Ekol Clarity 5 User manual

1

Ekol Clarity 5, 8, 12, Vision &

Double Sided User Manual

PLEASE KEEP SAFE FOR FUTURE REFERENCE

2

INTRODUCTION

SAFETY

Safety is the most important consideration when using and installing your stove. If not installed and used correctly, a

house fire could result. Installation must comply with relevant national and local Building Regulations and fire safety

standards.

IN THE EVENT OF CHIMNEY FIRE, EVACUATE THE PROPERTY AND CALL THE EMERGENCY SERVICES.

Your stove will be heavy, and care needs to be taken when lifting - 2 people will normally be required to lift.

UNPACKING

Your stove will have several of its components stored inside the stove itself for transportation.

The flue spigot can also be bolted to the flue outlet – the stove has two options for flue outlet – one on the top and one

at the rear. -Most people use the top outlet but depending on where you intend to position the stove in relation to

your chimney, you may wish to use the rear outlet – in this case, remove the blanking plate at the rear and secure into

the top outlet instead. The collar and blanking plate can be secured with the included bolts and allen key.

Inside the stove you will find a glove which must be used when opening the door or when adjusting air vents when the

fire is hot.

INSTALLATION

Installation of your stove must comply with relevant local and national Building Regulations and fire safety standards.

TECHNICAL

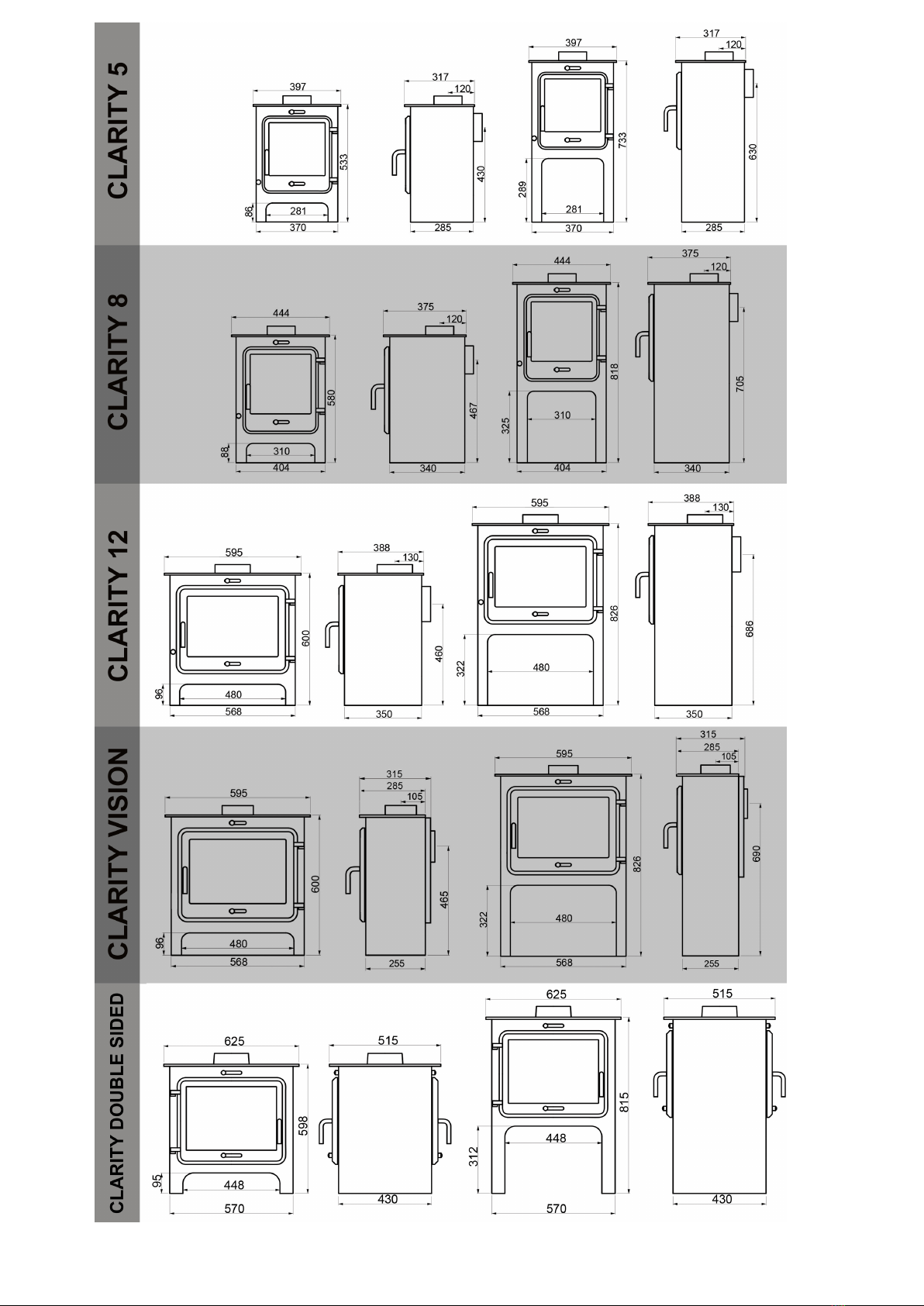

Model; “Ekol Clarity 5, 8, 12 ,Vision & Double Sided”

