Eldex MicroPro User manual

What You Will Need

Everything you need to operate your MicroPro Pump has been supplied, including plumbing

connections, solvent reservoir and the µPro pump.

For routine maintenance you will need 1/4”, 5/16”, and 1/2” wrenches, a 5/32” and 9/64” hex

keys, as well as a small flathead screwdriver. Depending on your configuration, other tools may

be required. Tools needed for routine and specialized maintenance of your µPro pump are

included in Eldex Part No. 1432.

Unpacking & Location

Unpack your µPro pump carefully. You should not discard any packing material, as you will

want to re-use it for storage and shipping. If any damage is evident from improper handling

during shipment, you should contact the freight company that delivered the unit and file a claim.

Use your µPro pump in a clean, well ventilated and dust free environment, free of corrosive or

explosive vapors. The µPro Pump is designed for table top use; do not install your pump on the

floor. The µPro Pump must be operated in an upright position. Safety may be impaired if use of

your µPro pump is not as instructed.

II. INSTALLATION

Contents: Page:

What You Will Need 2.1

Unpacking & Location 2.1

Setup Summary 2.2

Setup & Connections 2.3

Electrical 2.3

Plumbing 2.8

Software 2.10

Priming & Purging 2.13

Outlet Connection 2.15

Equilibration & Characterization 2.17

© 2000 Eldex Laboratories, Inc. 2.1

CAUTION: We have tested this pump with 2 propanol. Residual amounts of 2 propanol may

be in the syringe and connecting tubing. You may wish to flush with an appropriate, miscible

solvent.

You may be using a variety of fluids which require special handling procedures and safety

precautions. Consult the appropriate MSDS (Material Safety Data Sheet) supplied with the

materials you will be using. Be certain to follow all handling, safety, and disposal procedures

appropriate for the materials you use.

Setup Summary

Following is a brief summary of the setup procedures. Detailed explanations and procedures

follow.

Electrical

1. Check the voltage setting on the Power Entry Module; correct if necessary.

2. Connect the power cord.

3. Make the I/O (Input/Output) connections (if installed and desired).

Plumbing

1. Fill the solvent bottle(s).

2. Degas the fluid.

3. Attach the fitting for the tubing from the solvent reservoir to the inlet port.

Software Setup

1. Set the syringe temperature (if installed).

2. Set the default refill and purge rates.

Prime Pump

1. Prime the syringe.

2. Purge to the outlet.

Outlet Connection

1. Connect from the outlet of the µPro pump to the downstream device.

Equilibrate and Characterize

If your µPro pump is fitted with a pressure transducer and you wish to use pre-pressurization,

equilibrate and characterize the system. Characterizing the system will measure the resistance of

the downstream devices and allow the µPro to pre-pressurize quickly.

1. Run the µPro using REAL TIME until the system pressure is equilibrated.

2. Characterize the µPro using SETUP/CONFIGURATION.

2.2

Setup and Connections

Electrical

Power Entry Module

Before connecting the power cord, check that the voltage input is properly set for the conditions

you will be using. Figure 2.1 shows the power entry module. The voltage is indicated in the

Fuse Drawer window (1).

If the voltage is not correctly set:

1. Remove the Fuse Drawer (1) (use a small screwdriver to pry up the spring on the underneath

side of the drawer).

2. Remove the Voltage Selection Insert (2) and

re-position it so the correct voltage will show

through the fuse drawer window.

3. Replace the fuses (3) with ones appropriate for

the desired voltage (see p. 1.16).

The correct voltage should now appear in the window and you may plug the modular power cord

into the Power Inlet receptacle (4).

Inputs/Outputs

I/O functions are on two optional printed circuit boards (PCB). The I/O board provides access

for all contact closure or TTL inputs and outputs (inputs and outputs are set for contact closure;

to change to TTL, consult the factory). The Analog I/O board provides access for analog inputs

and outputs.

2.3

Figure 2.1: Power Entry Module

120

100

1. Fuse Drawer Window

2. Voltage Selection Insert

3. Fuses 4. Power Inlet Receptacle

NOTE: You can damage the instrument

by connecting it to an improper voltage!

I/O Board

Figure 2.2 shows the I/O board. Table 2.1 indicates the function of the positions on the I/O

board.

To wire the I/O board for remote inputs or outputs, use your fingers or a small screwdriver and

pry away the modular connectors. Using a small screwdriver, loosen the screw on top of the

position you wish to wire, insert the wire and tighten the screw.

