ELAU SB Series User manual

Edition BA * PMC-2 * EN * 01/98 Article number: 17130054-001

Instruction

Manual

PMC-2

Positioning

Motor Controller,

SB - motors

and

accessories

V20.XX.XX

PMC-2 Instruction Manual

Page 2BA * PMC-2 * EN * 01/98

COPYRIGHT

© All rights reserved to ELAU AG also in case of patent right applications.

No part of this publication may be reproduced, photocopied, stored on a retrieval system, or

transmitted or translated into another language or computer language without the express written

consent of the publisher, ELAU AG.

Disclaimer ELAU AG makes no representations or warranties with respect to the contents or use of

this manual or with respect to the PMC-2 and specifically disclaims any express or implied warranties

of merchantibility or fitness for any particular purpose. Further, ELAU AG, reserves the right to revise

the publication and to make change to any and all parts of the PMC-2 instruction manual, at any time,

without obligation to notify any person or entity of such revisions or changes.

Trademarks:

IBM PC, XT, AT, PS/2 are registered trademarks of the International Business Machine Corporation.

Microsoft, MS, and MS-DOS are registered trademarks, Windows and Windows 386 are trademarks

of the Microsoft Corporation.

Intel is a registered trademark and 80286, 80386, 80486, Pentium are trademarks of the Intel

Corporation.

Acrobat® Reader Copyright© 1987-1996 Adobe Systems Incorporated. All rights reserved.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated, which may be registered in

certain areas.

All other trademarks mentioned are the exclusive property of their manufacturers.

ELAU AG ELAU AG

Dillberg 12 Technisches Büro Nord

D-97828 Marktheidenfeld An der Kleimannbrücke 98

D-48157 Münster

Tel.: 0 93 91 / 606-0 Tel.: 02 51/1 41 49-0

Fax: 0 93 91 / 606-300 Fax: 02 51/1 41 49-20

eMail: [email protected]

Internet: http://www.elau.de

Mailbox: 09391 / 185 ISDN und analog

ELAU Automobil ELAU SYSTEMS GmbH ELAU SYSTEMS ITALIA S.r.l.

Antriebstechnik GmbH Oswald-Greiner-Str. 5 Via Tosarelli 302/A

Dillberg 11 D-04720 Döbeln I-40050 Villanova di Castenaso (BO)

D-97828 Marktheidenfeld

Tel.: 0 93 91/98 50 - 0 Tel.: 0 34 31/57 44-71+72 Tel.: 00 39/51/78 18 70

Fax: 0 93 91/98 50 - 10 Fax: 0 34 31/57 44-73 Fax: 00 39/51/78 18 69

Internet:

http://www.affari.com/elau.it/

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 3

Table of contents

1WHAT IS THE PURPOSE OF THIS INSTRUCTION MANUAL?..................................................... 5

2THE PMC-2 IN AN OVERVIEW.......................................................................................................... 6

2.1 INTRODUCTION.................................................................................................................................. 6

2.2 APPLICATION RANGE ......................................................................................................................... 7

2.3 PERFORMANCE FEATURES................................................................................................................. 7

2.4 COMMUNICATION............................................................................................................................... 8

2.5 OPERATION WITH BE-7....................................................................................................................... 8

2.5.1 Menu selection .......................................................................................................................... 9

2.5.2 Key input..................................................................................................................................10

2.5.3 Status information ....................................................................................................................11

2.5.4 Variable and parameter menu...................................................................................................12

2.5.5 I/Os and flags...........................................................................................................................13

2.5.6 Reset keys.................................................................................................................................13

2.6 OPERATING UNIT BE-8.....................................................................................................................14

2.6.1 Mechanics ................................................................................................................................14

2.6.2 Initial operation........................................................................................................................15

2.6.3 Variable menu ..........................................................................................................................16

2.7 PROGRAMMING.................................................................................................................................18

2.8 MOTORS ..........................................................................................................................................19

3SAFETY.................................................................................................................................................20

3.1 SYMBOL AND NOTE EXPLANATIONS ...................................................................................................20

