Elcon HiD 2000 Series Operator's manual

SERIES HiD 2000

INTRINSIC SAFETY ISOLATORS

User Instruction Manual

ELCON INSTRUMENTS

I/O Interface, Intrinsic Safety and Solutions

Warning: this manual is copyright of Elcon Instruments with all rights reserved.

This manual may not be copied, in whole or in part, without the written

consent of Elcon Instruments.

Elcon Instruments reserves the right to make changes of this manual

without notice.

• RD-ZIP-004

DOC.TECN. Ins.Man. IM-ENG-111/GB-A2-PN991169

SERIES HiD 2000 INTRINSIC SAFETY ISOLATORS

User Instruction Manual

ELCON INSTRUMENTS

I/O Interface, Intrinsic Safety and Solutions

I

Table of contents

1Introduction..................................................................................................................................................1-1

1.1 Overview ..............................................................................................................................................1-1

1.2 Explanation of Contents........................................................................................................................1-1

1.3 Key Features ........................................................................................................................................ 1-2

1.4 Hazardous Area Interfacing...................................................................................................................1-2

2Specifications ..............................................................................................................................................2-1

2.1 Product Selection..................................................................................................................................2-1

2.2 Ordering Information.............................................................................................................................2-2

2.3 Mechanical Specifications.....................................................................................................................2-3

2.4 Safety Specifications ............................................................................................................................ 2-4

2.5 Approvals and Markings........................................................................................................................2-5

2.6 Electrical Specifications - general .........................................................................................................2-6

2.7 Electrical Specifications - modules........................................................................................................2-7

2.7.1 HiD 2025/2026 Repeater Power Supply, Smart Transmitter........................................................... 2-7

2.7.2 HiD 2025SK/2026SK Repeater Power Supply, Smart Transmitter..................................................2-8

2.7.3 HiD 2029/2030 Repeater Power Supply, Smart Tx, Fully Floating..................................................2-9

2.7.4 HiD 2029SK/2030SK Repeater Power Supply, Smart Tx, Fully Floating................................................ 2-10

2.7.5 HiD 2031/2032 I/P Driver, Bus Powered....................................................................................... 2-11

2.7.6 HiD 2033/2034 I/P Driver, Loop Powered..................................................................................... 2-12

2.7.7 HiD 2035/2036 Loop powered Isolator for Fire and Smoke Detectors........................................... 2-13

2.7.8 HiD 2037/2038 I/P Driver, Bus Powered, Smart ........................................................................... 2-14

2.7.9 HiD 2061/2062 Temperature Converter, mV/TC........................................................................... 2-15

2.7.10 HiD 2071/2072 RTD/Potentiometer Converter.............................................................................. 2-16

2.7.11 HiD 2822/2824 Switch/Proximity Detector Repeater, Relay Output .............................................. 2-17

2.7.12 HiD 2842/2844 Switch/Proximity Detector Repeater, Open Coll. Output............................................ 2-18

2.7.13 HiD 2871/2872 Solenoid/Alarm Driver, Loop or Bus Powered ...................................................... 2-19

2.7.14 HiD 2873/2874 Solenoid/Alarm Driver, Bus Powered................................................................... 2-20

2.7.15 HiD 2875/2876 Solenoid/Alarm Driver, Loop or Bus Powered ...................................................... 2-21

2.7.16 HiD 2877/2878 Solenoid/Alarm Driver, Bus Powered................................................................... 2-22

2.7.17 HiD 2881 Solenoid/Alarm Driver, Loop or Bus Powered, IIB Output ............................................. 2-23

3System Operation........................................................................................................................................ 3-1

3.1 General description of the system......................................................................................................... 3-1

3.2 System design considerations...............................................................................................................3-1

3.3 Wiring of intrinsically safe circuits......................................................................................................... 3-1

3.4 Grounding information ..........................................................................................................................3-2

4Installation and Configuration.......................................................................................................................4-1

4.1 Unpacking.............................................................................................................................................4-1

4.2 Storage.................................................................................................................................................4-1

4.3 Operating environment .........................................................................................................................4-1

4.4 Installation ............................................................................................................................................4-2

4.5 Board polarisation................................................................................................................................. 4-2

4.6 Configuration ........................................................................................................................................4-2

4.7 Electrical Connections...........................................................................................................................4-3

4.8 EMC Guidelines....................................................................................................................................4-3

4.9 Heat Dissipation and Thermal Behaviour ..............................................................................................4-3

4.10 Cabinet Heat-Dissipation....................................................................................................................... 4-5

5Unit Operation ............................................................................................................................................. 5-1

5.1 HiD 2025/2026......................................................................................................................................5-1

5.2 HiD 2025SK/2026SK............................................................................................................................. 5-3

5.3 HiD 2029/2030......................................................................................................................................5-5

5.4 HiD 2029SK/2030SK............................................................................................................................. 5-7

5.5 HiD 2031/2032......................................................................................................................................5-9

5.6 HiD 2033/2034.................................................................................................................................... 5-11

5.7 HiD 2035/2036.................................................................................................................................... 5-13

5.8 HiD 2037/2038.................................................................................................................................... 5-15

5.9 HiD 2061/2062.................................................................................................................................... 5-17

5.10 HiD 2071/2072.................................................................................................................................... 5-20

5.11 HiD 2822/2824.................................................................................................................................... 5-23

5.12 HiD 2842/2844.................................................................................................................................... 5-26

II

5.13 HiD 2871/2872.................................................................................................................................... 5-29

5.14 HiD 2873/2874.................................................................................................................................... 5-32

5.15 HiD 2875/2876.................................................................................................................................... 5-35

5.16 HiD 2877/2878.................................................................................................................................... 5-38

5.17 HiD 2881............................................................................................................................................. 5-41

6Servicing .....................................................................................................................................................6-1

6.1 Maintenance......................................................................................................................................... 6-1

6.2 Functional Check & Troubleshooting.....................................................................................................6-1

6.2.1 HiD 2025/2026............................................................................................................................... 6-3

6.2.2 HiD 2025SK/2026SK......................................................................................................................6-4

6.2.3 HiD 2029/2030............................................................................................................................... 6-5

6.2.4 HiD 2029SK/2030SK......................................................................................................................6-6

6.2.5 HiD 2031/2032............................................................................................................................... 6-7

6.2.6 HiD 2033/2034............................................................................................................................... 6-8

6.2.7 HiD 2035/2036............................................................................................................................... 6-9