2.4

Figure 2.2: Input/Output Board

1234567891011121314

15 16 17 18 19 20 21 22 23 24 25 26 27 28

Modular Connectors

Table 2.1: I/O Functions

I/O position Function I/O position Function

1 & 2 Output 1 15 & 16 Run

3 & 4 Output 2 17 & 18 Run After Equilib.*

5 & 6 Output 3 19 & 20 Hold

7 & 8 Output 4 21 & 22 Stop

9 & 10 Output 5 23 & 24 Reserved*

11 & 12 Output 6 25 & 26 % Syringe

13 Ground 27 & 28 Pump Ready*

14 +24 Volts

*The function of these inputs and outputs differs when

using the pump in remote analog mode. See p.3.42 for

details.

Inputs

The µPro Pump can be remotely controlled from devices which send contact closures. Four

remote inputs are available on the I/O board as defined in Table 2.2:

Outputs

The µPro Pump can send contact closures to remote devices. Eight remote outputs are available

on the I/O board which are defined in Table 2.3.

2.5

Table 2.3: I/O Board Outputs

I/O Position Function Description

1 & 2 Output for control

of external device. Corresponds to first I/O entry on the local interface.

3 & 4 Output for control

of external device. Corresponds to second I/O entry on the local interface.

5 & 6 Output for control

of external device. Corresponds to third I/O entry on the local interface.

7 & 8 Output for control

of external device. Corresponds to fourth I/O entry on the local interface.

9 & 10 Output for control

of external device. Corresponds to fifth I/O entry on the local interface.

11 & 12 Output for control

of external device. Corresponds to sixth I/O entry on the local interface.

25 & 26 % Syringe

Dispensed Closes contact when pump has dispensed 95% of syringe

volume.

27 & 28 Pump Ready* Closes contact when pump has completed the equilibration part

of the file being run (when 17 & 18 are already closed, 27 & 28

do not close).

*The function of these inputs and outputs differs when using the pump in remote analog mode. See p.3.42 for details.

Table 2.2: I/O Board Inputs

I/O Position Function Description

15 & 16 Run Start Starts a file/cycle or file/sequence, or real time parameters,

including pre-pressurization & equilibration.

If contact 17 & 18 is closed, pump runs programmed file after

completing equilibration.

If contact 17 & 18 is not closed, pump runs under a hold

condition at the end of equilibration until contact 17 & 18 is

closed, when it proceeds with running the file.

17 & 18 Run After

Equilibration Start* Runs programmed file at end of equilibration (factory default

setting is closed).

19 & 20 Run Hold Freezes the clock; but, allows the pump to continue running

under existing conditions.

21 & 22 Run Stop Closing contact stops the pump and aborts the program.

23 & 24 Reserved*

*The function of these inputs and outputs differs when using the pump in remote analog mode. See p.3.42 for details.

Analog I/O Board

Figure 2.3 shows the Analog I/O board. Table 2.4 indicates the function of the positions on the

Analog I/O board.

To wire the Analog I/O board for remote inputs or outputs, use your fingers or a small

screwdriver and pry away the modular connectors. Using a small screwdriver, loosen the screw

on top of the position you wish to wire, insert the wire and tighten the screw.

Address and Configuration Ports

Two ports are on the rear panel are for system configuration (Figure 2.4). The upper port sets the

address of each pump in the system, while the lower port sets the hardware configuration of the

syringe (syringe size and pressure transducer type).

Do not change the settings of the address or configuration ports without consulting a factory

authorized technician. The various positions functions are indicated in Table 2.5.

2.6

Figure 2.3: Analog I/O Board

12 3 4 56

Modular Connector

Table 2.4: Analog I/O Board Functions

Analog

Position Function Analog

Position Function

1 Ground 4 5V

2 0-1V Pressure Output 5 Reserved**

3 0-1V %B* 6 Reserved**

*Output is 0-1V for flow rate in single syringe or reciprocating syringes modes. Output is 0-1V Pressure

Output for 2nd syringe in multi-independent syringe mode.

**Used only in remote analog control mode. See p. 3.42.

Serial Connections

One serial type port is provided on the rear panel for system control providing control of

additional µPro pump systems. The port is a female RS485. Contact a factory authorized

technician for appropriate cabling. Connecting the cabling is similar to typical computer serial

connections.

On “Master” µPro pump systems (systems with a local display and keypad), an additional serial

type port is provided on the rear panel for remote computer control (with appropriate software).

