Elamed EASYTON User manual

1

EASYTON Tonometer is covered by Russian Federaon’s Patent No. 2335234.

The tonometer complies with all the security requirements provided by

IEC 60601-1:2005 and IEC 60601-1-2:2014-04 internaonal standards.

The tonometer conforms with the European Economic Community Direcve

93/42/EEC.

1. DESCRIPTION AND DESIGN FEATURES.

OPERATING PRINCIPLE 3

2. PREPARATION FOR OPERATION 5

2.1. Baery Installaon and Replacement 5

2.2. Funconality Checkup Using the Tester 6

2.3. Disinfecon 7

3. DEVICE APPLICATION PROCEDURE 8

3.1. Pre-Measurement Steps 8

3.2. Measuring Procedure 8

4. POSSIBLE ERRORS AND TROUBLESHOOTING 11

5. MAINTENANCE SERVICE AND MINOR REPAIRS 12

6. SPECIFICATIONS 13

7. STORAGE AND TRANSPORTATION 13

8. MARKING 14

9. MANUFACTURER’S WARRANTY 16

10. ACCEPTANCE CERTIFICATE 17

11. APPENDIX A 17

TABLE OF CONTENTS Thank you for purchasing EASYTON transpalpebral digital

tonometer for intraocular pressure measurement (below

referred to as the Tonometer).

Indication for the tonometer usage:

The Tonometer Easyton is indicated for the measurement

of intraocular pressure in human eyes.

The Tonometer is a medical measuring instrument which is

approved for usage at healthcare facilities as an individual

means of IOP control.

Please make sure to carefully study the Operating Manual

before starting to use the Tonometer. Please consult your

attending doctor regarding the values of intraocular

pressure which are specific to you personally.

!Caution! Federal law restricts this device to sale by or on

the order of a physician.

IOP measurement is taken through closed eyelid and does

not require any anaesthesia.

2

Tonometer usage is contraindicated in the following cases:

• pathological condions of the upper eyelid

(inflammatory condions, scars, eyelid deformies);

• evident scleral and/or conjuncval pathology in the area of

the Tonometer rod’s acon;

• any diseases and condions that prevent the paent from

accepng and/or maintaining a sing posion, including:

- severe or crical general condion of the paent due to

various reasons;

- skeletal injuries with damage to the bones of the pelvis

and/or spine;

- diseases accompanied by a pronounced violaon of the

strength and tone of the muscles involved in posioning

of the body (strokes and their consequences, injuries and

diseases of the brain, myasthenia, etc.);

- postoperave period requiring restricons of the pa-

ent’s body posion (surgical intervenons on the small

pelvis area, early postnatal period, etc.).

•Make sure to examine the Tonometer body and rod for

presence of mechanical damages. Using the Tonometer if

any of these damages have been detected is PROHIBITED.

•Protect the Tonometer from shock and impact. When car-

rying the Tonometer around, put it into the plasc case,

with the protecve cap over its working part.

•Avoid penetraon of moisture inside the Tonometer. In

case if a liquid did get inside the device, let it dry at room

temperature for at least 4 hours before using it again and

check its funconality on the tester.

•Avoid high temperatures.

•Avoid thermal shock. This may cause malfunconing of

the Tonometer.

•Do not use the Tonometer in the shower and bathroom.

KEY SAFETY TIPS

!

!Attention! An exclamation point symbol displayed in the

Tonometer window, accompanied by continuous beeping

sound, is a signal of its inoperable condition and of

excessive pressure load of the rod upon the eyelid, which

may cause painful sensations for a patient.

!Precaution!

The Tonometer should not be used on eyes with

biomechanical properties altered by prior surgery or

disease.

3

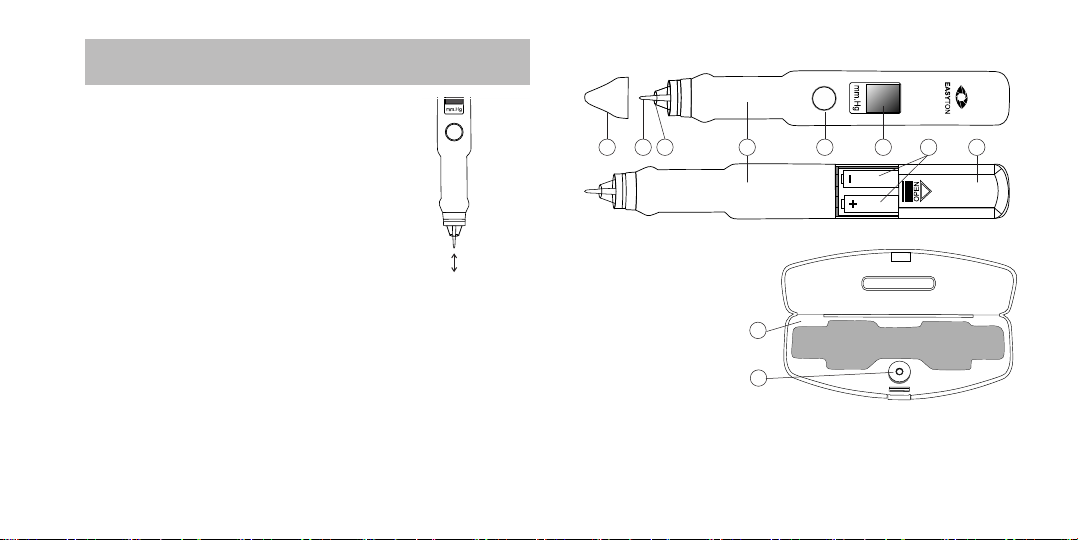

Schematic

representation

of the Tonometer rod

movements

1. DESCRIPTION AND DESIGN FEATURES.

OPERATING PRINCIPLE

When placing the Tonometer rod on the

eyelid and applying light pressure to the

device, the rod is slightly immersed in-

side the device and the formaon of a

measuring vibraonal effect begins.