6.2.8 HiD 2037/2038............................................................................................................................. 6-10

6.2.9 HiD 2822/2824............................................................................................................................. 6-11

6.2.10 HiD 2842/2844............................................................................................................................. 6-13

6.2.11 HiD 2871/2872............................................................................................................................. 6-15

6.2.12 HiD 2873/2874............................................................................................................................. 6-17

6.2.13 HiD 2875/2876............................................................................................................................. 6-19

6.2.14 HiD 2877/2878............................................................................................................................. 6-21

6.2.15 HiD 2881...................................................................................................................................... 6-23

6.3 Warranty............................................................................................................................................. 6-25

7Glossary ......................................................................................................................................................7-1

8Index ...........................................................................................................................................................8-1

9Appendix A..................................................................................................................................................9-1

9.1 HiD 2061/HiD 2062 Input Range Configurations....................................................................................9-1

9.1.1 Input type “mV”.............................................................................................................................. 9-1

9.1.2 Input type thermocouple “B”........................................................................................................... 9-2

9.1.3 Input type thermocouple “E”........................................................................................................... 9-3

9.1.4 Input type thermocouple “J”............................................................................................................ 9-4

9.1.5 Input type thermocouple “K”........................................................................................................... 9-5

9.1.6 Input type thermocouple “N”...........................................................................................................9-6

9.1.7 Input type thermocouple “R”...........................................................................................................9-7

9.1.8 Input type thermocouple “S”........................................................................................................... 9-7

9.1.9 Input type thermocouple “T”........................................................................................................... 9-8

9.1.10 Input type thermocouple “L” ........................................................................................................... 9-9

9.2 Thermocouple / mV Calibration........................................................................................................... 9-10

9.2.1 Equipment required...................................................................................................................... 9-10

9.2.2 Thermocouple or mV Input range modification............................................................................. 9-10

9.2.3 Thermocouple Input Range Calibration........................................................................................ 9-10

9.2.3.1 Copper Wires Calibration.......................................................................................................... 9-11

9.2.3.2 Compensating Wires Calibration .............................................................................................. 9-11

9.2.3.3 0 °C Reference Junction Calibration......................................................................................... 9-11

9.2.3.4 TC Calibrator with auto internal RJ compensation Calibration................................................... 9-12

9.2.3.5 TC Calibrator with auto remote RJ compensation Calibration ................................................... 9-12

9.2.4 mV Input Range Calibration......................................................................................................... 9-12

10 Appendix B................................................................................................................................................ 10-1

10.1 HiD 2071/HiD 2072 Input Range Configurations.................................................................................. 10-1

10.1.1 Input type RTD Pt100 Ω............................................................................................................... 10-1

10.1.2 Input type Potentiometer.............................................................................................................. 10-2

10.2 RTD / POT Calibration........................................................................................................................ 10-3

10.2.1 Equipment required...................................................................................................................... 10-3

10.2.2 RTD or POT Input range modification.......................................................................................... 10-3

10.2.3 Pt 100 ΩRTD Input range calibration........................................................................................... 10-3

10.2.4 Other types of RTD (to be specified when ordering)..................................................................... 10-3

10.2.5 POT Input range calibration ......................................................................................................... 10-4

1-1

1Introduction

This manual is intended to provide guidance for the installation, operation and maintenance of the HiD 2000 range

of intrinsic safety isolators.

To avoid damage, failure or improper operation, carefully read this manual before installing and operating the unit.

This manual and the related equipment should not be used by untrained personnel unless they are fully acquainted

with the principles of intrinsically safe system.

Elcon Instruments has published a complete tutorial entitled “Guide to Intrinsic Safety” covering most aspect of

intrinsic safety. The book can be obtained from Elcon Instruments free of charge.

1.1 Overview

The Elcon HiD 2000 Series is designed to be used in connection with process instrumentation system and consist

of a range of compact I.S. isolating interface modules to handle the input and output signals of a process plant.

Moreover a range of standard and custom made Termination Boards are available where the modules can be

plugged and quickly secured.

With this new full line of modular plug-in I.S. isolator a significant cost reduction is achieved in project planning,

plant design commissioning and service.

The module pack one, two or four isolated channels into a compact housing which can be inserted or removed

from the Termination Board without disturbing any of the wiring, no specialist knowledge is required, thereby

eliminating a frequent source of errors. The new “Quick Lok” method of fixing the module without the need for

tools reduces installation time and is very ease to operate. Pushing down a tab on each side of the module rotates

a securing foot which locks the unit to the Termination Board; to remove the modules simply lift the tabs. For

servicing, only the defective module needs to be removed and the replacement module plugged into the

Termination Board and locked by the quick mechanism. No special knowledge is required, the signal cables don’t

need to be detached and re-connected, eliminating a frequent source of errors.

Polarisation on the Board securely prevents modules from being swapped inadvertently.

The HiD 2000 Series product range has:

•high packing density, due to innovative circuit design using advanced surface mount components

•high performance, with high signal transfer accuracy and repeatability, low consumption, low heat

dissipation

•wide functionality, with a wide range of I/O signals, galvanic isolation, line fault alarm

•HiD 2000 Series products are Intrinsic Safety Certified according to CENELEC, CSA, FM, GOST, SEV,

SABS, SAA and other world-wide standards. Moreover, they meet European directives on EMC, and all

modules carry the CE marking.

1.2 Explanation of Contents

This instruction manual describes how to install, connect, check and maintain the HiD range of intrinsic safety

isolators:

•section 2 supplies the technical specifications of the units in a concise form

•section 3 describes system operation.

•section 4 describes how to install and configure the HiD modules

•section 5 shows how to operate the units

•section 6 deals with maintenance and troubleshooting issues

A Glossary and an Analytical Index for easy reference to topics complete the document.

This isolators manual is intended to be read and used in conjunction with the Termination Board User

Instruction Manual (IM-ENG 112/GB).