The port is a female RS232. Contact a factory authorized technician for appropriate cabling and

software. Connecting the cabling is similar to typical computer serial connections.

2.7

Table 2.5: Address/Configuration Port Functions

Address Port

Position Function Configuration

Port Position Function

0 Single Mode Master. 0 2mL syringe, no xducr.

1 Reciprocating Mode Master. 1 2mL syringe, 1k psi xducr.

2 Gradient Mode Master. 2 2mL syringe, 5k psi xducr.

3 Multi-Syringe Mode Master. 3 2mL syringe, 10k psi xducr.

4 Slave B or 2. 4 10mL syringe, no xducr.

5 Slave C or 3 or TLD in Binary

Gradient. 5 10mL syringe, 1k psi xducr.

6 Slave D or 4 or TLD in

Ternary Gradient. 6 10mL syringe, 5k psi xducr.

7 Gradient Master for TLD 7 10mL syringe, 10k psi xducr.

8 Reserved. 8 Reserved.

9 Reserved. 9 Reserved.

A Reserved. A Reserved.

B Reserved. B Reserved.

C Reserved. C Reserved.

D Reserved. D Reserved.

E Reserved. E Reserved.

F Reserved. F Reserved.

Figure 2.4: Address/Configuration Ports

RS485

Address Port

Configuration Port

Plumbing

Solvent Bottle

The µPro pump includes solvent bottles. 2mL syringe systems include a 200mL bottle; 10mL

syringe systems include a 400mL bottle.

Bottles come with standard GL-45 bottle caps and tubing assembly. The tubing assembly

includes plastic lines for fluid and helium with a fluid and helium filter. The helium line is

approximately 2 feet long and has a 1/4-28 fitting on the end. You may connect to this line using

a union to plumb helium.

Bottle Tray

In addition to the solvent bottles, a white plastic bottle tray is provided. The bottle tray is

intended to contain any fluid leaks. Place the bottle tray inside the unit, underneath the syringe,

with the wider part of the bottle tray oriented toward the rear. Place the bottle assembly in the

bottle tray.

Degassing

It is strongly recommended that you degas the fluid prior to using it. There are many means of

degassing the fluid, including ultrasonication and vacuum systems. Many users find helium

sparging convenient and effective. The µPro bottle assemblies are provided with the necessary

connections, as described above, to use helium degassing.

Inlet Connection

Attach the 1/4-28 tube nut to the inlet port of your µPro system. The specific location of your

inlet port depends on the configuration of your µPro system. Inlet ports will be on either a low

pressure active valve (if your system uses two low pressure active valves per syringe, the inlet

valve is to the left of the syringe) or a mechanical valve (see Figure 2.5). When using a dual

syringe system, the first syringe (syringe A when operating in binary gradient mode) is the

syringe under the display (to the right hand side of the system).

2.8

Figure 2.5: Inlet Connections

3

2

1

Low Pressure Active

Valve

1: Inlet Port

2: To Syringe

3: Purge Port

3

2

1

Mechanical Valve

1: Inlet Port

2: To Syringe

3: Outlet Port

NOTE! Do not strip the threads of the valve or fitting when making the inlet connection.

Purge Connection

Two functions are provided by the low pressure active valve (where present); providing an inlet,

and purging the syringe. A purge line may be provided with the µPro pump (a few feet of

Teflon®tubing with a 1/4-28 plastic tube nut attached). The purge line is connected to the upper

port of the low pressure active valve (see Figure 2.5). Do not strip the threads of the valve or

fitting.

Systems may use low pressure active valves for both system inlet (to left of syringe) and outlet.

Ternary and Quaternary Connection

A ternary or quaternary pump is supplied with a connection kit including both plumbing and

electronic connections needed. As additional ternary or quaternary syringes are added to a

binary gradient system, they are positioned adjacent to the left of the binary gradient system.

The pre-formed tubing and fittings are connected to port six of the slave pump and the mixer in

the binary gradient pump (see Figure 2.6). The cable is connected to the RS485. The power to

the slave pumps should be turned on before the binary gradient system power is turned on.

Transitional Liquid Delivery Connection

A transitional liquid delivery (TLD) pump is supplied with a connection kit including both

plumbing and electronic connections needed. The TLD pump is positioned adjacent to the right

of the binary gradient system. The output of the gradient pump is plumbed to position 5 of the

upper high pressure active valve. The pumping system’s output is plumbed to position 6 of the

upper high pressure active valve. The cable is connected to the RS485. The power to the TLD

pump should be turned on before the gradient system power is turned on.