The vibraon frequency of the «rod-

eye» ligament depends on the IOP.

The higher the IOP, the greater the fre-

quency of vibraons.

The Tonometer registers the vibraon

frequency, recalculates it into the IOP

value and displays it on its indicator.

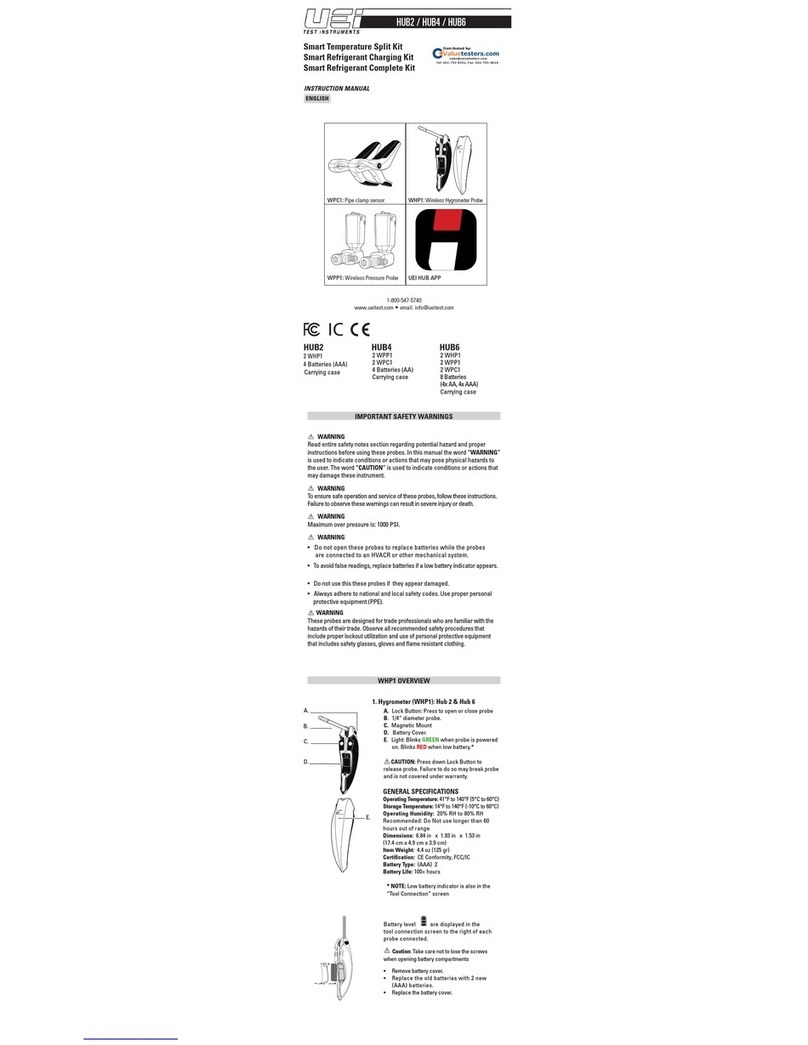

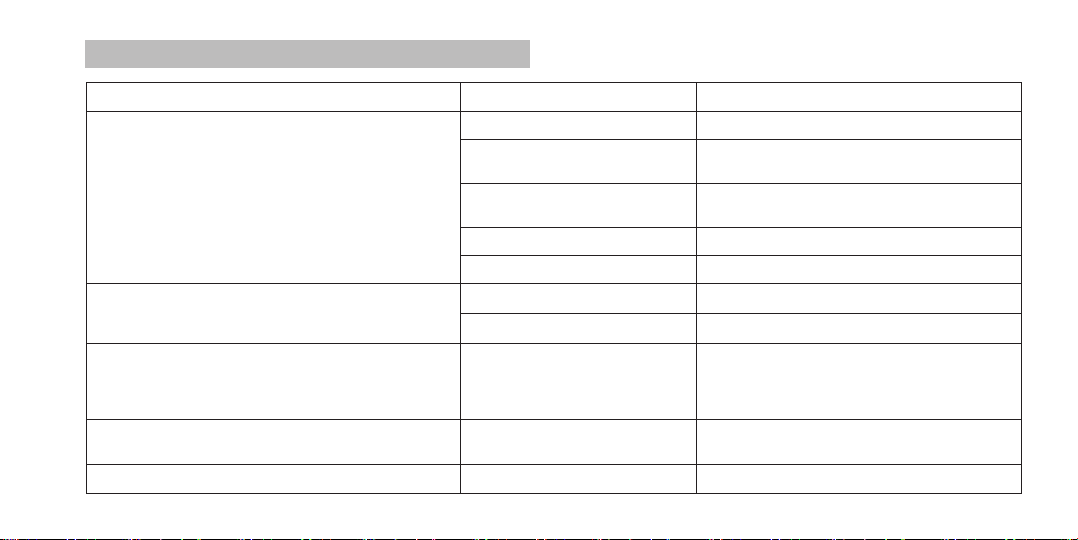

Key Design Features

A. Tonometer body

B. On/Offbuon

C. Display window

D. Vibrator rod

E. Buffer ring

F. Protecve cap

G. Baery case cover

H. Baeries

I. Case box

J. Tester

F D E A B C H G

I

J

Figure 1

Figure 2

4

Display Symbols

K. Baery level indicaon

L. Ready-for-operaon indicaon

M. Measured IOP reading

N. Square frame around the reading value = unstable posioning

of the Tonometer, or the paent’s eyelid or eye

O. IOP value below the measurement range (below 7 mmHg)

P. IOP value above the measurement range (above 50 mmHg)

L M N

K K K

Complete Set

• EASYTON Tonometer 1

• Built-in tester case 1

• 1.5 V battery standard size ААА, R03 2

• Operang Manual 1

• Retail packaging 1

Important Facts on Intraocular Pressure

Intraocular pressure measurement is a method of

eye health diagnostics used in ophthalmology.