1-2

1.3 Key Features

•high channel density results from innovative circuit design using surface mounted components

•high packing density, with ultra slim 4 channels 18 mm wide plug-in mounting modules, 4.5 mm per

channel

•single, dual and quadruple channels models

•high signal transfer accuracy and repeatability

•low power consumption and heat dissipation

•wide operating temperature range

•wide range of digital switches and analog I/O, including 4-20 mA, signal conversion, loop powered and

external supply configurations

•galvanic isolation to eliminate noise, ground loop problems and to provide Intrinsic Safety without a

high integrity safety earth connection

•line fault alarm detects open or short circuit of field cables

•sink or source outputs available on analog models

•configure using DIP switch located on side cover for easy field set up

•LED indication for power, signal status and line fault condition

•“Quick Lok” mechanism for easy and quickly mounting

•loop identification, coding and tagging

•accept DC power supply over a wide range (24V, -15% +25%)

1.4 Hazardous Area Interfacing

Correct and safe operation of Elcon HiD 2000 Series calls for expert installation and commissioning as well as

correct operation and meticulous maintenance.

Only those persons conversant with the installation commissioning, operation and maintenance of similar

apparatus and who has the necessary qualifications are allowed to work on HiD 2000 Series.

Make sure installation is carried out observing the safety regulations pertaining to the installation and operation of

electrical system and the directives and guidelines on explosion protection (Hazardous Area equipment should

comply with the descriptive system document).

The installation must be performed by qualified personnel, it must comply with the relevant national/international

standards (e.g. IEC 79-14, CEI 64-2, BS 5345 Pt. 4, DIN VDE 165) and in line with the established installation

rules and recommended practice (e.g. CEI 64-8, ANSI/ISA RP-12.6).

The conformity of hazardous area devices with the related system documentation must always be checked. This

instrumentation IS NOT intended for hazardous area installation, unless it is included in a proper explosion proof

enclosure which conforms to the applicable standards.

For I.S. applications, the maximum limit for AC power supply is 250 Vrms.

For more information on request Elcon will provide the manual “Guide to Intrinsic Safety”, a comprehensive

tutorial about the constraints imposed by the I.S. regulations.

2-1

2Specifications

This section lists the relevant specifications for all HiD modules. For a detailed description of unit functions and

operation, please refer to Section 5.

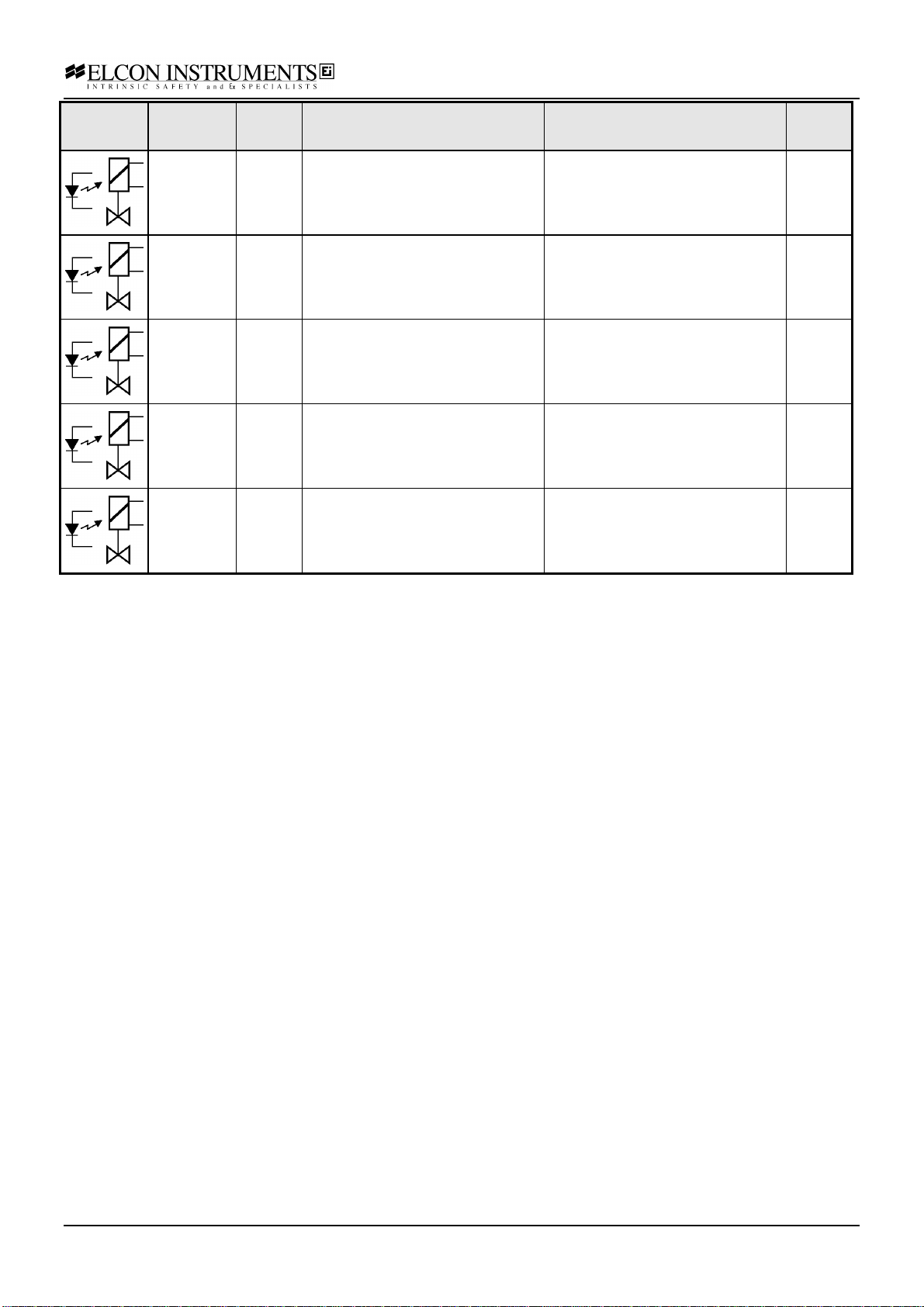

2.1 Product Selection

The following table shows the standard isolators available and their main features.