2.9

TIP: Thread the purge line through the grommet on the left side of the instrument and channel

to a waste vessel.

Software Setup

Before setting the parameters of temperature and refill/purge rates, you may find it useful to read

the local interface overview on pages 3.5-3.6.

When navigating the menu driven software, you can return to the Main Menu by pressing

∆MENU until the Main Menu appears.

Temperature

To set the temperature (if fitted to your configuration of the µPro) of the syringe, select softkey D

(SETUP/CONFIGURATION) from the Main Menu. Select softkey B(SETUP) from screen D

and softkey C(TEMPERATURE) from screen D1.

The display will change to D1.3. Enter an appropriate temperature. Valid entries are from 0 to

50°C. In order to control temperature, the setting must be at least 5°C above ambient

temperature (at least 7°C above ambient temperature is preferred).

Since temperature control is fully integrated into the µPro, it may not be immediately apparent

whether your µPro is fitted with temperature control. You can determine whether your system

has temperature control by observing whether a fan is blowing air over the syringe when the

power to the instrument is turned on.

2.10

TIP: Temperature control is critically important, especially at flow rates in the lower range of

the capacity of the syringe. Temperature control significantly enhances flow precision and

the reproducibility of your results.

S#1→

SET TEMP:XX°C

D1.3

Enter desired temperature

Press ENTER

REAL TIME

EDIT

RUN

SETUP/CONFIGURATION

MAIN MENU

A

B

C

D

Select softkey D

SETUP

CONFIGURATION

TLD CONFIGURATION

D

B

C

D

Select softkey B

PRE-PRESSURIZATION

REFILL/PURGE RATE

TEMPERATURE

PRESSURE CALIBRATION

D1

A

B

C

D

Select softkey C

TIP: If you are several layers deep in the software, pressing DISPLAY and then ∆MENU will

return you directly to the Main Menu.

Default Refill and Purge Rates

When you press ENTER from screen D1.3 (above) after entering a temperature setting, you are

returned to screen D1 (below). To set the default refill and purge rates, press softkey B

(REFILL/PURGE RATE) and screen D1.2 will be displayed.

The values entered in screen D1.2 apply to the syringe indicated in the upper right corner of the

display. Pressing softkey Atoggles to other syringes or which may be present on the system or

ALL (single syringe systems do not have S#X on the display).

Refill Rate

The refill rate determines the flow rate into the syringe. The best rate to enter depends on your

application.

At the maximum refill rate, the syringe refills from empty in approximately 30 seconds (since the

µPro system has a default operating mode of refilling at the end of each run, it will be unusual

for the syringes to have to be completely refilled).

Press ENTER to accept the default rate or enter a valid number and press ENTER.

Purge Rate

The PURGE RATE determines the flow rate out of the syringe during purge. The best rate to

enter depends on your application.

Usually, accepting the default purge rate will be the best choice. Highly viscous fluids may

require a lower purge rate to avoid an overpressure error.

Press ENTER to accept the default rate or enter the desired purge rate and press ENTER.

% of Syringe

The % OF SYRINGE field determines the approximate percentage of the syringe expelled with

each cycle of the purge routine.

Enter a valid whole number (1-100) and press ENTER or press ENTER to accept the default.

2.11

PRE-PRESSURIZATION

REFILL/PURGE RATE

TEMPERATURE

PRESSURE CALIBRATION

D1

A

B

C

D

Press softkey B

REFILL:XXXXX.XX S#X→

PURGE RATE:XXXXX.XX

% OF SYRINGE:XXX

# OF CYCLES:

D1.2

A

Enter desired values

TIP: The slower the refill rate, the less likely the possibility of the introduction of air into the

system as a consequence of cavitation; but, it will take longer to refill the syringes.

Usually, accepting the default refill rate provides an acceptable compromise for purposes

of purging the syringes. You may wish to slow the refill rate down when the system is

running files (see p. 3.19).

TIP: It will rarely be necessary to purge the entire syringe repeatedly. Most often a value of

50% will be sufficient to accomplish the purposes of purge, and save solvent and time.

# of Cycles

The # OF CYCLES field determines the number of times the syringe is purged and refilled.

Enter a valid whole number (0-99) and press ENTER or press ENTER to accept the default.

