eLab Peers eBOT ARM User manual

User Manual

V1.0

© eLab Peers 2017

All rights reserved.

V1.0 – October 2017

www.

e

Labpeers.com Page 3

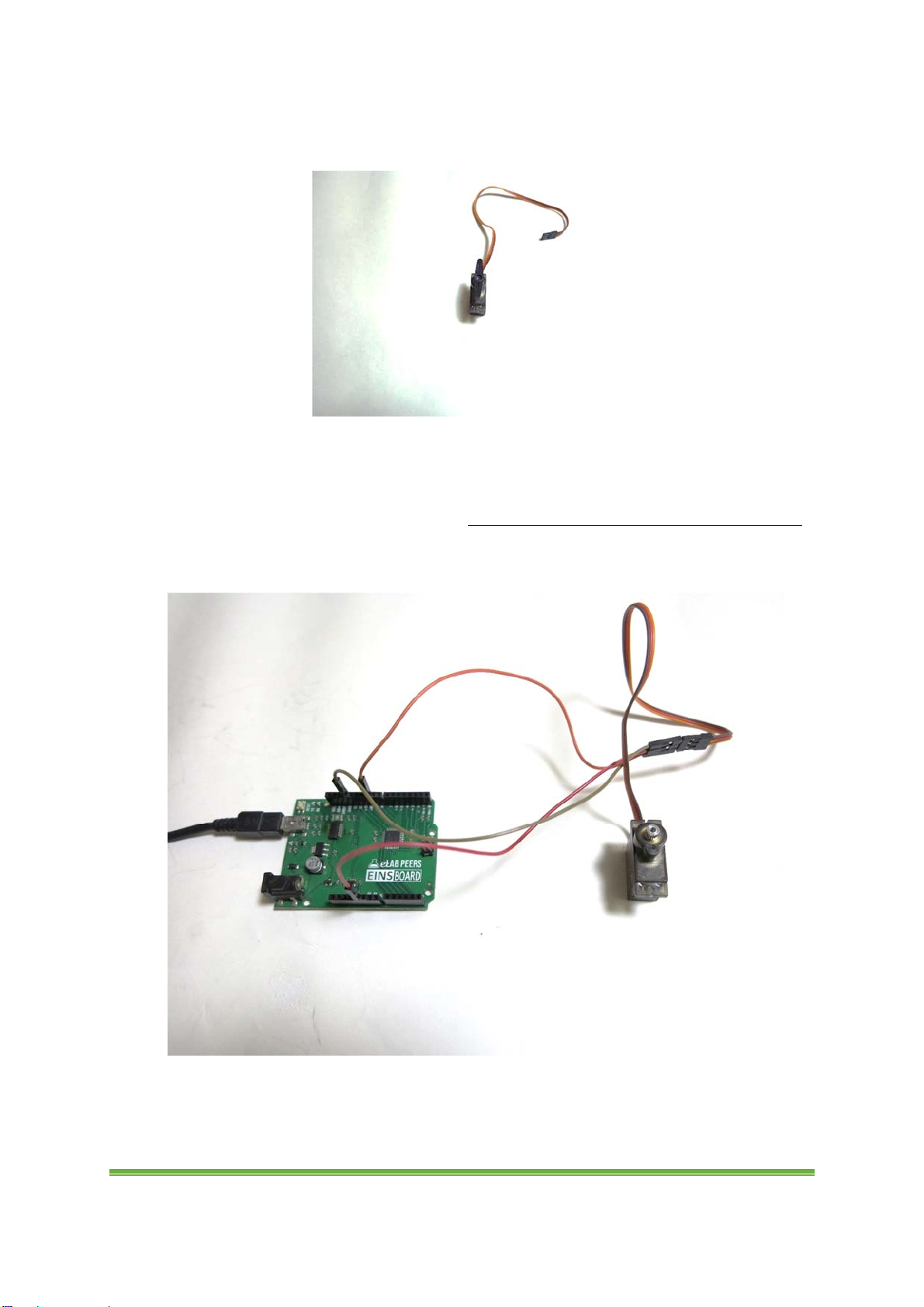

Part I Servo Calibration

1. Take a servo.

2. Pick a servo horn. Place it to output spline of the servo. Turn the servo horn

anti-clockwise until it gets stuck.

3. Take out the horn and place it to output spline again horizontally.

www.

e

Labpeers.com Page 4

4. Turn the horn again clockwise until the horn is in vertical direction. The output

spline is 90 degree approximately.

5. We can also calibrate the servos with Einsboard/Arduino compatible board.

Connect brown wire to GND on Einsboard, red to 5V and orange to digital pin 10.

Download Code for Servo Calibration from http://www.elabpeers.com/ebot-arm.html

and upload it to Einsboard. (Refer to Part VI Einsboard if there is any problem) Do the

same step for all servos.

6. There is another method of doing calibration. Connect servo to 8-Servo Controller

and adjust the servo via the software. (Please turn to Part III 8-Servo Controller for

details)

www.

e

Labpeers.com Page 5

Part II Assembly

A. Base

Please read through the instruction before start.