3.2 SAFETY INFORMATION ......................................................................................................................20

3.3 GENERAL SAFETY INSTRUCTIONS:......................................................................................................21

3.4 ASSEMBLY AND HANDLING ................................................................................................................22

3.5 SAFELY SEPARATED EXTRA-LOW VOLTAGES........................................................................................22

3.6 PROTECTION AGAINST TOUCHING ELECTRICAL PARTS..........................................................................22

3.7 PROTECTION OF DANGEROUS MOVEMENTS..........................................................................................23

4INSTALLATION NOTES.....................................................................................................................24

4.1 PROTECTION METHOD......................................................................................................................24

4.2 ESD PROTECTIVE MEASURES .............................................................................................................24

4.3 MOUNTING .......................................................................................................................................25

4.4 WIRING NOTES..................................................................................................................................29

4.4.1 General ....................................................................................................................................29

4.4.2 Electromagnetic Tolerance.......................................................................................................30

4.4.3 Mains .......................................................................................................................................33

4.4.4 DC-circuit ................................................................................................................................35

5INTERFACES........................................................................................................................................40

5.1 OVERVIEW .......................................................................................................................................40

5.2 X1 AND X2 POWER PARTS ...............................................................................................................41

5.3 X4 INPUTS AND OUTPUTS OF THE POSITIONING LEVEL ......................................................................42

5.4 X5 INPUTS AND OUTPUTS OF THE MOTOR CONTROLLER ...................................................................43

5.5 X6 RESOLVER...................................................................................................................................44

5.6 X7 COM1 AND X8 COM2...............................................................................................................44

5.7 INTERFACES OF THE ADDITIONAL CARDS.............................................................................................45

5.7.1 X12 encoder .............................................................................................................................46

5.7.2 X14 Analog I/O module ............................................................................................................51

5.7.3 Other option modules ...............................................................................................................51

5.8 MOTOR CONNECTOR SB-056...205.....................................................................................................52

5.8.1 Motor .......................................................................................................................................52

5.8.2 Resolver or SINCOS.................................................................................................................52

5.8.3 Brake........................................................................................................................................52

PMC-2 Instruction Manual

Page 4BA * PMC-2 * EN * 01/98

6WIRING OF THE PMC-2 IN THE SYSTEM......................................................................................54

6.1 MAINS AND MOTOR CONNECTION.......................................................................................................54

6.2 THE CONTROL CIRCUIT ......................................................................................................................55

7COMMISSIONING...............................................................................................................................56

7.1 PROCEDURE ......................................................................................................................................56

7.2 LIST OF PARAMETER VARIABLES (P)....................................................................................................58

7.2.1 General parameters..................................................................................................................58

7.2.2 Positioning control parameters.................................................................................................58

7.2.3 Parameter group 2 - speed regulators.......................................................................................59

7.2.4 Parameter group 3 - encoder data............................................................................................59

7.2.5 Parameter group 4 - motor data ...............................................................................................59

7.2.6 Parameter group 5 - setup........................................................................................................60

7.2.7 Parameter group 6 - text for operational unit ...........................................................................60

7.2.8 Parameter group 7 - communication.........................................................................................61

7.3 DIRECT PARAMETER VARIABLES (Y)..................................................................................................61

8DIAGNOSIS AND OPERATION..........................................................................................................62

8.1 IN GENERAL ......................................................................................................................................62

8.2 LEDS AND MONITOR OUTPUTS ...........................................................................................................62

8.3 LIST OF ALL ERRORS ..........................................................................................................................63

8.4 CHART WITH ERROR REACTIONS.........................................................................................................65

8.5 VARIABLES .......................................................................................................................................66

8.5.1 Access protection......................................................................................................................66

8.5.2 Variable types...........................................................................................................................66

8.6 SYSTEM VARIABLES (S)....................................................................................................................67

8.6.1 Not wirable logical system variables.........................................................................................67

8.6.2 Wirable logical system variables ..............................................................................................68

8.6.3 System variables group 2..........................................................................................................68

8.6.4 System variables group 3..........................................................................................................69

