Electro-Sensors TR400 User manual

Model TR400

Programmable Process Ratemeter

Installation & Operation Manual

Release Date: Oct, 2012

Model TR400

Programmable Process Ratemeter

Installation and Operation Manual

Part Number: 990−000500

Revision G

Electro-Sensors®, Inc.

6111 Blue Circle Drive

Minnetonka, MN 55343-9108

Contact us at:

Local: 952-930-0100

National: 1-800-328-6170

Fax: 952-930-0130

Web: www.electro-sensors.com

Sales www[email protected]

Support: [email protected]

i

Rev G

Introduction To This Manual

What is in this

manual? This installation and operations manual provides detailed technical information about

the TR400 Programmable Process Ratemeter. It should serve as your technical

resource to install, set up, operate, and test the TR400.

Who should use

this manual

(audience)

Keep in mind that the function of the TR400 installed in a mechanical process is to

monitor speed and direction; therefore, it must be installed by qualified personnel

only. This manual is designed for persons who have the primary responsibility to

install, set up, operate, and test the TR400.

The secondary audience would be those persons seeking technical information about

the electrical concepts and operation of the TR400.

Knowledge

level Persons installing, setting up, and operating the TR400 should have good knowledge

and understanding of electrical and mechanical concepts and principals pertaining to

Programmable Process Ratemeters. Again, the TR400 should be installed by

qualified personnel only.

Notices •Installing Electro-Sensors, Inc., products is the responsibility of the purchaser,

and is in no way guaranteed by Electro-Sensors, Inc.

•While the information in this manual has been carefully reviewed, Electro-

Sensors, Inc., assumes no liability for any errors or omissions in this manual.

Additionally, Electro-Sensors, Inc., reserves the right to make changes to any

part of the information in this manual or the product described herein without

further notices.

•No part of this manual may be photocopied, reproduced, or translated to another

language without the prior written consent of Electro-Sensors, Inc.

ii

Rev G

Introduction To This Manual

How this manual is organized

Manual

navigation tools This manual contains the following navigation tools:

•Table of contents

•Beginning section table of contents

•Index

Each is designed to help you find the information you need quickly.

Manual

sections This manual is divided into the following sections:

•Section 1: Warnings and Cautions, discusses personal injury possibilities and

potential damage to equipment.

•Section 2: TR400 Installation, discusses installing the TR400 into a panel.

•Section 3: TR400 Wiring and DIP Switches, discusses practical wiring

practices, wiring schematics, and configuring DIP switches.

•Section 4: TR400 Setup, discusses the TR400 parts and functions, and set up

information.

•Section 5: TR400 Programming, discusses programming the operational

variables of the TR400.

•Section 6: TR400 Diagnostics, discusses the tests used to verify the operation

and functionality of the TR400.

•Appendix A: TR400 Specifications, discusses the specifications for the TR400.

iii

Rev G

Table of Contents

How this manual is organized..........................................................................................................ii

T

ABLE OF

C

ONTENTS

...............................................................................................................................

III

S

ECTION

1.................................................................................................................................................1

W

ARNINGS

&

C

AUTIONS

..........................................................................................................................1

Introduction......................................................................................................................................1

About warnings and cautions...........................................................................................................2

Warnings..........................................................................................................................................3

Cautions...........................................................................................................................................4

S

ECTION

2.................................................................................................................................................5

TR400

I

NSTALLATION

..............................................................................................................................5

Introduction......................................................................................................................................5

Installation overview........................................................................................................................6

Installing the TR400 ........................................................................................................................7

S

ECTION

3.................................................................................................................................................9

TR400

W

IRING

&

DIP

S

WITCHES

.............................................................................................................9

Introduction......................................................................................................................................9

Recommended wiring practices.....................................................................................................10

TR400 wiring schematics ..............................................................................................................11

4-20 mA/0-10 Vdc analog output ..................................................................................................13

Switch input wiring........................................................................................................................14

Single-channel and quadrature signal wiring.................................................................................15

A and B channel input signal wiring..............................................................................................16

TR400 DIP switches......................................................................................................................17

S

ECTION

4...............................................................................................................................................19

TR400

S

ET

-U

P

P

ARAMETERS

.................................................................................................................19