1. Tear off the paper layer on all acrylic parts.

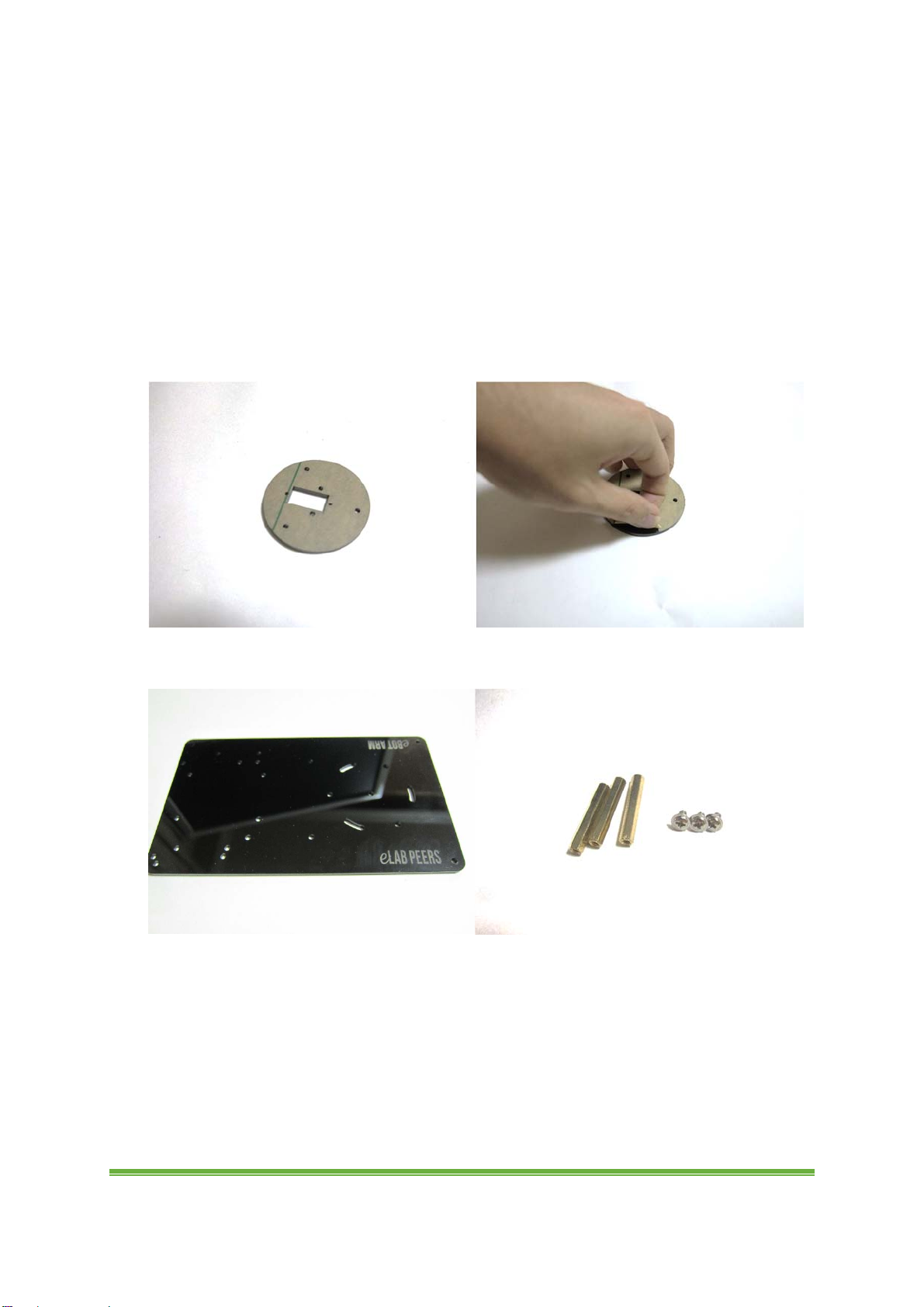

2. Prepare a base, 3 x 30mm metal standoff and 3 x M3 truss head 5mm screws.

www.

e

Labpeers.com Page 6

3. Fix the metal standoff with the screws as follow.

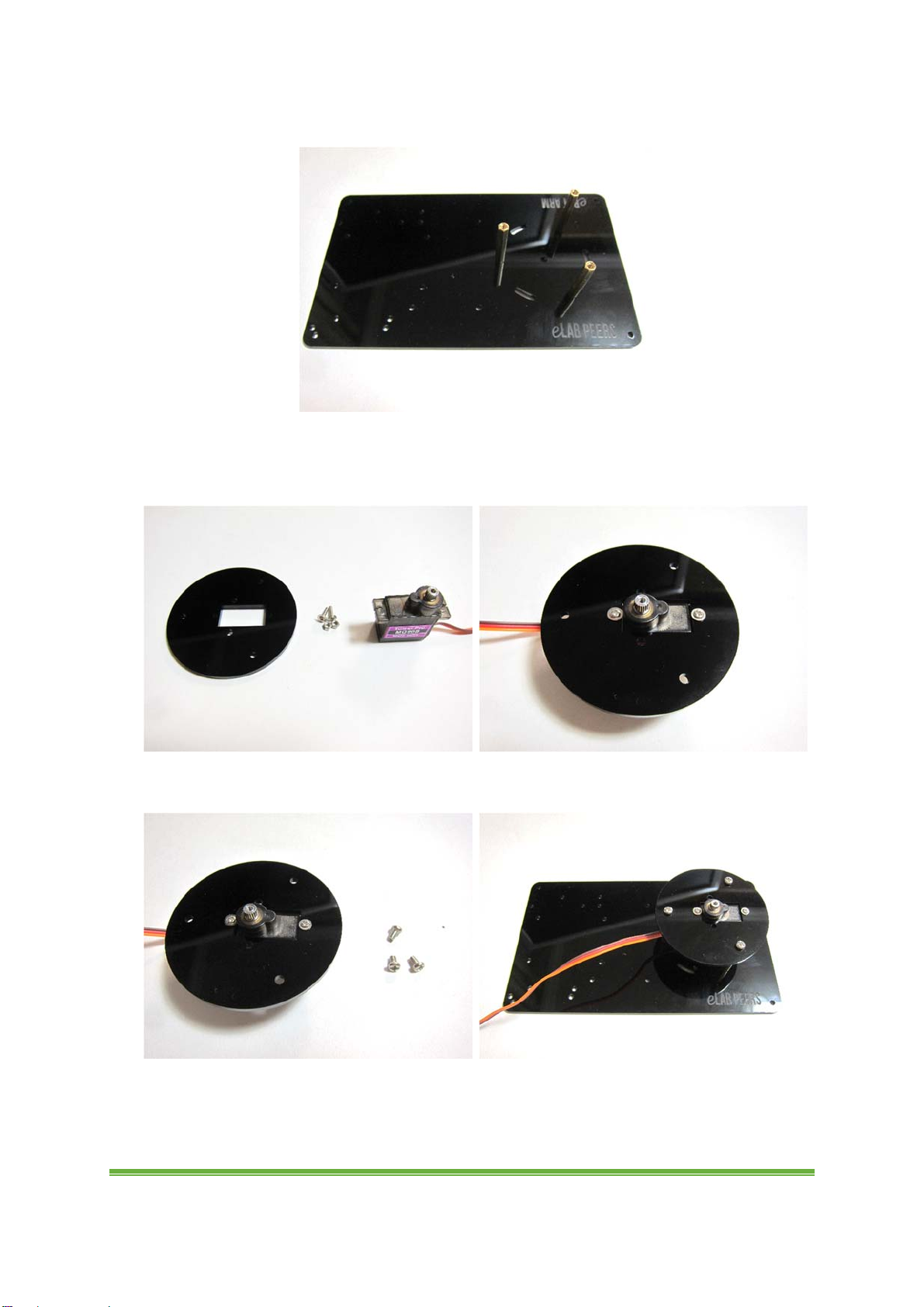

4. Take the round part as follow and fix a servo to it with 2 small truss head screws

and nuts.