Pressing RUN when the cursor is in either the PURGE RATE, % OF SYRINGE or the # OF

CYCLES fields will cause the syringe to purge and then refill. The µPro repeats this the number

of times entered; however, it executes these repeats purging the percentage of the syringe volume

entered.

Other Syringes in System

To program the same refill and purge rates for all syringes and run the cycle for all syringes

simultaneously, toggle softkey Ato ALL.

Toggle softkey Ato program and run the additional syringes independently.

2.12

TIP: You likely need to enter a higher value than the default in the # OF CYCLES field to be

certain that all the air has been expelled from the system. Usually 4 cycles of the purge

program will be adequate.

NOTE: At the end of a Refill/Purge routine, the syringe(s) will be in the fully forward, or

purged, state.

Priming and Purging

Inlet

To prime the syringe, first press softkey Awhile in screen D1.2 to check the refill and purge rates

for the syringes installed. Position the cursor on the PURGE RATE, % OF SYRINGE or # OF

CYCLES field and press RUN (when the S# field reads ALL, all syringes are run). The system

will automatically purge and refill the syringes the % of the syringe and number of times entered.

Outlet

Before purging the µPro to the outlet of the pump, you should turn PRE-PRESSURIZATION

OFF. To do this press ∆MENU from the D1.2 screen and select softkey A(PRE-PRESSURIZ-

ATION) to display screen D1.1. Toggle softkey Ato show PRE-PRESSURIZATION OFF.

Prime the output side of the µPro system using REAL TIME operation of the instrument. To

program REAL TIME operation, press DISPLAY and ∆MENU (or ∆MENU 3 times).

Press softkey Afrom the Main Menu. The cursor will appear in the FLOW field of screen A.

Enter a positive number to deliver flow to the output of the µPro pump (thereby purging the

outlet side of the µPro of any air or other solvents in the system) and press ENTER. 200µL/min or

so will usually be adequate to purge the outlet side of the µPro quickly.

Program the additional fields as desired (if you are using a gradient system, program the

additional percentages in equal amounts to prime all lines).

2.13

NOTE! During the priming and purging process be sure to check for inadequate degassing or

leaks at the various connections and correct as necessary.

PRE-PRESSURE:ON →

GAIN: LAST RUN →

CHARACTERIZATION

D1.1

A

B

C

Press DISPLAY & ∆

∆∆

∆MENU

REAL TIME

EDIT

RUN

SETUP/CONFIGURATION

MAIN MENU

A

B

C

D

Select softkey A

FLOW:XXXXX.XX

%B:XXX

ON:0 0 0 0 0 0

HI LIM:XXXXX LO:XXXX

A

Enter desired values

REFILL:XXXXX.XX S#X→

PURGE RATE:XXXXX.XX

% OF SYRINGE:XXX

# OF CYCLES:XX

D1.2

Press ∆

∆∆

∆MENU

PRE-PRESSURIZATION

REFILL/PURGE RATE

TEMPERATURE

PRESSURE CALIBRATION

D1

A

B

C

D

Select softkey A

PRE-PRESSURE:ON →

GAIN: LAST RUN →

CHARACTERIZATION

D1.1

A

B

C

Press softkey A to show OFF

Press RUN to run the system at the programmed values. Once all the air or other solvent has been

expelled from the outlet side of the µPro, press STOP.

2.14

NOTE! During the priming and purging process be sure to check for inadequate degassing or

leaks at the various connections and correct as necessary.

TIP: If multiple syringes are plumbed to a common outlet, as in gradient mode, program each

syringe to run at approximately equal flow rates (e.g., in gradient mode, after entering a

value in the flow field, enter 50% in the %B field (if a binary gradient system is being

used). Then press ENTER and RUN.

TIP: Air may become trapped in the mixer in gradient systems. This may be corrected by

plugging the output of the mixer and running the system until an elevated pressure is

attained (approximately 80% of system capability). Turning the flow to zero and allowing

the system to remain under pressure for 10-15 minutes will cause any air to become re-

absorbed.

Outlet Connection

Gradient Systems

The outlet of the µPro is at the outlet port of the mixer (see Figure 2.6). Connection to your

system is by a 10-32 tube nut and ferrule for 1/16” tubing. Slip the tube nut over the end of the

tubing and then slip the ferrule over the end of the tubing. Using a 1/4” wrench, remove the

fitting from the syringe input/output (see Figures 1.2 and 1.3). Insert the tubing end into the

syringe input/output.