8.6.5 System variables group 4..........................................................................................................70

8.6.6 System variables group 5..........................................................................................................71

8.6.7 System variables group 6 - memory module..............................................................................71

8.6.8 System variables group 7 - communication...............................................................................72

8.6.9 System variables group 8 - options ...........................................................................................72

8.6.10 System variables group 9..........................................................................................................72

9MAINTENANCE...................................................................................................................................74

9.1 SPARE PARTS, COMPONENTS ..............................................................................................................74

9.2 REPAIRS............................................................................................................................................75

9.2.1 Service......................................................................................................................................75

9.2.2 Unit exchange...........................................................................................................................76

10 TECHNICAL DATA..........................................................................................................................80

10.1 PMC-2 .............................................................................................................................................80

10.2 COMBINATIONS PMC-2 AND SB-MOTORS ..........................................................................................82

11 APPENDIX.........................................................................................................................................86

11.1 DECLARATION BY THE MANUFACTURER..............................................................................................86

11.2 MODIFICATIONS................................................................................................................................90

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 5

1What is the purpose of this instruction manual?

Structure and contents of this documentation

This instruction manual contains information about the interfaces of the PMC-2, its operation, the

main parameters and a description of available diagnosis messages and system variables.

This instruction is aimed exclusively at technically qualified staff with detailed knowledge in the sector

of automation technology, for only qualified staff have the necessary expertise to interpret and

implement safety instructions correctly.

For the sake of clarity, the instruction manual does not contain all details on all versions of the PMC-2

and cannot cover any feasible case of installation, operation or maintenance. In case of specific

problems not sufficiently explained here, please contact ELAU.

Further Literature:

PMC-2 Product information

German

English

Projecting manual

German Art.Nr. 17 13 00 55 - 000

User documentation

German Art.Nr. 17 13 00 51

English Art.Nr. 17 13 00 52

Italian Art.Nr. 17 13 00 53

Instruction manual PMC-2

German Art.Nr. 17 13 00 54 - 000

English Art.Nr. 17 13 00 54 - 001

Italian Art.Nr. 17 13 00 54 - 002

French Art.Nr. 17 13 00 54 - 003

Spanish Art.Nr. 17 13 00 54 - 004

Instruction manual PMC-2 BASIC Soft

German Art.Nr. 17 13 00 56 - 000

Product training

Naturally we also offer you comprehensive training.

It can be carried out in our offices or, on request, at the customer’s site.

The training is offered in German, English or French language.

The functions of the PMC-2 are explained to the customer not only in theory, but also in practical

exercises.

Further information is available on request.

PMC-2 Instruction Manual

Page 6BA * PMC-2 * EN * 01/98

2The PMC-2 in an overview

The PMC-2 digital positioning motor controller is the cost optimal and complete solution in future-

oriented technology for your positioning and synchro tasks.

2.1 Introduction

Until now a servo positioning has been realized by means of a positioning control and a separate

motor controller.

Now there is the PMC-2, where you will find these two components integrated in one single unit.

The advantages of this conception are as follows:

- no difficulties in adapting positioning control <-> motor controller

- deep system view until down to the motor current via system variables

- one software for positioning and synchro procedures

- one interface for setting parameters and programming of both components

- highly flexible process language

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 7

2.2 Application range

All applications requiring a high dynamic, flexible, and precise positioning of brushless AC servo

motors.

Typical applications are in tact and angle-synchronous machines:

- food and packaging machines

e. g. measurers, foil transport, cut into sections referred to labels, rotating blades

- printing and paper machines

e. g. book binding

- textile machines

e. g. sewing, weaving, thread transfers

- plastics machines

e. g. foil transport, cutting

- hosting engines and mounting techniques

e. g. round tables, pallets, feeding, removing

- special purpose machines

e. g. flying shear, perforating installations

2.3 Performance features

The PMC-2 positioning motor controller provides the following performance features:

•flexible positioning control and digital motor controller in one case

•direct electric mains with integrated mains filter (600 Volt technology)