5. Take 3 x M3 pan head 8mm screws and fix the part to the base.

www.

e

Labpeers.com Page 7

6. Fix another round part with 2 x M3 pan head 12mm screws and nuts as follow.

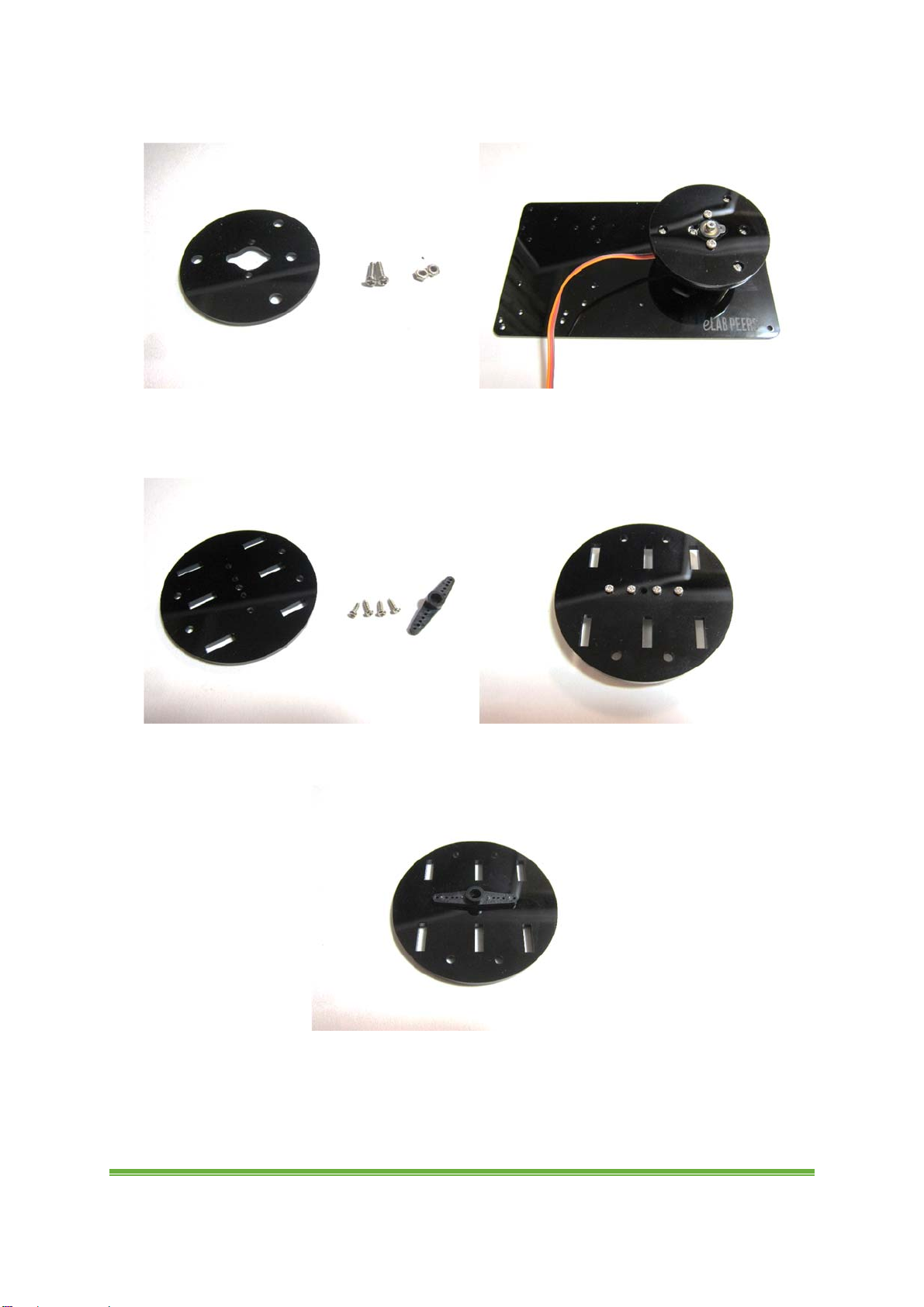

7. Take a round part, 4 small screws with sharp point and a plastic servo horn. Fix the

horn to the round part as follow.

8. Another view.

www.

e

Labpeers.com Page 8

9. Fix this round part with a 7mm pan head screw to the servo on the base as follow.

www.