Make sure that the end of the tubing “bottoms” firmly. Hold the tubing in place with one hand

while you use a 1/4” wrench to tighten the fitting 1/4 turn past “finger-tight”. Remove the tubing

from the syringe output and re-attach original tubing connection at syringe input/output. Attach

the seated outlet connection to the mixer output.

In ternary and quaternary applications, single syringe µPro pumps are connected to the mixer.

In a continuous flow gradient system with a TLD pump, the gradient pump is connected to port 5

of the upper high pressure active valve. The pumping system’s output is connected to port 6 of

the upper high pressure active valve. Detailed plumbing schematics are located in the Appendix.

Isocratic & Gradient Slave (High Pressure Active Valve) Systems

The outlet of the pump is port 6 of the high pressure active valve (see Figure 2.6). Connection to

your system is by a 10-32 tube nut and ferrule for 1/16” tubing. Follow the procedure described

for Gradient Systems concerning attaching the tube nut and ferrule to the 1/16” tubing.

Mechanical Valve Systems

The outlet of the pump is from the upper valve on the cylinder (see Figure 2.6). Connection to

your system is by a 10-32 tube nut and ferrule for 1/16” tubing.

You can seat the tube nut and ferrule in the port to the syringe.

Low Pressure Active Valve Systems

The outlet of the system is from the upper port on the outlet valve (to right of syringe).

Connection to your system is by a 1/4-28 plastic tube nut and ferrule for 1/16” tubing.

Do not strip the threads of the valve or fitting.

2.15

NOTE! Do not seat the ferrule in the mixer output, since doing so may damage the internal

components of the mixer.

Figure 2.6: Outlet Connections

3

2

1

Low Pressure Active

Valve

1: From Inlet Valve

2: To Syringe

3: Outlet Port

3

2

1

Mechanical Valve

1: Inlet Port

2: To Syringe

3: Outlet Port

1

2

345

6

High Pressure Active

Valve

6: Outlet Port

Mixer

1: Output to System

2: Ternary Inlet

3: Quaternary Inlet

1

3

2

Mixer Configuration

Gradient versions of the µPro pump are fitted with a mixer. The mixer uses a cartridge system to

accommodate mixers with different volumes. The different volumes allow you to exchange

mixer sizes easily to optimally configure the µPro to your flow rate. Table 2.6 indicates the

various mixers presently available.

When shipped from the factory, a 2mL µPro system is fitted with the 15µL mixer, a 10mL µPro

system is fitted with the 50µL mixer. 2mL µPro systems are also provided with a 5µL mixer as

an accessory (to install the 5µL mixer, be sure the remove the stir bar), 10mL systems are

provided with a 170µL mixer as an accessory.

To determine the mixer size in your unit, see page 5.5 for the procedure on replacing mixer

cartridges.

2.16

Table 2.6: Mixer Sizes

Mixer Size Mixer Type Syringe Size Flow Rate Range Mark to Distinguish

5µL 3 stage static 2mL 1-10µL/min PEEK with nipple

15µL 1 stage dynamic 2mL 10-40µL/min All PEEK material

50µL 3 stage dynamic 2mL and 10mL 20-100µL/min 2 steel bands

170µL 3 stage dynamic 10mL 100µL/min+ Grooves on steel bands

TIP: Thread your outline line through the grommet on the right side of the instrument.

Equilibrate and Characterize

If your µPro pump is fitted with a pressure transducer and you wish to use pre-pressurization,

equilibrate and characterize your system once the pump has been primed.

Equilibration

The equilibration conditions you choose will depend on your application. Generally, you will

want to equilibrate under conditions identical to those at the beginning of the file you will be

running. You will want to run equilibration with the system connected to the downstream

devices you will be using during the running of the file. An aim of equilibration is to determine

the operating pressure of the system so that system characterization accuracy is enhanced.

To equilibrate the system select REAL TIME operation (if you have not changed the menu from

the last point of these procedures, you are already in REAL TIME operation) from the Main

Menu by pressing softkey A.

The cursor will appear on the first line of the display. The flow rate you enter depends on your

application. Since the goal of equilibration is to determine the operating pressure of the system

at the desired flow, the final flow rate run to equilibrate should be the flow you will run in your

application. However, because syringes will need to compress a volume due to the

compressibility of fluids, you may want (for a relatively short period of time) to enter a higher

flow rate to accomplish this compression quickly. You can quickly and easily change the

entered flow rate by positioning the cursor in the FLOW field, enter a new flow rate and press

ENTER.