Field

Device Model N° of

Ch. Hazardous Area Signal Safe Area Signal Fault Bus

Output

HiD 2025

HiD 2026

1

2

4-20 mA (15.5 V) floating supply to Smart

or non Smart two wire Transmitters 4-20 mA (or 1-5 V) output isolated from

input, Smart compatible

HiD 2025/SK

HiD 2026/SK

1

2

4-20 mA (15.5 V) floating supply to Smart

or non Smart two wire Transmitters 4-20 mA load sink, isolated from input,

Smart compatible

HiD 2029

HiD 2030

1

2

4-20 mA (15.5 V) floating supply to Smart

or non Smart two or three wire Transmitters 4-20 mA (or 1-5 V) output isolated from

input and power supply, Smart compatible,

Line Fault Detection

√√

√√

HiD 2029/SK

HiD 2030/SK

1

2

4-20 mA (15.5 V) floating supply to Smart

or non Smart two or three wire Transmitters 4-20 mA load sink, isolated from input and

power supply, Smart compatible, Line Fault

Detection

√√

√√

HiD 2031

HiD 2032

1

2

4-20 mA to I/P converters, electrovalve

actuators and displays Bus powered, 4-20 mA signal from DCS,

PLC or other control device

HiD 2033

HiD 2034

1

2

4-20 mA to I/P converters, electrovalve

actuators and displays Loop Powered, 4-20 mA signal from DCS,

PLC or other control device

HiD 2035

HiD 2036

1

2

Fire and Smoke Detectors or I/P Converter Loop Powered, 1.5 to 50 mA signal from

DCS, PLC or other control device

HiD 2037

HiD 2038

1

2

4-20 mA and Smart signal to I/P

converters, electrovalve actuators and

displays

Bus powered, 4-20 mA signal from DCS,

PLC or other control device, Line Fault

Detection, Smart compatible

√√

√√

HiD 2061

HiD 2062

1

2

Thermocouple or mV 4-20 mA (or 1-5 V) output isolated from

input

HiD 2071

HiD 2072

1

2

RTD or Potentiometer 4-20 mA (or 1-5 V) output isolated from

input

HiD 2822

HiD 2824

2

4

Dry Contact or Proximity Switch DPST relay per channel, Line Fault

Detection

SPST relay per channel, Line Fault

Detection

√√

√√

HiD 2842

HiD 2844

2

4

Dry Contact or Proximity Switch 2 open-collector outputs per channel, Line

Fault Detection

1 open-collector output per channel, Line

Fault Detection

√√

√√

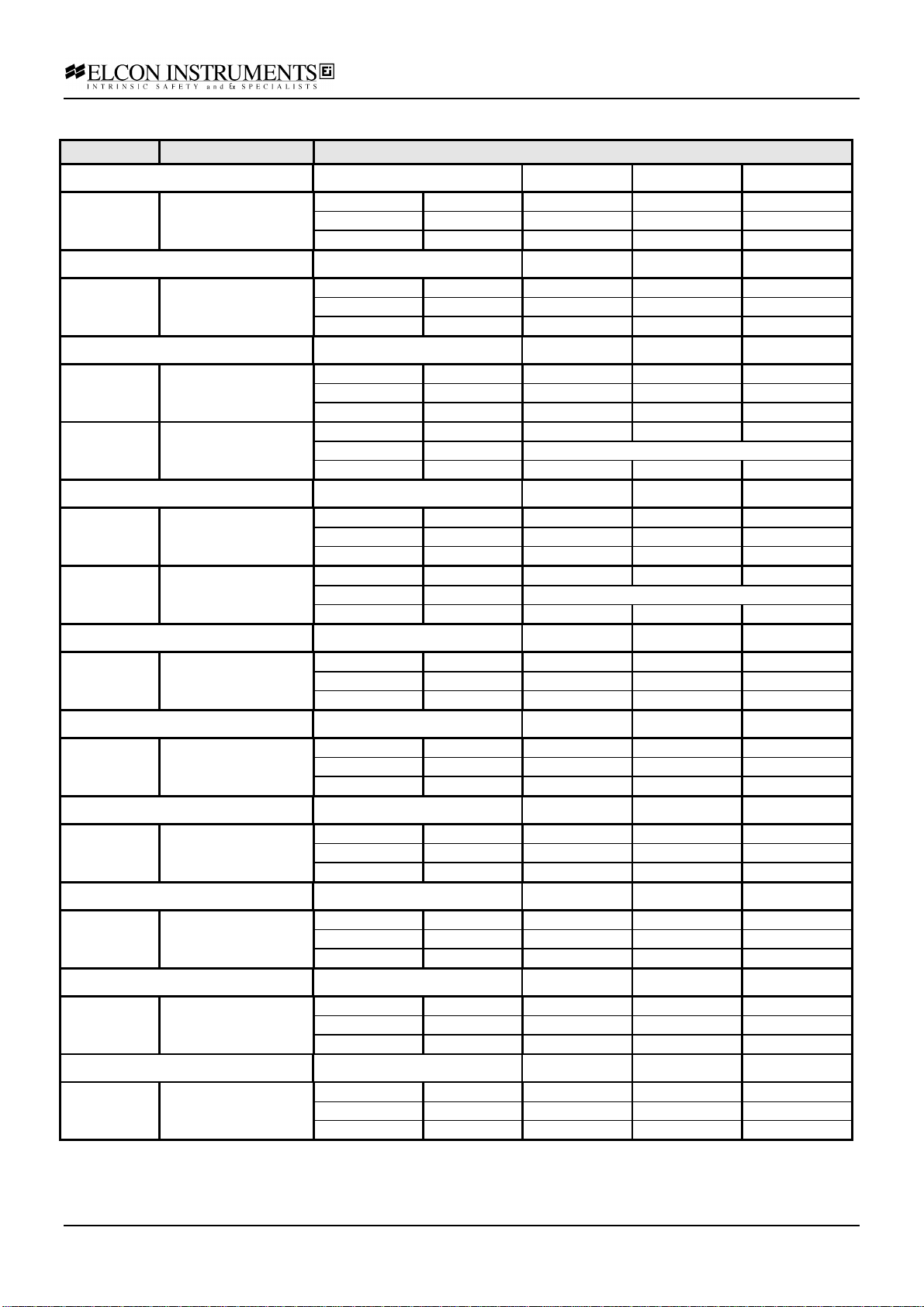

2-2

Field

Device Model N° of

Ch. Hazardous Area Signal Safe Area Signal Fault Bus

Output

HiD 2871

HiD 2872

1

2

40 mA at 12 V to drive solenoid valve,

audible or visual alarm (LED) Bus powered and/or loop powered,

controlled by external contact from DCS or

control device

HiD 2873

HiD 2874

1

2

40 mA at 12 V to drive solenoid valve,

audible or visual alarm (LED) Bus powered, controlled by external contact

or logic level from DCS or control device,

Line Fault Detection

√√

√√

HiD 2875

HiD 2876

1

2

40 mA at 11.2 V to drive solenoid valve,

audible or visual alarm (LED) Bus powered and/or loop powered,

controlled by external contact from DCS or

control device

HiD 2877

HiD 2878

1

2

40 mA at 11.2 V to drive solenoid valve,

audible or visual alarm (LED) Bus powered, controlled by external contact

or logic level from DCS or control device,

Line Fault Detection

√√

√√

HiD 2881 1

60 mA at 13 V to drive solenoid valve, IIB

Gas Group Bus powered and/or loop powered,

controlled by external contact or logic level

from DCS or control device, Line Fault

Detection

√√

2.2 Ordering Information

The ELCON family of HiD Intrinsic Safety Isolators are designed for simple ordering, you simply have to specify

the Model Number from the product selection table.

