Electrex Atto RCM D4 ECT User manual

INSTALLATION GUIDE

!

COPYRIGHT

Electrex is a trademark of Akse S.r.l. All rights reserved.

It is forbidden to duplicate, adapt, transcript this document without Akse written

authorization, except when regulated accordingly by the Copyright Laws.

WARRANTY

This product is covered by a warranty against material and manufacturing defects for a 24

months period from the manufacturing date.

The warranty does not cover the defects that are due to:

• Negligent and improper use

• Failures caused by atmospheric hazards

• Acts of vandalism

• Wear out of materials

• Firmware upgrades

Akse reserves the right, at its discretion, to repair or substitute the faulty products

The warranty is not applicable to the products that will result defective in consequence o

f

a negligent and improper use or an operating procedure not contemplated in this manual.

RETURN AND REPAIR FORMALITIES

Akse accepts the return of instruments for repair only when authorized in advance. Th

e

transport costs are at customer charge.

RE-SHIPPING OF REPAIRED PRODUCT

The terms for re-shipment of repaired products are ex-works, i.e. the transport costs ar

e

at customer charge.

Products returned as detective but found to be perfectly working by our laboratories, will

be charged a fl at fee to account for checking and testing time irrespective of the warrant

y

terms.

SAFETY

This instrument was manufactured and tested in compliance with IEC 61010-1 CAT III

-

300V class 2 standards for operating voltages up to 300 VAC rms phase to neutral.

In order to maintain this condition and to ensure safe operation, the user must comply with

the indications and markings contained in the following instructions:

• When the instrument is received, before starting its installation, check that it i

s

intact and no damage occurred during transport.

• Before mounting, ensure that the instrument operating voltages and the main

s

voltage are compatible then proceed with the installation.

• The instrument power supply needs no earth connection.

• The instrument is not equipped with a power supply fuse; a suitable external

protection fuse must be foreseen by the contractor.

• Maintenance and/or repair must be carried out only by qualifi ed, authorized

personnel

• If there is ever the suspicion that safe operation is no longer possible, the instrumen

t

must be taken out of service and precautions taken against its accidental use.

Operation is no longer safe when:

•There is clearly visible damaged.

•The instrument no longer functions.

•After lengthy storage in unfavorable conditions.

• After serious damage occurred during transport

The instruments must be installed in respect of all the local regulations.

OPERATOR SAFETY

Warning: Failure to observe the following instructions may lead to a serious danger o

f

death.

• During normal operation dangerous voltages can occur on instrument terminals and

on voltage and current transformers. Energized voltage and current transformer

s

may generate lethal voltages. Follow carefully the standard safety precautions whil

e

carrying out any installation or service operation.

• The terminals of the instrument must not be accessible by the user after the installation.

The user should only be allowed to access the instrument front panel where th

e

display is located.

• Do not use the digital outputs for protection functions nor for power limitation functions.

The instrument is suitable only for secondary protection functions.

• The instrument must be protected by a breaking device capable of interrupting both

the power supply and the measurement terminals. It must be easily reachable by th

e

operator and well identifi ed as instrument cut-off device.

• The instrument and its connections must be carefully protected against short-circuit.

Precautions: Failure to respect the following instructions may irreversibly damage to th

e

instrument.

• The outputs and the options operate at low voltage level; they cannot be powered b

y

any unspecifi ed external voltage.

• The application of currents not compatible with the current inputs levels will damag

e

to the instrument.

Further documentation may be downloaded from our web site www.electrex.it.

This document is owned by company AKSE that reserves all rights.

DECLARATION OF CONFORMITY

Akse hereby declares that its range of products complies with the following directives EM

C

2014/30/EU, 2014/35/EU and complies with the following product’s standard CEI EN

61326 - Ed. 2.0 (2012) – IEC 61326 - Ed. 2.0 (2012), CEI EN 61010- Ed. 3 (2010) – IE

C

61010- Ed. 3 (2010). The product has been tested in the typical wiring confi guration and

with peripherals conforming to the EMC directive and the LV directive.

Atto RCM D4 ECT

MODELS

PFA74D1-D2-B ATTO RCM D4 ECT RS485 230÷240V 2DI 2DO

4COMMON TRANSDUCER / ANALYZER

2

1

LED

LED description:

LED (1) A green LED pulses indicating the operation of the instrument

LED (2) Two LEDs pulsate indicating the communication activity of the RS485 port (red

TX LED, green RX LED)

MECHANICAL CHARACTERISTICS

Case Self-extinguishing plastic material class V0

Protection degree IP40 on front panel

Size 70 x 90 x 58 mm (4 DIN modules)

