Elcometer Protovale 120 User manual

English

Elcometer Protovale 120

Rebar Locator

Operating Instructions

DISCONTINUED

English

R

This product meets the emc directive 89/336/EEC, amended 92/31/EEC and 93/38/EEC. The

Elcometer Protovale 120 Rebar Locator has been tested in accordance with EU regulations

governing Electromagnetic Compliance and it meets the required directives.

Note: Performance may be affected if the unit is operated within a radio frequency electromagnetic field

strength greater than 3V/m.

and Protovale are registered trademarks of Elcometer Limited.

All other trademarks acknowledged.

© Elcometer Limited. England. 2009.

All rights reserved. No part of this document may be reproduced, transmitted, transcribed, stored (in a retrieval

system or otherwise) or translated into any other language in any form or by means (electronic, mechanical,

magnetic, optical, manual or otherwise) without the prior written permission of Elcometer Limited.

A copy of this Instruction Manual is available for download on our Website via www.elcometer.com/

downloads.

Doc. No:TMA-0277 Iss. 03

Part No: 18550

DISCONTINUED

R

1

CONTENTS

Section Page

1 About your Rebar Locator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Getting started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Using the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Measuring depth of cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Trouble shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Spare parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 Related equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DISCONTINUED

R

2

Thank you for your purchase of this Elcometer Protovale 120 Rebar Locator. Welcome to Elcometer.

Elcometer are world leaders in the design, manufacture and supply of inspection equipment for concrete

and coatings.

Our concrete inspection products include a comprehensive range of concrete, and civil engineering

inspection equipment. Our coatings products cover all aspects of coating inspection, from development

through application to post application inspection.

The Elcometer Protovale 120 Rebar Locator is a world beating product. With the purchase of this instrument

you now have access to the worldwide service and support network of Elcometer. For more information visit

our website at www.elcometer.com

1 ABOUT YOUR REBAR LOCATOR

The Elcometer Protovale 120 Rebar Locator is a handheld instrument for fast and accurate location and

orientation of concrete reinforcement bars.

1.1 WHAT THE BOX CONTAINS

• Elcometer Protovale 120 Rebar Locator

• Search head

• 4 x LR6 (AA) alkaline batteries

• Leather carry case

• Operating instructions

The instrument is packed in a cardboard and foam package. Please ensure that this packaging is disposed

of in an environmentally sensitive manner. Consult your local Environmental Authority for further guidance.

DISCONTINUED

R

3

To maximise the benefits of your new instrument, please take some time to read these Operating

Instructions. Do not hesitate to contact Elcometer or your Elcometer supplier if you have any

questions.

2 GETTING STARTED

2.1 FITTING BATTERIES

The Elcometer Protovale 120 Rebar Locator uses dry cell batteries only. Sealed alkaline batteries are

recommended however rechargeable equivalents may also be used.

4 x LR6 (AA) alkaline batteries are supplied in the kit.

To fit or replace the batteries:

1. Remove the instrument from the carrying case.

2. Remove the battery compartment cover.

3. Fit the batteries taking care to ensure correct polarity.

4. Replace the battery compartment cover.

5. Replace the instrument in the carrying case ensuring that the speaker output grille lines up with the

hole in the case.

Note: Remove the batteries from the instrument if it is to remain unused for a long period of time. This will

prevent damage to the instrument in the event of malfunction of the batteries.

Note: Alkaline batteries must be disposed of carefully to avoid environmental contamination. Please consult

your local Environmental Authority for information on disposal in your region.

Do not dispose of any batteries in fire.

DISCONTINUED

R

4

2.2 CONNECTING THE SEARCH HEAD

Screw the TNC plug of the search head

into the socket marked ‘head’ on the front

panel of the control unit, taking care not to

cross the threads.

2.3 SWITCHING ON/OFF

Switch the machine on by turning the

ZERO SET rotary control clockwise from

the OFF position until it just clicks on.