All user configurable units are delivered with a “default” configuration as specified in Section 2.7. For an additional

charge, Elcon can deliver units configured as specified by the customer.

Each unit is delivered with a detailed Installation Sheet containing all the information required to set up the isolator

on site.

2-3

2.3 Mechanical Specifications

Mounting Plug-in on Termination Board

Dimensions Width 18 mm

Depth 106 mm

Height 128 mm

Case material Policarbonate

Flame retardant compliant to UL 94 V2

Unit weight about 140 gr

Blister packing size Width 30 mm

Depth 145 mm

Height 165 mm

Dimensional Drawing

2-4

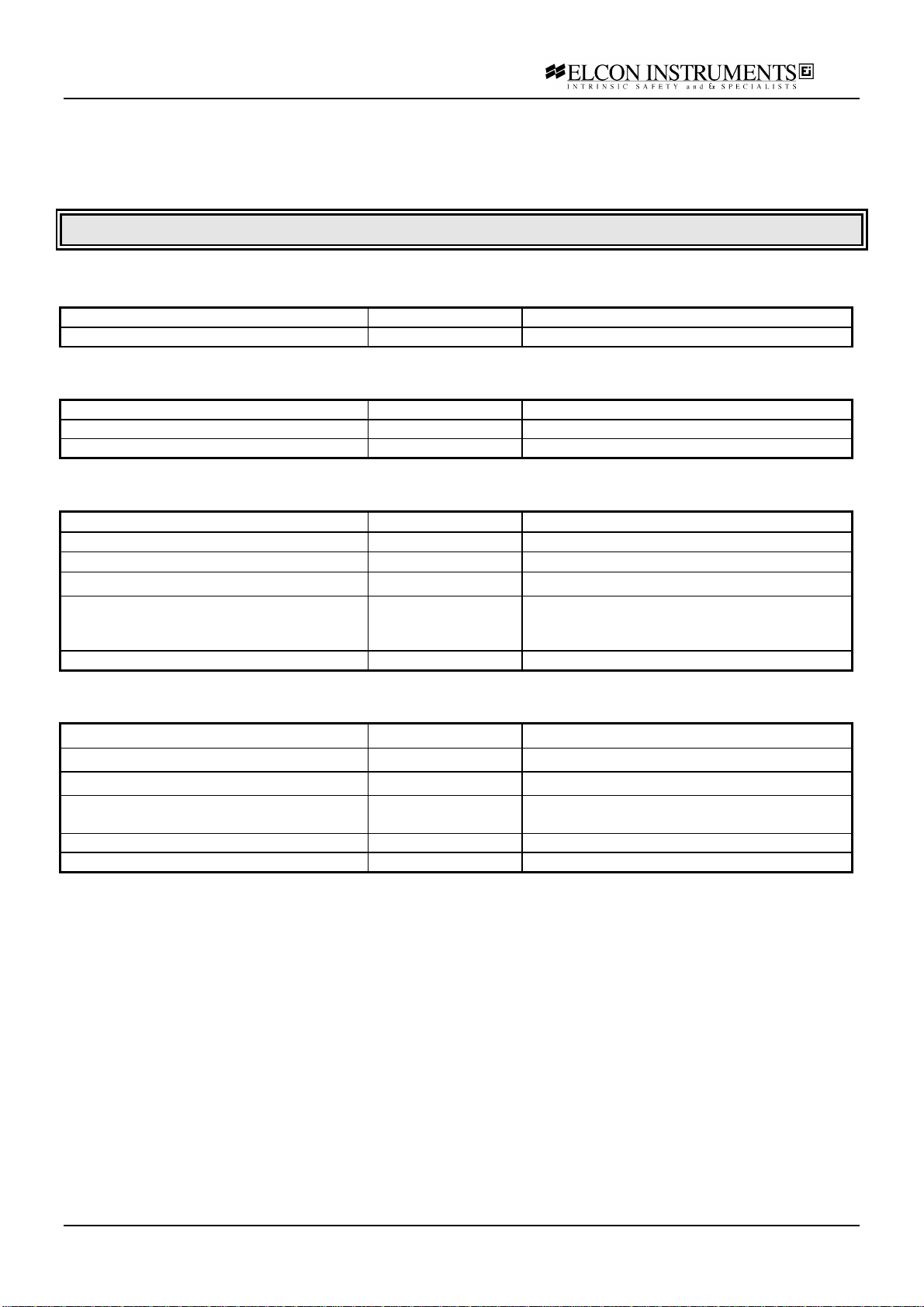

2.4 Safety Specifications

Terminal Safety Description Maximum External Parameters

HiD2025/2026 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2025SK/2026SK Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2029/2030 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

Uo = 1.2 V II C A-B

4-7 Io = 50 mA II B C-E Non energy storing apparatus connection

5-6 Po = 25 mW II A D-F-G

HiD2029SK/2030SK Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

Uo = 1.2 V II C A-B

4-7 Io = 50 mA II B C-E Non energy storing apparatus connection

5-6 Po = 25 mW II A D-F-G

HiD2031/2032 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2033/2034 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2035/2036 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2037/2038 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2061/2062 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 13.1 V II C A-B 1.97 70 520

1-4, 7-8 Io = 22 mA II B C-E 13.8 250 1860

2-3, 5-6 Po = 72 mW II A D-F-G 60 580 4300

HiD2071/2072 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 13.1 V II C A-B 1.97 70 520

7-1-4-8 Io = 22 mA II B C-E 13.8 250 1860

3-2-5-6 Po = 72 mW II A D-F-G 60 580 4300

2-5

Terminal Safety Description Maximum External Parameters

HiD2822/2824 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 13.1 V II C A-B 1.97 70 520

1-4, 2-5 Io = 22 mA II B C-E 13.8 250 1860

3-6, 7-8 Po = 72 mW II A D-F-G 60 580 4300

HiD2842/2844 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 13.1 V II C A-B 1.97 70 520