e

Labpeers.com Page 9

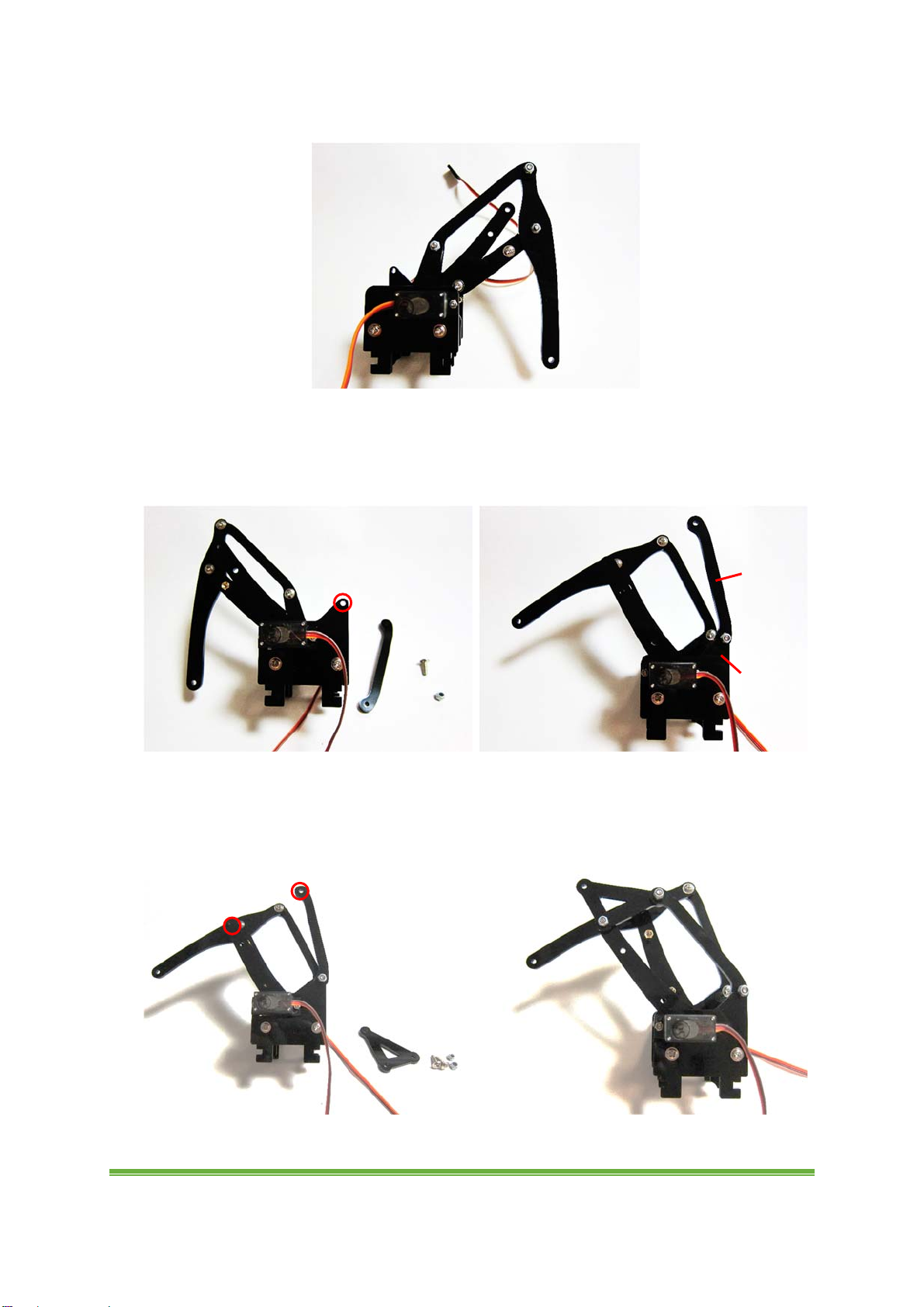

B. Body

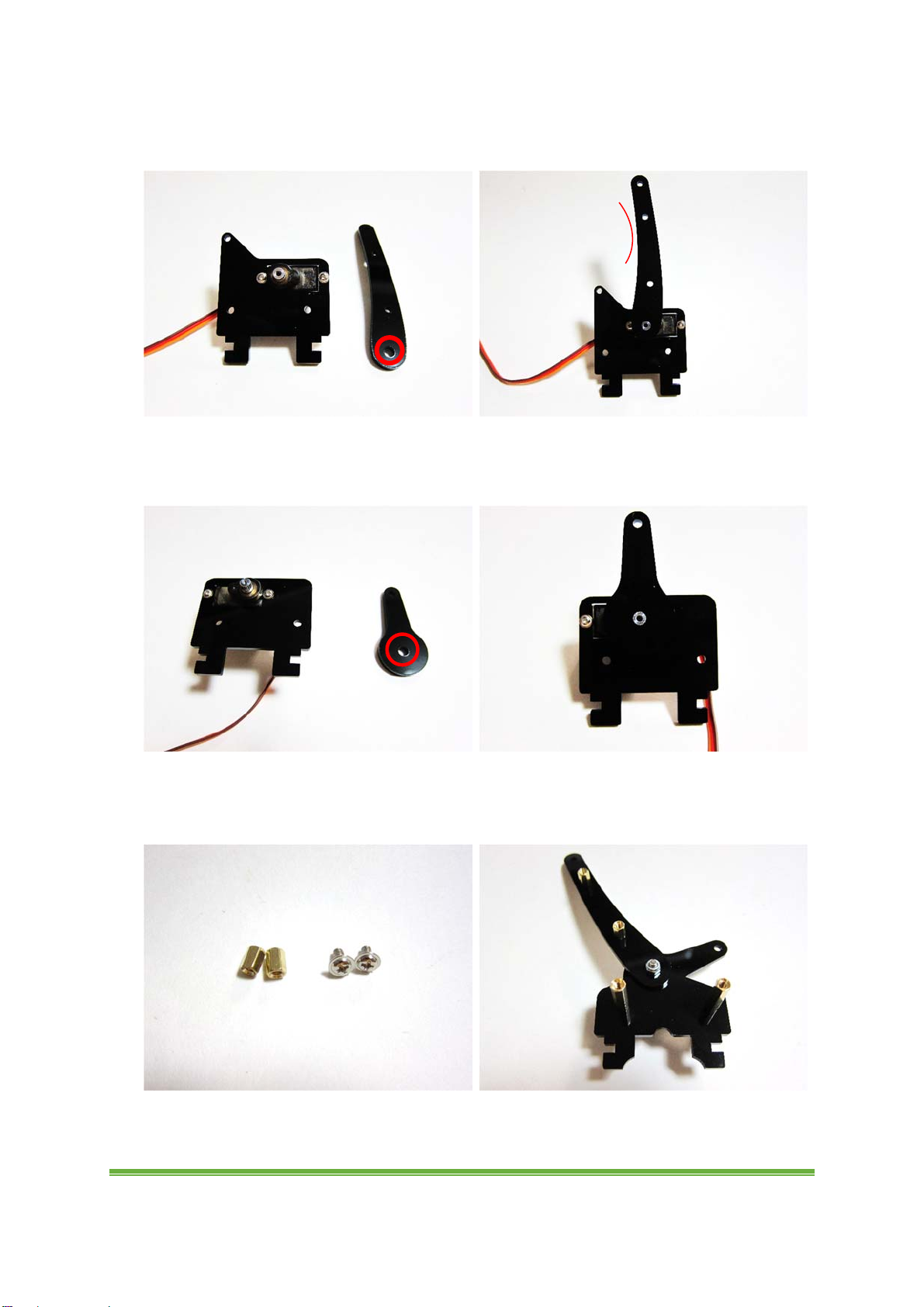

1. Take the part as follow and fix a servo to it with 2 small truss head screws and

nuts.

