ELECTRODRIVE Liftmaster Strong Arm User manual

Strong Arm

Operating Manual

Strong Arm Operating Manual—OM0008E/2

This manual contains important safety, installation and operating instructions for this

unit. Read this manual thoroughly and completely, and retain for future reference. This

unit can cause serious injury to personnel or damage to property if used incorrectly,

therefore do not use this machine for any other purpose apart from its intended use.

Using this unit incorrectly may void warranty.

Any damage audible or visible to this unit should be addressed at the time of discovery.

Electrodrive Pty Ltd can provide parts and service support on request through its

service partner company:

Serviced Equipment Pty Ltd

p: 1300 934 471

e: service@fallshaw.com.au

Made in Australia by:

Electrodrive Pty Ltd

2A Ayton Street, Sunshine North VIC Australia 3020

p: 1300 934 471 (within Australia)

p: +61 (03) 9300 8521 (International)

w: www.electrodrive.com.au

© Electrodrive

Strong Arm—Operating Manual

3

Contents

Introduction..................................................................................................................... 4

Assembly......................................................................................................................... 5

Brake winch handle ...................................................................................................... 5

Slew Handle.................................................................................................................. 5

Operating instructions ................................................................................................... 6

Safety check ................................................................................................................. 6

Using the Strong Arm ................................................................................................... 6

Adjusting the boom ...................................................................................................... 6

Maintenance ................................................................................................................... 7

Warranty .......................................................................................................................... 8

Unauthorised maintenance........................................................................................... 8

Misuse .......................................................................................................................... 8

General wear items not covered under warranty.......................................................... 8

Appendix 1: Specications ............................................................................................ 9