Introduction....................................................................................................................................19

TR400 parts and functions.............................................................................................................20

TR400 set-up parameters...............................................................................................................22

S

ECTION

5...............................................................................................................................................23

TR400

P

ROGRAMMING

...........................................................................................................................23

Introduction....................................................................................................................................23

Programmable variables.................................................................................................................24

How to select a variable and view its data.....................................................................................27

Keypad keys used to access and program variables ......................................................................29

How to select and change a variable’s numerical value ................................................................30

Programming rate and signal parameters.......................................................................................32

Programming the display operation...............................................................................................33

Programming the relay outputs......................................................................................................35

Programming the analog output.....................................................................................................38

Programming the switch inputs .....................................................................................................39

Programming the display features .................................................................................................40

iv

Rev G

Table of Contents

S

ECTION

6...............................................................................................................................................41

TR400

D

IAGNOSTICS

..............................................................................................................................41

Introduction....................................................................................................................................41

Keypad and display test.................................................................................................................42

Relay output test ............................................................................................................................43

Switch input test.............................................................................................................................44

Analog output calibration ..............................................................................................................45

Resetting the variables...................................................................................................................47

Setting and changing the security code number.............................................................................48

System slowdown test....................................................................................................................50

Viewing shaft deviation.................................................................................................................51

Clearing the LRC code...................................................................................................................52

TR400

S

PECIFICATIONS

..........................................................................................................................53

I

NDEX

......................................................................................................................................................55

1

Rev G

Section 1

Warnings & Cautions

Introduction

This section discusses warnings and cautions to guard against the possibility of

injury to persons and damage to equipment. Since the TR400 monitors the speed and

direction of various mechanical systems, observe all warnings and cautions that

pertain to the mechanical systems as well.

In this section These are the topics:

Topic See Page

About warnings and cautions 2

Warnings 3

Cautions 4

2Rev G

S1−

−−

−Warnings & Cautions

Caution

Warning

About warnings and cautions

Important

notice Read through the warnings and cautions in this section before attempting to install,

set up, or operate the TR400. Warnings and cautions appear in this section and

throughout this manual.

Definitions Warnings are given when there is the possibility of injury to persons.

Cautions are given when there is the possibility of damage to equipment.

The warning label will appear as follows:

The caution label will appear as follows:

Continued on next page

3

Rev G

S1−

−−

−Warnings & Cautions

Warnings

Always turn the power source OFF before wiring the TR400. Failure to observe this warning

could result in an electrical shock or damage to the equipment.

During a Stop condition, any slight movement of the shaft or magnetic disc could activate the

control relay and start the motor. To prevent starting the motor accidentally, always use proper

LOCKOUT, TAG OUT procedures. Failure to observe this warning could result in an injury to

persons or damage to equipment.

Do not touch the Pulser Disc or Wrap while it is spinning. Failure to observe this warning could

result in a hand injury.

Always wear protective eye goggles when using power tools. Failure to observe this warning

could result in an eye injury or blindness.

Practical wiring practices must be followed when wiring industrial equipment such as the

TR400. Failure to follow practical wiring practices could result in an injury to persons or damage

to equipment.

The TR400 is a programmable process ratemeter and must be installed by qualified personnel

only. Failure to observe this warning could result in an injury to persons or damage to

equipment.

Only qualified personnel should attempt to connect any wires to the TR400. Failure to observe

this warning could result in an injury to persons.

Continued on next page

Warning

Warning

Warning

Warning

Warning

Warning

Warning

4Rev G

S1−

−−

−Warnings & Cautions

Cautions

Power to sensors is provided at TB2

−

6 (+12 Vdc) and TB2

−

5 (common) on the TR400. Wiring

to those inputs should be shielded cable with the shield tied to TB2

−

5 common only. Failure to

observe this caution could result in improper sensor function.

Always turn the power source OFF before wiring the TR400. Failure to observe this caution

could result in damage to the TR400.

Never use shielded cable

U

with extra conductors

U

. Extra conductors can act as antennas, picking

up electrical noise. Failure to observe this caution could result in improper sensor operation.

The TR400 standard uses 115 Vac, 6 VA @ 60/50 Hz, with 230 Vac as an option. Make sure

you know the correct supply voltage before applying power to the TR400. Failure to observe

this caution could result in damage to the TR400.