1-4, 2-5 Io = 22 mA II B C-E 13.8 250 1860

3-6, 7-8 Po = 72 mW II A D-F-G 60 580 4300

HiD2871/2872 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 3 50

7-1-4 Io = 110 mA II B C-E 0.74 11 200

6-2-5 Po = 720 mW II A D-F-G 2.51 22 400

HiD2873/2874 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 3 50

1-4 Io = 110 mA II B C-E 0.74 11 200

2-5 Po = 720 mW II A D-F-G 2.51 22 400

HiD2875/2876 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

7-1-4 Io = 93 mA II B C-E 0.74 16.5 230

6-2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2877/2878 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V II C A-B 0.097 4.1 58

1-4 Io = 93 mA II B C-E 0.74 16.5 230

2-5 Po = 610 mW II A D-F-G 2.51 33 470

HiD2881 Cenelec (groups) USA Co (µµF) Lo (mH) L/R (µµH/ΩΩ)

Uo = 26.25 V

1-4 Io = 184 mA II B C-E 0.5 4.5 127

Po = 1.2 W II A D-F-G 1.9 8.5 241

2.5 Approvals and Markings

The HiD series complies with all the mandatory European standards and bears the CE marking.

AUTHORITY CERTIFICATE/FILE NO. STANDARD APPROVED FOR

CESI EX-97.D.054

EX-97.D.055 EN 50.020

EN 50.014 [EEx ia] IIC

CSA Pending C 22.2 No. 157

C 22.2 No. 142 CL. I, II, III;

Div 1; Gr. A to G

FM Pending FM Cl. No. 3610 Entity

FM Cl. No. 3600

FM Cl. No. 3611

Cl. I, II, III;

Div 1; Gr. A to G

Cl. I, II, III; Div 2

SCS EX 97Y4109X BS 6941:1988 Ex N IIC T4

SAA Pending AS 2380.1

AS 2380.7 [Ex ia] IIC

Certifications to other world wide standards are in existence or pending.

2-6

2.6 Electrical Specifications - general

This section lists the characteristics that apply to all HiD modules in the product range. For details about the

individual module features, please refer to Section 5

Reference Conditions

Temperature 23 °C (74 °F)

Relative humidity 50 %

Nominal supply voltage 24 Vdc(20.4 to 30V)

Load where applicable 250 Ω

Full scale value 20 mA

Environmental Conditions Limits

Operating Temperature(derating can apply) 0 to 60 °C (32 to 140 °F)

Storage temperature -20 to 70 °C (-4 to 158 °F)

Relative humidity

(non condensing - up to 35 °C – 95 °F) 5to 90 %

Isolation

Hazardous Area to Safe Area 1500 Vrms for 1 minute

Safe Area input – output circuits to supply

circuit (where applicable) 250 Vrms for 1 minute

Hazardous area to

Hazardous Area channels 500 Vrms for 1 minute

Electromagnetic Compatibility (EMC)

Phenomena Family Standards Test Method Standards

Generic Emission EN 50.081-2

Radiated and conducted emission EN 50.011

Generic Immunity EN 50.082-2

RF Radiated ENV 50140

RF Radiated 900 MHz ENV 50204

RF Conducted ENV 50141

Electrostatic Discharge (ESD) EN 61000-4-2

Electric Fast Transient / Burst EN 61000-4-4

N.B. these EMC specifications satisfy the CE marking requirements

Mounting

Modules plug-in, no tools required for replacement

All HiD devices are protected against reverse polarity power supply connection (on Termination Board).

Common to all relevant modules is the provision of a separate fault output which is bussed on the Termination

Boards to provide a collective signal per interface assembly.

Protection class IP30 (IEC 529)

2-7

2.7 Electrical Specifications - modules

This section include the detailed electrical specifications for each module type.

All values are typical and at reference conditions unless otherwise specified.

2.7.1 HiD 2025/2026 Repeater Power Supply, Smart Transmitter

DC supply

Current consumption 50 mA @ 24 V, 20 mA output (per channel)

Power dissipation 0.8 W @ 24 V (per channel)

Hazardous Area Signal (Input)

Signal range 4-20 mA Overload limited at 26 mA typ.

Voltage available for transmitter and lines 15.5 V min @ 20 mA

Ripple content 10 mVrms

Safe Area Signal (Output)

User selectable 4-20 mA or 1-5 V 1-5 V on 250 Ωinternal shunt

Ripple content 10 mVrms on 250 Ωload required for communications

Load 0 to 650 Ω

Load effect ≤0.1 % of full scale from 0 to 650 Ω

Frequency response of comm. Channel

Tx to output 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Output to Tx 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Response time 40 msec 10 to 90% step change

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale (Current output)

Linearity < ±0.1 % of full scale

Temperature drift < ±0.01 %/°C

Selector switches Output 4-20 mA or

1-5 V (250 Ω, 0.1 % internal shunt)

Factory set as 4-20 mA

LED Indicators Power ON Green

2-8

2.7.2 HiD 2025SK/2026SK Repeater Power Supply, Smart Transmitter

DC supply

Current consumption 50 mA @ 24 V, 20 mA output (per channel)

Power dissipation 1.3 W @ 24 V supply, 24 V external supply from

DCS or PLC (per channel)

Hazardous Area Signal (Input)

Signal range 4-20 mA Overload limited at 26 mA typ.

Voltage available for transmitter and lines 15.5 V min @ 20 mA

Ripple content 10 mVrms

Safe Area Signal (Output)

Sink mode from external supply 4-20 mA Overload limited at 26 mA typ.

Working voltage range 7-30 V

Frequency response of comm. Channel

Tx to output 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Output to Tx 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Response time 40 msec 10 to 90% step change

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale

Linearity < ±0.1 % of full scale

Temperature drift < ±0.01 %/°C

Selector switches None

LED Indicators Power ON Green

2-9

2.7.3 HiD 2029/2030 Repeater Power Supply, Smart Tx, Fully Floating

DC supply

Current consumption 60 mA @ 24 V, 20 mA output (per channel)

Power dissipation 1.05 W @ 24 V (per channel)

Hazardous Area Signal (Input)

Voltage available for transmitter and lines 15.5 V min @ 20 mA

Ripple content 10 mVrms

Input range 4-20 mA Overload limited at 26 mA typ.