Parameter

Clarity 5

Clarity 8

Clarity 12

Clarity Vision

Clarity Double Sided

Heat Output Range, kW:

1-5

3-8

5-12

1-5

5-14

Nominal Heat Output, kW:

5.0

6.4

10.5

5.0

11.4

Efficiency at Nominal Output, %:

78.9

78.3

75.9

78.9

76.2

Mean CO emission (at 13 % O2), %:

0.09

0.09

0.10

0.10

0.07

Mean flue gas temperature, °C:

280

304

380

247

333

Flue gas mass flow, g/s:

4.4

5.2

7.4

5.1

9.6

Mean CnHm emission (at 13 % O2), Nmg/m3:

61

52

45

76

61

Mean NOx emission (at 13 % O2), Nmg/m3:

98

89

52

90

111

DIN Plus particulates (at 13 % O2), Nmg/m3:

8

11

17

28

28

Minimum distance to combustible Back Wall, mm:

820

400

680

250

N/A

Minimum distance to combustible Side Wall, mm:

800

375

580

400

900

Suitable for 12mm hearth

5” / 125mm flue size

6”/150mm

6”/150mm

DEFRA Exempt for burning wood in Smoke Control

Areas

EcoDesign 2022 For Wood Burning

Clearskies

3

The stove must not be installed within the specified minimum distances to combustible materials as shown in

the table above. Adjacent walls should be of non-combustible materials and construction, preferably masonry

or brickwork.

When installed inside a fireplace recess (with solid non-combustibles walls) we recommend a minimum 50mm

clearance at the sides and rear of the stove to allow good air circulation and achieve best performance.

Note: The Clarity 5 model has been designed to fit safely inside a 16” (406mm) wide fireplace opening. In this

case the clearance will be less than the 50mm suggested above, but this is still acceptable on this model.

Approved for burning wood logs in Smoke Control areas (DEFRA).

CE tested to EN 13240:2001 by KIWA Gastec (Cheltenham, UK).

EcoDesign 2022 for burning wood.

Your stove will require a constant air supply and should not be used at the same time and in the same

room/space as extractor fans or any device which may draw air supply away from the stove.

The stove should be installed on a level floor with adequate load bearing capacity.

The stove needs to stand on a hearth of non-combustible materials not less than 12mm thick conforming to

Building Regulations.

A Carbon Monoxide detector must be fitted in the same room as the appliance.

NOT suitable for installation in a shared flue system.

If installed in a standard type chimney, a register plate needs to be fitted inside the chimney.

When purchasing flue pipe, 5”/125mm diameter is required for the Clarity 5, Clarity 8, Clarity Vision and

Clarity Double Sided (with 6”/150mm required for the Clarity 12 & Double Sided). The flue pipe must be fitted

INSIDE the flue spigot and sealed with a generous amount of Fire Cement.

We recommend that you have a qualified fitter install your stove. You can find a HETAS qualified installer in

your area by going to the HETAS website – www.hetas.co.uk.

4

5

OPERATING INSTRUCTIONS

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a

smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any

fixed boiler if located in a designated smoke control area. It is also an offence to acquire an "unauthorised

fuel" for use within a smoke control area unless it is used in an "exempt" appliance ("exempted" from the

controls which generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise

smokeless fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales this

power rests with Ministers in the devolved administrations for those countries. Separate legislation, the Clean

Air (Northern Ireland) Order 1981, applies in Northern Ireland. Therefore, it is a requirement that fuels burnt

or obtained for use in smoke control areas have been "authorised" in Regulations and that appliances used to

burn solid fuel in those areas (other than "authorised" fuels) have been exempted by an Order made and

signed by the Secretary of State or Minister in the devolved administrations.

The “Ekol Clarity 5, 8, 12 Vision and Double Sided” has been recommended as suitable for use in smoke

control areas when burning seasoned wood.

Further information on the requirements of the Clean Air Act can be found here:

http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and

supervision of smoke control areas and you can contact them for details of Clean Air Act requirements.

FUEL

Wood- All types of wood are suitable provided they are wells seasoned, UNTREATED, and have a moisture

level between 12% and 20%. For soft woods, typically they will need to have been left in suitable storage for

9+ months in order for the moisture to evaporate. For hardwoods, this will usually be 18 months+. It is

recommended that logs should be no more than 5” or 125mm in diameter. Logs should be no more than

260mm in length. If you are unsure of the moisture content of your fuel, then you can buy a moisture meter

which will indicate the moisture levels in your fuel.

Liquid fuels must NEVER be used.

WARNING: Wet timber should not be used as this will create excess tar deposits in the chimney and stove and

could increase the risk of chimney fire. Timber which is not of a suitable moisture content will also create

more smoke and harmful emissions.

Manufactured smokeless coals and anthracite can be used and will all have different qualities and effects. –

Do NOT use Petro-Coke based fuels or any petroleum-based fuels as this will invalidate the warranty. Any

coal burned should be coal suitable for a multi-fuel stove (some coal is only for use on open fires and burns

too hot for a stove).

Never use your stove as incinerator to burn waste or rubbish.

