Electro-Tech systems 863 Technical specifications

RESISTANCE/CURRENT METER

Model 863/6487

BASIC OPERATING INSTRUCTIONS

10/10

1

IMPORTANT

SAFETY INSTRUCTIONS

The equipment described in this Manual is designed and manufactured to operate within defined

design limits. Any misuse may result in electric shock or fire. To prevent the equipment from

being damaged, the following rules should be observed for installation, use and maintenance.

Read the following safety instructions before operating the equipment. Retain these instructions

in a safe place for future reference.

POWER

POWER CORD: Use only the power cord specified for this instrument and certified for the

country of use. If the power (mains) plug is replaced, follow the wiring connections specified

for the country of use. When installing or removing the power plug hold the plug, not the

cord.

The power cord provided is equipped with a 3-prong grounded plug (a plug with a third

grounding pin). This is both a safety feature to avoid electrical shock and a requirement for

correct equipment operation. If the outlet to be used does not accommodate the 3-prong plug,

either change the outlet or use a grounding adapter.

FUSES: Replace fuses only with those having the required current rating, voltage and

specified type such as normal blow, time delay, etc. DO NOT use makeshift fuses or short the

fuse holder. This could cause a shock or fire hazard or severely damage the equipment.

POWER LINE VOLTAGE (MAINS): If the line (mains) voltage is changed or isolated by an

autotransformer the common terminal must be connected to the ground (earth) terminal of

the power source.

OPERATION

DO NOT OPERATE WITH COVERS OR PANELS REMOVED. Voltages inside the

equipment consist of line (mains) that can be anywhere from 100-240VAC, 50/60Hz and

in some equipment, test voltages up to 500VDC.

DO NOT OPERATE WITH SUSPECTED EQUIPMENT FAILURES. If any odor or smoke

becomes apparent turn off the equipment and unplug it immediately. Failure to do so may

result in electrical shock, fire or permanent damage to the equipment. Contact the factory for

further instructions.

DO NOT OPERATE IN WET/DAMP CONDITIONS: If water or other liquid penetrates the

equipment, unplug the power cord and contact the factory for further instructions. Continuous

use in this case may result in electrical shock or fire.

DO NOT OPERATE IN HIGH HUMIDITY: Operating the equipment in high humidity

conditions will cause deteriation in performance, system failure, or present a shock or fire

hazard. Contact the factory for further instructions.

2

DO NOT OPERATE IN AREAS WITH HEAVY DUST: Operating the equipment in high dust

conditions will cause deteriation in performance, system failure, or present a shock or fire

hazard. Contact the factory for further instructions.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE: Operating the equipment in the

presence of flammable gases or fumes constitutes a definite safety hazard. For equipment

designed to operate in such environments the proper safety devices must be used such as

dry air or inert gas purge, intrinsic safe barriers and/or explosion-proof enclosures.

DO NOT USE IN ANY MANNER NOT SPECIFIED OR APPROVED BY THE

MANUFACTURER: Unapproved use may result in damage to the equipment or present

an electrical shock or fire hazard.

MAINTENANCE and SERVICE

CLEANING: Keep surfaces clean and free from dust or other contaminants. Such

contaminants can have an adverse affect on system performance or result in electrical

shock or fire. To clean use a damp cloth then let dry before use. Do not use detergent,

alcohol or antistatic cleaner as these products may have an adverse affect on system

performance.

SERVICE: Do not attempt to repair or service the instrument yourself unless instructed by

the factory to do so. Opening or removing the covers may expose you to high voltages,

charged capacitors, electric shock and other hazards. If service or repair is required,

contact the factory.

3

1.0 INTRODUCTION

The Model 863/6487 is a high-resolution programmable picoammeter containing a ±505V

DC variable voltage source. It provides an ohms function (V/I) with direct readout for

utilization as a wide range resistance meter. It provides a vacuum fluorescent display of

the measured parameters along with analog and digital (RS-232 and IEEE-488) outputs.

A complete set of detailed operating instructions is contained in the Keithley User’s

Manual supplied with each instrument.

The following instructions are limited to the set-up and measurement of resistance or

resistivity utilizing the ETS 800 series resistance/resistivity probes or test fixtures or any

other compatible probes or test fixtures. The cable supplied has been specially adapted

for direct interface with probes equipped with standard .162” banana jacks.