Intraocular pressure generally has 3 basic condi-

tions:

• normal

• hypertension (high pressure)

• hypotension (hypotony)

Stascally, the normal range of true IOP (Р0) is

within 10 to 21 mmHg. IOP may be irregular or

may change in the course of the day. The normal

value may vary in the range of 2-2.5 mmHg.

O

K

P

K

Figure 3

5

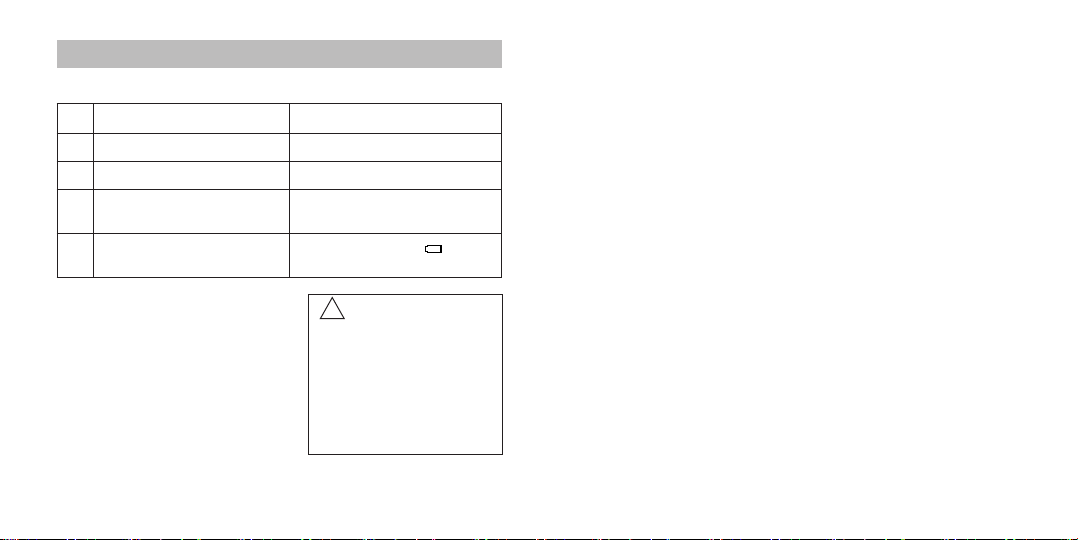

2. PREPARATION FOR OPERATION

2.1. Battery Installation and Replacement

The current baery status is marked with the power level indica-

tor in the top lecorner of the Tonometer display.

Baeries fully

charged

Baeries parally

discharged

Low baery

If the baƩeries are discharged, the Tonometer will not switch on.

Batteries are to be replaced with the Tonometer switched off.

If you plan to use the device again only in a few months’ Ɵme,

make sure to take the baƩeries out.

Turn the Tonometer over so

that its front panel is facing

downwards.

Slide the battery case cover

in the direction of the arrow

marked on it.

Insert / replace the two AAA

batteries in such a way so

that their «+» (positive) and

«–» (negative) contacts would

match the polarities marked

inside the battery case.

Put the battery case cover

back on.

press your finger

against the housing

slide the cover in

as far as it can go

Attention! Immediately after inserting

the batteries, switch the Tonometer

on and offby shortly pressing the On/

Offbutton.

This is done to check proper installation

of the batteries, and the Tonometer is

set into the micro-consumption mode.

!

1

2

3

4

Figure 4

Figure 5

6

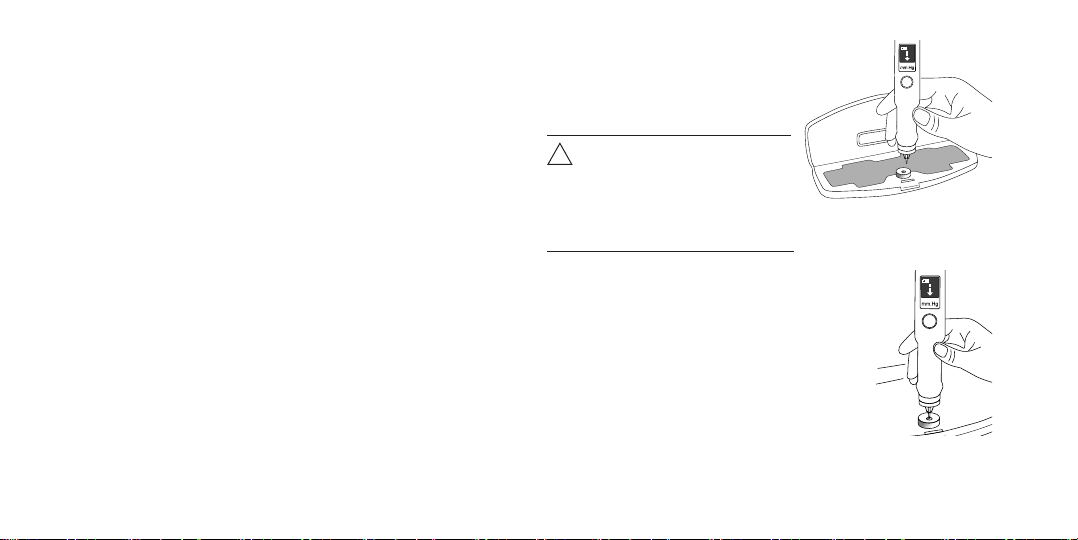

Position the Tonometer

vertically above the tester.

The heel of the hand holding

the device should rest against

the table surface.

Keeping the heel of the hand fixed

on the table, insert the device rod

down into the center of the tester

pinhole. Dip the Tonometer buffer

ring as far down as it can go into the

circular groove of the tester. The lower

surface of the Tonometer ring should

be aligned with the circular groove

surface as much as possible.