2. Take the part as follow and fix a servo to it with 2 small truss head screws and

nuts.

3. Take the part as follow. Pick 2 metal standoff with screw point and pass them

through the holes as follow. (Note the position)

A

B

www.

e

Labpeers.com Page 10

4. Fix 2 x 17mm metal standoff to the part.

5. Another view.

6. For C, take the parts, a M3 truss head 15mm screw and seal nut as follow. Please

note that the holes circled below should be in round shape. Fix these parts together

with the following order. Do not fix the nut too tight or too loose. Make sure the parts

can be moved freely. (Note the direction)

Top

Middle

Bottom

C

C

Short Long

www.

e

Labpeers.com Page 11

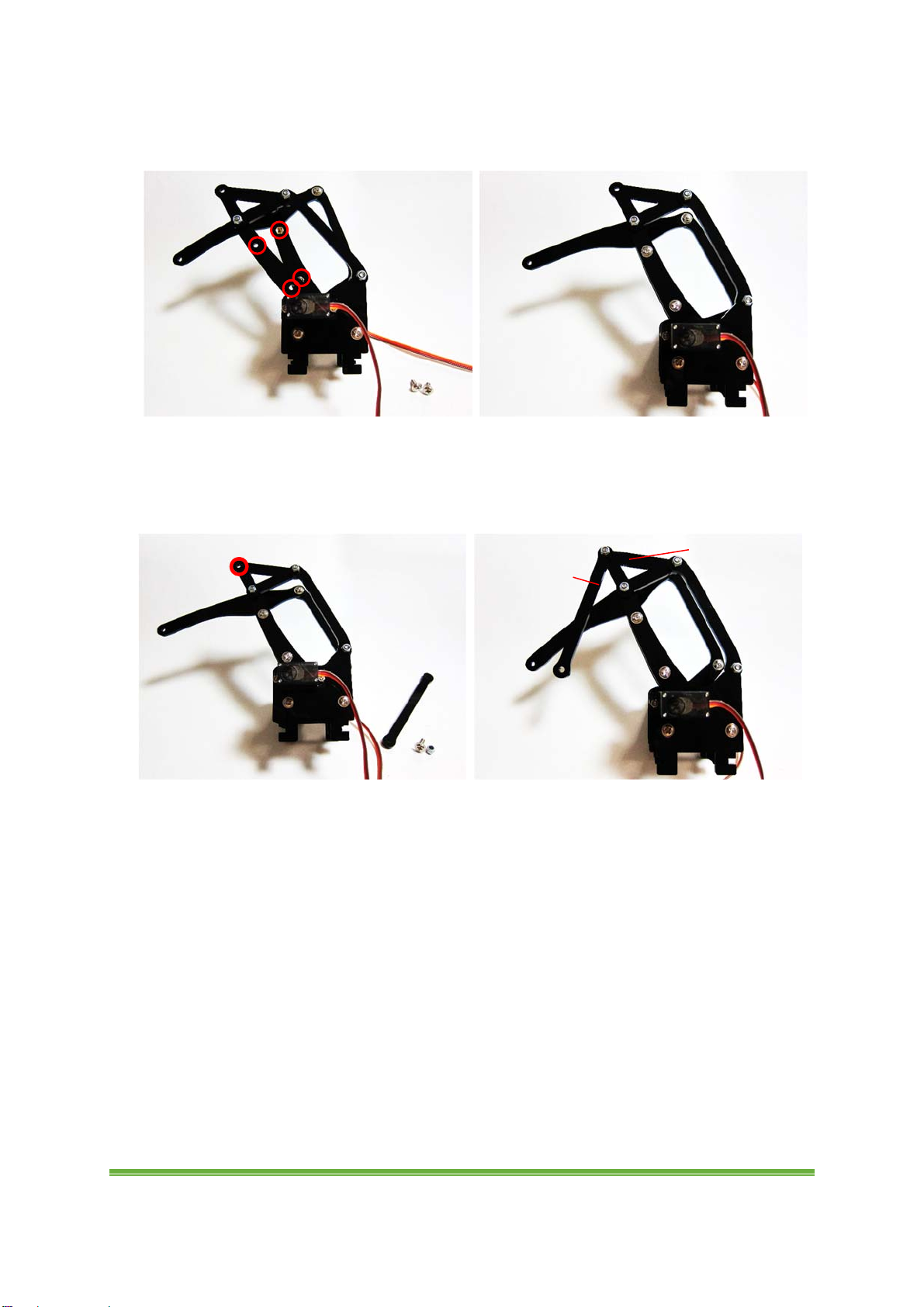

7. For B, take the parts as follow. Please note that the hole circled below should be in

zigzag shape. Fix the part to the servo. (Note the direction)

8. For A, take the parts as follow. Please note that the hole circled below should be in

zigzag shape. Fix the part to the servo. (Note the direction)

9. For C, take 2 x M3 truss head 6mm screws and 6mm metal standoff. Fix them to C

as follow. (Note the position)

B

A

C

www.

e

Labpeers.com Page 12

10. Take 2 x M3 truss head 6mm screws. Fix Band Ctogether as follow. Curve of the

parts for upper arm should be in the same direction.

