Elcometer 5300 User manual

English

Elcometer 5300

Ball Type Drying Time Recorder

Operating Instructions

5300_TMA_0332_00_03 A5.fm Page -1 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

English

The Elcometer 5300 Ball Type Drying Time Recorder has been

tested in accordance with EU regulations governing Electro-

magnetic compliance and it meets the required directives.

is a registered trademark of Elcometer Instruments Ltd.

All other trademarks acknowledged.

© Copyright Elcometer Instruments Ltd. 2005 - 2007.

All rights reserved. No part of this Document may be reproduced, transmitted,

transcribed, stored (in a retrieval system or otherwise) or translated into any

language, in any form or by any means (electronic, mechanical, magnetic,

optical, manual or otherwise) without the prior written permission of

Elcometer Instruments Ltd.

A copy of this Instruction Manual is available for download on our Website via

www.elcometer.com/downloads.

Doc.No. TMA-0332 Issue 03

Text with Cover No: 19497

5300_TMA_0332_00_03 A5.fm Page 0 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

1

CONTENTS

Section Page

1 About your Drying Time Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 What the box contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 The parts of the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 The controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Testing a specimen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Specimen trace analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Related equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5300_TMA_0332_00_03 A5.fm Page 1 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

2

hank you for purchasing this Elcometer 5300 Ball Type Drying Time

Recorder. Welcome to Elcometer.

Elcometer are world leaders in the design, manufacture and supply of

inspection equipment for coatings and concrete. Our products cover all aspects

of coating inspection, from development through application to post application

inspection.

Your Elcometer 5300 Ball Type Drying Time Recorder, is a world beating

product. With the purchase of this product you now have access to the

worldwide service and support network of Elcometer. For more information visit

our website at www.elcometer.com

1 ABOUT YOUR DRYING TIME RECORDER

The Elcometer 5300 Ball Type Drying Time Recorder is used to determine the

drying time of paint and other coatings such as glue, cosmetic products,

varnish, inks, biologic material and adhesives.

A layer of the coating is applied to a glass surface and a stainless steel ball is

dragged across the glass as the coating dries. At the end of the test the Drying

Time Recorder stops automatically and the imprint of the ball on the coating

surface is examined to determine the point at which the coating dries.

The Elcometer 5300 Ball Type Drying Time Recorder has ten separate lanes

which allow ten different coating formulations to be tested simultaneously.

The load on each ball is 11 g, however this can be increased to 21 g using the

supplied weights.

1.1 What the box contains

• Elcometer 5300 Ball Type Drying Time Recorder

• 12 glass strips

• 10 x 10 g weights

• Operating instructions

Your Elcometer 5300 Ball Type Drying Time Recorder is packed in a cardboard

and foam package. Please ensure that this packaging is disposed of in an

environmentally sensitive manner. Consult your local Environmental Authority

for further guidance.

To maximise the benefits of your new Elcometer 5300 Ball Type Drying Time

Recorder please take some time to read these Operating Instructions. Do

not hesitate to contact Elcometer or your Elcometer supplier if you have

any questions.

T

5300_TMA_0332_00_03 A5.fm Page 2 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

3

2 GETTING STARTED

This section of the instructions is intended for first-time users of the Elcometer

5300 Ball Type Drying Time Recorder. It contains information on the parts and

controls of the instrument and advice on safe use of the equipment. When you

have finished reading this section you will be ready to start using your

Elcometer 5300 Ball Type Drying Time Recorder.