•T1-operation according to VDI 2853

•dc-circuits of several PMC-2 are parallelly switchable (power compensation)

•completely digital concept

•multiple processor technology (32 bit processor plus VECON chips)

•one programming interface for POS and MC

•unit exchange without PC (Memory Module)

•highly dynamic brushless AC servo motors SB-056...205 in high-voltage technology with

resolver or SINCOS encoder

•extensive cross linkage abilities

•own input and output level (digital and analog I/Os)

•independent operation

•modular extension possibilities via option modules

•connection of absolute or incremental encoders possible

•matured diagnosis

•simple and flexible programming language ECL-3 with multitasking functions

•system variable conception with deep system view until down to the motor current

•realization of positioning and/or synchro functions (electrical gear, disk cam function) with one

software

•sampling rate position controller 0,33 ms

•CE in conformity

PMC-2 Instruction Manual

Page 8BA * PMC-2 * EN * 01/98

2.4 Communication

The PMC-2 positioning motor controller communicates:

- with a PLC via inputs/outputs,

- with a PLC via serial data transfer,

- with operational and display units via serial data transfer

- with the Industrial I/O-Lightbus over option module

- with the INTERBUS-S (Remote bus) over option module

- with the PROFIBUS-DP

2.5 Operation with BE-7

MENU EMENU E ENTERENTER

MAX.. D R EHZAHL

P5 02 3 000

ERROR

QUIT

ERROR

QUITCECE

The PMC-2 can optionally be equipped with the BE-7 operational unit. Only dock the BE-7 via a d-sub

connector. You need the BE-7 for commissioning if you do not a have a PC with EPAS-3 or in

diagnosis cases. German, English, French, Italian and Spanish texts facilitate the dialogue with the

PMC-2.

Access protection

The conception of the PMC-2 includes an access protection mechanism. Parameters and variables

are divided in several access authorisation levels for writing and reading.

Performance features of the BE-7:

- parameter editor

parameters

direct parameters

- variable editor

inputs

outputs

flags

user variables

system variables

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 9

2.5.1 Menu selection

PMC-2 Instruction Manual

Page 10 BA * PMC-2 * EN * 01/98

2.5.2 Key input

The keys cannot be modified in menu "key input“.

„NEW“ means here the entry to another authorisation level, but not the modification of the key.

The keys are set in "General Parameters" P0.18 „Code_Foreman“ and P0.19 „Code_Installer“.

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 11

2.5.3 Status information

/T1: standard operation

T1 set up, LOW-Power-operation active

Operating mode: parameter 1st initialisation

Error1 class 1 error

inactive no enable or class 2 error

-> active dc-circuit tension builds up

active PMC-2 in automatic control, but without operating mode

-> manual dc-circuit tension builds up and manual operation preselected

manual manual operation

-> auto dc-circuit tension builds up and automatic operation

preselected

auto automatic operation

Information: E_Off emergency stop active

Qstop quick stop active

stop start/stop on LOW (in operating mode Auto)

Sstep single step active

stops/moves: stops drive does not move

moves drive moves

ref/nref: ref drive is homed

nref drive is not homed

Diagnosis number: EXXX current diagnosis number

PMC-2 Instruction Manual

Page 12 BA * PMC-2 * EN * 01/98

2.5.4 Variable and parameter menu

After the input of a parameter (Pxxx), the BE-7 will ask you, if you want the modified parameter

record to be transferred to the PMC-2.

A transferred parameter record will only be accepted into the working memory with a positive edge

(LOW -> HIGH) on input "Enable".

All other inputs will be accepted right away.

If an arrow key is pressed longer than 1 second, the auto repeat function will be activated.

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 13

2.5.5 I/Os and flags

Inputs can only be read.

System outputs can only be read.

Programmable outputs can be read and influenced.

Flags can be read and influenced.

2.5.6 Reset keys

With the BE-7 certain behaviour patterns of the PMC-2 can be selected for reset of the PMC-2.

During RESET the BE-7 key must be pressed down.

