9

Accurate Function Test

If a more accurate test is required to conrm that your heater is delivering the

specied heat output, two electricity meter readings will need to be taken from

the properties main electricity meter, with an exact one hour interval (ie: take

one meter reading and then a second reading exactly one hour later) then by

subtracting the rst reading from the second reading the number of units (kilo

watts / kW) consumed can be calculated. Note that your heater is also rated in

kW hours.

The pool pump and heater will need to be running continuously during the test

(ie: with the heater red light ’On’) To avoid inaccurate results when performing

this test, it is important to refrain from using other high current consuming

appliances in the property (such as tumble dryer, showers, cookers etc). A large

domestic pool pump of 1 horsepower will draw less than 1-kW in a one hour

period. The conclusion of the test should prove that for example a 6-kW heater

and a ½ horsepower pump will draw between 6.3-kW ~ 6.5-kW in one hour. It is

impossible for an electric heater to waste energy, if it is drawing power then that

power will be turned into heat that will be transferred to the water.

Trouble Shooting

HEATER WILL NOT SWITCH TO ‘Heater on’ (RED LIGHT)

In most cases this will be the result of one of the following points not being met:

Possible cause 1: The required water temperature has been achieved.

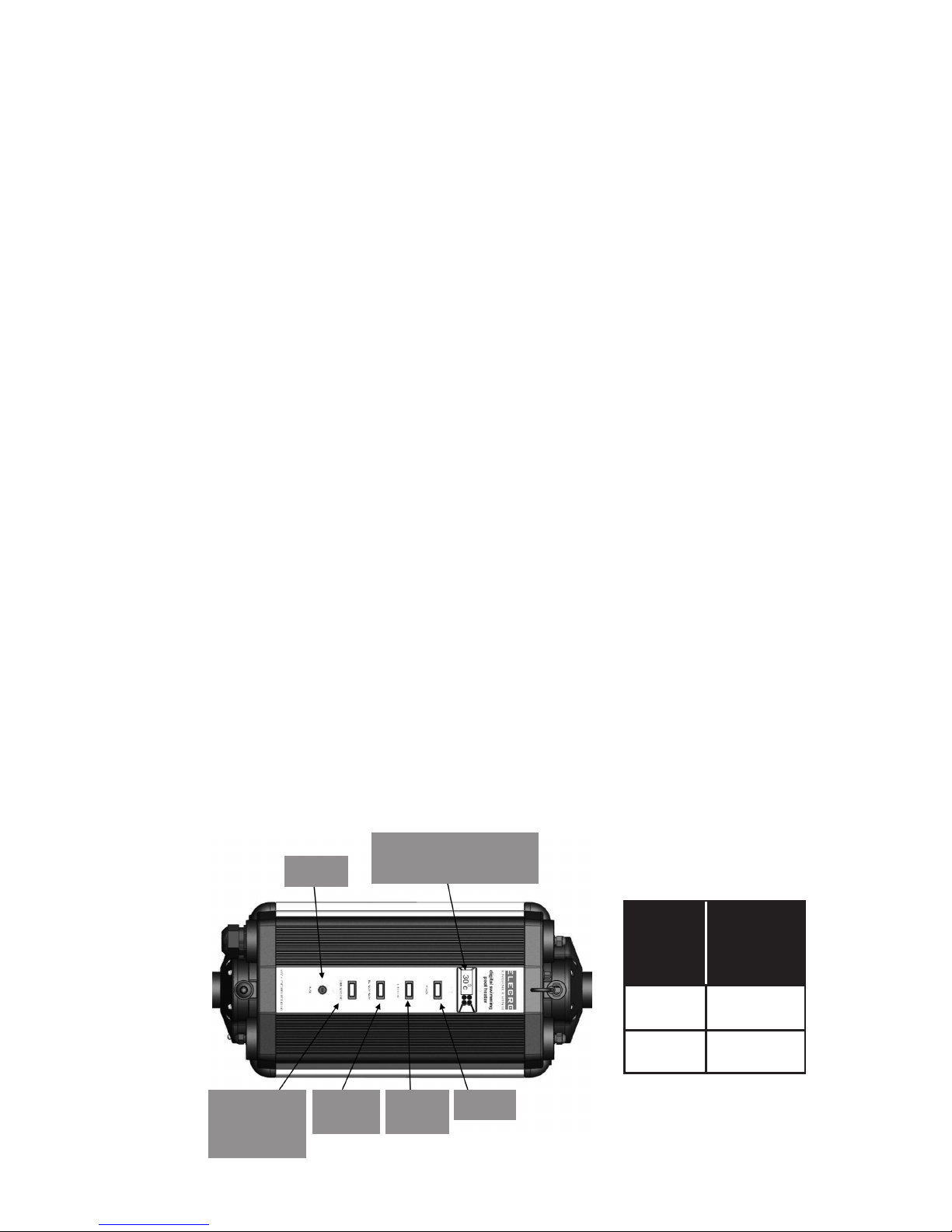

Remedy: To conrm increase the required temperature by pressing the ‘P’

button to show the current required temperature, then use the arrow keys to

increase the value above the current water temperature, press the P button

again to store the required temperature.