Do not touch the Pulser Disc or Wrap while it is spinning. Failure to observe this caution could

cause an interruption in pulse generation, resulting in a disruption in the mechanical process

being monitored.

When the digital input function is programmed as a Reset input and the switch input remains

closed, the relay will never turn OFF regardless of the operating condition. A momentary

contact closure of the switch is advised. Failure to observe this caution could result in damage

to the equipment.

Only qualified personnel should attempt to connect any wires to the TR400. Failure to observe

this warning could result in damage to the equipment.

Caution

Ca

ution

Caution

Caution

Caution

Caution

Caution

5

Rev G

Section 2

TR400 Installation

Introduction

This section discusses unpacking and then installing the TR400 into a panel.

In this section These are the topics:

Topic See Page

Installation overview 6

Installing the TR400 7

6Rev G

S2−

−−

−TR400

Installation

Installation overview

The TR400 is a programmable process ratemeter and must be installed by qualified personnel

only. Failure to observe this warning could result in an injury to persons or damage to

equipment.

Unpacking the

TR400 After unpacking the TR400, save the following items:

•Packing list

•All instructions and other documentation

Verify that all parts were shipped via the packing list.

Continued on next page

Warning

7

Rev G

S2−

−−

−TR400 Installation

Installing the TR400

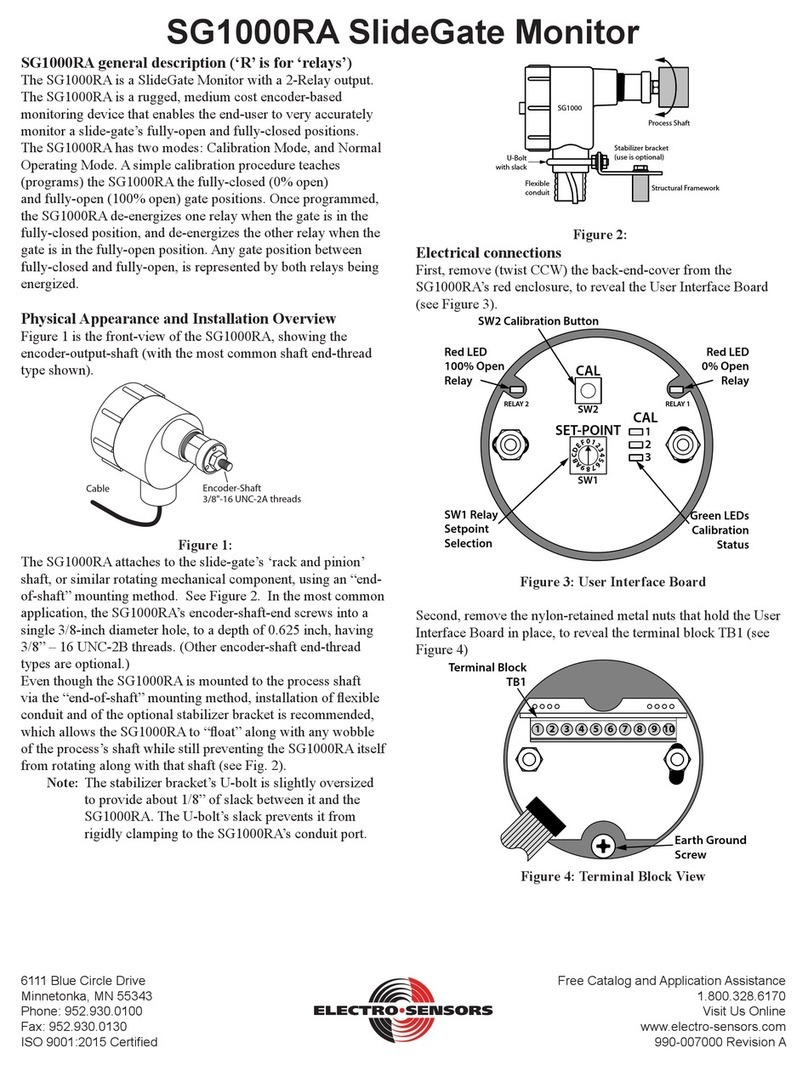

Panel cutout To install the TR400 into an instrument panel, do the following:

Step Action

1. Cut a rectangular hole in the panel to the dimensions shown in Figure 1.

2. Loosen the screws holding the mounting bracket to the TR400 and

remove it, as shown in Figure 1.