BE-7 key Function

ERROR QUIT load the default paramter set from ROM

CE after loading the parameter set, P0.26 ”COM1_Application” is changed to

SINEC_L1_S and P0.27 ”COM1_Address” to 1 in RAM.

ENTER prompt no ECL program

PMC-2 Instruction Manual

Page 14 BA * PMC-2 * EN * 01/98

2.6 Operating unit BE-8

2.6.1 Mechanics

BA_BE8.cdr

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 15

2.6.2 Initial operation

Power supply of the BE-8 (article number 13130205) is via the COM1 or COM2 interfaces of the

PMC-2.

Jumper occupation:

J1 J2 J3 J4

free used free not fitted

The serial interface of the BE-8 is connected to the COM1 or COM2 interface of the PMC-2.

(Setting of the serial interface: 9600, N, 8, 1)

Cables for RS 485

Plug PMC-2

D-sub pin

Pin

Plug BE-8

D-sub socket

Pin

1 1

2 2

3 3

4 4

5bridge 5

6pin 5 - 6 6

7 7

8 8

9 9

10 10

11 11

12 12

13 13

14 14

15 15

CAUTION If the BE-8 is served by the COM2 interface pin 14 and pin 15, the cables

should have a minimum diameter of 0.25 mm2.

Note:

The screen is unilaterally linked to the control by the plug casing.

CAUTION The BE-8 should be connected to the PMC-2 only in tension-free state.

To activate the BE-8, the parameter P0.21 COM2_application or P0.26 COM1_application must be

set to BE-8.

Note:

•Changes in the parameter P0.21 (or P0.26) are not taken over until after RESET at the PMC-2.

•If BE-8 was selected in the parameter P0.21 (or P0.26), also the PMC-2 expects that a BE-8 is

connected. Otherwise the warning E587 ”BE-Timeout” is triggered.

•If you still get no display in the BE-8, you have probably not yet defined any variables (parameter

group 6 -> see 2.6.3 Variable menu).

PMC-2 Instruction Manual

Page 16 BA * PMC-2 * EN * 01/98

2.6.3 Variable menu

20 V variables (V0 to V19) can be edited with EPAS-3. Display text, lower limit, upper limit and format

are set in parameter group 6.

•The variables must be inputted in a row with no gap, because all following variables after format

0.0 are ignored.

•If the input is to be blocked, the lower limit must be higher than the upper limit.

•Variables are not taken over until format contains a number > 0.0.

•If a variable is inserted or deleted, it is not taken over until after RESET at the PMC-2.

•If the display text, a limit or the format of an existing variable is changed, this is taken over after

enable LOW -> HIGH (standard parameter takeover).

Example:

Parameter Variable Display text Lower limit Upper limit Format

P 6.00 V0000 Velocity 0100 3.0

P 6.01 V0001 Laying width 010000 5.3

P 6.02 V0002 000.0

P 6.03 V0003 000.0

P 6.04 V0004 000.0

P 6.05 V0005 000.0

P 6.06 V0006 000.0

P 6.07 V0007 000.0

P 6.08 V0008 000.0

P 6.09 V0009 000.0

P 6.10 V0010 000.0

P 6.11 V0011 000.0

P 6.12 V0012 000.0

P 6.13 V0013 000.0

P 6.14 V0014 000.0

P 6.15 V0015 000.0

P 6.16 V0016 000.0

P 6.17 V0017 000.0

P 6.18 V0018 000.0

P 6.19 V0019 000.0

Note:

Format 5.3 means that the number has altogether 5 digits, of which 3 after the decimal point.

Laying width 3.200

Velocity 20

•Working line is the lower line.

•The variable value is flashing.

Note:

In case of large number formats and long texts, it may happen that the number overwrites the

variable text from the right end.

CAUTION

If the number to be displayed is larger than the format set, the highest digits

are displayed.

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 17

•select next-lower variable

•cancel input (old value is retained)

•select next-higher variable

•cancel input (old value is retained)

•deletes the last digit as long as the input is not completed

•takes over the inputted value

•quits an error in the PMC-2

•prepare input (variable value is set to 0)

•no function yet

•no function yet

CE

ENTER

ERROR

QUIT

MENUE

F2

F1

PMC-2 Instruction Manual

Page 18 BA * PMC-2 * EN * 01/98

2.7 Programming

EPAS-3 is responsible for the programming of the PMC-2.