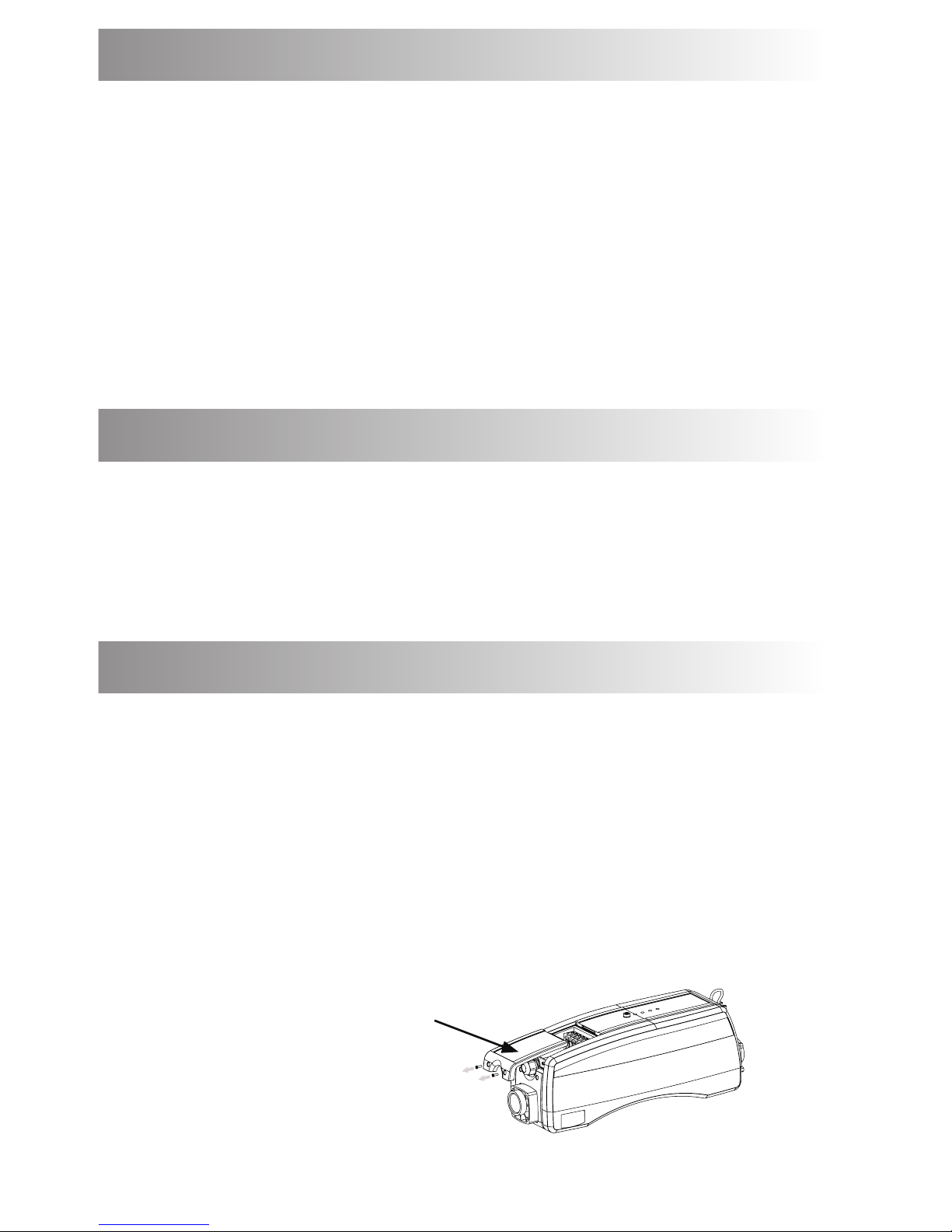

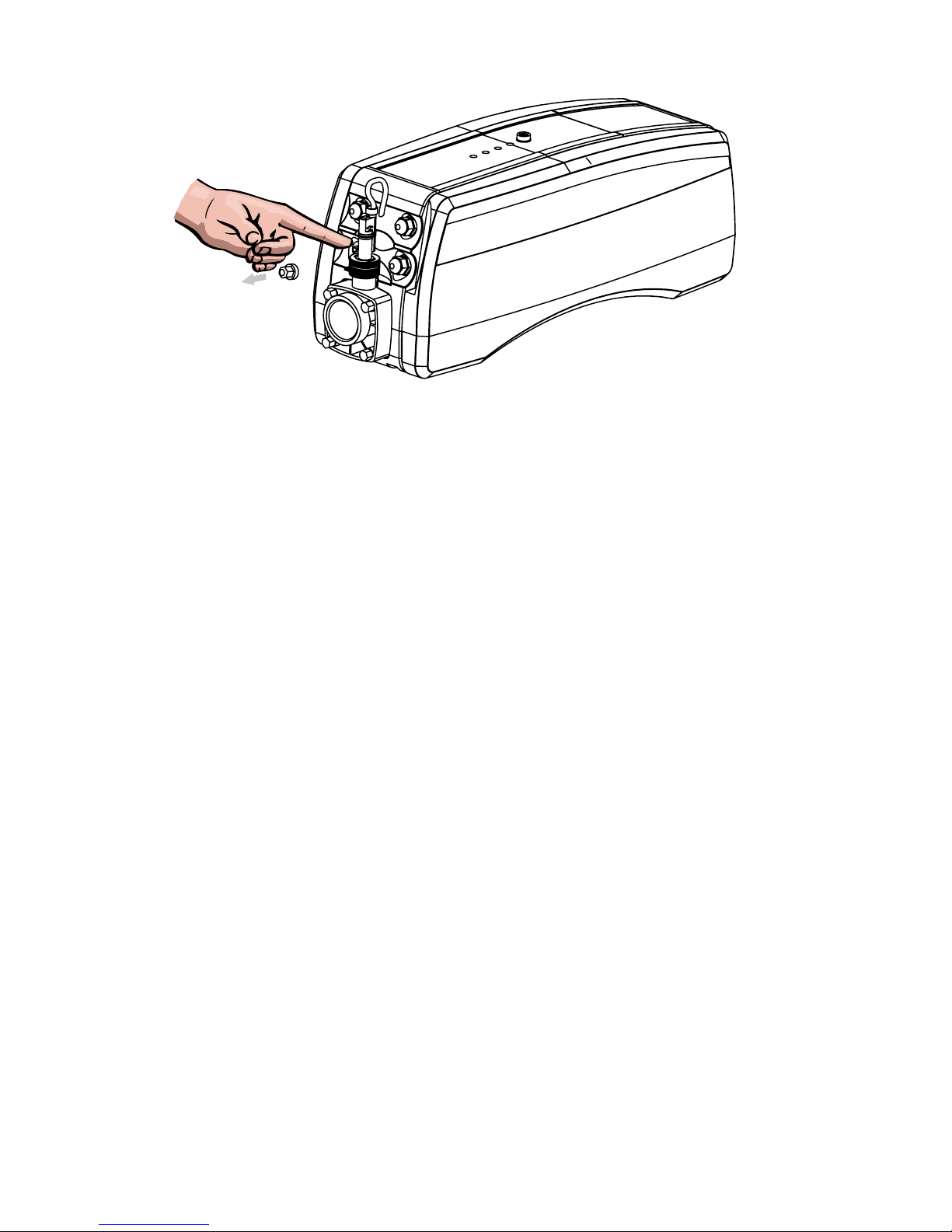

Possible cause 2: The ‘thermal safety cut out’ has tripped.