At this point, the measuring mode is

actuated, which is perceived by the

hand as light vibration. Meanwhile,

the pressure value is displayed in the

Tonometer window.

2.2. Functionality Checkup Using the Tester

The Tonometer funconality is to be checked on the tester at

least once a week, as well as in the following cases:

• aer long idle periods

• aer dropping the device

• aer changing the baeries

• in any other cases when you doubt if the Tonometer

works properly

To check the Tonometer functionality on the tester, do as

follows:

Open the Tonometer case.

Take the device out and put the opened case with the

tester on a table.

Position the Tonometer with the rod up and take the

protective cap off.

Shortly press the On/Offbutton to switch the

Tonometer on.

A moving arrow displayed in the Tonometer window

indicates its readiness for operation.

Hold the Tonometer with your fingers by the cylinder-

shaped part of its housing.

Place the Tonometer with the measuring rod down and

position its housing so as to be able to see the readings

on the display.

Attention! Upright positioning

of the Tonometer (allowed

deviation from vertical axis

should not exceed 15 degrees)

must be preserved during all

measurements.

!

ready-for-

operaon

1

2

3

4

5

6

7

8

9

Figure 6

Figure 7

7

measurement

mode

measurement

completed

Keeping the device fixed in this

position, keep an eye on the

digital value of the pressure

displayed in the Tonometer

window. The measuring mode will

continue until the device is lifted

away from the tester. The digital

reading on the display should not

diverge from the one listed in the

«Specifications» section of this

Manual by more than two units.

Raise the Tonometer above the

tester. The measuring mode

is thus completed, and the

measured value is captured on the

display.

The measuring can be repeated

for as many times as needed,

following Clauses 9, 10, and 11 of

this section.

Deactivate the Tonometer by

shortly pressing the On/Off

button.

Put on the protective cap, with the

Tonometer rod turned upwards,

and put the device into its case.

10

11

12

13

14

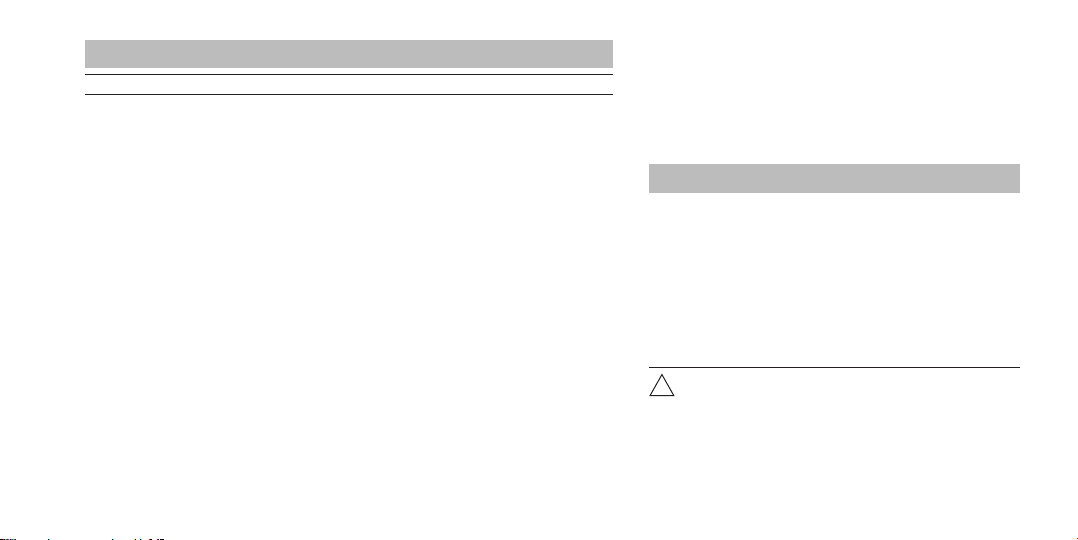

2.3. Disinfection

Please disinfect the Tonometer while it is switched off.

Disinfecon of the buffer ring and Tonometer rod should be performed

before and aer each new paent’s IOP measurement.

To perform the disinfecon procedure, do as follows:

Pour use the Rapicide PA disinfeccting solution into tray.

Holding the Tonometer with the rod down, treat the buffer

ring and the lower part of the rod immerse in solution for at

least 15 minutes.

Attention! Only the working parts of the Tonometer need to be

immersed, at a distance not exceeding 1 cm from the edge of the

ring (see Figure 10).

!

Remove disinfected the Tonometer from the

tray using aseptic procedure and rinse them

in sterile water.

Thoroughly rinse the buffer ring and the

lower part of the rod by immersing it in a

large volume of water and keep it immersed

for a minimum of 1 minute.

Manually flush the buffer ring and the lower

part of the rod with large volumes of rinse

water. Avoid penetration of moisture inside the Tomometer.

1

2

3

4

5Figure 10

Figure 8

Figure 9

8

Disinfection of the outer surfaces of the Tonometer body

(others than the rod and the buffer ring) is performed as

may be needed, using 3% hydrogen peroxide solution mixed

with 0.5% solution of a household detergent.

After disinfection, wipe the outer surfaces of the display

with a dry sterile cloth.

The process of disinfection of the tonometer was validated

and was recognized as acceptable by the results of tests in

the mycobiological laboratory.

Attention! Avoid penetration of the disinfectant solution

inside the Tonometer.

!