Tailor-made installations are realised with the ECL-ELAU Control Language, which has been

successfully used many times in the positioning controls SX-1, SX-2, and SX-3.

ECL-3, for the product family PMC-2, gives the user a powerful tool due to its multitasking

capabilities. The compiled ECL-3 program is activated by the ECL runtime system. Up to 8 parallel

ECL program parts can be executed at the same time.

For example, one ECL program part takes care of the positioning jobs, whereas a second part

concentrates on monitoring functions. Due to the fact that the ECL program is filed in machine code

of the micro processor, a high processing speed can be achieved.

The division in single instructions and half textual language elements facilitate the structure of easy-

to-survey and easily readable programs.

The ECL-3 offers a comprehensive range of commands:

- program organisation commands

- relative and absolute positioning commands

- synchro positionings (electrical gear, disk cam)

- label positionings

- variable transfer commands

- time commands

- logic and arithmetic commands

The program is created with a menu-guided programming surface on an IBM compatible PC with

EPAS-3.

Performance features of EPAS-3:

-pull down menus according to SAA standard

- mouse or keyboard operation

- ECL-3 editor with syntax check

- parameter editor

- variable editor

- filing

- printing

- window system

Instruction Manual PMC-2

BA * PMC-2 * EN * 01/98 Page 19

2.8 Motors

Since ELAU defines itself as a system supplier, it includes high dynamic brushless servo motors SB-

056...205 to its range of products.

Performance features of the servo motors:

- torque range from 0,5 to 90 Nm

- Fe Nd B magnets for high temperatures

- resolver feedback; optionally absolute or incremental encoder

- sinusoidal EMK

- high voltage technology = low currents

- low mass moment of inertia

- high durability

- system of protection IP 64

- high overload capability; fivefold peak torque

- with brake, separate fan or gear available

- motor connection and feedback system via connector.

The range of motors provides 5 lines:

SB-056

SB-070

SB-105

SB-145

SB-205

The abbreviation SB stands for Servomotor Brushless, the numbers represent the flange dimensions.

There are several torque graduations for each line each providing, in addition to this, different

nominal speeds.

The torque graduations in Nm:

SB-056 0.6

SB-070 0.5 11.5 2

SB-105 2468

SB-145 8 15 22 28

SB-205 27 50 70 90

The speed graduations in RPM:

SB-056 5000

SB-070 4000 6000

SB-105 2000 3000 4000

SB-145 2000 3000 4000

SB-205 1000 2000 3000

PMC-2 Instruction Manual

Page 20 BA * PMC-2 * EN * 01/98

3Safety

3.1 Symbol and note explanations

Safety symbol

You will find this symbol with all safety instructions in this

instruction manual which could be a danger to life and limb of

persons. Therefore observe these notes thoroughly and act

extremely carefully in those cases. Please pass these safety

instructions also to other users.

Caution notes You will find this "Caution" signal in this instruction manual where

you should comply with the directions, instructions, notes and the

right course of works as well as where you should avoid a damage

or destruction of the equipment.

3.2 Safety information

for electrical equipment of machines for the machine manufacturer.

The machine manufacturer has to undertake a danger, error and risk analysis on the specific

conditions of his machine and - with consideration to the effective safety instructions - to watch the

corresponding safety installations and measures.

The safety is guaranteed, if uncontrolled movements can be avoided from the standstill and during

controlled move of the drive.

The safety arrangements have to be done in a way that no dangerous status could arise in case of an

error.

What the safety for persons is concerned this can be achieved, if it is made sure that no person can

enter or catch hold of the danger area of the station during its operation (passive protection with

access locks, safety fences,...).

The following rules, directions, and instructions are to be observed:

•VDE-0113 part 1

•EN 292 part 1 and part 2

•universally valid regulations for prevention of accidents

•Initial operation must not begin until it has been proven that the machine where the products are

built in complies with the EU directive 89/336/EEC (machine directive).