The machine is now working, and set to

minimum sensitivity.

2.4 BATTERY TEST

Press the left-hand switch down to the (spring-loaded) “BATT” position. If the meter needle is within (or

above) the green diamond on the black % scale, the batteries are OK. If the needle is below (reading less

than 70 on the black % scale), the batteries should be replaced - see “Fitting batteries” on page 3.

When the switch is released, it returns to the central “LOW” position.

2.5 DEPTH RANGE

The other two positions of the left-hand switch select “LOW” or “HIGH” depth range:

• The LOW position is for shallow to normal depths of cover, and is adequate for the majority of

situations.

12--20mmO

DISCONTINUED

R

5

• The HIGH position extends the depth range, and will only be required when locating particularly deep

bars, and should not be used if the cover is less than 60 mm (2½").

Note: Whenever the depth range is changed, it will be necessary to re-adjust the ZERO SET rotary control

- see “Sensitivity adjustment” on page 5.

2.6 AUDIBLE SIGNAL

The right hand switch is used to turn the built-in loudspeaker either on (AUDIO position) or off (MUTE

position).

If headphones are required, they should be plugged into the 3.5 mm mono jack socket labelled PHONES.

This signal is not affected by the audio switch.

2.7 SENSITIVITY ADJUSTMENT

If the ZERO SET rotary control is turned slowly clockwise (with the search head well clear of any metal), a

point is reached when the sound produced (if AUDIO on) is a steady ticking, and the meter is close to the

ZERO mark. Further clockwise rotation will cause the meter to deflect to the right, and the sound to increase

in frequency through a buzz to a whine. Maximum sensitivity is achieved when the sound is set to a low

tickover, and is appropriate when searching for deeply embedded bars. More often however, this setting

gives more sensitivity than is necessary or desirable, and the ZERO SET rotary control can and should then

be turned back as required.

Note: The needle must be brought to the ZERO mark before using the Elcometer Protovale 120 Rebar

Locator to indicate the depth of cover - see “Measuring depth of cover” on page 12.

DISCONTINUED

R

6

2.8 SEARCH HEAD ORIENTATION

Despite having a circular face, the search head is in fact

directional and has a sensitive axis running across the face

parallel to the line of the handle.

The relative orientation of this axis to the line of the rebar

affects the signal strength, and it is by this means that the

direction of a rebar can be determined, and complex structures

resolved.

3 USING THE INSTRUMENT

The best way to learn how to use your Elcometer Protovale 120 Rebar Locator is to practise on situations

where the position and direction of the rebar are known (or visible). Start with the simple case of a single

rebar, and then move up in stages through parallel bars, crossed bars; and finally the special case of welded

fabric (which responds differently). Note that since the machine is not affected in any way by the concrete

itself, experience gained on bars measured "in air" will be just as applicable to bars in concrete.

In all cases, start on the LOW range, and only use HIGH if it is definitely necessary.

3.1 SINGLE BARS

Hold the search head with the line of the handle parallel to the bar, and scan across sideways. If the

machine had been set to maximum sensitivity, a very strong signal will be produced at all typical distances.

If the sensitivity is progressively reduced, the "width" of the signal will become narrower, and it will become

apparent that the maximum signal occurs when the search head is exactly over the bar. The exact position

max

min

DISCONTINUED

R

7

of the bar can also be found by moving the search head in, first from one side and then the other, and noting

in each case where the signal starts; the bar then lies exactly midway between these two points.

If the search head is now rotated whilst being held at a constant distance from the bar, the largest signal

will be given when the handle is parallel to the bar, but little or no signal when at right angles.

This direction-finding feature will be used in all situations.