3. Slide the TR400 into the cutout.

4. Replace the mounting bracket and tighten the screws

do not over

tighten. See Figure 1.

Note: Allow a minimum of 1.5 inches of clearance on all sides of the TR400 (all

dimensions are in inches).

4.85"

3.10"

2.61"

4.31"

5.50"

4.28"

2.58"

Insert Mounting Bracket

Remove Mounting Bracket

Front

View

Panel

Cutout

6.25"

Side View

Top

View

Figure 1: TR400 Dimensions

8Rev G

S2−

−−

−TR400

Installation

Intentionally Left Blank

9

Rev G

Section 3

TR400 Wiring & DIP Switches

Introduction

This section discusses electrical information concerning the TR400, including wiring

practices, wiring schematics, and DIP-switch settings.

In this section These are the topics:

Topic See Page

Practical wiring practices 10

TR400 wiring schematics 11

4-20 mA/0-10 Vdc analog output 13

Switch input wiring 14

Single channel and quadrature signal wiring 15

A and B channel input signal wiring 16

TR400 DIP switches 17

10 Rev G

S3−

−−

−

TR400 Wiring & DIP Switches

Recommended wiring practices

Recommended wiring practices must be followed when wiring industrial equipment such as the

TR400. Failure to follow the practical wiring practices listed below could result in an injury to

persons or damage to equipment.

Wiring

practices The following is a list of recommended wiring practices for installing industrial

equipment. It is critically important that you observe and follow these wiring

practices when wiring the TR400.

•All control signals must be shielded cable. The shield must be tied to common or

earth ground at the receiving end only. In some environments, earth ground may

contain excessive electrical noise. If you encounter problems using earth ground

as a shield-tie point, switch the shields to signal common. All connections to the

controller are considered signal unless they carry AC voltage.

•Never use a shielded cable with unused conductors. The unused conductors act

as antennas. Attempting to tie the unused conductors to ground or other signal-

carrying wires will create different antenna configurations. In many cases, an

unshielded wire could be less susceptible to electrical noise. Always make sure

that a shielded cable with the correct number of conductors is pulled.

•All control signals must be separated from power wires. Power wiring includes

any AC or DC wires carrying voltages with a current potential of greater that one

(1) amp or a voltage greater than 24 volts. This includes, but is not limited to,

115 Vac, 230 Vac, and 460 Vac. Do not bundle shielded cables and power wires

together.

•Do not run signal cables along high magnetic or electrostatic generators. This

includes, but is not limited to motors, fans, contactors, igniters, etc. Aluminum

shielded cable does not stop magnetically induced noise; braided shielded cable

only partially reduces magnetically induced noise.

•An earth ground wire must be installed on microprocessor-based equipment

when required. Do not rely on the enclosure’s contact with the panel for earth

ground. Earth ground is often used in noise-rejection circuitry as well as for

safety.

•Contactors, solenoids, and relay coils connected to the same AC power source or

in the same enclosure panel as the controller must be suppressed with a

capacitor-resistor filter across the coil. These can be made with a 1 kV capacitor

and a ¼-watt resistor in series, or they can be purchased in a pre-made package.

Use a capacitance value of 0.1 µF or larger and a resistance value of 500 ohms or

less.

•When AC voltage is stepped down for use with equipment, a capacitor-resistor

network or a filter should be placed across the secondary.

Warning

11

Rev G

S3−

−−

−TR400 Wiring & DIP Switches

TR400 wiring schematics

Only qualified personnel should attempt to connect any wires to the TR400. Failure to observe

this warning could result in an injury to persons.

Do not wire the TR400 to 230 Vac or 10-30 Vdc unless it has been specially wired for that

voltage. The standard voltage setting is 115 Vac. Failure to observe this caution could result in

damage to the TR400.