11. Take 2 x M3 truss head 6mm screws. Fix it with Atogether as follow.

12. Put another part between the circled holes shown and fix it with M3 truss head

15mm screw and seal nut as follow. Do not fix the nut too tight or too loose. Make sure

the parts can be moved freely. (Note the position)

C

B

A

www.

e

Labpeers.com Page 13

13. Another view.

14. Fix the part for lower arm with M3 truss head 10mm screw and seal nut as follow.

Do not fix the nut too tight or too loose. Make sure the part can be moved freely. (Note

the position)

15. Move the parts so that two circled holes are align. Place an acrylic ring between

two holes. Fix them with M3 truss head 15mm screw and seal nut as follow. Do not fix

the nut too tight or too loose. Make sure the parts can be moved freely. (Note the

position)

Top

Bottom

www.

e

Labpeers.com Page 14

16. Another view.

17. Flip it. Fix the part with M3 truss head 10mm screw and seal nut as follow. Do not

fix the nut too tight or too loose. Make sure the part can be moved freely. (Note the

position)

18. Fix triangle part with 2 x M3 truss head 10mm screws and seal nuts as follow. They

should be fixed in the correct order. Do not fix the nut too tight or too loose. Make sure

the parts can be moved freely. (Note the position)

Top

Bottom

www.

e

Labpeers.com Page 15

19. Move the parts so that the circled holes are align. Fix them with M3 truss head

6mm screw to metal standoff as follow. (Note the position).

20. Fix the part to the circled hole with M3 truss head 10mm screw and seal nut as

follow. They should be fixed in the correct order. Do not fix the nut too tight or too

loose. Make sure the parts can be moved freely. (Note the position)

Top Bottom

www.