3.2 PARALLEL BARS

As with a single bar, the handle of the search head should be aligned

with the bars, and the search head scanned across the bars. At

maximum sensitivity, a strong signal may well be produced

everywhere, but as the sensitivity is progressively reduced, the signal

will drop to a minimum when the search head is halfway between

bars. Unless the search head is very close to the bars, further

reduction in sensitivity will produce a "null" of silence between the

bars, and a maximum when the search head is exactly over a bar. In

this way, the centres of the spaces between the bars can be located

just as accurately as the bars themselves.

Note: If the search head is turned through 90 degrees so that the line

of the handle is at right angles to the bars, the signal will be much

weaker and the resolution reduced - so do not use this orientation in normal operation.

DISCONTINUED

R

8

3.3 CROSSED BARS

This refers to the common structure of one set of parallel bars running

vertically, and a second set running horizontally but not touching the

first set.

First map out the horizontal bars by holding the search head with the

handle horizontal, and scanning vertically along lines which run

between the vertical bars. When the sensitivity is reduced as

necessary, the horizontal bars will be resolved exactly as in the

previous example of parallel bars. Still keeping the handle horizontal,

repeat the vertical traverses, but try moving the search head vertically

up and down as well; it will be found the horizontal bars are clearly

resolved, regardless of whether the search head is also over a vertical

bar or not.

Now turn the search head so the handle is vertical, and scan horizontally. This time the vertical bars (and

the spaces between them) are clearly indicated, whilst the horizontal bars are largely ignored. (Note that if

the vertical bars are significantly different from the horizontal bars in either size or distance, the optimum

setting of the ZERO SET rotary control may also be slightly different).

To sum up: the maximum signal occurs when the search head is over a bar and aligned parallel to it; a

minimum (or null) signal occurs when the search head is in the centre of the space between bars, whatever

the alignment (at the crossing-points, a signal is obtained from each bar).

DISCONTINUED

R

9

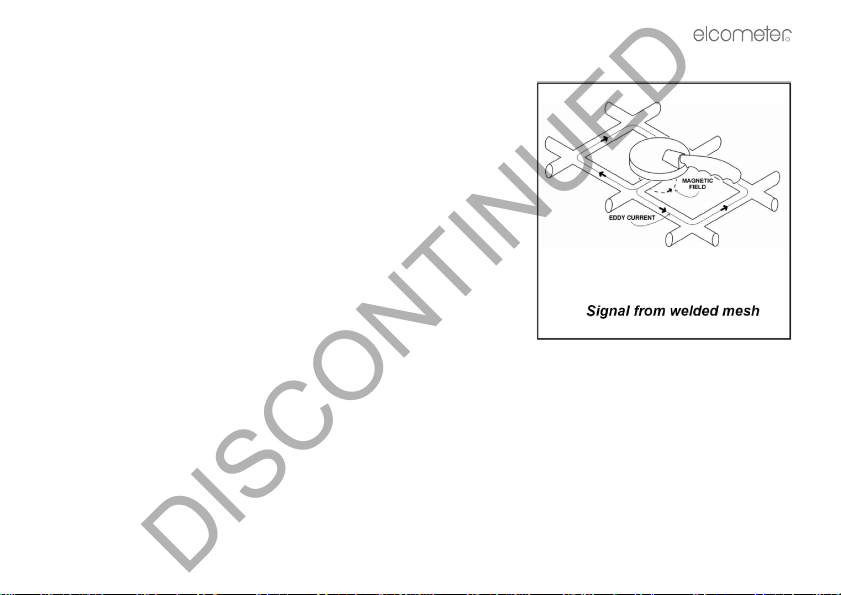

3.4 WELDED MESH FABRIC

This refers to a structure like the previous case of crossed bars, but

where the bars are joined at each crossing-point and therefore in

electrical contact.

This means that every space is now surrounded by a "picture frame"

which represents a continuous electrical path, and this results in an

additional response which did not occur in any of the previous

examples.

As with the previous examples, it will be necessary to reduce the

sensitivity somewhat otherwise the machine may signal

continuously.

