ELECTRO-VOICE®

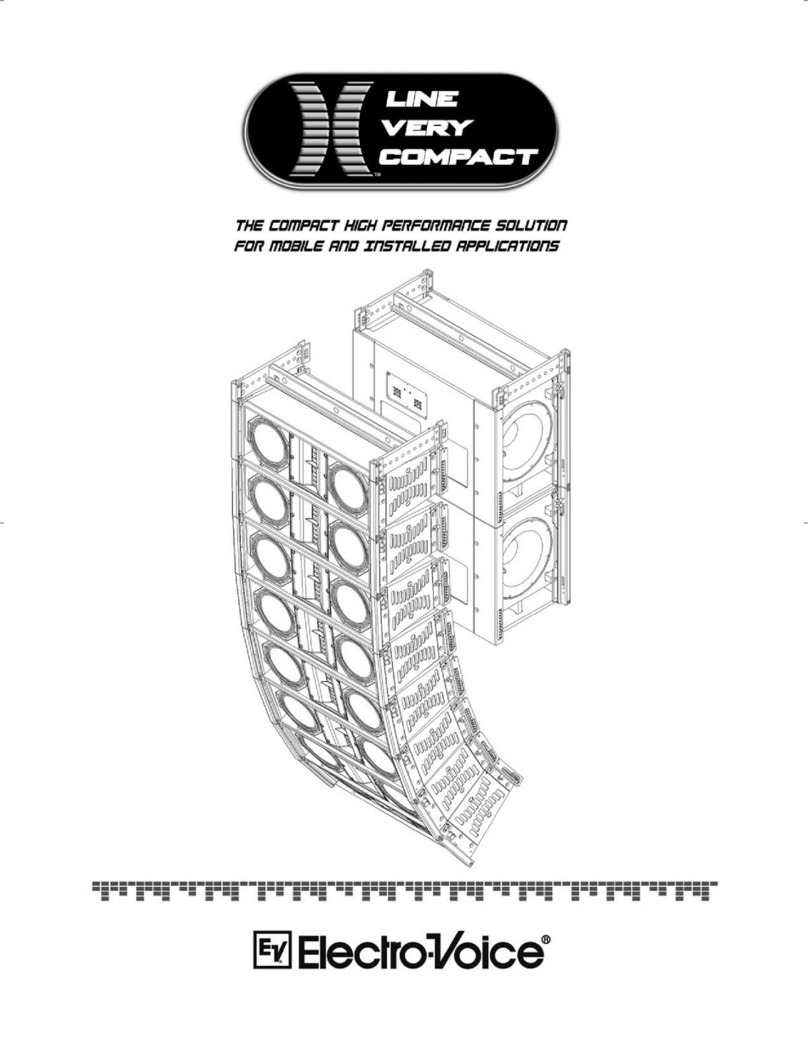

X-Line

TM

Rigging Manual

6

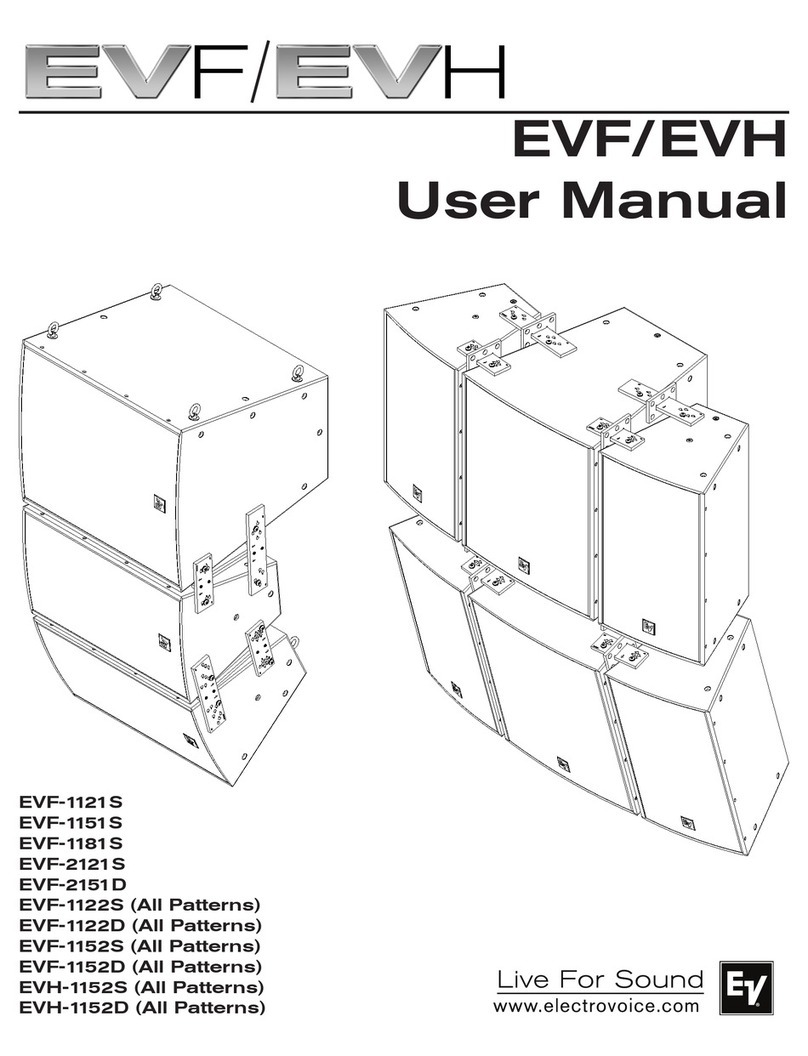

The grid is suspended by two hoist motors that are attached to two pickup points on the top of the

grid one at the front and one at the back. The two grid pickup points are in line and are

adjustable front to back to help distribute the loads between the hoist motors. For smaller arrays

(8 boxes or less), two one-ton hoist motors are recommended. For larger arrays (more than 8

boxes), two two-ton hoist motors are recommended. Two one-ton hoist motors can be used;

however, the front-to-back distribution of the weight becomes much more critical than with two-ton

hoists.