6

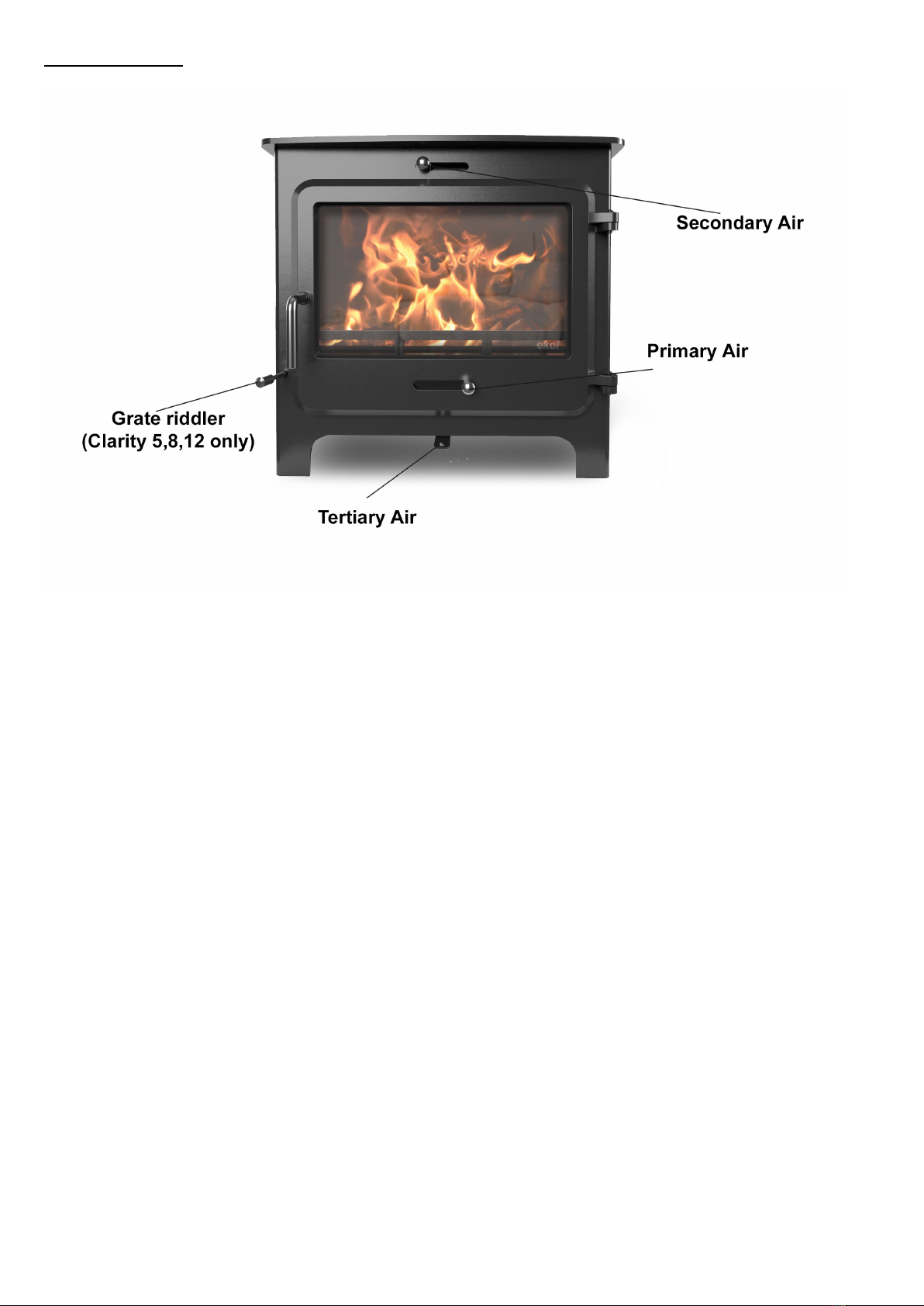

STOVE CONTROLS

Your stove has three sets of air inlet areas-

The upper vent above the door provides air supply for the air-wash system and allows air into the higher areas

of the fire box – this is called the Secondary Air – when this vent is open, the door glass is kept clean by high

speed air rushing downwards across the inside of the glass. By moving the Secondary vent knob to the right,

airflow into the stove is increased. The secondary air vent is set such that the closure plate does not seal fully,

thus allowing some constant air supply into the stove.

The lower vent knob on the bottom of the door controls the provision of Primary Air – this is the primary

source of air supply for combustion. Sliding the knob to the right increases the amount of Primary airflow into

the stove.

The (third) Tertiary vent control is located underneath the stove and controlled by a lever/ knob tucked under

the bottom shelf. Pulling the lever out increases the airflow into the stove. The air is then channelled through

a chamber on the back of the stove and enters the firebox via a series of small holes. Pushing the lever fully in

closes of this air intake partially. This intake cannot be fully closed. This ensures the stove maintains level of

combustion not likely to create excessive smoke.

7

TOOLS

The glove is provided for adjusting the air inlets and for opening the door when the stove is hot, as these

knobs will heat up when in use. NOTE – all parts of the stove will become hot during use and care needs to

be taken to avoid injury through burning.

