition of the registers to be read

from the network devices and definition of the

registers to be written on the network devices;

•Firmware and/or configuration update.

Note. Configuration and commissioning of the ekinex®

gateway require specialized skills about KNX networks

and knowledge of the specific ETS automation project.

In order to acquire such skills, it is essential to attend

trainings and workshops organized at KNX-certified

training centers. For further information: www.knx.it.

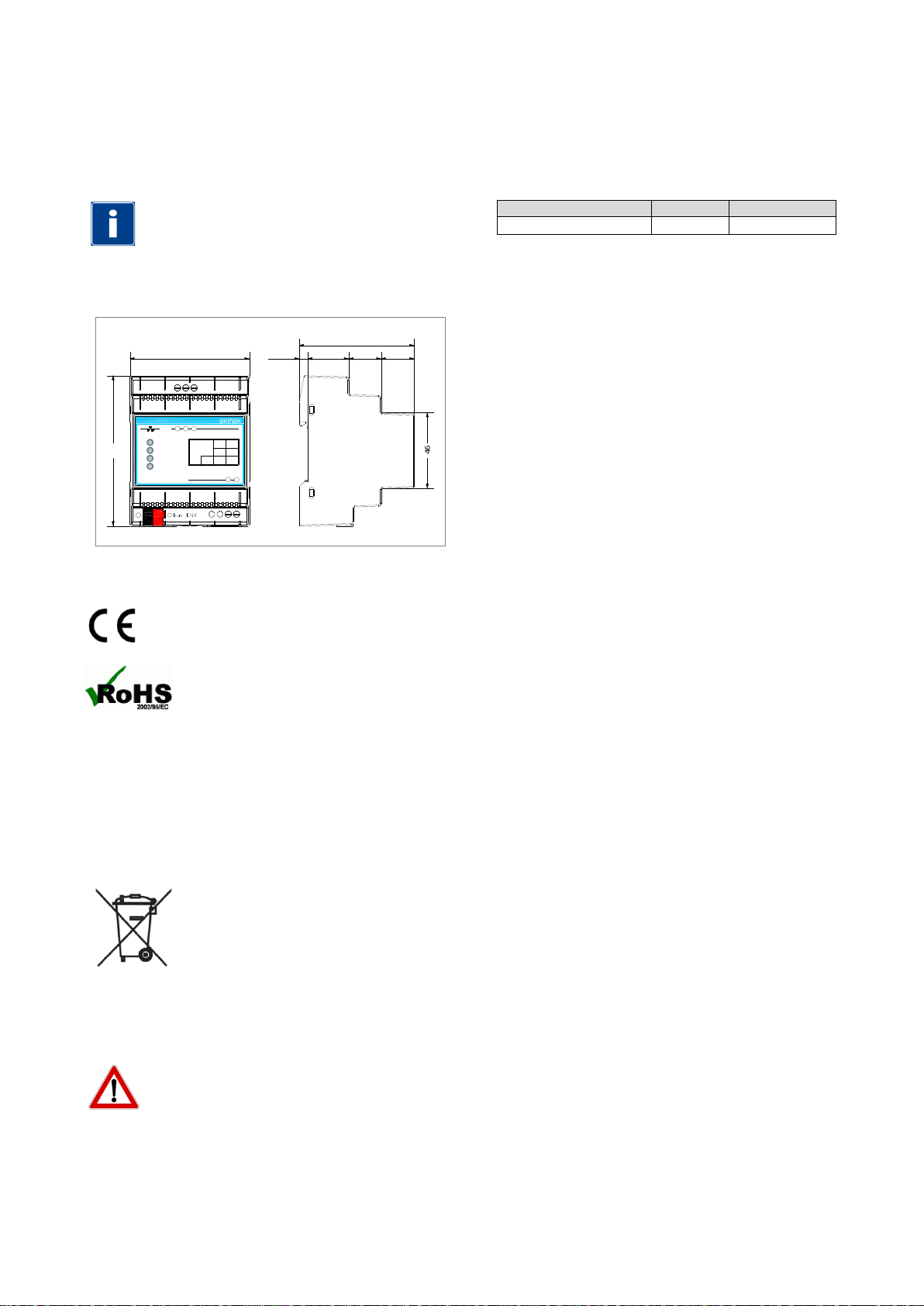

Dimensions [mm]

Certifications

The product complies with the Low Voltage

Directive (2006/95 / EC) and Electromagnetic

Compatibility Directive (2004/108 / EC)

The product is compliant with 2002/95 /

EC Directive about usage restriction of

certain hazardous substances in electrical and electronic

equipment (commonly referred to as the Restriction of

Hazardous Substances or RoHS).

Maintenance

The device is maintenance free. To clean it, use a dry

cloth. Using solvents or other aggressive substances is

strictly forbidden.

Disposal

The product described in this data

sheet, at the end of its useful life, is

classified as waste from electronic

equipment, according to the European

Directive 2002/96 / EC (WEEE),

implemented in Italy by Legislative

Decree no. 151 of 25 July 2005, and can not be disposed

as solid municipal waste.

Importante! Improper disposal of the product may cause

serious damage to the environment and human health.

For proper disposal refer to collection and treatment

informations provided by local authorities.

Document

This data sheet refers to the release A1.0 of the ekinex®

device code EK-BH1-TP-485 and is available for

download on the site www.ekinex.com PDF (Portable

Data Format).

Filename

Release

Update

STEKBH1TP485_EN.pdf

A1.0

11 / 2015

Warning

•Installation, electrical connection, configuration and

commissioning of the device can only be carried out

by qualified personnel.

•Opening the housing of the device causes the

immediate end of the warranty period.

•ekinex® KNX defective devices must be returned to

the manufacturer at the following address: EKINEX

S.p.A. Via Novara 37, I-28010 Vaprio d’Agogna (NO)

Italy.

Other information

•This application manual is aimed at installers, system

integrators and planners

•For further information on the product, please contact

the ekinex® technical support at the e-mail address:

www.ekinex.com

•KNX® and ETS® are registered trademarks of KNX

Association cvba, Brussels

© EKINEX S.p.A. The company reserves the right to make changes to

this documentation without notice.

72 525 20 20

70

46

90

Failure

KNX

Modbus

Device state

EK-BH1-TP-485

Modbus Master RS485 RTU

/ KNX TP Converter 1 2

8...24 Vac +V 0V

POWER S.

12...35 Vdc

3 4 5 RS485ETHERNET

Dev.

Line

Area

RT-Com RT+

DQEKBH1TP485

This manual suits for next models

1

Other Ekinex Gateway manuals

Popular Gateway manuals by other brands

LST

LST M500RFE-AS Specification sheet

Kinnex

Kinnex Media Gateway quick start guide

2N Telekomunikace

2N Telekomunikace 2N StarGate user manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries Superlink SC-WBGW256 Original instructions

ZyXEL Communications

ZyXEL Communications ZYWALL2 ET 2WE user guide

Telsey

Telsey CPVA 500 - SIP Technical manual