e

Labpeers.com Page 16

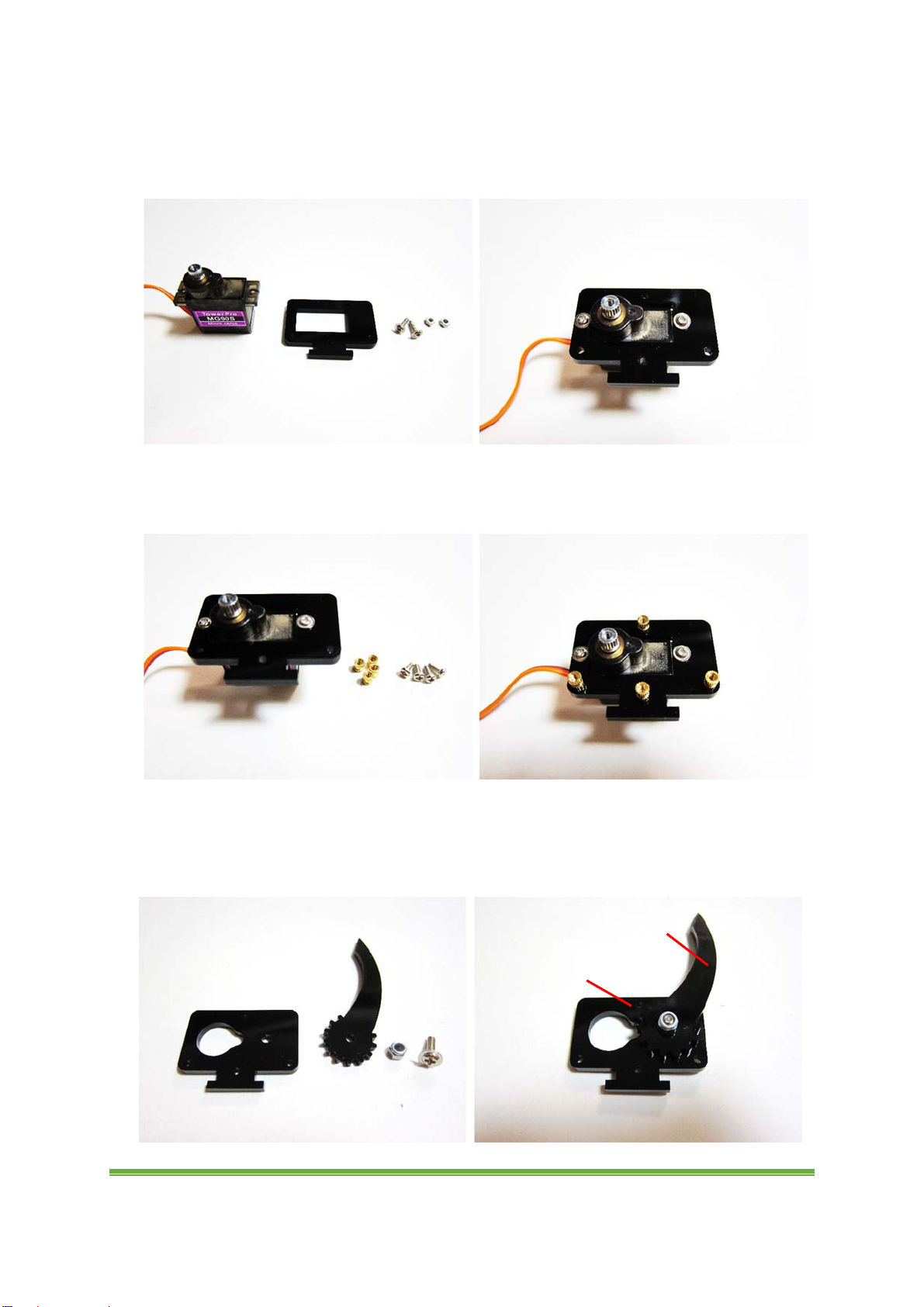

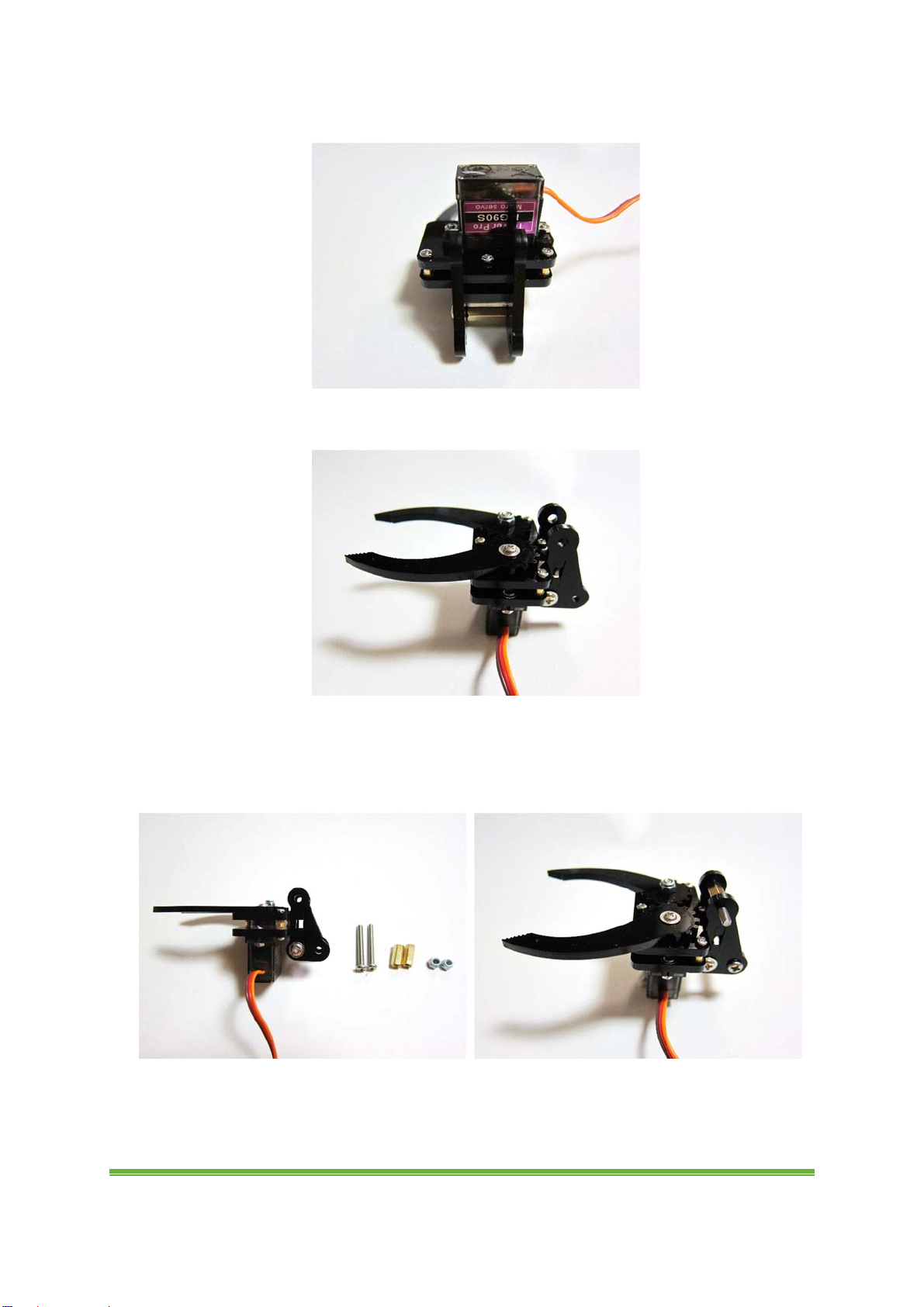

C. Claw

1. Take the part as follow. Fix a servo to it with 2 small truss head screws and nuts.

2. Take 4 small metal standoff and 4 small 5mm pan head screws. Fix the metals

standoff to the part as follow.

3. Fix the parts with M3 truss head 10mm screw and seal nut as follow. They should be

fixed in the correct order. Do not fix the nut too tight or too loose. Make sure the parts

can be moved freely. (Note the position)

Top

Bottom

www.