LIGHTING THE FIRE

•Prior to lighting the fire for the first time, ensure that-

•Installation and building work are complete.

•The chimney is suitable and sound and has been swept and free from obstruction.

•Adequate ventilation and provision for combustion air has been made.

•That the stove installation has been carried out in accordance with Building Regulations and any

applicable local regulations as well as these installation instructions.

•That chimney draw has been checked and within specification. (The stoves has been tested at nominal

output with a flue draught of 12 Pa) Flue draughts in excess of 18 Pa when warm will have a negative

effect on the efficiency, could cause premature wear and damage to the stove.

ENSURE THAT YOU HAVE READ AND UNDERSTOOD THESE INSTRUCTIONS BEFORE LIGHTING THE FIRE, AND

THAT YOU ARE CONFIDENT THE STOVE HAS BEEN INSTALLED CORRECTLY.

The Entire Stove Will Become HOT!

The glove is provided for adjusting the air inlets and for opening the door when the stove is hot, as these

knobs will heat up when in use.

NOTE – all parts of the stove will become hot during use and care needs to be taken to avoid injury through

burning.

ESSENTIAL INSTRUCTIONS BEFORE USE – It is essential to follow these ‘tempering-in’ instructions in order to

avoid serious damage to your stove. The castings of your stove require very gentle ‘normalising’ to release

stresses in the metal formed during the casting process. The high temperature paint finish also requires

curing: -

Initial paint curing:

Note: NEVER wipe the stove in the early stages (prior to paint fully curing), as the paint will be very

soft and will damage easily. NEVER attempt to clean or wipe the paint surface when warm or hot. Please read

the following and follow thoroughly.

The stove is finished in specialist high temperature coating which is air-dry but not yet cured. The stove should

be brought up to temperature gradually over the course several fires to complete this process. If the stove

gets too hot or not hot enough during this process, then the curing process can fail causing issues with the

paint surface.

1) For the first three fires (all on the same night), use KINDLING ONLY, with each burning for 15-20 minutes

and each fire using approx 500 grams of kindling. Start the second and third kindling fires whilst the fire is still

warm from previous fires, but with around 30 minutes cooling time in between. Once the three kindling fires

have burnt through, and whilst the stove is still warm, but slightly cooled, light a normal fire with three dry

logs weighing around 1.2 kgs in total. This fire should burn for between 45 and 60 minutes. Now allow to

FULLY COOL naturally. The paint should now be cured.

8

2) Once the curing process has been completed satisfactorily, normal fires can be lit –

Next Stage - stove tempering:

For the first 3 hours burning use just small wood fires, then for the next 15-20 hours, total burn time, fires

must be very gently increased in temperature and log size and load and NO SOLID FUELS (products other than

wood) must be used during this period. A stove thermometer will be a valuable tool in helping you to achieve

this and to ensure an efficient burn rate in future. After these small fires, gently increase fires over the course

of a week or so. Starting a large fire too soon is likely to damage the stove in which case will not be covered by

the warranty.

Ignition (On-going, once above procedure has been followed)

•Ensure all air inlets are fully open.

•Construct a pile of kindling in the middle of the grate using approximately 500g of kindling wood.

•Light with a single chemical firelighter.

•Partially shut the door but leaving it cracked open slightly.

•After about 5 minutes or when the fire is well established, shut the door.

•After a further 3-5 minutes as the fire starts to die, add a further three small logs weighing approx 0.75

kg (Clarity 5) or 1kg (Clarity 8) 2kg (Clarity 12) 0.75kg (Clarity Vision) or 1.5kg (Double Sided) total.

•Once theses logs are alight, and after about 7 minutes or so, a normal load of 3-4 logs weighing

approximately 1.4kgs (Clarity 5) or 2.5kg (Clarity 8) 3.8kg (Clarity 12) 1.45kg (Clarity Vision) or 3kg

(Double Sided) in total can be added.

•Once this load is burning well, the Primary air vents can be closed, with the Secondary and Tertiary

vents left open.

Refuelling

•Open the Primary air vents.

•Add up to 1.4kg (Clarity 5) or 2.5kg (Clarity 8) or 3.8kg (Clarity 12) 1.4kg (Clarity Vision) or 3kg (Double

Sided) of wood.

•After about 2-3 minutes or when flames from the fresh fuel fully established, close the Primary vents.

•At high power output, your stove will require refuelling approximately every 60 minutes.

•It is important to follow these instructions in order to achieve clean burning and to maximise the

efficiency of the stove.

•Do not leave the fire unattended until flames are well established on the newly charged logs.

•Always refuel onto hot embers.

•Reduced burn rates can be achieved by reducing the openings of the Secondary and Tertiary air vents.

Refuelling on to a low fire bed

•If there is insufficient burning material in the fire-bed to light a new fuel charge, excessive smoke

emission can occur. Refuelling must be carried out onto a sufficient quantity of glowing embers and

ash that the new fuel charge will ignite in a reasonable period. If there are too few embers in the fire

bed, add suitable kindling to prevent excessive smoke

Fuel overloading

•The maximum amount of fuel specified in this manual should not be exceeded, overloading can cause

excess smoke.