When you have entered the appropriate flow rate and press ENTER, the cursor will appear on the

second line, where you will enter the appropriate %B (if multiple syringes are present and

gradient mode is chosen) and press ENTER.

If you wish to activate one of the six external events you may do so (0 is OFF, 1 is ON). Press

enter through these fields so the cursor is positioned in the HI LIM (high pressure limit) field.

Enter a high pressure limit and press ENTER. The cursor will move to the LO (low pressure limit)

field. Enter an appropriate low pressure limit and press ENTER.

Replace the front cover if you have not done so already. Pressing RUN will cause the µPro

system to run the syringes under the specified conditions.

You will want to allow the system to pump for a period of time sufficient for the pressure to

stabilize at the final flow rate. Once the pressure has stabilized, you may characterize the

system.

2.17

REAL TIME

EDIT

RUN

SETUP/CONFIGURATION

MAIN MENU

A

B

C

D

Select softkey A

FLOW:XXXXX.XX

%B:XXX

ON:0 0 0 0 0 0

HI LIM:XXXXX LO:XXXX

A

A

B

C

D

Enter desired values

TIP: If multiple syringes are plumbed to a common outlet, as in gradient mode, you will want to

program the additional syringes (or % B, etc.) at the rates they will operate at during the

beginning of your file. For example, if the program you intend to run begins at 5% B,

program 5%B during this “REAL TIME” equilibration.

Chacterization

The purpose of characterizing the system is to determine the resistance of the system so the fluid

in the syringes will be compressed and the syringes will quickly begin to deliver fluid to the

downsteam system.

Before beginning characterization, press STOP to stop running the equilibration step described

above and make a note of the operating pressure as shown on the Display screen. You should

allow the system pressure to fall below your target pressure before characterizing.

To characterize the system, press ∆MENU to return to the Main Menu. Press softkey Dto select

SETUP/CONFIGURATION. From screen D, press softkey Bto select SETUP and screen D1

will appear.

From screen D1 select softkey A(PRE-PRESSURIZATION) to display screen D1.1. Press

softkey Ato toggle the PRE-PRESSURIZATION field to ON. Select softkey C(CHARACTER-

IZATION) to display screen D1.1.1.

Enter the pressure value you arrived at after stabilization during equilibration plus 10% in the

TARGET PRESSURE field. With the cursor in the MAX FLOW field, enter the maximum flow

rate you want the system to run at during pre-pressurization.

2.18

FLOW:XXXXX.XX

%B:XXX

ON:0 0 0 0 0 0

HI LIM:XXXXX LO:XXXX

A

A

B

C

Press ∆

∆∆

∆MENU

REAL TIME

EDIT

RUN

SETUP/CONFIGURATION

MAIN MENU

A

B

C

D

Select softkey D

SETUP

CONFIGURATION

TLD CONFIGURATION

D

B

C

D

Select softkey B

PRE-PRESSURE:ON →

GAIN: LAST RUN →

CHARACTERIZATION

D1.1

A

B

C

Toggle softkey A to show ON

Select softkey C

TARGET PRESS:XXXXX

MAX FLOW: XXXXX.XX

%B:XXX

D1.1.1

Enter pressure, flow, %B

Press ENTER

PRE-PRESSURIZATION

REFILL/PURGE RATE

TEMPERATURE

PRESSURE CALIBRATION

D1

A

B

C

D

Select softkey A

TIP: Usually a minimum value of 100µL/min., or 5 to 10 times the actual flow rate (whichever

is greater) is a good value to enter in the MAX FLOW field. Too high a value will cause the

system to overshoot the pressure, too low a value will cause the system to take an

excessive amount of time in characterizing and pre-pressurizing.

If you have a gradient µPro, the %B field will be displayed on line three (%C will appear on

ternary systems and %D will appear on quaternary systems). Enter the value for %B which you

will use as your starting conditions. Press ENTER and screen D1.1.2 will be displayed.

Press RUN and the display will change to screen D1.1.3. The pump will begin running and

calculating the resistance of the system. When it has finished characterizing, a value will be

displayed in the GAIN VALUE field and the pump will stop running. You may press DISPLAY

during the characterization process to monitor the progress if you wish (the FLOW field in the

Display screen will display 0.00 when characterization is complete).

Now the system has been characterized and you are ready to run programmed files.