Wiring

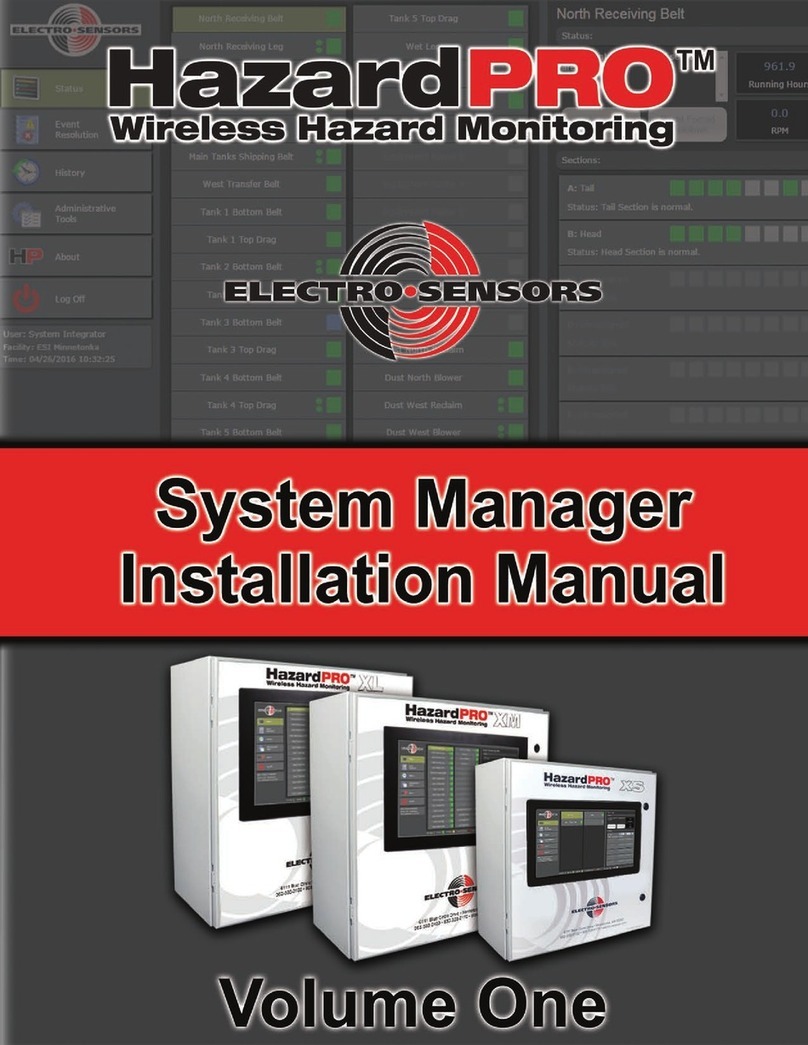

schematic Figure 2 shows the various wiring schemes for the TR400.

TB1

1

2

3

4

5

6

(+)

(-)

(+) Line(L1)

(-) Neutral(L2)

Line

(same potential

as TB1-1) 1

2

3

4

5

6

TB3

TB2

1

2

3

4

5

6

7

8

NC

Common

+12 V Supply

Signal A

Signal B

Quad Only

Relay

Output 2

Relay

Output 1

Offset Pot

Span Pot 4-20 mA

PLC

NC

DC power AC Power TB3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Relay

Output 1

Relay

Output 2

Relay

Output 3

Relay

Output 4

Relay

Output 5

Relay

Output 6

2 Relay option 6 Relay optionMain board

Figure 2: TR400 Wiring

Continued on next page

Caution

Warning

12 Rev G

S3−

−−

−

TR400 Wiring & DIP Switches

TR400 wiring schematics, continued

During a Stop condition, any slight movement of the shaft or magnetic disc could activate the

control relay and start the motor if the Motor Auxiliary, Normally Open Contact (MS Aux n.o.) is

not wired in series. To prevent starting the motor accidentally, always use the proper

LOCKOUT TAG OUT procedures. Failure to observe this warning could result in an injury to

persons or damage to equipment.