3. DEVICE APPLICATION PROCEDURE

3.1. Pre-Measurement Steps

1

2

3

4

5

3.2. Measuring Procedure

•

•

•

•

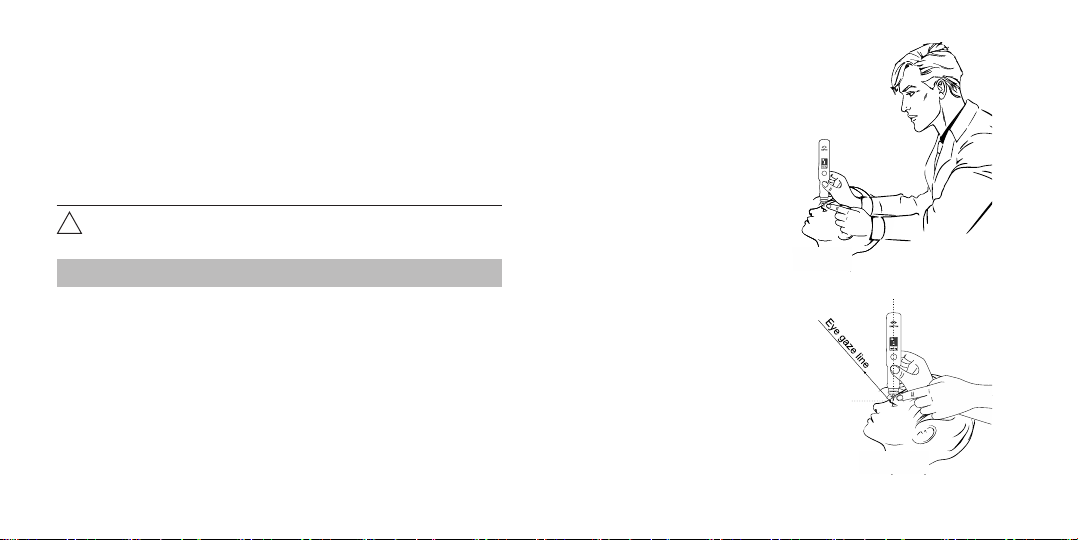

Hold the activated

Tonometer with your fingers

by the cylinder-shaped part

of its housing.

Place the device with its rod

facing downwards. Turn the

Tonometer so as to be able to

see the readings on the display.

Stand at the patient’s side

slightly behind them.

The patient’s gaze must be fixed

at a test object (for instance,

their own hand), heir eye gaze

line making up an angle of 45°

from upright direction.

Take the Tonometer out of its case.

Position the Tonometer with the rod up and take the

protective cap off.

Disinfect the Tonometer (see Cl. 2.3).

Shortly press the On/Offbutton to switch the

Tonometer on. When activated, the Tonometer

produces a beeping sound.

Check for presence of a moving arrow on the Tonometer

display, which indicates its readiness for measuring.

Check the Tonometer functionality using

the tester (see Cl. 2.2).

Before measuring, the patient should

be in a sitting position with his

head tilted back so that the

position of the head was as

close to horizontal as possible.

6

7

Figure 11

Figure 12

9

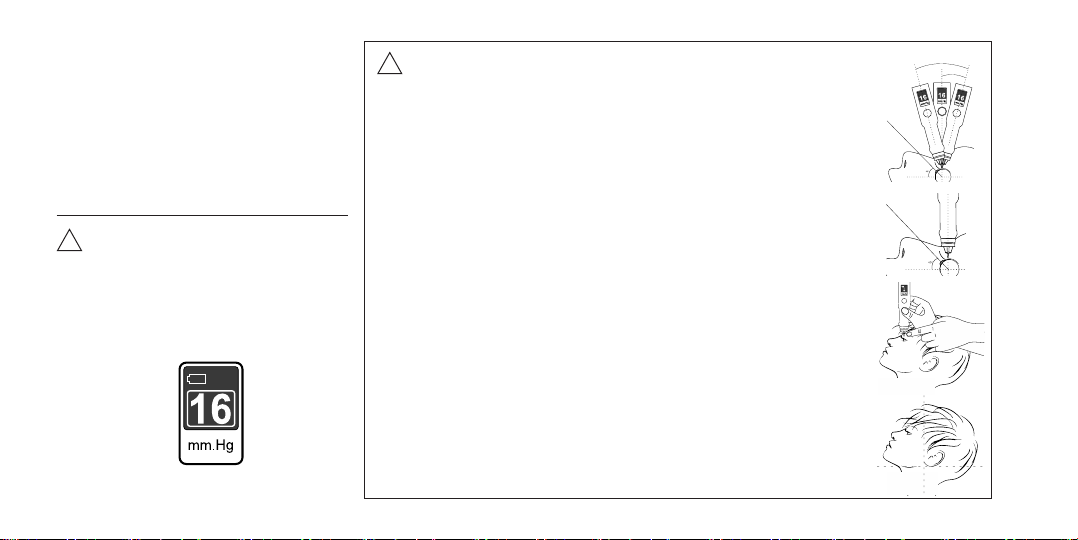

•The vertical position of the

instrument rod on the surface of the

eye is an essential condition for the

accuracy of IOP measurement. Place

the Tonometer rod on the upper

eyelid of the patient 2-3 mm from its

edge (in the sclera region), holding

the tonometer body strictly vercally.

The contact area of the tonometer

rod should fall on the upper por-

on of the sclera corresponding to

corona ciliaris in Meridian 12 (Figure No 14). Recom-

mended installaon points are indicated in the figure.

Attention! Avoid slipping of the eyelid onto the cornea

while taking the measurement!

!

•

•

The heel of the hand holding the Tonometer should rest

against the patient’s forehead. The smoothness and

preciseness of movements required for the measuring

process is achieved by resting the hand against the

patient’s head (forehead), as well as trained through

continuous usage.

Stretch the upper eyelid with a finger of your free hand

in a way to ensure alignment of the upper eyelid edge

with the upper corneal edge. Fixate and hold the eyelid

in this position, without pressing on the eyeball.

• Holding the Tonometer vertically

down, smoothly lower it down

by 2-3 mm. At this point, dynamic

force is actuated, which is

perceived as light vibration.

During the measuring process,

make sure that the buffer ring does not touch the

eyelid, but remains 2-3 mm above the eyelid surface.