9

Operation with door left open

•Operation with the door open can cause excess smoke. The appliance must not be operated with the

appliance door left open except as directed in the instructions.

Dampers left open

•Operation with the air controls or dampers open can cause excess smoke. The appliance must not be

operated with air controls or dampers door left open except as directed in the instructions.

UK Clean Air Act 1993 - Smoke Control Areas

The Ekol Clarity 5, 8, 12, Vision and Double Sided wood-burning stoves are suitable for use in smoke control

areas when used in accordance with these instructions.

WARNING- The high temperature paint covering the stove will give off some fumes during the initial few uses

of the stove. The fumes are non-toxic, but some people may find them unpleasant – Ensure the area is well

ventilated during this period.

The output ratings of this stove are based on around 1.4kg (Clarity 5) / 2.5kg (Clarity 8) / 3.8kg (Clarity 12)

/ 1.45kg (Clarity Vision) / 3kg (Double Sided) of seasoned logs which would require refuelling every hour.

This stove is suitable for intermittent burning and should not be used constantly for extended periods. Not

suitable for overnight burning.

Under certain abnormal weather conditions, e.g. down draughts, it may be difficult to get sufficient draw

through the appliance to achieve good combustion. When this happens, the stove should not be used.

CLEANING/MAINTENANCE

Regular cleaning of the stove is essential for safety and efficiency. The ash-pan should be checked/ emptied at

least after every use, and during use if burning for longer periods. Extra care must be taken when removing

warm or hot ashes.

Step by step maintenance instructions:

1) A minimum of once per year the flue system should be cleaned/swept by a qualified chimney sweep or suitably

qualified stove installer. The servicing of the appliance can usually be carried out at the same time. Whether the system

needs sweeping more frequently than this will depend on use.

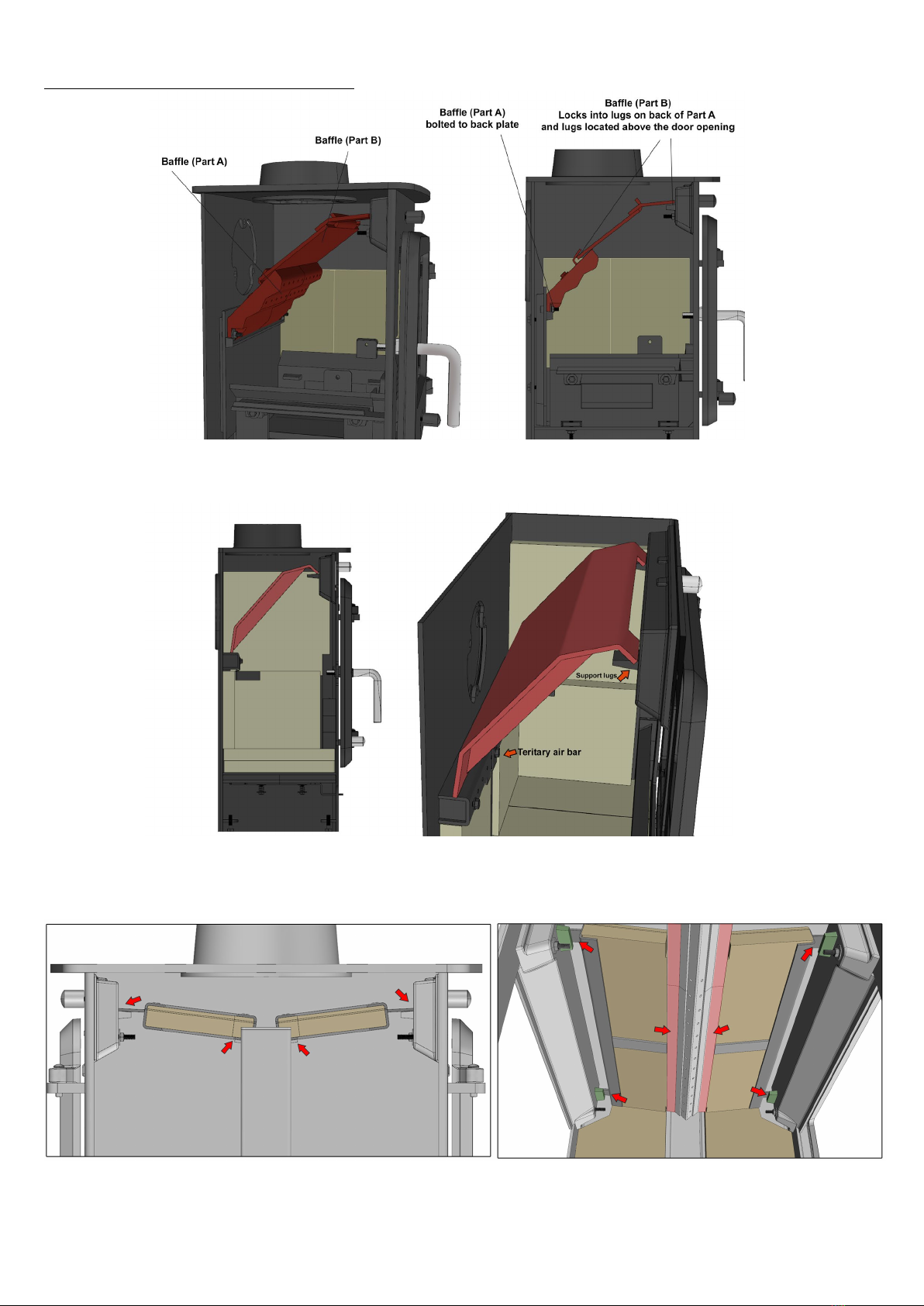

2) Baffle plate should be removed and checked for debris twice a year as a minimum depending on use.