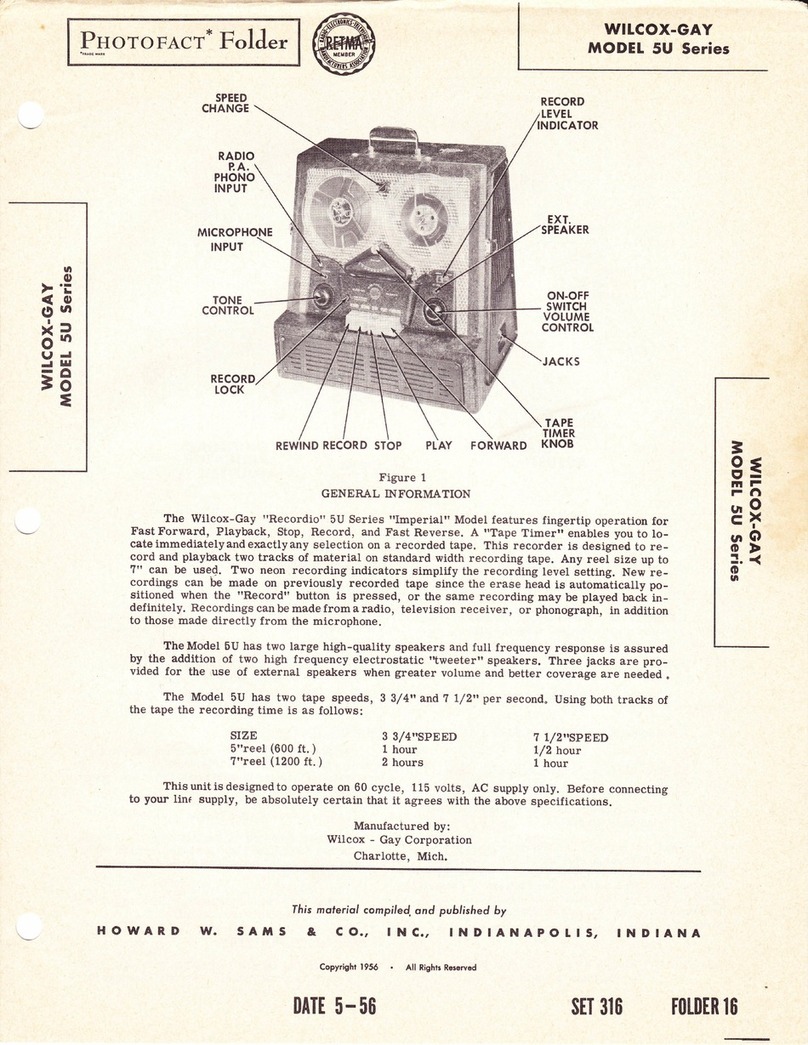

2.1 The parts of the instrument

Figure 1. Parts of the Elcometer 5300 Ball Type Drying Time Recorder

2.2 The controls

The controls of the instrument are very simple.

2.2.1 Power on/off

To switch the instrument on or off, press the power on/off switch at the rear of

the instrument.

Carriage

Carriage start/stop button

Carriage speed selector

Drive coupling knob

Power

on/off

switch

5300_TMA_0332_00_03 A5.fm Page 3 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

4

2.2.2 Carriage start/stop

To start the carriage, press the carriage start/stop button. The carriage will stop

automatically when it reaches the end of the test.

2.2.3 Carriage speed

Your instrument has six carriage speeds which are selected by rotating the

carriage speed selector on the left side of the machine.

2.2.4 Moving the carriage

To move the carriage to the start position (or any other position), disconnect the

carriage from the drive mechanism by rotating the drive coupling knob

clockwise. When the carriage is uncoupled, the carriage can be pushed by hand

to any position. Rotate the drive coupling knob anticlockwise to reconnect the

carriage to the drive mechanism.

2.3 Caution

The Elcometer 5300 Ball Type Drying Time Recorder has been manufactured

with your safety in mind. However, improper use can result in damage to the

machine.

Please observe the precautions discussed in these operating instructions.

To reduce the risk of electric shock, do not open the housing of the

Drying Time Recorder. There are no user-serviceable parts inside.

To reduce the risk of fire or electric shock, do not expose the Drying

Time Recorder to rain or excess moisture.

The mains plug on your Drying Time Recorder may be fitted with a fuse. When

replacing this fuse, ensure a fuse of the correct rating is used.

Carriage speed

selector position

Carriage speed

(cm per hour)

1 1.2

2 3

3 6

4 12

5 30

6 60

5300_TMA_0332_00_03 A5.fm Page 4 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

5

3 TESTING A SPECIMEN

1. Connect the Drying Time Recorder to the mains supply.

2. Switch on the instrument.

3. Adjust the height of each ball so that it is perpendicular to the glass

specimen and then tighten the thumb screw. In this position the tool

provides a load of 11 g ± 1.5 g. Do the same for all 10 balls.