Avoid slipping of the eyelid onto

the cornea while taking the

measurement.

Attention! When the Tonometer is

lowered too far down, it produces a

continuous single-tone beep, which

stops automatically when the device

is raised high enough for measuring.

!

•1 or 2 seconds after lowering the Tonometer down, it

produces a beep indicating that the measurement is

completed, and the measured IOP value is displayed in

its window. The measuring process will continue until

the device is lifted away.

To end the process, lift the device up. At the moment

when the measurement is taken, the device produces

another beep, and the measured IOP value is displayed

in the window.

Figure 13

Figure 14

Figure 15

10

Attention! If the positioning of the

Tonometer, the patient’s eyelid

or eye, is unstable during the

measuring process, the resulting

reading may appear on the display in

a square frame. If this happens, the

measurement needs to be re-taken.

!

•

•

In case if the sound signal didn’t

come offat all or came offwith a

delay of more than 3 seconds, the

measuring needs to be repeated.

Deactivate the Tonometer by

shortly pressing the On/Offbutton.

Put the protective cap back on,

with the Tonometer rod up, and

put the device back into its case.

Attention! To obtain the most accurate IOP

measurement results, the following conditions

must be observed:

!

•The Tonometer body should be posioned strictly

upright.

When measuring, try to hold the tonometer body

strictly upright, avoiding its deviaon by more than 15

degrees.

•The Tonometer rod should be posioned at right

angle against the eye surface.

To achieve that, align the Tonometer rod axis with the

geometric center of the eyeball.

•Smoothness and preciseness of movements during

the measuring process.

These can easily be achieved when the hand holding

the Tonometer is resng against the paent’s head

(forehead).

•The paent's posion at the me of measurement.

At the me of the measurement, the paent should

be in a sing posion with his head lted back so that

the posion of the head is as close to horizontal as

possible.

15о

30о

Figure 16

Figure 17

Figure 18

Figure 19

Figure 20

11

4. POSSIBLE ERRORS AND TROUBLESHOOTING

Problem Possible cause Troubleshooting method

The Tonometer does not switch on The batteries are dead Replace the batteries

The batteries are seated

incorrectly

Insert the batteries with due regard to the

polarity markings (+ / -)

The contact of the batteries is

unstable

Replace the batteries. Clear the contacts of the

battery holders using an erasing rubber

The On/Off button is broken Repair at a maintenance service facility

The Tonometer itself is broken Repair at a maintenance service facility

The Tonometer readings obtained with the tester

deviate from the values specified in the Manual by

more than 2 units

The Tonometer is de-calibrated Calibration at a maintenance service facility

The Tonometer is broken Repair at a maintenance service facility

After the measurement is completed (and the

Tonometer lifted up), the vibration action does not

stop or stops only after a notable delay (more than a

second)

The rod motion sensor is de-

calibrated

Calibration at a maintenance service facility

When switching the Tonometer on, it does not display

any indications, and an alarm signal is produced

The Tonometer display is broken Repair at a maintenance service facility

The batteries run low too soon (in less than 30 days) Excessive power consumption Repair at a maintenance service facility

12

5. MAINTENANCE SERVICE AND MINOR REPAIRS

Maintenance Procedure

Procedure Frequency

1. Routine inspection At least once a day

2. Cleaning from dust and dirt As may be necessary

3. Functionality checkup Before each IOP

measurement procedure

4. Battery changing When the symbol « »

appears on the display

Minor Repairs

During routine inspection, make

sure to check the integrity of the

Tonometer body and to check

for mechanical damages of the

vibrator rod.

The Tonometer functionality

checkup is to be done as

described in the clause titled

«Tonometer Functionality

Checkup Using the Tester».

Do not attempt any

repairs by yourselves.

Should you have any

doubts regarding

correct operation of the

device, please contact

the Manufacturer or its

representative office.

!

Minor repairs of the Tonometer are provided by the

Manufacturer or its representative facility, after a technical

inspection of the malfunction nature and degree has been

performed by the Manufacturer’s experts.

The following may indicate presence of a malfunction:

•mechanical damages of the Tonometer housing and

(or) vibrator rod;

•divergence of the Tonometer readings obtained with

the tester from the ones listed in the «Specifications»

section;

•absence of readings on the display despite presence of

the sound of the rod vibration specific for measuring;

•absence of the power level indication symbols.

During minor repairs, troubleshooting is done by

replacement or recovery of the parts and elements;

adjustment of the Tonometer is conducted to ensure its

compliance with the parameters listed in this Manual. Upon

completion of the repairs, the Tonometer is returned to the

user, and its warranty period is renewed starting from the

date of return.

Safety Measures

No special precautions are required while conducting the

repairs.

13

6. SPECIFICATIONS

Parameter Parameter value

Device Transpalpebral digital tonometer for

intraocular pressure measurement

Model EASYTON

IOP readings range, mmHg 7-50

Accuracy, mmHg, within the range of:

7-23 mmHg ±2

above 23 mmHg ±5

Repeatability (coefficient of variation), % ≤8,1

Accuracy of display, mmHg 1

Display unit Millimeter of mercury (mmHg)

IOP measurement time, sec, max 2

Power consumption during

measurement, mA, max 100

Power supply: No. of elements and voltage 2 × 1.5V, standard size ААА, R03

Display LCD

Data output Display window

Overall dimensions (L×H×W) mm, max 173 × 27 × 21

Weight, g, max 88, incl. batteries

Operating conditions:

operating temperatures range, °Сfrom +10 to +35

relative air humidity,%, max 80

atmospheric pressure, mmHg 630-800

Mean service life, no less than 5 years

7. STORAGE AND TRANSPORTATION

The Tonometer may

be stored in a closed

non-heated room at a

temperature from

-50 °Сto +40 °Сand

relative air humidity

of up to 98% (at a

temperature of + 25 °С).