Note that the weight of an array can be quite substantial and the grid, chain

hoists and building structural supports used to suspend the array must be

capable of supporting such a load with a sufficient safety factor. The reader is

directed to References section of this manual for a list of rigging references (for

background in general rigging practice) and mechanical engineering references

(for background in structural engineering analysis).

1.2 Enclosure igging Hardware Details

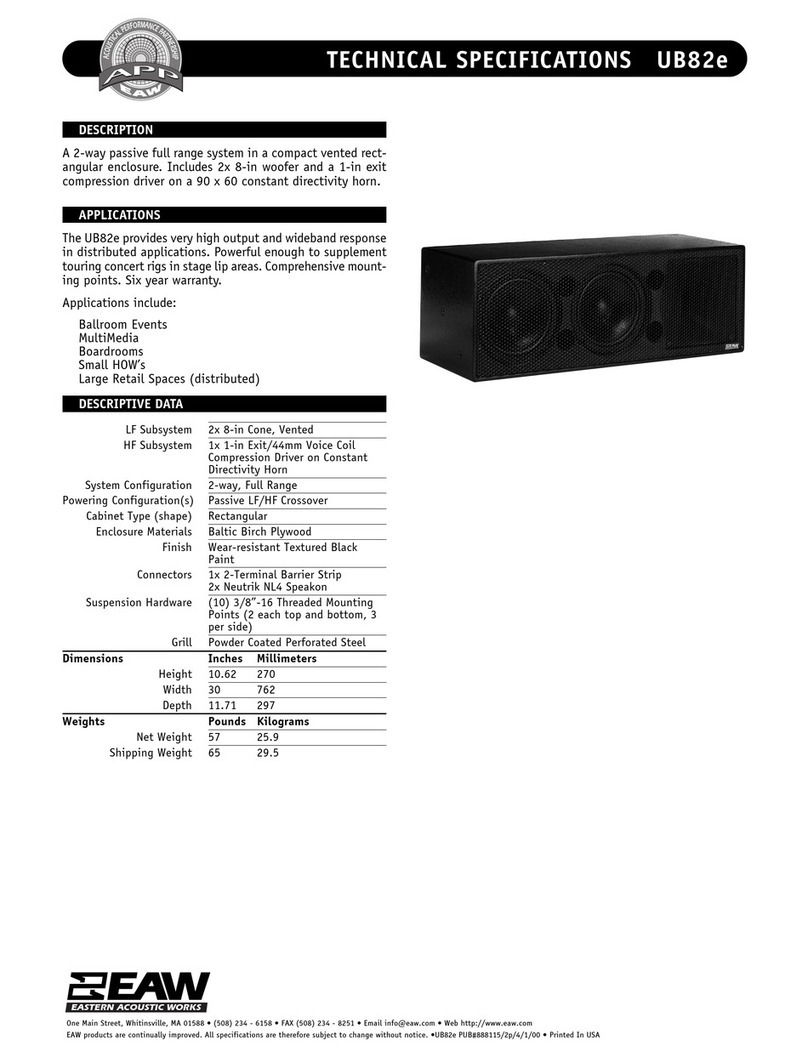

The X-Line loudspeaker systems have rigging at both the front and rear of the enclosures. The

Xvls, Xvlt and Xsub systems all have the same rigging hardware on both the front and rear of the

enclosures. While the Xfil1 and Xfil2 use the same rigging as the others on the rear of the

enclosures, they use different rigging at the front. Figure 2 shows key dimensions, weights and

centers of gravity for all of the X-Line loudspeaker systems. Figure 3 shows the enclosure rigging

hardware details and key dimensions.

A proprietary high-strength aluminum-alloy track is used at the rear of the enclosures near the top

and bottom for the attachment of two Xvhg rigging hinges, two Xvhl rigging hinges, two Xvhp pick-

up hinges, or one Xvbp pull-up bar. The track/bracket assembly is extruded as a single piece. One

assembly ties into the back and top of the enclosure, while a second assembly ties into the back

and bottom of the enclosure. Four high-strength, aluminum-alloy bars inside the enclosure tie the

top and bottom track/bracket assemblies together, minimizing the load applied to the enclosure

shell. The cutouts in the rear rigging track are shown in Figure 3a and 3b. The large cutout at the

end of the track is for inserting the rigging hinges. The small holes in the base of the track are for

locking the rigging hinges. The round cutouts are provided so two Electro-Voice RS-1B double-

stud swivel-ring fittings may be installed for light-duty lifting applications and for pull-ups. (The

track is also compatible with the New Haven NH32102-2 double-stud fittings.)

At the front of the Xvls, Xvlt and Xsub enclosures is another pair of proprietary high-strength,

aluminum-alloy track/bracket assemblies, which are also extruded as a single piece. One

assembly ties into the left side, top, bottom of the enclosure, while a second assembly ties into the

right side, top and bottom of the enclosure. The front track extends from the top to the bottom on

both sides of the enclosure, eliminating the load applied to the enclosure shell. On both sides of

the enclosure, the front rigging track has six cutouts near the top and bottom, as shown in Figure

3c. The triple-stud fittings on the Xvsg and Xvsl chain rigging straps may be installed at any of the

cutouts. The relative angle between a pair of enclosures (or the top enclosure and the grid) is set

by the position of the front rigging-strap fittings in the track cutouts.