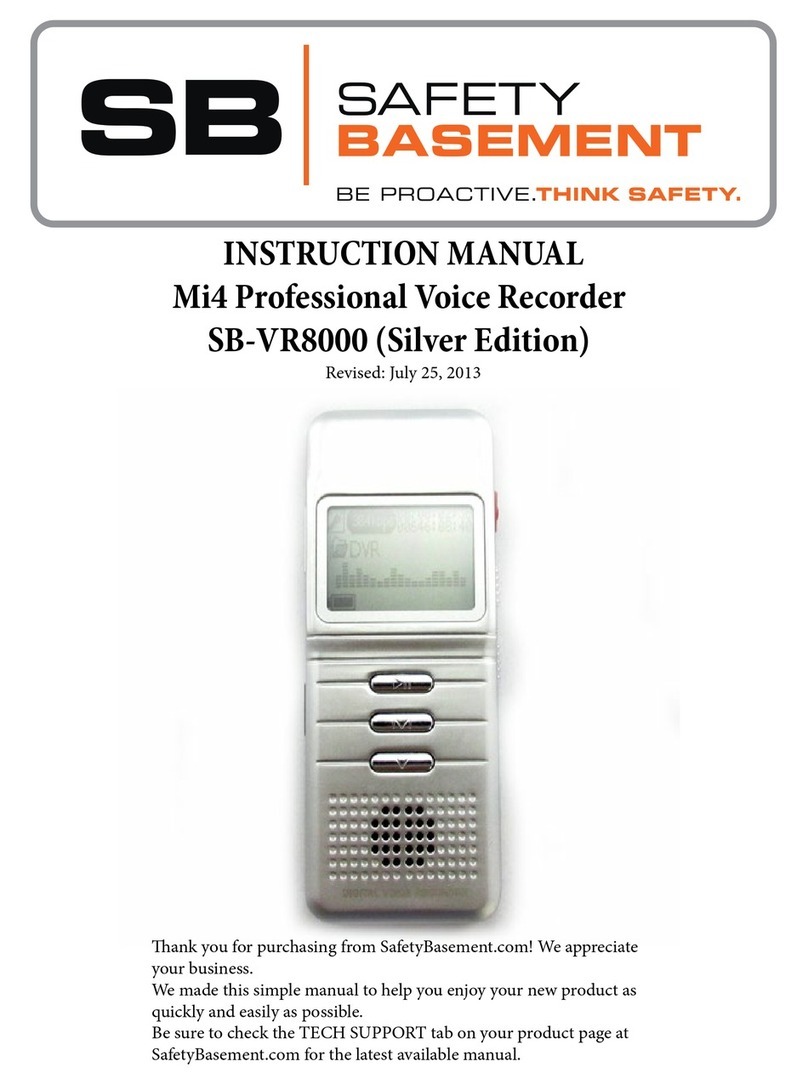

4. Apply the coating to the glass plates using an Elcometer 3505 Cube Film

Applicatora(Figure 2).

Figure 2. Applying the coating using an Elcometer 3505

5. Place the glass plates on the instrument.

6. Rotate the drive coupling knob clockwise and push the carriage to the 0

(start) position. Rotate the drive coupling knob anti-clockwise to connect the

carriage to the drive mechanism.

a. To order an Elcometer 3505 Cube Film Applicator, see “Accessories” on page 9.

5300_TMA_0332_00_03 A5.fm Page 5 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