As with the case of crossed bars, little or no signal is given when the

search head is in the centre of a space between four bars (assuming

that the sensitivity is reduced sufficiently). A signal is certainly given

when the search head is over a bar and aligned parallel to it, but this

is not the maximum signal.

If the search head is held with the handle vertical, and scanned vertically between vertical bars, the

maximum signal occurs every time the search head is over a horizontal bar. Similarly, with the handle

horizontal, scanning sideways between the horizontal bars gives the maximum signal at each vertical bar.

DISCONTINUED

R

10

To sum up: the maximum signal occurs when the search head is over a bar and the handle is at right angles

to the bar; a minimum or null signal occurs when the search head is in the centre of a space between bars,

at any orientation.

Maximum signal Medium signal Minimum signal

DISCONTINUED

R

11

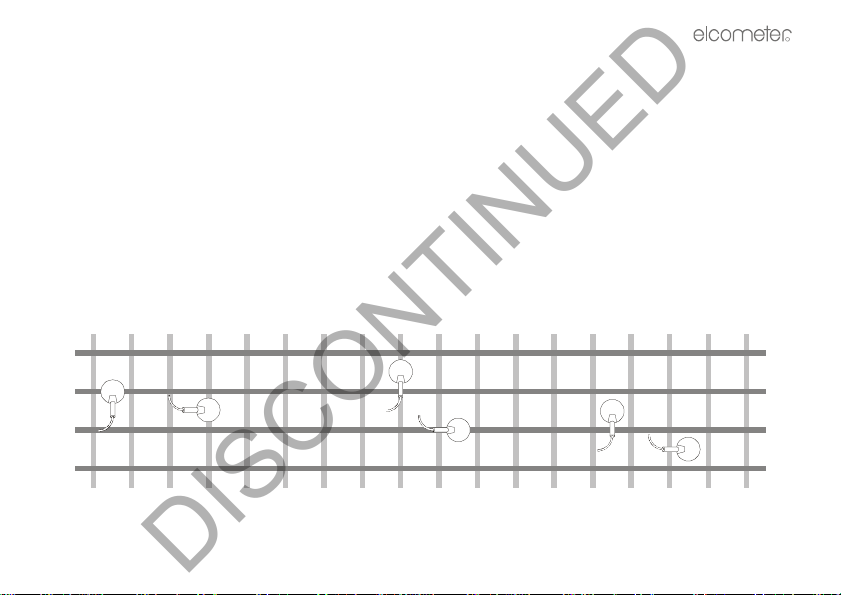

3.5 LOOSELY-JOINED FABRIC

When crossed bars are joined by wires or stirrups, it may not always be obvious whether the bars are in

good electrical contact or not, and so may or may not behave as welded mesh (though it usually behaves

like separated crossing bars).

Under these circumstances, remember that the minimum signal always occurs in the centre of the space

between bars, regardless of the nature of the fabric structure and the orientation of the search head.

The recommended procedure therefore is to first map out these spaces. If the aim was to find "safe spots"

for drilling, the object will then have been achieved.

Having found all the spaces, the bars must now be between these spaces, and so the bar locations are now

determined. Investigation of the behaviour of the signal (and the effect of search head orientation) over the

bar positions will now reveal the nature of the structure itself.

Maximum signalMedium signal Minimum signal

DISCONTINUED

R

12

4 MEASURING DEPTH OF COVER

The Elcometer Protovale 120 Rebar Locator can also be used to estimate depth of cover over bars of

between 12 mm and 20 mm diameter. The range switch and the ZERO SET rotary control now have a more

precise significance:

• the LOW range selects covers from 1 cm to 8 cm (10 mm to 80 mm)

• the HIGH range selects 5 cm to 14 cm (50 mm to 140 mm)

• the ZERO SET rotary control is used to bring the needle to the ZERO mark before taking a

measurement.

4.1 PROCEDURE

1. Use the instrument to determine the location and orientation of the reinforcing bars.

2. When the location and orientation of the reinforcing bars is known, select the appropriate depth range.

The depth range will probably be the LOW position. If in any doubt, always try LOW range first.