Input resistance for current source 40 Ω

Safe Area Signal (Output)

User selectable 4-20 mA or 1-5 V 1-5 V on 250 Ωinternal shunt

Ripple content 10 mVrms on 250 Ωload required for communications

Load 0 to 650 Ω

Load effect ≤0.1 % of full scale from 0 to 650 Ω

Frequency response of comm. Channel

Tx to output 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Output to Tx 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Response time 70 msec 10 to 90% step change

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale (Current output)

Linearity < ±0.05 % of full scale

Temperature drift < ±0.01 %/°C

No fault detection > 1 mA or < 23.5 mA input current

Fault detection < 0.2 mA or > 24 mA Input current

Selector switches Output 4-20 mA or

1-5 V (250 Ω, 0.1 % internal shunt)

Factory set as 4-20 mA

LED Indicators Power ON

Fault Green

Red (per channel)

Fault output Open Collector

Transistor common to both channels

2-10

2.7.4 HiD 2029SK/2030SK Repeater Power Supply, Smart Tx, Fully Floating

DC supply

Current consumption 40 mA @ 24 V, 20 mA output (per channel)

Power dissipation 1.05 W @ 24 V supply, 24 V external supply from

DCS or PLC (per channel)

Hazardous Area Signal (Input)

Voltage available for transmitter and lines 15.5 V min @ 20 mA

Ripple content 10 mVrms

Input range 4-20 mA Overload limited at 26 mA typ.

Input resistance for current source 40 Ω

Safe Area Signal (Output)

Sink mode from external supply 4-20 mA Overload limited at 24 mA typ.

Working voltage range 7-30 V

Frequency response of comm. Channel

Tx to output 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Output to Tx 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Response time 70 msec 10 to 90% step change

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale

Linearity < ±0.05 % of full scale

Temperature drift < ±0.01 %/°C

No fault detection > 1 mA or < 23.5 mA input current

Fault detection < 0.2 mA or > 24 mA Input current

Selector switches None

Factory set as 4-20 mA

LED Indicators Power ON

Fault Green

Red (per channel)

Fault output Open Collector

Transistor common to both channels

2-11

2.7.5 HiD 2031/2032 I/P Driver, Bus Powered

DC supply

Current consumption 35 mA @ 24 V, 20 mA output (per channel)

Power dissipation 0.75 W @ 24 V (per channel)

Hazardous Area Signal (Output)

Output 4-20 mA on a load of 0 to 750 Ωmax

Load effect ≤0.1 % of full scale from 0 to 750 Ω

Output ripple 15 mVrms

Response time 50 msec 10 to 90% step change

Safe Area Signal (Input)

Input current 4-20 mA reverse polarity protected

Input drop-out < 4 V with field wiring intact

Input current < 1.2 mA with field wiring open

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale

Linearity < ±0.1 % of full scale

Temperature drift < ±0.01 %/°C

Selector switches None

LED Indicators Power ON Green

2-12

2.7.6 HiD 2033/2034 I/P Driver, Loop Powered

Hazardous Area Signal (Output)

Output 4-20 mA on a load of 0 to 500 Ωmax

Load effect ≤0.2 % of full scale from 0 to 500 Ω

Output ripple 40 µA peak to peak

Response time 50 msec 10 to 90% step change

Safe Area Signal (Input)

Input voltage 7-30 V Powered by the loop, reverse polarity protected

Input current 4-20 mA Powered by the loop

Voltage drop-out 7 V @ 20 mA and 500 Ωload

Open circuit consumption < 0.8 mA @ 24 V

Power dissipation 0.14 W @ 20 mA (per channel)

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale

Linearity < ±0.1 % of full scale

Temperature drift < ±0.01 %/°C

Selector switches None

LED Indicators None

2-13

2.7.7 HiD 2035/2036 Loop powered Isolator for Fire and Smoke Detectors

Hazardous Area Signal (Output)

Fire and Smoke Detectors

Output 1.5-50 mA

Output characteristic (simplified) Vout=(Vin-1.6)-(0.4xIout)

Vout=(25-1.6)-(0.4xIout) 6 V < Vin < 25 V (Iout=mA,

Vout=V)

25 V < Vin < 30 V

Analog Output I/P applications

Output 4-20 mA on a load of 0 to 750 Ωmax

Load effect ≤0.3 % of full scale from 0 to 750 Ω

Output ripple 150 µA peak to peak

Response time 50 msec 10 to 90% step change

Safe Area Signal (Input)

Operating voltage range 6-30 V powered by the loop, reverse polarity protected

Input current 1.5-50 mA powered by the loop

Voltage drop-out 9.6 V @ 20 mA and 500 Ωload (4 V @ 4 mA)

Open circuit consumption < 0.6 mA @ 24 V

Power dissipation <0.7 W @ 40 mA, 24 V (per channel)

Performance at Reference Conditions

Current transfer error < ±300 µA typ. 6 V < Vin < 25 V / 1.5 mA < Iout < 50 mA

Calibration accuracy < ±0.1 % of full scale (4-20 mA range)

Linearity < ±0.1 % of full scale (4-20 mA range)

Temperature drift < ±0.01 %/°C

Selector switches None

LED Indicators None

Output characteristic: (measured, typical)

2-14

2.7.8 HiD 2037/2038 I/P Driver, Bus Powered, Smart

DC supply

Current consumption 40 mA @ 24 V, 20 mA output (per channel)

Power dissipation 0.85 W @ 24 V (per channel)

Hazardous Area Signal (Output)

Output 4-20 mA on a load of 0 to 750 Ωmax

Load effect ≤0.1 % of full scale from 0 to 750 Ω

Output ripple 15 mVrms

Response time 50 msec 10 to 90% step change

Safe Area Signal (Input)

Input current 4-20 mA reverse polarity protected

Input drop-out < 4 V with field wiring intact

Input current < 1.2 mA with field wiring open

Frequency response of comm. Channel

Field to Input 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Input to Field 0.5 to 40 KHz within 3 dB, (-6 dB @ 100 KHz)

Performance at Reference Conditions

Calibration accuracy < ±0.1 % of full scale

Linearity < ±0.1 % of full scale

Temperature drift < ±0.01 %/°C

Short wire fault detect < 70 Ω

Open wire fault detect > 100 KΩ

Selector switches None

LED Indicators Power ON

Fault Green

Red (per channel)