2.19

TIP: You will want to re-run the equilibration and characterization routines described above

when you change the system in a way which alters the systems resistance (e.g., use a

different column). Since characterization defines the system resistance, changes in the

flow rate alone do not require re-running the characterization routine.

SYSTEM IS

IDLE

REAL-TIME USER-FILE

1.0000 1.0000

D1.1.2

SYSTEM IS

CHARACTERIZING

REAL-TIME USER-FILE

1.0000 1.0000

D1.1.3

2.20

Table of contents

Other Eldex Water Pump manuals

Popular Water Pump manuals by other brands

DAYLIFF

DAYLIFF DWY370 Installation & operating manual

MP PUMPS

MP PUMPS PO 30 Instruction bulletin

UNIBLOC

UNIBLOC PD600 Operation & service manual

Edwards

Edwards XDS46i instruction manual

AquaScape

AquaScape AquaForce 1000 GPH Installation & maintenance instructions

Bijur Delimon

Bijur Delimon BS-B operating instructions

AFRISO

AFRISO PrimoSol 130 Series operating instructions

GO Industries

GO Industries Adam Pumps TECH FLOW 3C TRANSLATION OF ORIGINAL INSTRUCTIONS

Pentair

Pentair FREEFLO installation guide

Jesco

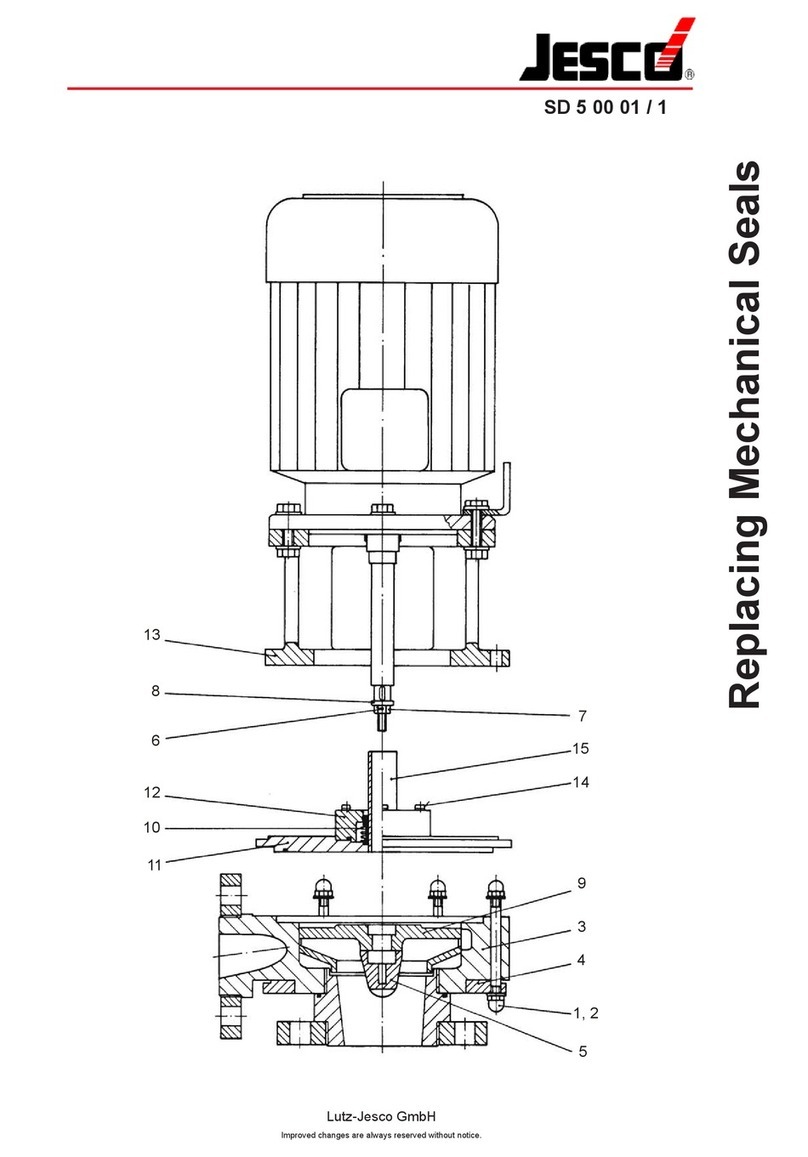

Jesco SD 5 00 01/1 quick start guide

Grundfos

Grundfos DWK Series Service instructions

RICE HYDRO

RICE HYDRO TRE-8 Manufacturer operating instructions