3. Hold the search head away from metal and bring the meter needle to the ZERO mark using the ZERO

SET rotary control.

4. Position the head on the concrete surface so that it is:

• exactly over the bar to be measured

• exactly parallel to the bar

• and not over any transverse bars.

The cover in cm can now be read from the appropriate scale (for the LOW range, use the middle blue scale;

for the HIGH range, use the upper red scale); note that these scales read from right to left. The scales have

DISCONTINUED

R

13

divisions every half-centimetre (5 mm) up to 6 cm on the LOW range and up to 8 cm on the HIGH range,

and every centimetre thereafter.

The black 0-100 scale at the bottom can be used to compare signal strengths, or for preparing calibration

curves for bar sizes outside the 12 mm to 20 mm range (see “Bar size” below).

4.2 PRECAUTIONS WHEN MEASURING COVER

BATTERY VOLTAGE

The Elcometer Protovale 120 Rebar Locator is calibrated for a battery voltage corresponding to a BATT test

indication in the middle of the green diamond. This voltage corresponds to a battery halfway through its

usable life, and so yields adequate accuracy during most of the battery life. A brand new set of batteries

which, on BATT test, indicate to the right of the green diamond will, on cover measurement, indicate to the

right of the true cover, and therefore read low by up to about 5 mm. Similarly a nearly-exhausted battery

which reads to the left of the diamond on BATT test, will read to the left of the true cover, ie. high by up to

5 mm.

BAR SIZE

The Elcometer Protovale 120 Rebar Locator is calibrated for a bar of 16 mm diameter, and this calibration

also adequately suits the adjacent sizes of 12 mm and 20 mm. For bar sizes outside this range, the

Elcometer Protovale 120 Rebar Locator will overestimate the depth of smaller bars, and underestimate the

depth of larger bars. For example, at nominal battery voltage, a 10 mm bar will read high by 3 mm to 4 mm

on the LOW range and by 5 mm to 7 mm on the HIGH range; a 25 mm bar will read low by about 4 mm at

shallow covers or about 10% when deeper. If measurement of cover over bars outside the 12 mm to 20 mm

diameter range is a regular requirement, a calibration chart could be drawn up, using the linear 0 to 100%

DISCONTINUED

R

14

black scale on the meter; any such user-calibration should bear in mind the effect of battery voltage

described in the section above.

ADJACENT BARS

Over a structure of parallel bars, the cover indication will only be reliable if the spacing of the bars is greater

than their depth of cover; as the spacing reduces, so the Elcometer Protovale 120 Rebar Locator will read

progressively low. Transverse bars near the point of measurement may also cause the meter to read low,

and so the point of measurement should be chosen with care.

WELDED MESH

As explained earlier under the instructions for bar location, welded mesh generates an additional signal

when the head is over, but at right angles to, a bar, and this signal must not be used for cover estimation.

Therefore, not only is it important to ensure that the head is accurately over and parallel to the bar to be

measured, it must also be well away from transverse bars. In general, no reliance should be placed upon a

cover measurement over welded mesh, unless the spacing of bars parallel to the bar under measurement

is significantly greater than the depth, and the spacing of bars transverse to it is at least twice the depth;

and even then, the result should be interpreted as a lower limit, not an upper limit.

CONGESTED AREAS

It will be seen from the preceding sections that the effect of bar congestion is to cause the Elcometer

Protovale 120 Rebar Locator to read low when estimating cover. Therefore if the indicated cover is equal

to or greater than the minimum cover specified for the concrete structure, it may in general be assumed that

DISCONTINUED

R

15

the cover is indeed adequate, as long as any effects due to either low battery voltage or small diameter bars

have been allowed for.