The Model 863/6487 when used as a resistance meter measures over the resistance

range of 0.8 ohms to 5 x 1017 ohms (by V/I calculation). Test voltage is adjustable from 0

to ±505 Volts. Selectable current limits of 2.5mA, 250uA and 25uA for the 50V and 500V

ranges, with a 25mA additional limit for the 10V range are provided. Specified

measurement accuracy is better than 0.6% between 1 x 103to 1 x 1012 ohms after a one

hour warm-up period. The instrument does not use exponents in the readout of

resistance, but rather, the symbols of K for kilohms, T for terohms, etc. TABLE 1 below

lists the relationship between displayed symbols and the corresponding exponents.

Table 1 – Exponential Equivalents

Indicated Range: Exponential Equivalent:

Ω100

KΩ103

MΩ106

GΩ109

TΩ1012

PΩ1015

The instrument is preprogrammed at ETS to provide the most common measurement

parameters required in current EOS/ESD, EIA, ASTM and Military Standards and

specifications. If other test voltages or sampling intervals are desired, the procedures for

reprogramming these parameters are contained in SECTION 4.0 - REPROGRAMMING.

4

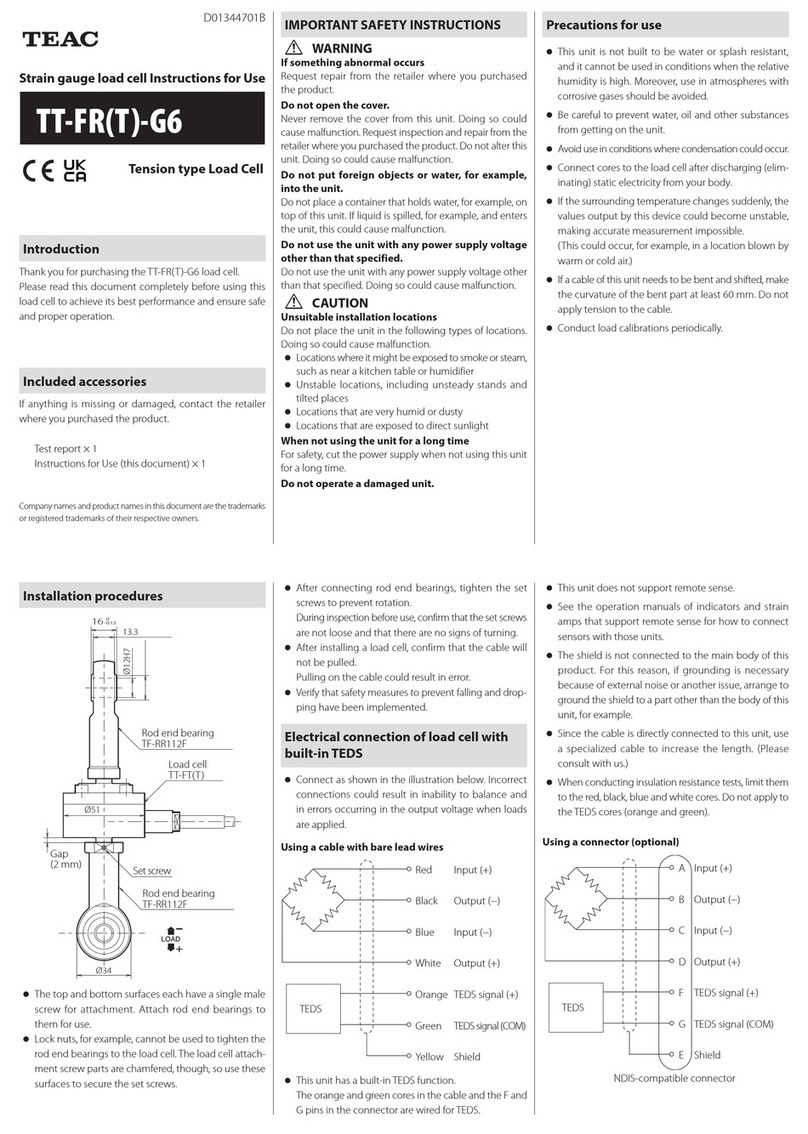

1.0 CONNECTIONS

Connect the desired probe or test fixture to the Model 863/6487 using one of the setups

shown in Figures 2.0–2,3,4 & 5. The cable schematic is shown Figure 2.0-1.