6

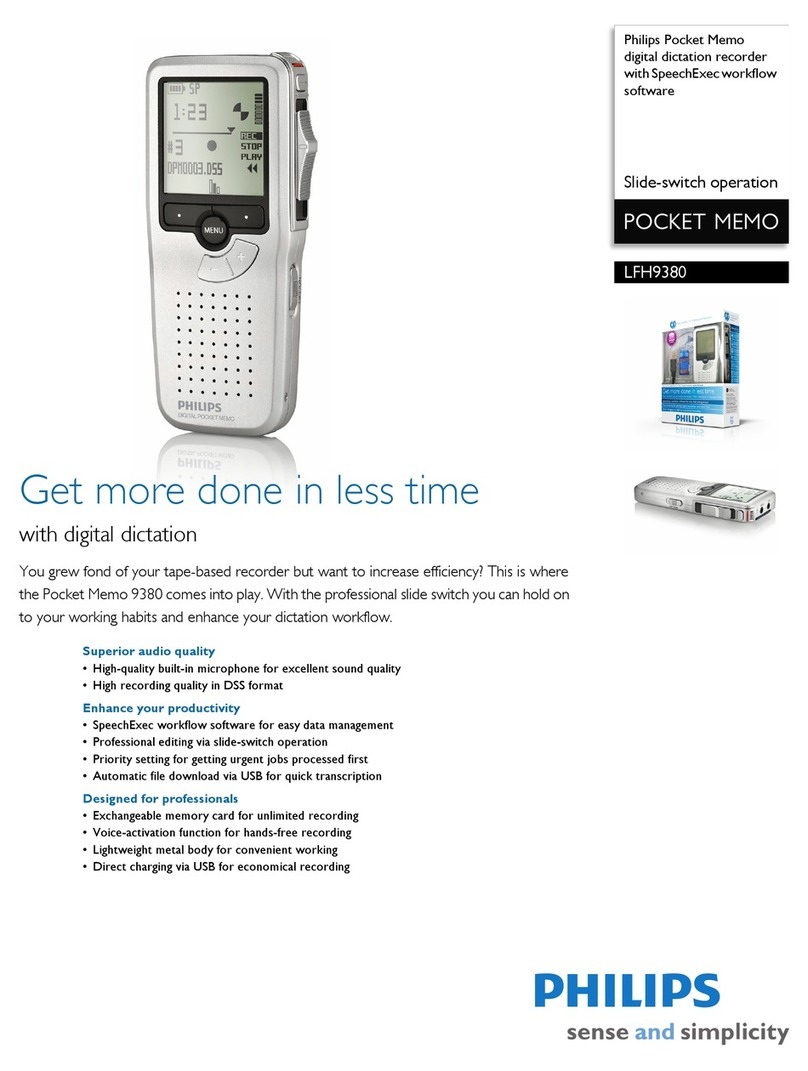

7. Rotate all the balls down onto the specimens (Figure 3).

Figure 3. Rotate the balls down onto the specimens

8. If necessary, add the 10 g weights to increase the load.

9. Set the carriage speed using the carriage speed selector.

10.Press the carriage stop/start button.

The carriage will travel along the length of the specimens and will stop

automatically at the end of its travel.

11.At the end of the test, rotate the balls away from the specimens.

12.Using the guidelines given in the test standardb, examine the specimens to

determine the position on the trace where the coating dried. By moving the

carriage to this position, the distance can be read from the graduated scale

on the body of the instrument. Divide this distance by the carriage speed to

give the drying time.

13.When the test is completed, clean the balls and glass plates thoroughly.

b. See “Specimen trace analysis” on page 7 for an example of a typical trace analysis.

5300_TMA_0332_00_03 A5.fm Page 6 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