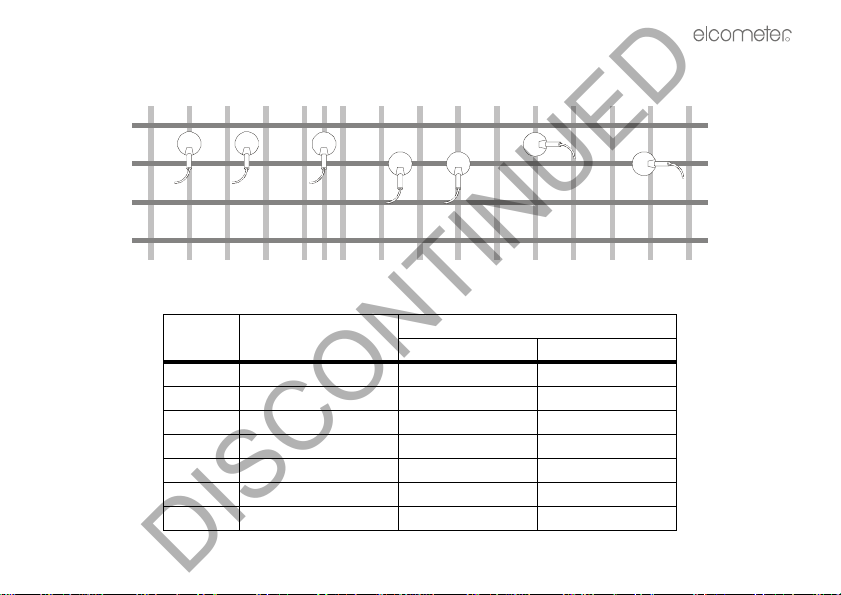

Table 1: Effects of congestion upon cover readings

Location Description Effect upon cover reading

Unconnected bars Welded mesh fabric

A Correct correct correct

B Not over bar very high high

C Close parallel bars slightly low low

D Not parallel to bar very high very low

E Over transverse bar slightly low very low

F Not parallel to bar very high very low

G Close to transverse bar low low

A B C D E FG

DISCONTINUED

R

16

5 TROUBLE SHOOTING

Any fault conditions encountered can usually be cleared by checking:

• the battery voltage and cell polarity

• the battery contacts for spring tension and corrosion

• the search head plug and socket for good electrical and mechanical connection.

6 MAINTENANCE

The Elcometer Protovale 120 Rebar Locator is designed to give many years reliable service under normal

operating and storage conditions.

No special maintenance is necessary, though the unit should be wiped clean of dirt and moisture after use.

Two points in particular will ensure long-term trouble free operation:

• To prevent damage to the coil plug and socket, keep the threads clean and free from mud and grit.

• To prevent corrosion damage from leaking batteries: make sure the unit is switched OFF after use; and

remove the batteries if the unit is to be stored unused for any period of time.

The instrument does not contain any user-serviceable components. In the unlikely event of a fault, the

instrument should be returned to your local Elcometer supplier or directly to Elcometer. The warranty will be

invalidated if the instrument has been opened. Contact details can be found on the outside cover of these

instructions, or on the Elcometer website, www.elcometer.com

DISCONTINUED

R

17

7 SPARE PARTS AND ACCESSORIES

The following replacement and optional items are available from Elcometer or your local supplier.

8 RELATED EQUIPMENT

Elcometer produces a wide range of concrete and coatings inspection equipment. Users of the Elcometer

Protovale 120 Rebar Locator may also benefit from the following Elcometer products:

• Elcometer Adhesion and Bond Strength Testers

• Elcometer Concrete Crack Microscopes

• Elcometer Concrete Moisture Meters

• Elcometer Concrete Test Hammers

• Elcometer Concrete Covermeters

For further information contact Elcometer, your Elcometer supplier or visit www.elcometer.com

Description Sales Part No.

100 mm (4") Directional Search Coil for Rebar TW999198F

150 mm (6") Extra-Depth Directional Search Coil TW999198E

DISCONTINUED

Table of contents