Warped/misshapen baffle plates can be a warning sign that the stove has been over-fired (allowed to excessively heat

on one or more occasions).

3) Once removed, brush the baffle using a stiff brush or wire brush to remove any deposits. Clear any debris from the

upper parts of the stove above where the baffles normally sit.

4) Inspect firebricks on both the sides, rear and base for cracks - (some are normal and not a fault. Nor are they

detrimental to the workings of the stove, however it is good practice to be aware as any develop and over time if they

worsen, they may need replacing). If you feel a crack in the firebrick is just cosmetically unsightly it can be filled with a

small amount of fire cement.

10

5) Vacuum or brush out the inner stove box thoroughly.

6) Visually check that the glass is still making a good seal against its rope on the inside of the door frame and that it’s

retaining clips remain firmly in place to the touch.

7) Check that the door is making a good seal with the body of the stove all around (over time the rope will flatten out

and loose some flexibility - when this happens and when it is no longer sealing fully all the way round, it needs to be

replaced). The rope size used here is a 10mm-Soft type.

8) Blemishes or scratches to the paintwork can be touched up using a suitable high temperature stove paint in

a spray can. Ensure the stove is cool and clean before applying and follow the paint manufacturer’s instructions. Contact

Saltfire Stoves directly if you are unsure which paint to use.

Throughout the season, it is good practice to keep the stove in generally good clean order which will prolong the life of

serviceable components and enhance the experience you have with your fire.

9) NEVER wipe the stove in the early stages (prior to paint fully curing), as the paint will be very soft and will damage

easily.

10) To keep the outer body clean, simply dust over with a clean soft duster when cold.

11) If there are marks which cannot be removed with a duster, use a slightly moistened cloth very gently, but only when

the stove is cool and has not been in use. Then pat dry with absorbent paper towel.

12) Regularly vacuum soot and dust from around the inside of the door and around the glass and rope seals.

13) If glass gets dirty on the inside from soot, clean with liquid ‘stove glass cleaner’ and a soft cloth OR with

an “Atmosfire Dry Wiper”, produced by Schott, (manufacturers of stove glass), and available online. Do this as

soon as possible once the soot appears, but only when the fire is completely cool. Never use newspaper or soot or any

other abrasive or cleaning method on the glass.

If the glass becomes stained from the inside, the air-wash vent may need opening more during use. (See

‘troubleshooting guide’ for other possible causes).

The high temperature paint which your stove is finished in should last several years with normal use, but

when it does eventually require re-finishing, black heat resistant paint in spray cans can be purchased from

most hardware stores. – Do not use regular paint which is not high temperature resistant.

After prolonged periods of not using the fire, the stove and flue system should be checked for blockages prior

to re-lighting.