7

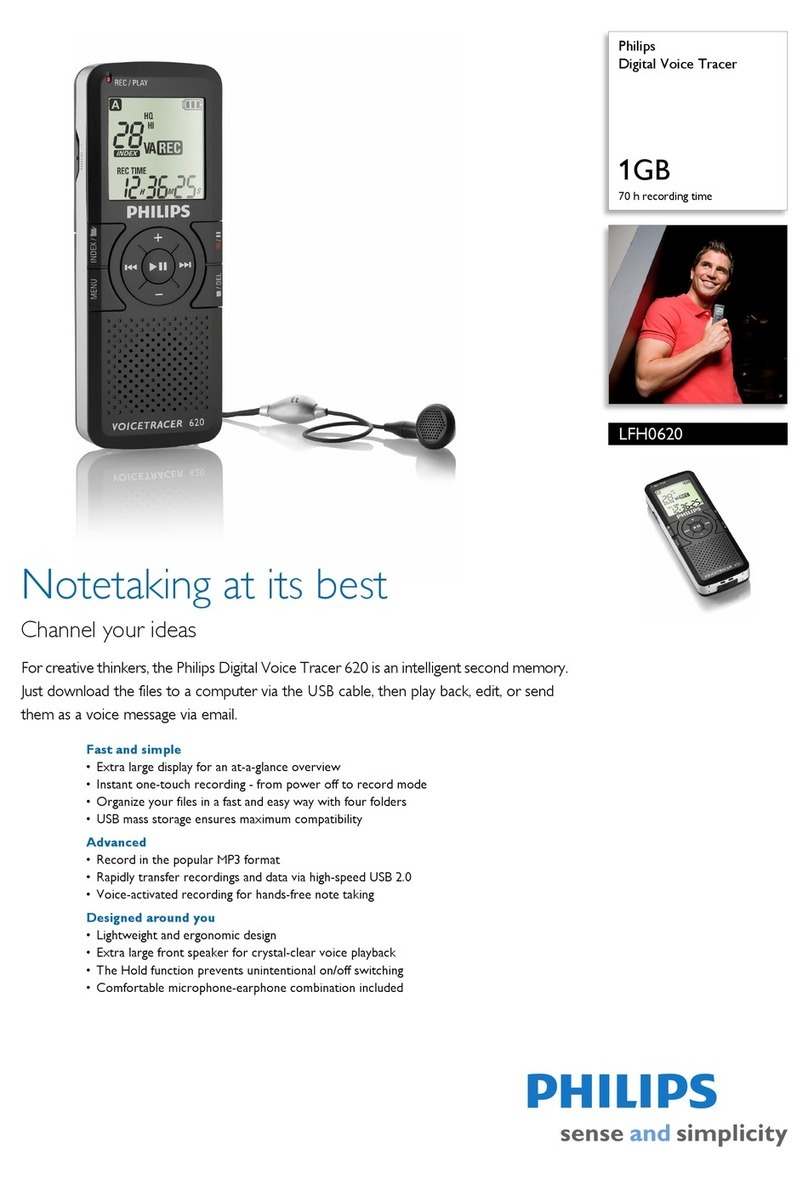

4 SPECIMEN TRACE ANALYSIS

The following example of how to analyse the trace left by the balls on a paint

coating is taken from the standard NF T 30-037.

Figure 4. Specimen trace analysis

1. Levelling: Because paint flows when it is wet, the trace is covered by paint

after the ball has passed, therefore no permanent trace is left in the paint

film.

2. Basic trace: The paint has started to dry.

3. Setting: The paint film is ruptured by the ball. At this stage dust will not

adhere to the paint film.

4. Surface dry: A skin has formed over the paint. At this stage the paint does

not adhere to the ball.

5. Dry: The paint is no longer marked by the ball.

1 2 3 4 5

5300_TMA_0332_00_03 A5.fm Page 7 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

8

5 MAINTENANCE

The Elcometer 5300 Ball Type Drying Time Recorder is designed to give many

years reliable service under normal operating and storage conditions.

Every six months, or sooner when used intensively, lubricate the carriage drive

mechanism inside the instrument using SKF ball bearing grease.

The Elcometer 5300 Ball Type Drying Time Recorder does not contain any

internal user-serviceable components. In the unlikely event of a fault, the

Elcometer 5300 Ball Type Drying Time Recorder should be returned to your

local Elcometer supplier or directly to Elcometer.

Details of Elcometer offices around the world are given on the outside cover of

these Operating Instructions. Alternatively visit the Elcometer website,

www.elcometer.com

6 TECHNICAL SPECIFICATION

Carriage speed: 1.2 cm (0.5") to 60 cm (24") per hour

Operating voltage: UK, 240 V AC 50 Hz

EUR, 220 V AC 50 Hz

US, 110 V AC 60 Hz

Power consumption: 100 W

Fuse rating - plug (if fitted): 4 A

Fuse rating - machine: 50mA (2 off)

Dimensions: 860 mm x 420 mm x 170 mm

(34" x 16.5" x 6.7")

Weight: 18 kg (40 lb)

5300_TMA_0332_00_03 A5.fm Page 8 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

9

7 ACCESSORIES

The Elcometer 5300 Ball Type Drying Time Recorder is complete with all the

items required to get started.

The following accessories are available from your local supplier or direct from

Elcometer:

Description Part Number

Glass strips, set of 10 KT005300P001)

Ball tool, set of 5 KT005300P002

10 g weights, set of 5 KT005300P003

Elcometer 3505 Cube Applicator, 1 reservoir K0003505M001 (metric)

Elcometer 3505 Cube Applicator, 1 reservoir K0US3505M001 (imperial)

8 RELATED EQUIPMENT

In addition to the Elcometer 5300 Ball Type Drying Time Recorder, Elcometer

produces a wide range of other equipment for determining the physical

characteristics of surface coatings.

Users of the Elcometer 5300 Ball Type Drying Time Recorder may also benefit

from the following Elcometer products:

• Elcometer Spiral Bar Coaters

• Elcometer Motorised Film Applicators

• Elcometer Leneta Test Charts

• Elcometer Wet Film Gauges

• Elcometer Washability, Brushability and Abrasion Testers

• Elcometer Hardness Testers

• Elcometer Elasticity and Impact Testers

For further information contact Elcometer, your local supplier or visit

www.elcometer.com

5300_TMA_0332_00_03 A5.fm Page 9 Thursday, August 30, 2007 2:50 PM

DISCONTINUED

Table of contents