•Operation is allowed only if national rules on electromagnetic tolerance for the respective

application are adhered to. In the EU the valid directive is 89/336/EEC.

•DIN EN 50178 on equipment of high-voltage systems with electronic operating means

CAUTION

This manual suits for next models

6

Table of contents

Popular Controllers manuals by other brands

MecVel

MecVel ALI4 Use and maintenance handbook

MarelliMotori

MarelliMotori M40FA640A/A Mark I user manual

Ribimex

Ribimex Ribiland PRPCTRL11 User and maintenance manual

blossom-ic

blossom-ic Magelan ZR-3997 Assembly instructions

GEM

GEM 1242PTAZ Assembly instructions

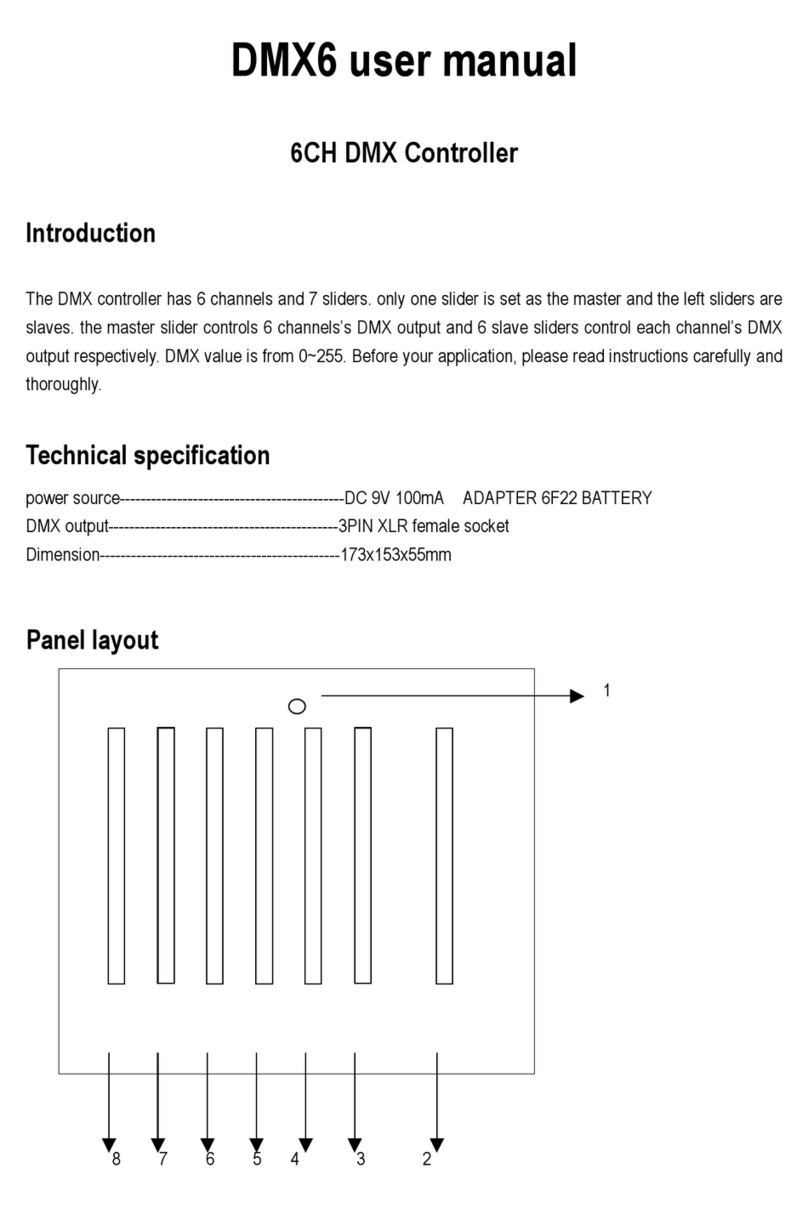

mbt Lighting

mbt Lighting DMX6 user manual