The device can be

transported by all

covered vehicles in

microclimatic regions

with a moderately cold

climate at ambient air

temperatures from -50 °С

to +50 °С.

Attention! After a long storage or transportation

at temperatures below +10 °C, keep the

Tonometer in a room at a temperature from +10

to +35 °C for at least 4 hours.

!

Tonometer readings obtained with the tester in the

IOP measurement ________________ ±2 mmHg.

(to be filled in at device acceptance)

14

8. MARKING

The Tonometer is marked with the following symbols:

Refer to the operang manual

The Tonometer’s working part is the

sufficiently protected against electric shock

The product is licensed with Approval

Cerficate of Measuring Instruments

Compliant with CU TR 020/2011 Technical

Regulaons of the Customs Union

Compliant with MDD 93/42/ЕЕС

Safety and effectiveness of the tonometer in the intended

environment of use is supported by testing that was

conducted in accordance with the following standards:

ISO 10993-1 «Medical products. Assessment of medical

products biological effect. Part 1. Assessment and investigation»

ISO 10993-9 Biological evaluation of medical devices – Part 9:

Framework for identification and quantification of potential

degradation products

ISO 10993-10 Biological evaluation of medical devices – Part 10:

Tests for irritation and skin sensitization

ISO 10993-11 Biological evaluation of medical devices – Part 11:

Tests for systemic toxicity

ISO 10993-12 Biological evaluation of medical devices – Part 12:

Sample preparation and reference materials

ISO 15223-1:2016 Medical Devices – Symbols To Be Used

With Medical Device Labels, Labelling, And Information To Be

Supplied – Part 1: General Requirements

IEC 60601-1-2:2014 (4th edition) Medical electrical equipment

– Part 1-2: General requirements for basic safety and

essential performance – Collateral standard: Electromagnetic

compatibility – Requirements and tests

IEC 61000-4-2:2012 Electromagnetic compatibility (EMC) –

Part 4-2: Testing and measurement techniques – Electrostatic

discharge immunity test

15

IEC 61000-4-3:2006+AMD1:2007+AMD2:2010 Electromagnetic

compatibility (EMC) – Part 4-3: Testing and measurement

techniques – Radiated, radio-frequency, electromagnetic field

immunity test

IEC 61000-4-8:2009 Electromagnetic compatibility (EMC) – Part

4-8: Testing and measurement techniques – Power frequency

magnetic field immunity test

CISPR 11:2009 +A1:2010 Industrial, scientific and medical

equipment – Radio-frequency disturbance characteristics –

Limits and methods of measurement

DIN EN ISO 15223-1:2013 Medical devices – Symbols to be

used with medical device labels, labelling and information to be

supplied – Part 1: General requirements (ISO 15223-1:2012)

ANSI Z80.I0-2014 Ophthalmic instruments. Tonometers

During pre-market testing process the comparability testing

to a Goldman type reference tonometer was performed on

eyes in according to ANSI Z80.10-2014 and satisfied results

was reached. The resulting Pearson correlation coefficient

is more 95% (see pictures below). This indicates the high

accuracy of the EASYTON tonometer compared to the

Goldman tonometer. As a result of the tests, the required

accuracy and repeatability of the measurements were

confirmed.

mmHg

mmHg

mmHg

mmHg

16

9. MANUFACTURER’S WARRANTY

The Manufacturer hereby guarantees that the quality of

the Tonometer conforms to the requirements stated in the

Operating Manual, provided that the conditions of proper

storage, transportation, and usage are met by the Customer.

Guaranteed service life (warranty period) is 24 months from

the date of sale.

Within the warranty period, the Manufacturer shall repair

or replace the defective Tonometer free of charge, upon

presentation of the warranty service coupon.

Warranty provisions

The warranty is only valid if the Customer has a correctly filled-

in warranty coupon, with the factory serial number and date of

sale indicated, and a vivid stamp of the trading company.

The warranty does not cover the following cases:

•if the Tonometer bears traces of outside interference

or repair attempts by non-authorized servicing

companies;

•if unauthorized changes into the design or construction

of the Tonometer have been detected;

•if the Tonometer has any mechanical damages;

•if the Tonometer has been damaged as a result of

penetration of foreign objects, substances or liquids.

The batteries are not covered by this warranty.

When the service life or operational life cycle of the

batteries expires, the Customer is to replace them of their

own accord.

The guaranteed shelf life is 24 months.

Please send a faulty Tonometer for repairs, together with

the Operating Manual and an enclosed explanatory note, to

the Manufacturer’s representative at the following address:

For any quesons on the device quality and maintenance service,

please contact the Manufacturer’s representave.

17

10. ACCEPTANCE CERTIFICATE

EASYTON transpalpebral digital tonometer for intraocular

pressure measurement factory serial number

is manufactured and accepted in compliance with the

technical specification GIKS.941329.102 TS and is hereby

validated as ready-for-service.

Software version No. GIKS.17-0104.3.

Date of producon Stamp

EASYTON transpalpebral digital tonometer for intraocular

pressure measurement is packed according to the require-

ments specified in the design documentaon.