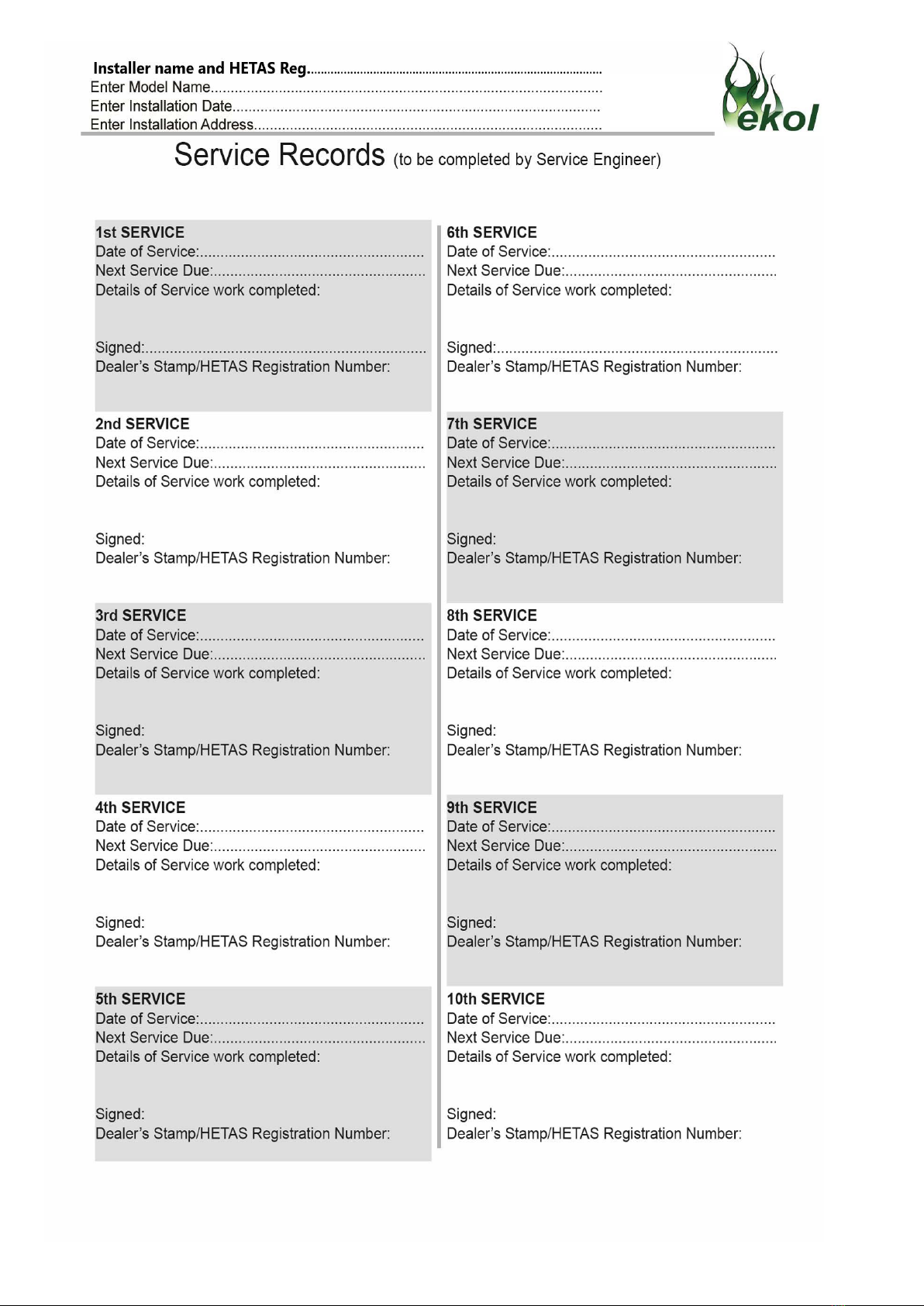

We recommend regular servicing and safety checks are carried out by a qualified engineer.

There must be no unauthorised modification of the appliance. Use only replacement parts recommended by

the manufacturer.

11

Baffle Plate Position (Clarity 5, 8 and 12)

Baffle Plate Position (Clarity Vision Only)

Ensure the Baffle Plate sits correctly on top of the Tertiary air bar and the lugs located above the inside of the door opening.

Baffle Plate Position (Clarity Double Sided Only)

Baffle plates sit on the flat bars in front of the tertiary cross bar, and lugs located above the doors (see green on diagram below)

12

GUARANTEE

The main body of your stove is guaranteed for 5 years when all guarantee terms are followed including

registering your guarantee via the website within 30 days of purchase. Please register here:

http://www.defrastoves.com/guarantee-registration.htm Failure to register within 30 days will limit your

guarantee to 12 months from date of purchase. This does not include glass, grates, baffle, retaining bars, inner

linings/firebricks, door seals, paint finish, over-firing incorrect use or installation not carried out by a

competent person or in accordance with building regulations. – You should have zero problems with your

stove unless it is abused and if treated well your stove will last and last.

What to do in the event of a chimney fire: -

•cut off the air supply to the stove, i.e. close the primary and secondary air supplies

•move any combustible materials well-away from the stove

•get everyone out safely

•make sure that the fire brigade has clear access

•call 999 If you have any questions or concerns regarding the safe use of your stove, please contact us.

Troubleshooting Solutions for Stove Problems

Installed and used correctly your stove will provide years of warmth with little effort but used incorrectly will be difficult

to achieve the results you expect and can be damaged.

Combustion is a complex chemical process with many variables, all of which need to be correct for your stove to burn

correctly. Taking the time to understand these variables and the combustion process will make your life with your new

stove a happy one.

1. Stove is difficult to light / keep lit

Common causes:

a. Damp fuel – Wood should be maximum 20% moisture and ideally 12-15%. We strongly advise purchasing a digital

moisture meter to test your logs. Always split logs in half and test the centre of the log.

b. Poor draught and chimney strength – Your chimney needs to pull through adequate air for combustion. Flue draught

should be between 12Pa and 18Pa – if in doubt consult a local expert.

c. Logs too big – Always start fires small and gradually build them up. Begin with paper or solid firelighters, building a

small fire with kindling (small sticks of wood) until the kindling is well alight and hot. Then gradually build the fire with

your wood logs (not too thick). (Splitting the logs will increase the surface area allowing more thorough burning). Once

the firebox is up to temperature, slightly larger logs can be added.

d. Chimney/flue blocked – Excessive soot should not be allowed to build up in the flue – flues should be professionally

cleaned when required and, in any case, at least once per year, or more if your chimney / fuel type is causing excessive

soot to build up.

13

2. Fuel burns too quickly

The rated output on your stove is based on burning dry seasoned hardwood and re-fuelling every hour. By turning down

the vent controls the fuel will burn slower and last longer.

