Industrieweg 87

2651BC Berkel & Rodenrijs

4EVAC Compact 500 quick guide

DoP OD 16.47

Page 2of 33

Table of Contents

1. What’s in the box?................................................................................................................................................................... 3

2. What else do I need to make it run? ................................................................................................................................ 3

3. Where do I start?..................................................................................................................................................................... 4

4. Unboxing 4EVAC Compact 500 ......................................................................................................................................... 4

5. Mounting Compact 500 onto a wall................................................................................................................................. 5

6. Installation.................................................................................................................................................................................. 6

Open the cabinet........................................................................................................................................................... 6

Mains.................................................................................................................................................................................. 8

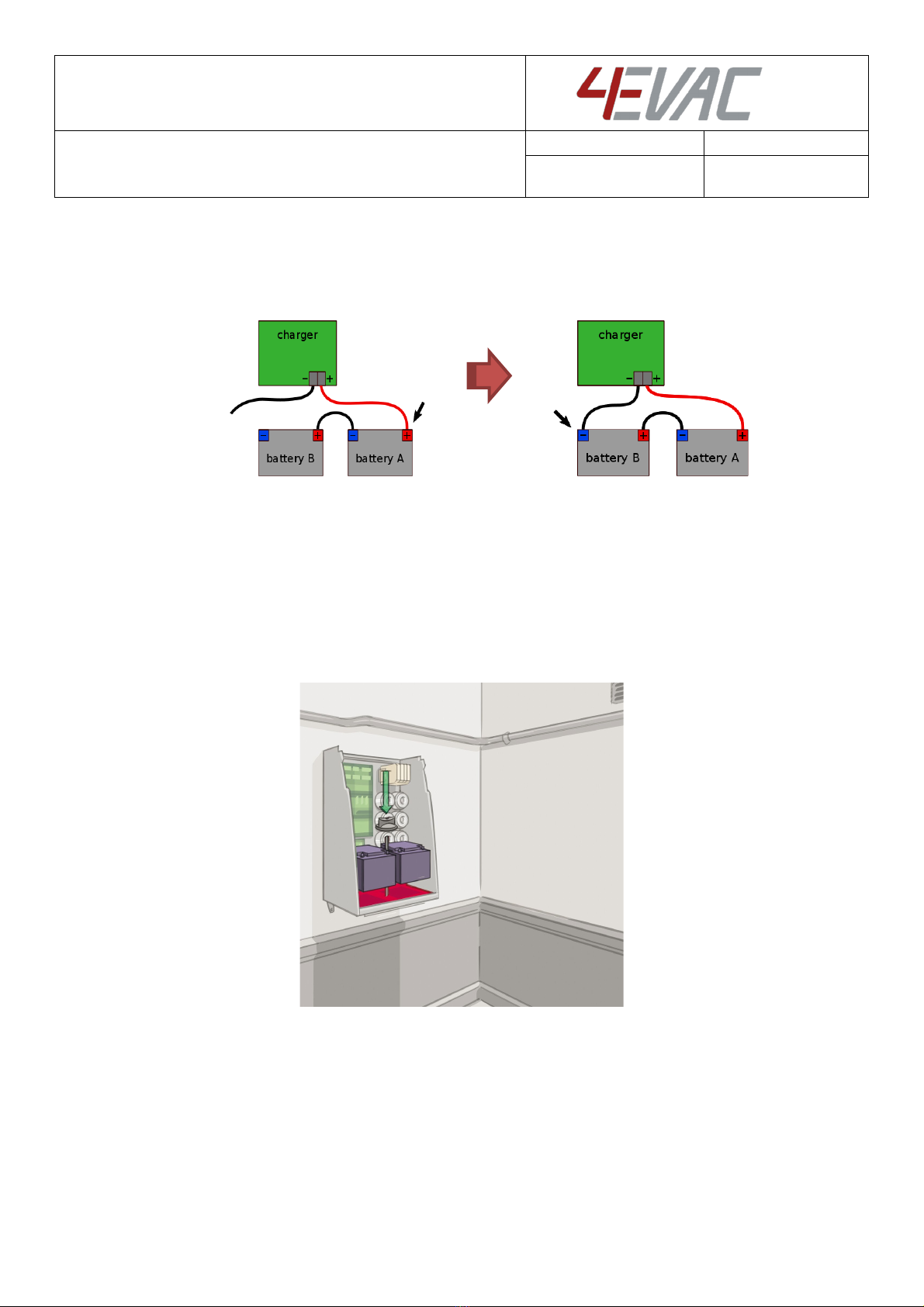

Battery ............................................................................................................................................................................... 8

EVAC / SILENCE / RESET inputs............................................................................................................................... 11

System status relay outputs ...................................................................................................................................... 11

6.5.1. EVAC out ...........................................................................................................................................................12

6.5.2.FAULT out .........................................................................................................................................................12

6.5.3.RESET out ..........................................................................................................................................................12

GPI / GPO ........................................................................................................................................................................12

Loudspeaker lines.........................................................................................................................................................13

6.7.1. Bridging to 200 W..........................................................................................................................................13

6.7.2. EOL board.........................................................................................................................................................16

Analog audio input (BGM) ........................................................................................................................................17

Network ports................................................................................................................................................................17

6.9.1. Global network (G-Net)................................................................................................................................18

6.9.2.Local network (L-Net) ..................................................................................................................................20

Memory card..................................................................................................................................................................21

Device ID setting..........................................................................................................................................................22

7. Startup and commissioning...............................................................................................................................................23

Power-on / power-off sequence............................................................................................................................23

Battery setting...............................................................................................................................................................23

Power supply equipment indications ...................................................................................................................25

Loudspeaker line impedance calibration ............................................................................................................26

Amplifer unit indications...........................................................................................................................................28

8. Connections and recommended cable types..............................................................................................................30

9. Technical specifications........................................................................................................................................................31