Fault output Open Collector

Transistor common to both channels

Table of contents

Other Elcon Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Dali Wireless

Dali Wireless Matrix PS Installation & commissioning guide

Reliance

Reliance 500 Series Instructions for use

Parkside

Parkside PBKZ 1 A1 operating instructions

FTC

FTC SRT FOOTLOOP Use and maintenance instructions

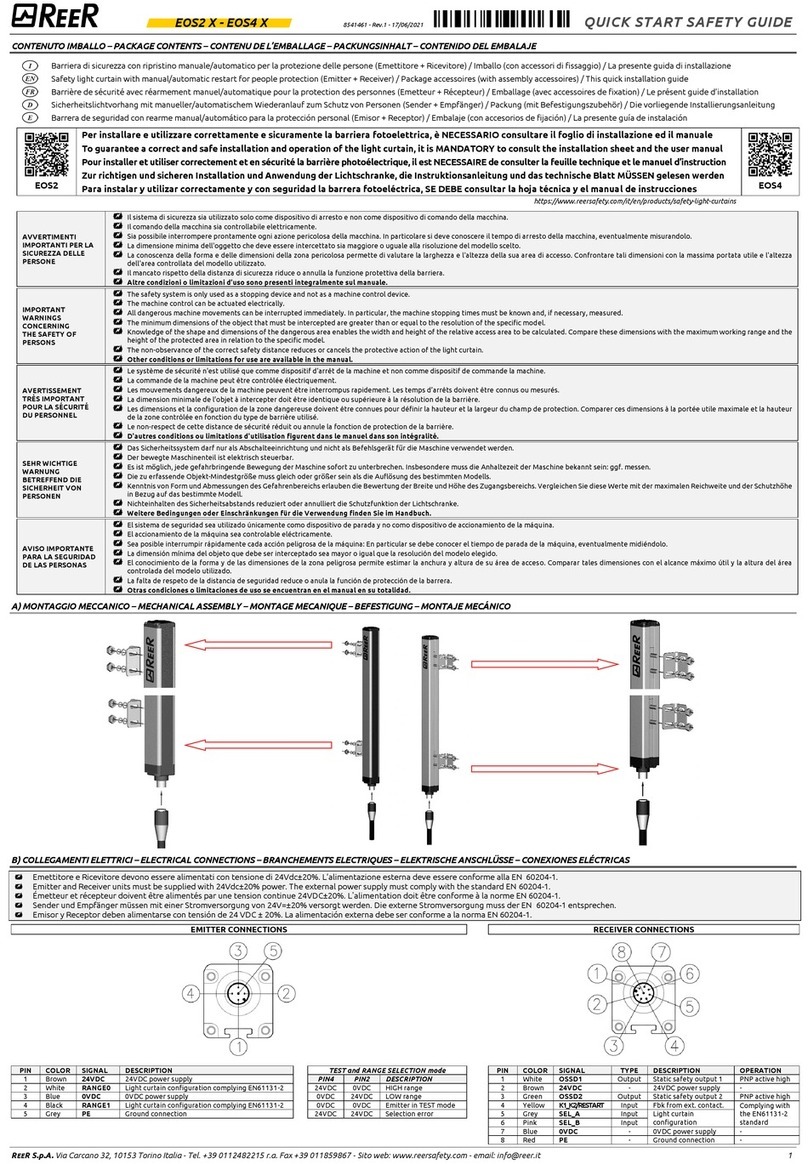

Reer

Reer EOS2 X quick start guide

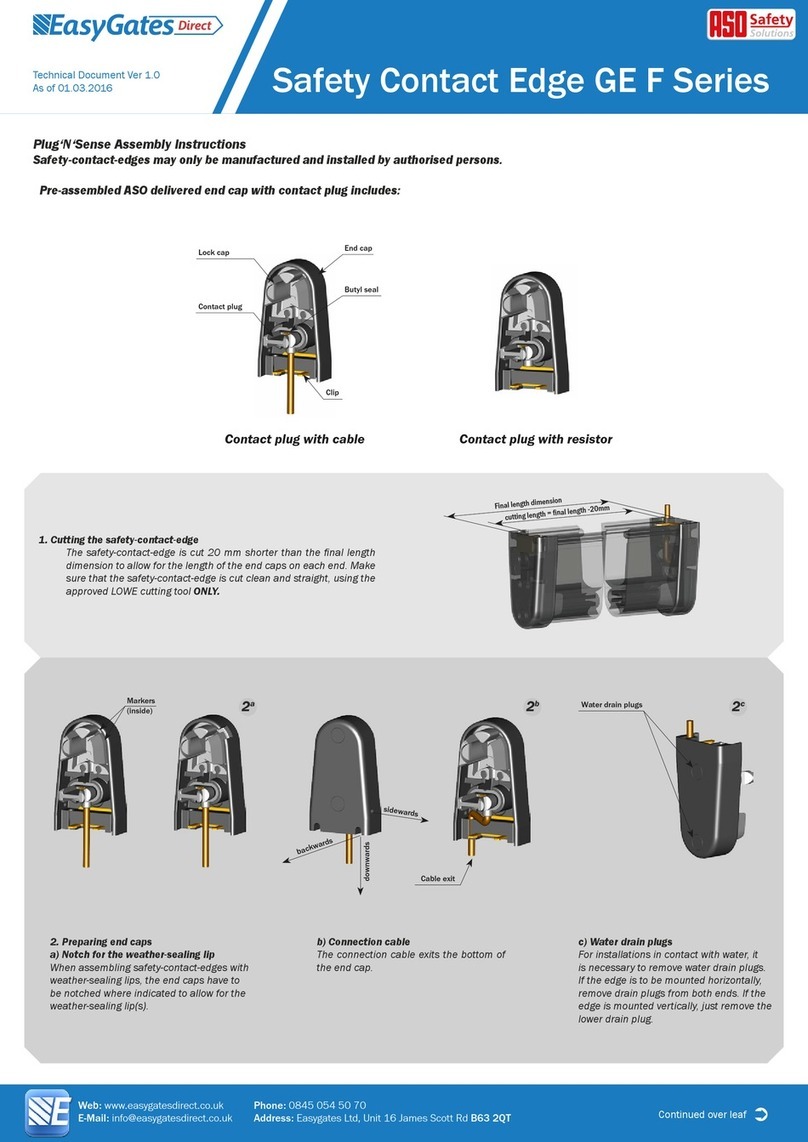

EasyGates

EasyGates ASO Safety Contact Edge GE F Series Assembly instructions