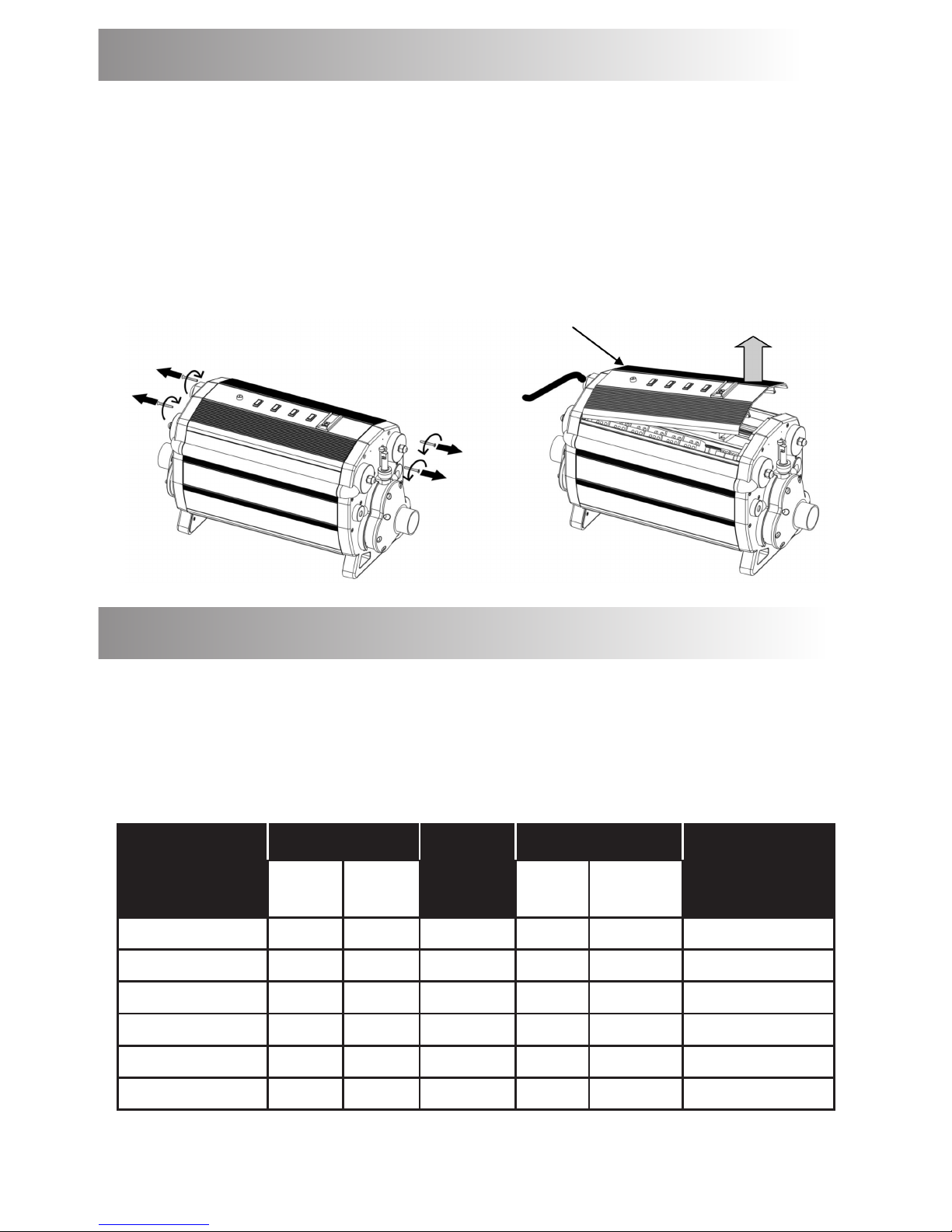

Remedy: Remove the black button cover and press red button to re-set (see g.

7) If a positive click is felt, the cause of the tripping must be investigated and

could be caused by a debris build-up or air pocket trapped inside the ow tube

of the heater.