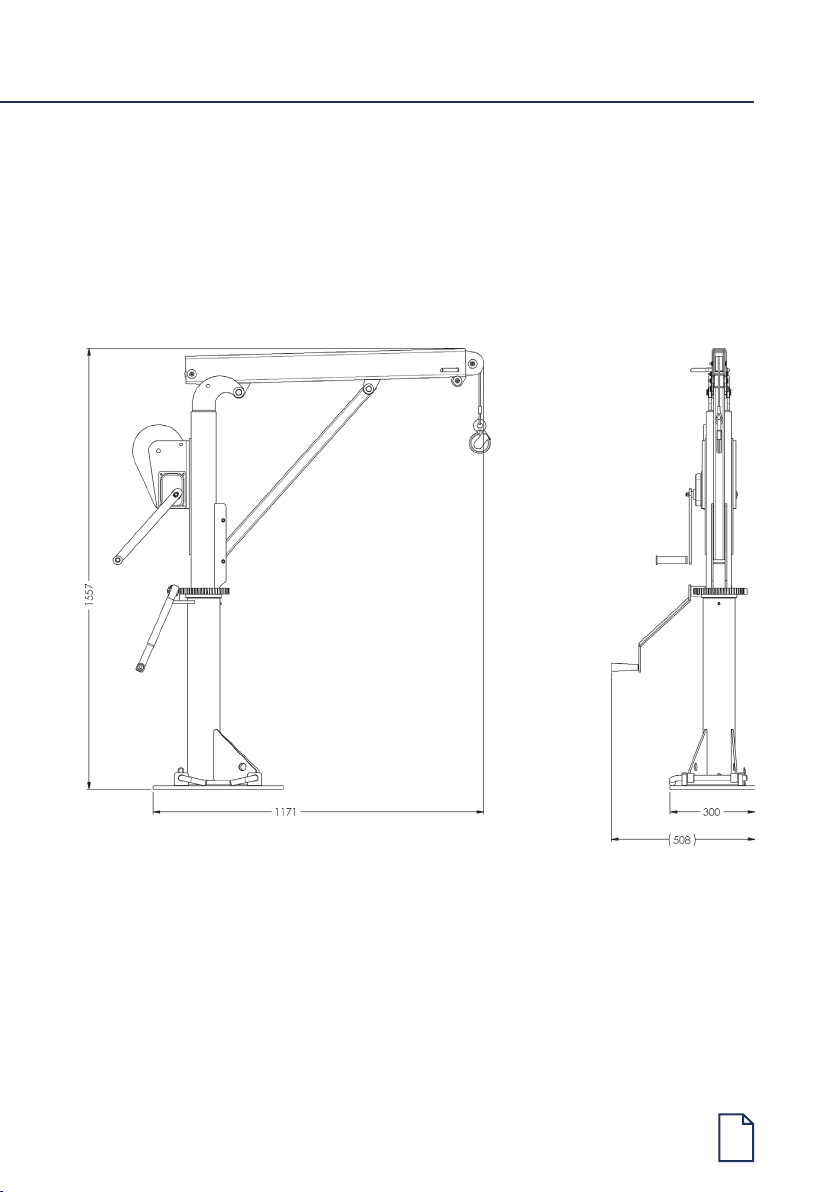

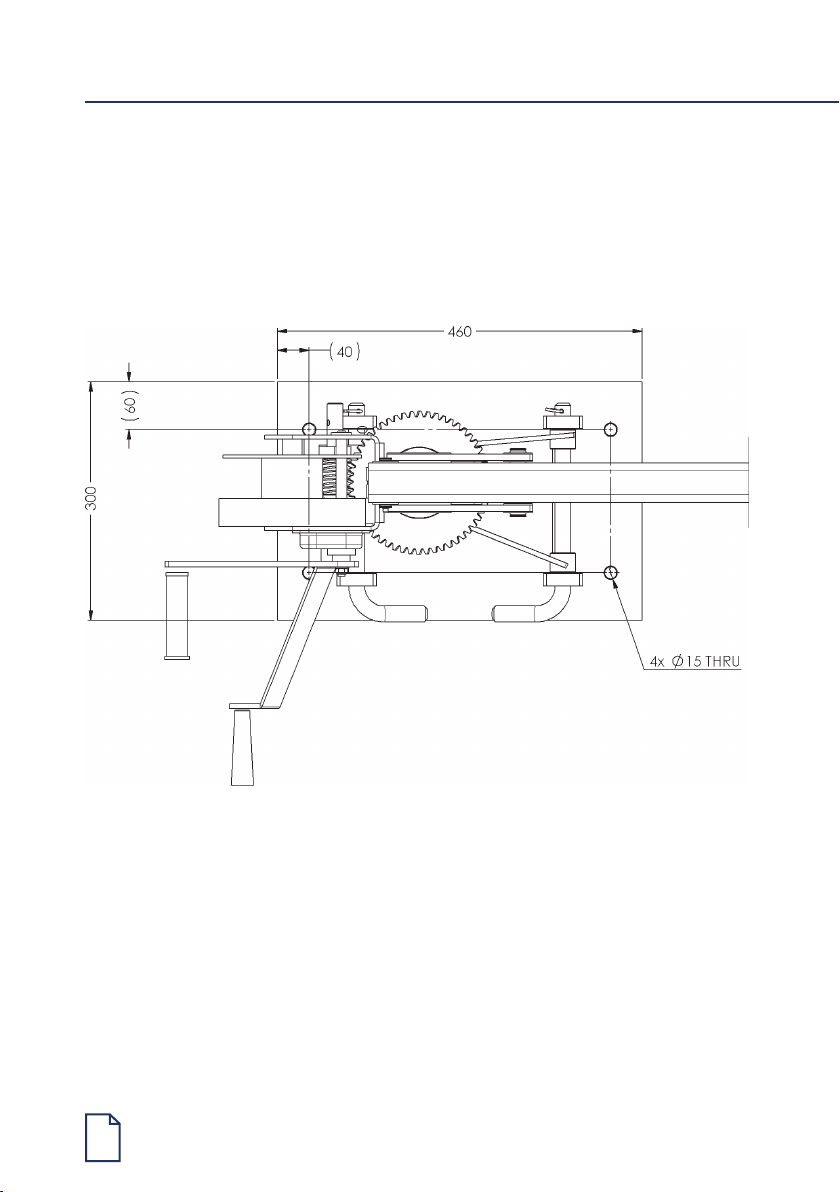

Appendix 2: Mounting plate......................................................................................... 10

Appendix 3: Boom length and weight guidelines ...................................................... 11

Service log .................................................................................................................... 12