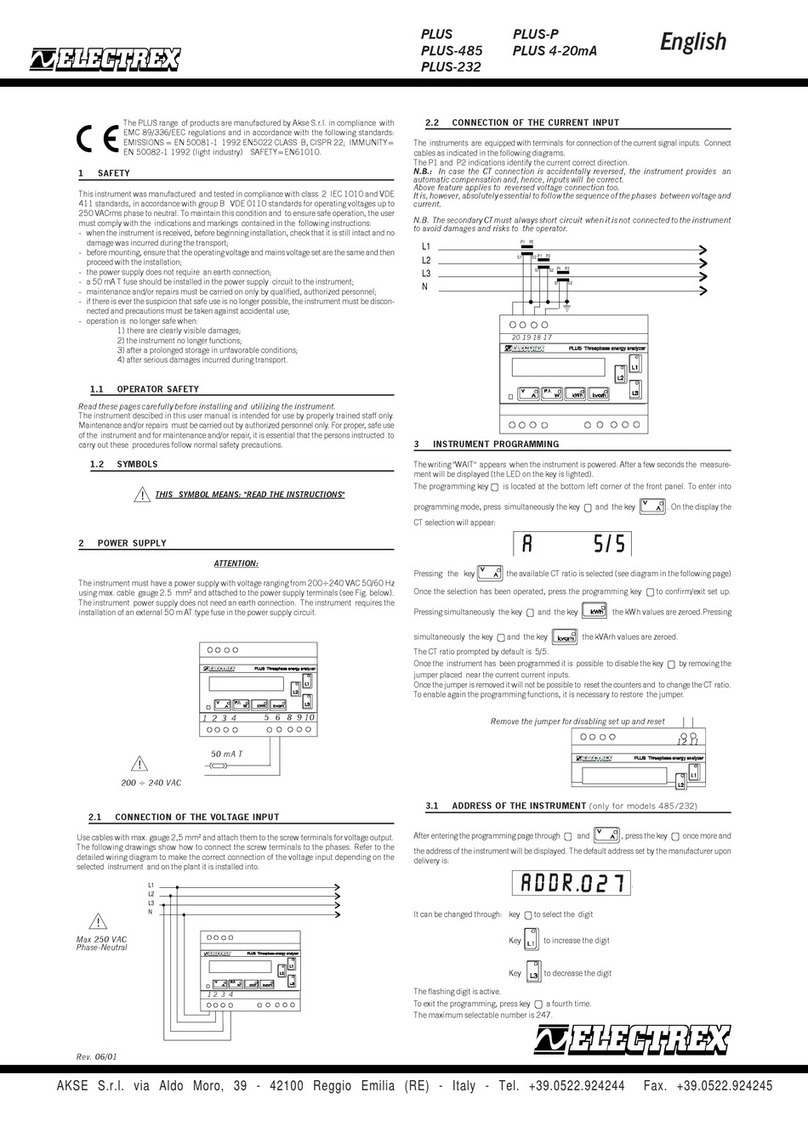

VOLTAGE INPUTS

Direct Up to 300 Vrms phase-neutral

or 519 Vrms phase to phase

Overload: 900 Vrms phase to phase for 1 sec

Power supply 230/240Vac +/- 10% 50/60Hz

Self consumption < 2,5VA

SETUP SEQUENCE

PARAMETERS VALUES AVAILABLE DEFAULT

DIGITAL OUT 1

POLARITY (note A) N.O.,N.C. N.O.

DIGITAL OUT 2 (see DIGITAL OUT 1)

INPUTS - OUTPUTS

OUTPUTS INPUTS

10 C1 Common 1 (negative) 19 C2 Common 2 (negative)

11 O1 Diff erential intervention 20 I2 Function test

12 C2 Common 2 (negative) 21 C1 Common 1 (negative)

13 O2 Pre-alarm intervention 22 I1 Diff erential intervention reset

OUTPUTS INPUTS

Maximum applicable voltage: 27 Vdc Supply voltage (external): from 10 to 30

Vdc

Maximum switchable current: 27mA Current consumption: from 2 to

10mA

Max. count frequency 10 or 100Hz

N.B. Digital outputs (Optocoupled NPN transistor

type for DIN 43864).

N.B. For gas meters a galvanic separation is

needed per ATEX standards

101112

1920

AUX

AUX

13

2122

NO

C

NC

NO

C

NC

R

e

l

a

y

R

e

l

a

y

230 V~

24V =

N L

- +

NOTE: A

N.O. Normally open

N.C. Normally closed

TABLE n.1 - Eg. Modbus registers reading parameters, for the complete list refer to

the instrument’s protocol)