NOTE: The Keithley 237-ALG-2 triaxial cable is not normally supplied with the 6487 and

is purchased separately and modified by ETS for ease of use in making resistance

measurements. The red and black banana plugs on the triax connector end of the cable

are to be plugged into the Voltage Source connectors (red=HI, black=LO) on the rear

panel of the 6487.

Figure 2.0-1: Cable Schematic

WARNING: Hazardous voltages are present when the OPERate

button is pressed.

The Keithley 6487 uses an interlock system that is designed to prevent inadvertent

contact with hazardous voltages. A safety cover or fixture is strongly

recommended, especially if the equipment is used in a Production environment.

ETS has jumpered pins 1 and 2 of the interlock plug to allow operation when the

plug is inserted into the INTERLOCK connector on the rear panel. As a result, the

operator must be sure to remain clear of the equipment, probe contacts, etc.

when voltage is present (Blue warning light ON.)

5

Ground Plane is used when measuring insulative materials per ASTM D257

Insulating Plane is used when measuring static dissipative materials per ESD S11.11

Figure 2.0-2: Surface Resistance/Resistivity

To external

Ground

connection

Ground Plane

Insulating

Plane

6

Figure 2.0-3: Volume Resistance/Resistivity

Figure 2.0-4: Point-to-Point Resistance

Conductive

Plan

e

Insulated

Plane

V-Source

Ground

V-Source Not connected

Red cable

supplied with

Model 850

Sense

7

Figure 2.0-5: 2-Point Resistance

2.0 OPERATION

The Model 863/6487 is preprogrammed at ETS to measure resistance or resistivity with

either a 10V, 100V or 500V test voltage by selecting one of the three user configurations,

USR0, USR1 or USR2 respectively. (USR0 is programmed as the power-up default

setting.) Other voltages can be easily selected by the user at any time. See SECTION 4.0

of this manual.

The following instructions should be followed to ensure consistent and accurate

resistance measurements:

1. Turn the instrument on by pressing the POWER switch. The display will cycle

through a self-check program. It is recommended that the instrument be allowed to

warm up for one hour prior to use. However, the instrument can be used immediately

after turn on if necessary. If the instrument is used on an ongoing basis the power

should be left on in standby mode (OPERATE switch off.)

2. Place the appropriate test probe on the sample to be measured. Ensure that good

surface contact is made between the probe and the sample.

3. Select a test voltage of either 10, 100, or 500V by selecting USR0, USR1, or USR2

respectively. (Press SETUP, use RANGE up/down arrows to select USR, then press

ENTER.) The instrument is defaulted at the factory for USR0 (10V). See Section 4.1

for selecting other test voltages.

8

4. To begin a test and take a reading, press the OPER push button. A blinking dot on

the display will flash each time a sample is taken at an approximately six (6) second

sampling rate that is preset by ETS. If another sampling rate is desired, refer to

Section 4.2 for resetting the RATE value.

AUTORANGE is enabled as the default. With AUTORANGE enabled (AUTO

indicator on), the instrument will automatically adjust to the correct measuring range.

Occasionally, it may be necessary or desirable to utilize manual ranging. When using

manual ranging, choose an appropriate range value based on the voltage source

setting and the expected measured resistance: I=V/R. Press either the ▼or ▲

range pushbuttons to select the desired range. This will automatically disable the

AUTORANGE mode. (Note: The resistance range selected is not shown on the

meter, only the current range is displayed.)

To reinstate AUTORANGE, press the AUTO pushbutton. The AUTO indicator will

light on the display.

NOTE:

When measuring low resistances, the test voltage must be reduced so

that the set maximum current is not exceeded. When this level is

exceeded, the display will indicate OVRFLOW (overflow) or I-LIMIT. To

determine the maximum voltage that can be used, calculate:

V = IR.

= (25x10-3) R (10V or less)

or = (2.5x10-3) R (>10V)

The lowest resistance that can be measured is 0.8 ohms. TABLE 2

lists the suggested voltages for different minimum resistances.