Common causes:

a. Excessively strong chimney draught – If by turning down the vents the fire still burns too quickly, this is normally due

to excessively strong draught on the chimney. This will lead to over-firing of the stove, which is inefficient, losing

excessive heat into the chimney and pulling too much cold air through the house. A flue damper fitted into the first

section of flue pipe can help to calm a chimney draught.

b. Fuel type/size – try experimenting with different types of wood/fuel and different sized logs. Coal and slightly larger

logs will burn slower. Softwood such as pine will burn particularly fast. Kiln dried wood is NOT recommended – It is likely

to burn too fast – always use seasoned, naturally dried logs (hardwood) where possible.

3. Smoke comes back into room

A small amount of smoke entering the room when you open the stove door is normal but should stop after a few

seconds….

If smoke ever leaks constantly into the room stop using the fire immediately, shut down all vents on the stove, open

windows and exit the room. Do not use the stove until a local expert has established the problem.

Common causes:

a. Insufficient air supply into the room – do you have an air brick of sufficient size to feed the stove with air?

b. Blocked chimney – have the chimney swept and checked by a registered chimney sweep.

c. Insufficient chimney draught – can be due to a variety of reasons – please refer to previous text under “Poor draught

and chimney strength”

d. Rapid condensation of the gases - causing them to slow down and back up in the chimney – this can be due to too

broad a chimney/flue, relative to the size of the appliance or the flue not being adequately insulated. You may need a

flue liner and/or insulation in the chimney.

14

4. Glass gets dirty quickly

Common causes:

a. Top vents not open – Your stove has a top vent this controls the Airwash system – the top vent needs to be

constantly open adequately to ensure enough air is coming into the stove. No Airwash will work fully when the stove is

burning very slowly (slumbering).

b. Primary Vent left open – Primary vent when left open will interfere with the operation of the Secondary (Airwash),

causing blackening of the window. Always shut Primary once fire is established, and only ever open as much as

necessary to get the fire going or to give a short ‘boost’ to new wood when refuelling.

c. Poor fuel – wet wood or softwood (e.g. pine) will produce a lot of tar, creosote and soot, dirtying the glass and

eventually blocking the flue.

d. Insufficient chimney draught – see previous note under “Poor draught and chimney strength”.

e. Baffle plates incorrectly fitted – see previous diagram for correct positioning of baffles.

f. Fuel loaded to close to window – The wood needs a good clear distance away from the glass – otherwise it will

produce thick black marks on the glass and interfere with the Airwash airflow.

5. Not enough heat being produced

Common causes:

a. Poor quality fuel – logs should be dry well seasoned hardwood.

b. Poor draught and chimney strength – see previous notes.

c. Excessive draught – too much heat being lost up the chimney – try a damper in the flue.

d. Insufficient air supply - Check air supply is sufficient / vents on stove are clear. Does the room have a vent?

e. Not enough fuel being burned – the rated output of your stove is based on burning beech wood (typical of most

hardwoods), refuelling once per hour. 1kg of this wood has approximately 4-5 kw hours of energy.

f. Larger stove / stove with higher output required for room size.

6. Too much heat in room

Common causes:

a. Excessive chimney draw – try fitting a damper unit in flue

b. Too much air supply – close down primary vent, then if still too hot reduce tertiary and secondary vents.

c. Stove may be too large for room size.

15

7. Grate deformed / Baffle plate deformed

Your stove will have been designed to operate correctly for many years with a relevant quantity of fuel and re-loading

times. The grate and baffle plate can over time start to bow/deform – this can only be caused by very high

temperatures. Using Solid Fuel products can accelerate this process but burning wood at too high a temperature can

also cause damage to internal parts.

Common causes:

a. Excessive chimney draw– try a damper in the flue.

b. Excessive primary air supply – close down primary vents.

c. Incorrect fuel – NEVER use Petroleum Coke, Bituminous fuel, Housecoal or any unauthorised fuel.

d. Stove overloaded – excessive burning of too much fuel.

The baffle plate and the inner linings of the stove, and the grate all designed to be replaceable parts – call us if you need

to order new ones.

If you are experiencing problems including insufficient heat being provided – to help establish the cause and

solution we will need to know specifically what fuel you are burning and the rate (kg per hour) at which you

are burning the fuel, and in the case of wood, the average moisture content of the centre of the logs (we

suggest using a moisture meter to check moisture levels in logs).

Only by monitoring this burning rate over the course of several burn cycles can we quantify the outputs being

produced and begin to establish a cause of the problem.

If you are experiencing these problems please email us at enquiries@defrastoves.com with your invoice

number, name and purchase date, detailing as much information as possible considering all of the above

information (and the general troubleshooting advice we give for all stoves). The more accurate and detailed

the information the quicker we will be able to help you to establish improvements you can make to your

system.

©Copyright Ekol Stoves 2023

16

Other manuals for Clarity 5

1

This manual suits for next models

4

Table of contents

Other Ekol Wood Stove manuals

Popular Wood Stove manuals by other brands

RAIS

RAIS attika NEXO 100 GAS installation guide

WoodPro

WoodPro WS-TS-1500 owner's manual

Contura

Contura C 586W installation instructions

Palazzetti

Palazzetti EVA GENERAL INFORMATION - WARNINGS - INSTALLATION - MAINTENANCE

Lopi

Lopi 1250 Republic owner's manual

Panadero

Panadero CAPRI 3V Usage and maintenance instructions