Motor

shutdown

schematic

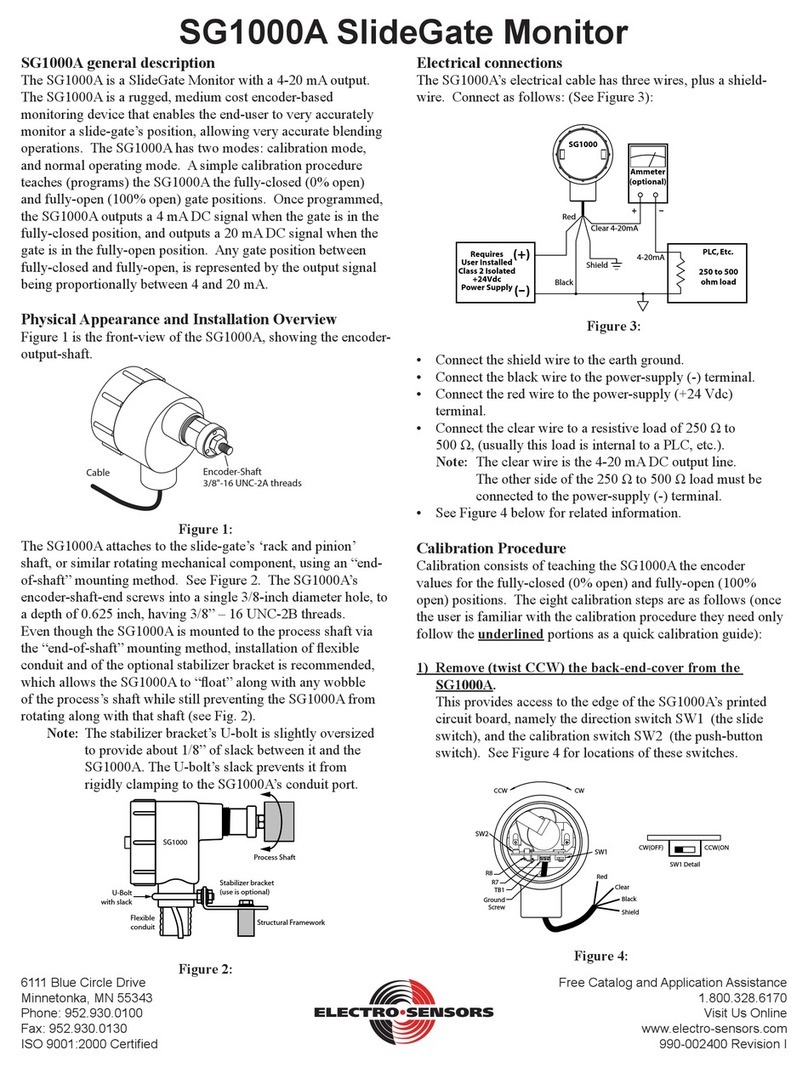

Figure 3 shows a Stop Command Wiring schematic, designed to prevent an

accidental motor startup.

Figure 3: Wiring Schematic to Disable the Alarm on a Stop Command

Input power

wiring The TR400 standard comes set-up for 115 Vac, 6VA at 50/60 Hz. An external 1/16

amp slow-blow fuse must be provided by the customer. AC power will tie to TB1−1,

Line, and TB1−2, Neutral. Optionally it can be ordered in 230 Vac and 10-30 Vdc.

See Figure 2.

Warning

MS Motor Starter (not supplied)

OL Over Load

n.o. Normally open (relay is in a deactivated

state)

MS

TR400

Line Neutral

Start

Momentary

Internal

On TR400

Warning Light,

Horn, Solenoid, etc.

Internal

On TR400

Stop

Maintained

MS

Aux

MS OL

n.o.