Table 2 – Suggested Test Voltages

5. There is a delay while the instrument measures and calculates the next displayed

value. In addition, there may be an additional delay due to electrification of the

material. This is a charging effect and will depend on the material being measured. It

is more noticeable at the higher resistance ranges. Continue the test until the

readings appear to stabilize. At the conclusion of the test, turn off the voltage source

Resistance Range: (Ω)Test Voltage: (Volts)

0.5 0.01 (25mA)

5 0.10 |

50 1.00 |

500 10.00 |

5K 10.00 (2.5mA)

50K 100.00 |

250K 500.00 |

9

by pressing the OPER pushbutton (blue warning indicator off). This returns the

instrument to the standby mode.

NOTE:

The Model 863/6487 reads only measured resistance. Resistivity

probes and test fixtures that have multiplication factors such as the

ETS Model 803B (x10 built-in), must have these multiplication factors

applied to the displayed reading to convert resistance to resistivity.

3.0 REPROGRAMMING

The Model 863/487 is preprogrammed at the factory to enable the user to immediately

place

the instrument into service as a precision wide range resistance meter, meeting most

common resistance and resistivity test specifications.

This section covers reprogramming the instrument to default to other test voltages and

sampling rates. Refer to the Keithley manual for information on reprogramming other

parameters.

3.1 Test Voltages

Open circuit test voltages from 0 to 505 Volts can be selected by the user. The new

values will remain in memory until they are either changed or the instrument is

turned off.

Press either of the VSOURCE up/down arrows to enter the voltage adjustment

mode. Then press either the ◄or ►pushbuttons to move the cursor (flashing

digit). Each digit may then be changed individually by pressing the ▲or ▼

pushbuttons under V-SOURCE until the correct value is obtained. Repeat this

sequence until all of the digits are set to the desired level then press ENTER.

If the current limit prompt appears, in most cases you may skip it by pressing EXIT

after adjusting the voltage.

10

Figure 4.1–1: Source Voltage Adjust

3.2 Sampling Rate (TRIGGER INTERVAL)

The sampling rate (RATE) is set by ETS for the maximum sampling rate

(NPLC:60.00) using the CONFIG RATE menu. This presents a more stable display

when making high resistance measurements. The sampling rate is expressed in

terms of the Number of Power Line Cycles (NPLCs). See page 4-4 of the Keithley

Manual for a detailed explanation.

There are two ways of changing the sampling rate:

Press the RATE key to select SLOW, MED (Medium) or FAST

or

Press the CONFIG then RATE keys to enter the desired number of power line

cycles (NPLCs) between samples. To convert into time: One power line cycle at

60Hz = 16.66 ms; 50Hz = 20 ms. This number can range from 0.01 to 60 for 60Hz

or 0.01 to 50 for 50Hz power. The arrow keys are used for entering the number in

the same manner as described in section 4.1 for adjusting source voltage.

10/10

11

APPENDIX

DEFAULT SETTINGS

ETS CONFIGURATION PARAMETERS

The following lists the configuration parameters in the 6487 that are changed from the

Keithley Factory defaults by ETS:

1. Ohms mode selected

2. Sampling rate (RATE) set for a slow sampling rate (NPLC:60.00) using the CONFIG RATE

menu. See section 4.2

3. Source Voltage settings:

USER0 – 10V

USER1 – 100V

USER2 – 500V

4. USER0 is selected as the power on default using the CONFIG SETUP menu.

SAVING USER SETUPS

To save a User Setup, configure the Model 863/6487 for the desired measurement

application, then press SAVE and select the desired setup (0 = USR0, 1 = USR1, 2 = USR2)

and press ENTER to complete the process.

To save the power on-setup, press CONFIG and then SETUP, and select FACT, USR0,

USR1, USR2 or GPIB and press ENTER. FACT is the Keithley factory default setting.

RESTORING SETUPS

Press SETUP to display the restore menu, then select the setup (FACT, USR0, USR1, USR2

or GPIB) and press ENTER. FACT is the Keithley Factory default setting.

This manual suits for next models

1

Table of contents

Other Electro-Tech systems Measuring Instrument manuals