Elecro Engineering B-100 Installation instructions

Other Elecro Engineering Swimming Pool Heater manuals

Elecro Engineering

Elecro Engineering 800 Series Parts list manual

Elecro Engineering

Elecro Engineering EVOLUTION Installation instructions

Elecro Engineering

Elecro Engineering Titan Optima Series Installation instructions

Elecro Engineering

Elecro Engineering In-Line + Swimming Pool Heater Parts list manual

Elecro Engineering

Elecro Engineering Cygnet Evolution 2 Installation instructions

Elecro Engineering

Elecro Engineering 800 Series User manual

Elecro Engineering

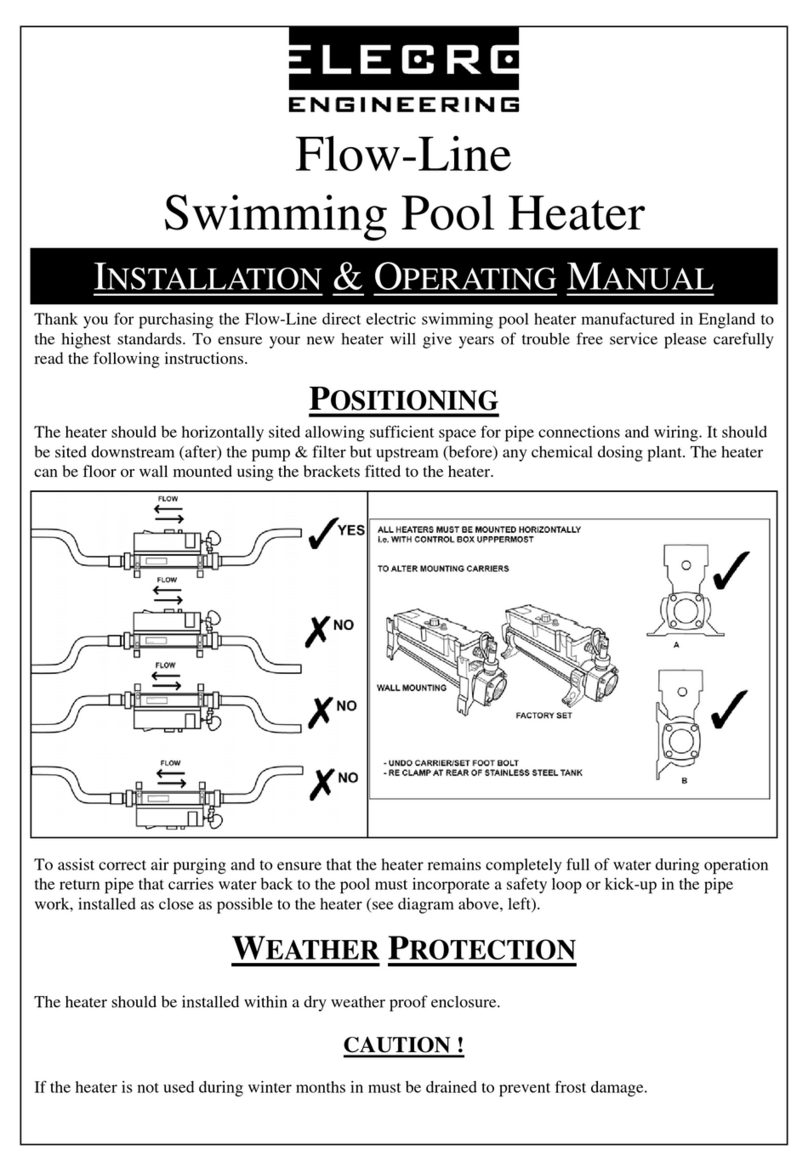

Elecro Engineering FLOW-LINE Installation instructions

Elecro Engineering

Elecro Engineering TiTANIUM Parts list manual

Elecro Engineering

Elecro Engineering FLOW LINE Installation instructions

Elecro Engineering

Elecro Engineering IN-LINE+ Installation instructions

Popular Swimming Pool Heater manuals by other brands

Pentair Pool Products

Pentair Pool Products MiniMax CH 150 Operation & installation manual

Jandy

Jandy LJ Installation and operation manual

Pentair Pool Products

Pentair Pool Products MiniMax NT Series Operation & installation manual

Raypak

Raypak P-R185A to P-R405A, C-R185A to Installation and operating instructions

Hayward Pool Products

Hayward Pool Products HP40A Installation instructions manual

Laars

Laars Lite 2 LC Installation and operation manual

SUPREME

SUPREME Heatseeker Solar Pool Heating user guide

UTC

UTC ICP HMP-03 Installation instructions and homeowner's manual

Pentair

Pentair ETi 400 installation guide

Hayward

Hayward ENP2M-9A Installation instructions manual

BriskHeat

BriskHeat TOT Series instruction manual

Hayward

Hayward C-SPA-XI 5.5 Installation & operation manual