e

Labpeers.com Page 17

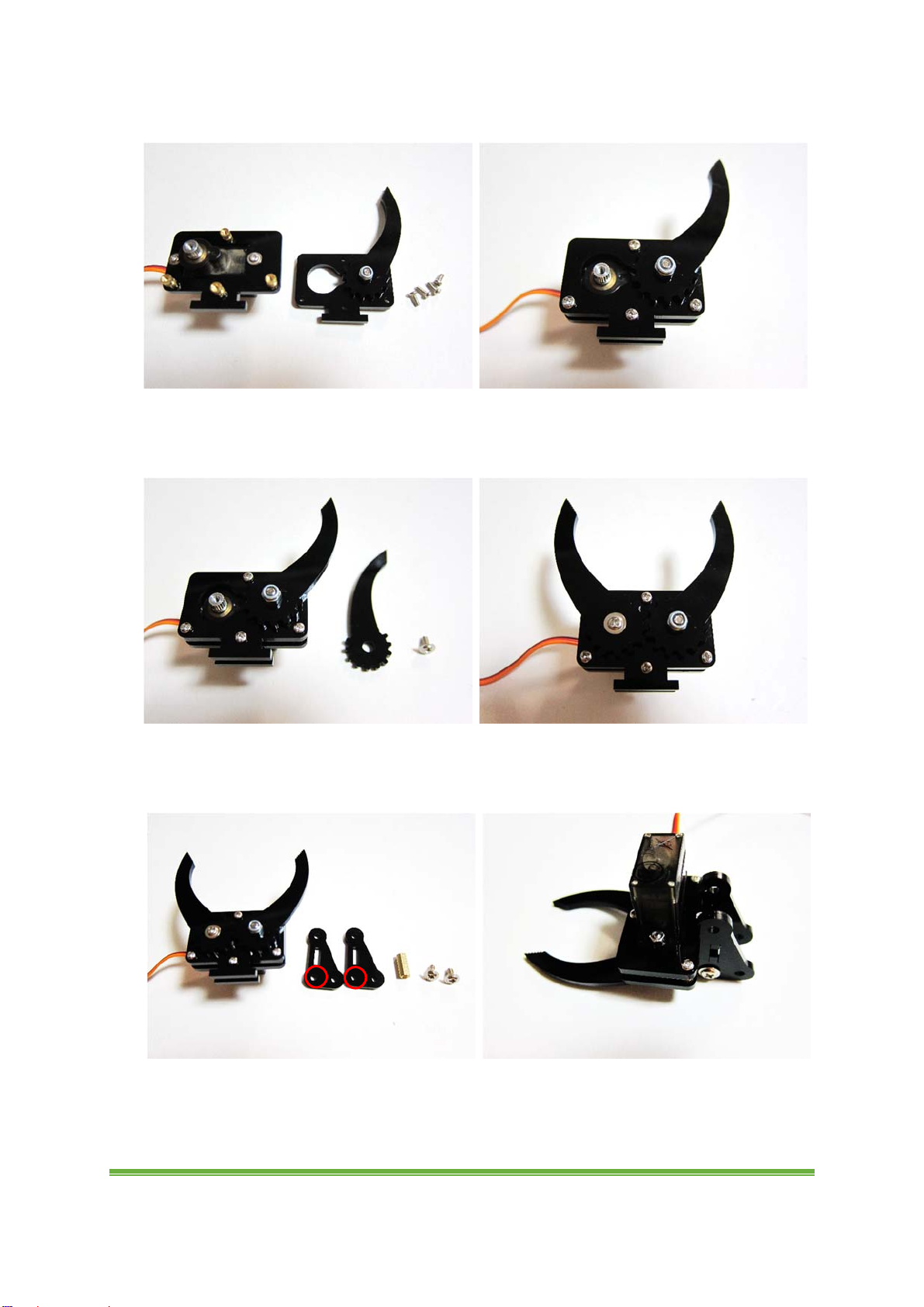

4. Fix two parts together with 4 small 5mm pan head screws as follow.

5. Take another part of claw and small truss head screw. Fix the claw to the servo as

follow.

6. Lock the claw with two triangle parts. Put 11mm metal standoff between two

circled holes. Fix it with 2 x M3 truss head 5mm screws.

www.

e

Labpeers.com Page 18

7. Another view.

8. You may also choose to lock the claw with inverse position.

9. Put 2 x 11mm metal standoff between two triangle parts. Hold them with 2 x M3

pan head 25mm screws. Do not fix with seal nuts at this stage. (Note the direction of

screws)

www.

e

Labpeers.com Page 19

10. Another view.

11. Fix the claw to the arm with seal nuts. Do not fix the nut too tight or too loose.

Make sure the parts can be moved freely.

www.

e

Labpeers.com Page 20

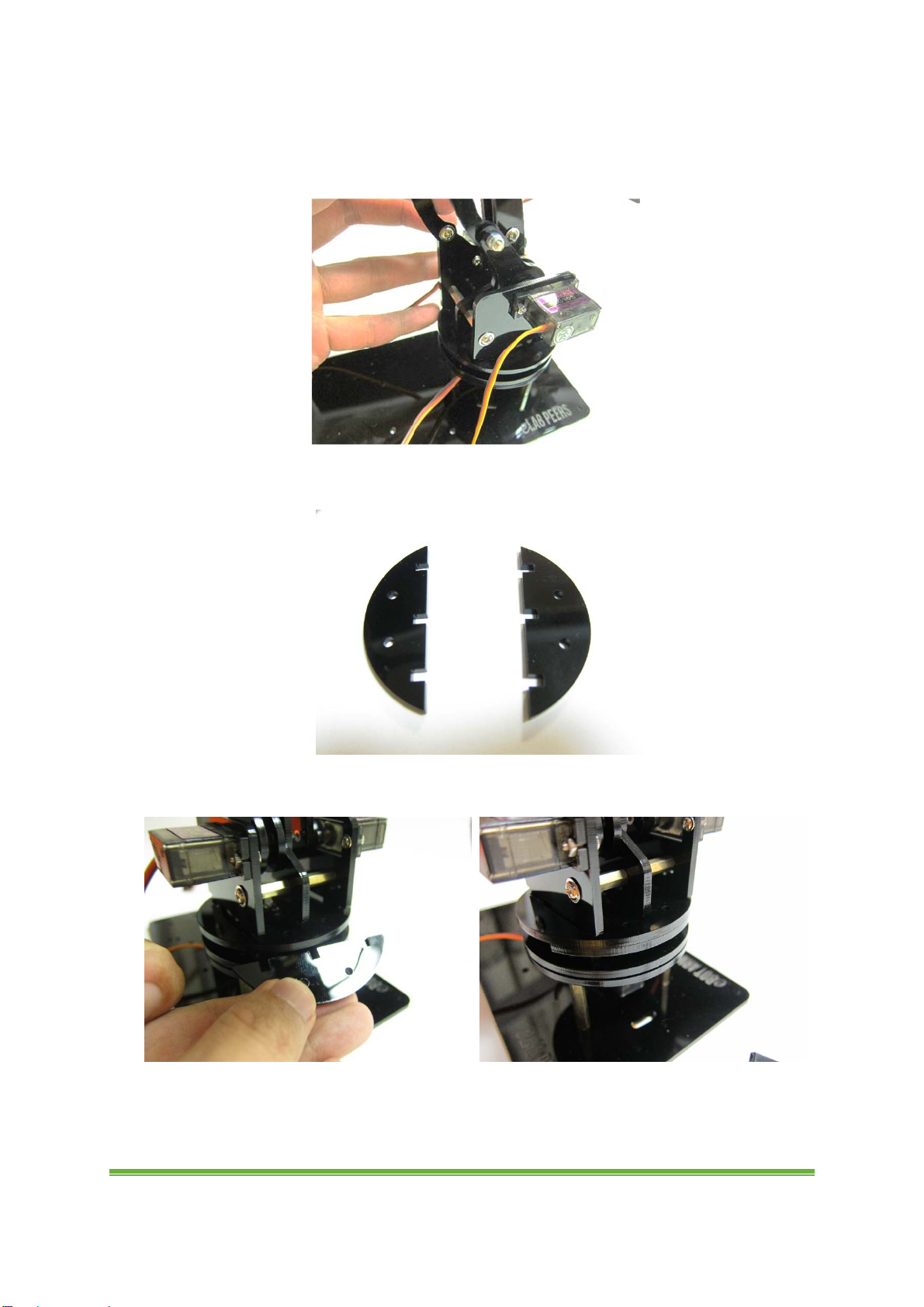

D. Combine

1. Place the arm to the base as follow.

2. Take the parts shown below. These part can lock the arm to the base.

3. Place one part to the gap between the base and the joints under the arm.