Motor Shutdown with Alarm

13

Rev G

S3−

−−

−TR400 Wiring & DIP Switches

4-20 mA/0-10 Vdc analog output

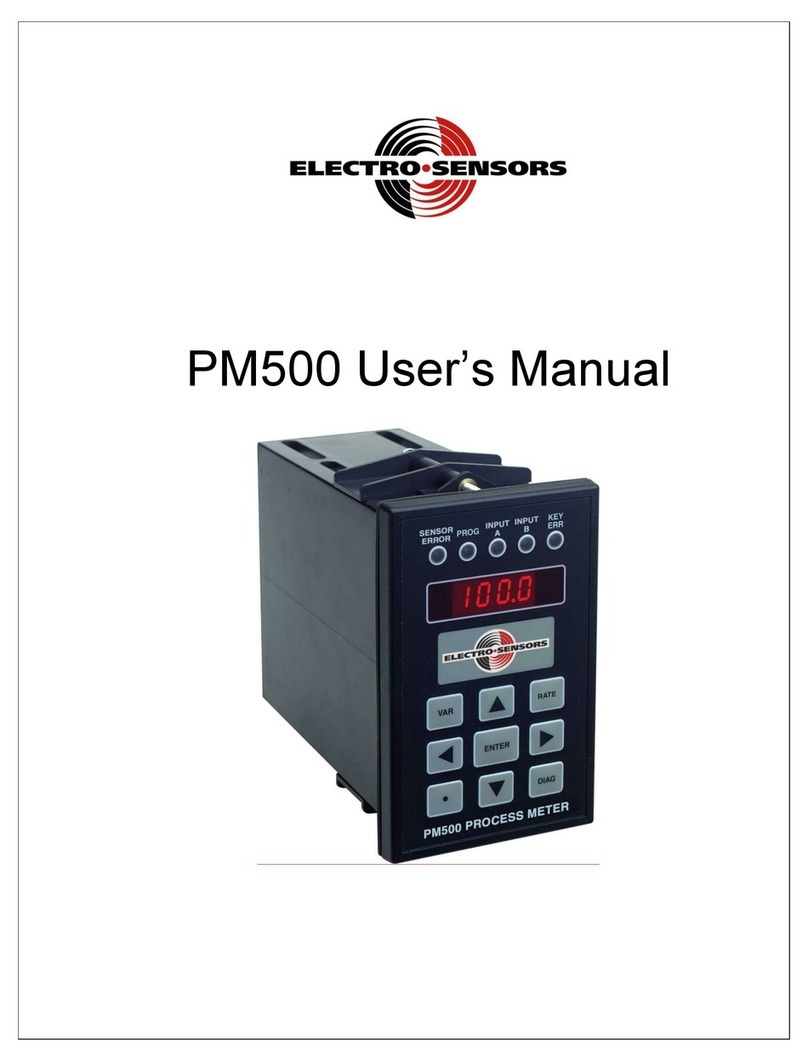

4-20 mA/0-10

VDC analog

output

The 4-20mA output supports a maximum load resistance of 500 ohms. The analog

output plus (+) signal is at TB1−5, and the negative (-) signal is at TB1−4, as shown

in Figure 4. This applies for both 0-10VDC

1

and 4-20mA

See the Diagnostics section for additional information about the analog outputs.

1

2

3

4

5

6

TB1

(–)

(+)

Analog Output

Offset Pot

Span Pot

4-20 mA/0-10 Vdc

4–20 mA/

0–10Vdc

DC Power AC Power

(+) Line (L1)

(-) Neutral (L2) NC

Analog Output Aux

Figure 4: Wiring for Analog Outputs 4-20 mA/*0-10 Vdc

Analog Output

Aux Analog Output Aux is currently only used with the TR400 when the optional 6 relay

board is installed. When the 6 relay option board is installed, 4-20mA is output at

TB1-5 and 0-10Vdc is output at TB1-6. The common for both is at TB1-4. Only one

output can be calibrated at a time. Only one output should be connected and used at a

time.

1

When analog is ordered, 4-20mA is standard and 0-10VDC is optional.

14 Rev G

S3−

−−

−

TR400 Wiring & DIP Switches

Switch input wiring

Switch inputs

and wiring There are three (3) switch inputs that are programmable using variable 14. They are

used to Reset the outputs, or to freeze the display. Inputs 1, 2, and 3 require a voltage

equal to the supply voltage, which is at the same potential as the input Line (L1)

voltage. The opposite sides (non accessible) of these solid-state inputs are tied to

input Neutral (L2). Wire input 1 to TB2−1, input 2 to TB2−2, and input 3, to TB2−3.

See Figure 5.

TB1

1

2

3

4

5

6

TB2

1

2

3

4

5

6

7

8

DC Power AC Power

(+) Line (L1)

(-) Neutral (L2)

Switch Inputs

Figure 5: Wiring for Switch Inputs

Table of contents

Other Electro-Sensors Measuring Instrument manuals