Date of packing

Packed by Stamp

(signature of a person responsible for acceptance)

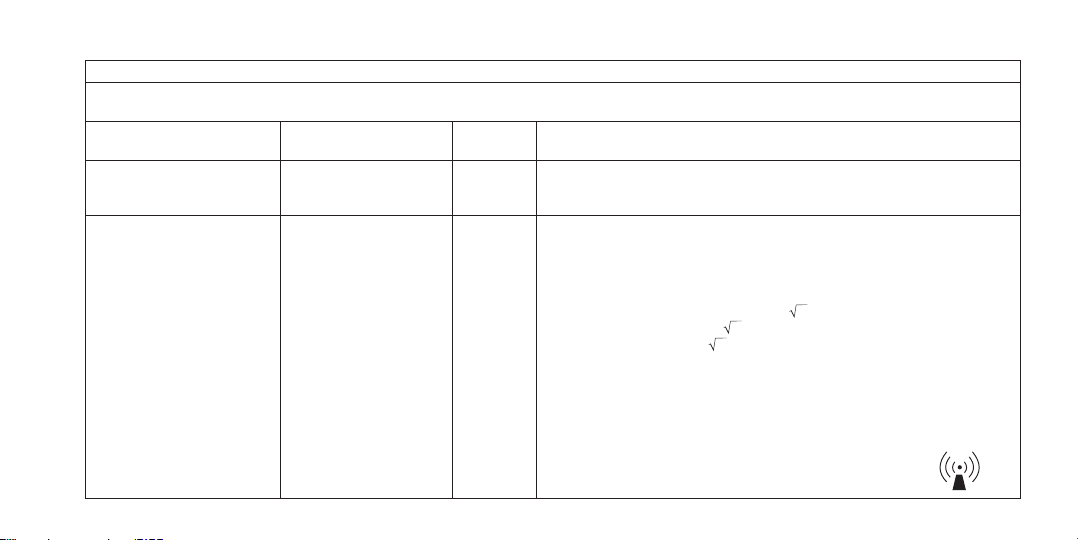

Manufacturer's manual and declaration – electromagnetic emission

The tonometer is intended for use in the electromagnec environment spec-

ified below. The purchaser of the tonometer should ensure its use in the

specified electromagnec environment

Electromagnetic

emissions test

Compliance Electromagnetic environment –

instructions

Radio-interferences

according to CISPR 11

Group 1 The tonometer uses radio-frequen-

cy energy only to perform internal

funcons. The emission level of the

radio frequency interference is low

and might not lead to disturbances

in the funconing of the electronic

equipment located close to it

Radio-interferences

according to CISPR 11

A Classes The tonometer is suitable for use

in all the locaons, not used for do-

mesc purposes and not connected

to low-voltage distribuon networks

The harmonic current

components

of IEC 61000-3-2

Not applied

11. APPENDIX A

Table 1

18

Manufacturer’s manual and declaration – interference resistance

The tonometer is intended for use in the electromagnec environment specified below. The purchaser or user of the tonometer should ensure its use in the specified

electromagnec environment.

Interference resistance test The test level according to IEC 60601 Compliance level Electromagnetic environment – instructions

Electrostac discharge (ESD)

according to IEC 61000-4-2

±8 kV – contact discharge

±2,4,8,15 kV – air discharge

Complies The floor in the facility must be covered with wood, concrete

or ceramic tiles. If the floor is covered with synthetic material,

relative humidity must be minimum 30%

Electrical fast transient/burst

according to IEC 61000-4-4

±2 kV – for powersupply lines

±1 kV – for input-output lines

Not applied Power quality in mains in accordance with the typical

conditions of a commercial or hospital environment

High energy

microsecond pulse interferences

according to IEC 61000-4-5

±2 kV Not applied Power quality in mains must be provided in accordance

with the typical conditions of the commercial or hospital

environment

Voltage dips, average interrup-

ons and voltage fluctuaons

in the input power lines

according to IEC 61000-4-11

- UH=0%, 0,5 cycle

(0,45,90,135,180,225,270 and 315 dagrees

- UH=0%, 1 cycle

- UH=70%; 25/30 cycles (0 dagrees)

- UH=0%, 250/300 cycle

Not applied Power quality in mains in accordance with the typical

conditions of a commercial or hospital environment If the

user of the device needs to provide seamless operation in the

conditions of possible interruptions of the line voltage, it is

recommended to power the device from an uninterruptive

power supply or battery

Power frequency magnec field

(50/60 Hz) according

to IEC 61000-4-8

30 A/m Complies The levels of power frequency magnetic field must be provided

in accordance with the typical conditions of the commercial or

hospital environment

Note: UH– is the voltage level of the mains unl test exposure is applied

Table 2

19

Manufacturer’s manual and declaration – interference resistance

The tonometer is intended for use in the electromagnec environment specified below. The customer or the user of the tonometer should ensure its use in the

specified electromagnec environment.

Interference resistance test The test level

according to IEC 60601

Compliance

level

Electromagnetic environment – instructions

Conducted disturbances

induced by RF fields according

to IEC 61000-4-6

3 V (root-mean-square)

in-band from 150 kHz to

80 MHz

Not applied Evaluaon of the effecveness of the effect on conducted interference induced by

radio-frequency electromagnec fields

Radio-frequency electromag-

nec field according

to IEC 61000-4-3

3 V/m in-band from 80 MHz

to 2.7 GHz

Complies The distance between the mobile radiotelephone communicaon systems used and

any element of the tonometer, including the cables, should not be less than the

recommended separaon distance which is calculated in accordance with the ex-

pressions below with reference to the frequency of the transmier.

Recommended separation distance:

d = 1,2 P

d = 1,2 P (from 80 to 800 MHz);

d = 2,3 P (from 800 MHz to 2.7 GHz).

Where d is the recommended separation distance, m b);

P is the nominal maximum transmitter output power, W, as specified by the

manufacturer.

The field density in the propagation of radio waves from stationary radio transmitters,

according to the results of observations of the electromagnetic situation a), should

be lower than the level of correspondence in each frequency band b). The effect of

interference may occur near the equipment marked with the symbol

Table 3

Other manuals for EASYTON

1

Table of contents

Other Elamed Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Hioki

Hioki TM6102 instruction manual

Sanwa

Sanwa YX-361TR instruction manual

LaserLiner

LaserLiner MasterCross-Laser 2GP operating instructions

ATD Tools

ATD Tools ATD-3696 instructions

HB Products

HB Products HBSC2 Instruction manual supplement

SW Stahl PROFI Tools

SW Stahl PROFI Tools S3531 instruction manual