INPUT REGISTERS

REGISTER DESCRIPTION TYPE UNIT

30219 Frequency of U1N (f) Float IEEE754 [Hz]

30221 Phase to Neutral Voltage, RMS Amplitude (U1N) Float IEEE754 [V]

30223 Phase to Neutral Voltage, RMS Amplitude (U2N) Float IEEE754 [V]

30225 Phase to Neutral Voltage, RMS Amplitude (U3N) Float IEEE754 [V]

30233 Phase Current, RMS Amplitude (I1) Float IEEE754 [A]

30235 Phase Current, RMS Amplitude (I2) Float IEEE754 [A]

30237 Phase Current, RMS Amplitude (I3) Float IEEE754 [A]

SETUP SEQUENCE

PARAMETERS VALUES AVAILABLE DEFAULT

RS-485

ADDR (485 address) 1 ... 247 27

COM (Baud rate) 2400, 4800, 9600, 19200, 38400 38400

COM (Data Bit) 7 or 8 8

COM (Parity) N = no parity, E = even parity,

O = odd parity N

COM (Stop bit) 1 or 2 2

S.T. (Silent Time) 0 ... 1000 mS (Step of 10) 100

NETWORK

IMAX 5 ... 16 A / 5 ... 16 mA 5/.005

CUTOFF (Current) 0 ... 16 0

DIFFERENTIAL

RCD ENABLING CH 1, 2, 3 CH 1

INTERVENTION

THRESHOLD 0 ... X mA 30 mA

PRE-ALARM THRESHOLD 0 ... X mA 30 mA

INTERVENTION TIME 0 ... 5000 mS 0

PRE-ALARM TIME 0 ... 5000 mS 0

PRE-ALARM HYSTERESIS 0 ... 100 % 5 %

TABLE n.2 (Eg. Modbus registers writing parameters, for the complete list refer to

the instrument’s protocol).

HOLDING REGISTERS

REGISTER DESCRIPTION TYPE

41001 RCD status:

Bit 0 = CH 1 intervention

Bit 1 = CH 2 intervention

Bit 2 = CH 3 intervention

Bit 4 = CH 1 pre-alarm

Bit 5 = CH 2 pre-alarm

Bit 6 = CH 3 pre-alarm

Integer

41002 RCD enabling:

Bit 0 = Channel 1 (default)

Bit 1 = Channel 2

Bit 2 = Channel 3

Integer

41003 RCD tripping threshold (mA) Integer

41004 RCD tripping time (ms) Integer

41005 RCD pre-alarm threshold (mA) Integer

41006 RCD pre-alarm time (ms) Integer

41007 Pre-alarm hysteresis Integer

The instrument is equipped with a separate power supply. The power supply terminals

are numbered (17) and (18). Use cables with max cross-section of 2,5 mm2 if stranded,

4 mm2 if rigid.

POWER SUPPLY

17 18 1920U1 U2 U3 N

AUXVOLTAGE INPUT POWER

2122

1

2

SERIAL LINE CONNECTION

S1 S2 S1 S2 S1 S2 A B

T

101112

I1 I2 I3 RS-485 AUX

13

POWER SUPPLY

1 230/240Vac +/- 10% 50/60Hz

2 F: 500 mA T

Max cable length: 1000 meters.

RS485

Address 27

Baud rate 38400

Parity None

Bit of Stop 2

3P3W

3P4W1P2W

2P2W

CURRENT CONNECTION

Use only the CT’s provided with the instrument. Connect the CT outputs to the terminals

marked I1, I2, I3 according to the applicable diagrams that follow. Each input corresponds

to a diff erential channel.

S1 S2 S1 S2 S1 S2

CH1 CH2 CH3

L1

L2

1P2W

2P2W / 3P3W-B

Use cables with max cross-section of 2,5 mm2 if stranded, 4 mm2 if rigid and connect them

to the terminals marked VOLTAGE INPUT on the instrument according to the applicable

diagrams that follow.

VOLTAGE CONNECTION

U1 U2 U3 N

VOLTAGE INPUT

L

N

U1 U2 U3 N

VOLTAGE INPUT

L1

L2

L3

N

U1 U2 U3 N

VOLTAGE INPUT

L1

L2

L3

U1 U2 U3 N

VOLTAGE INPUT

L1

L2

L3

N

U1 U2 U3 N

VOLTAGE INPUT

L

N

3P4W / 3P4W-B-3U / 3I

3P3W / 3P3W-B-3U

3I

3P4W-B

U1 U2 U3 N

VOLTAGE INPUT

L1

N

L2

L3

3CH

EXAMPLE CONNECTION OF 3 DIFFERENTIAL CHANNELS

L1

L2

L3

N

S1 S2 S1 S2 S1 S2

CH1 CH2 CH3

L1

N

L1

L2

L3

The instrument can measure up to 3 specifi c diff erential channels at the same time. Enable

the corresponding RCD channels according to the wiring used.

S1 S2 S1 S2 S1 S2

CH1 CH2 CH3

L1

N

S1 S2 S1 S2 S1 S2

CH1 CH2 CH3

L1

L2

L3

N

S1 S2 S1 S2 S1 S2

CH1 CH2 CH3

L1

L2

L3

akse srl Via Aldo Moro, 39 42124 Reggio Emilia Italy

P.I. 01544980350 R.E.A. 194296 Cap. Soc. Euro 85.800,00 i.v.

Subject to modifi cation without notice.

Edition 2020 09 03 ENG0351

Made

in Italy

Pensato, progettato e prodotto in Italia

Engineered and manufactured in Italy

Other Electrex Protection Device manuals