4

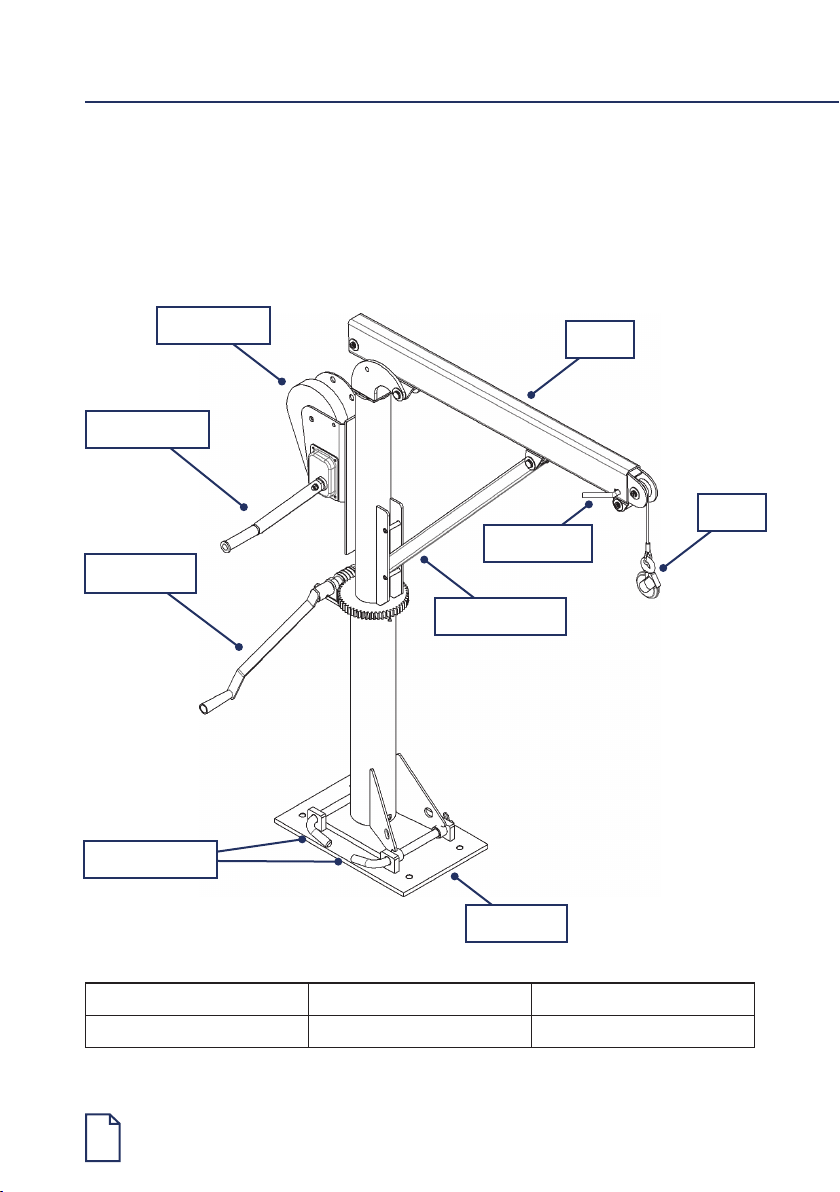

Introduction

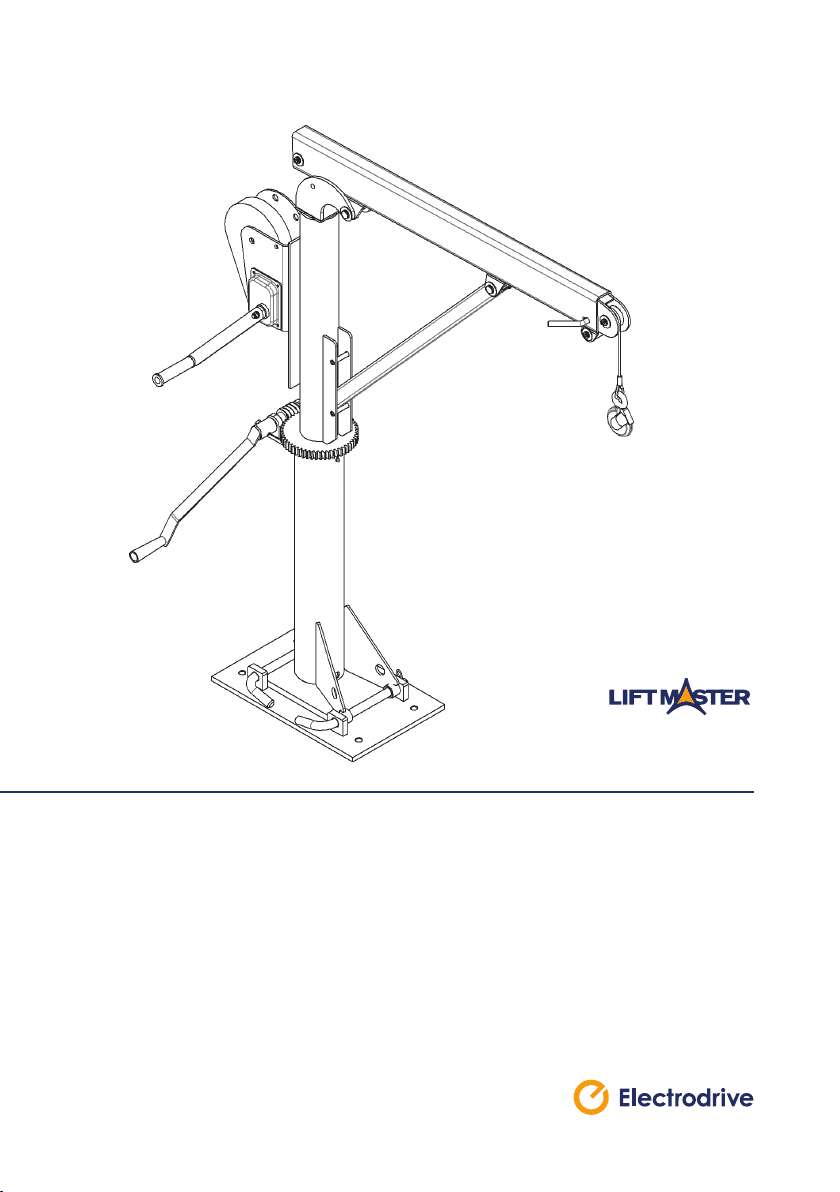

The Liftmaster Strong Arm is a cantilever crane used for carrying heavy loads up onto

an elevated surface.

Model Working Load Limit Max Load

SIS4HW 500 kg 500 kg

Brake winch

Winch handle

Slew handle

Retaining pins

Base plate

Boom

Boom support

Locking pin

Hook

Strong Arm—Operating Manual

5

Assembly

Onsite installation and mounting must be done by a qualied engineer.

See Appendix 1 for mounting plate diagram for hole placement.

Brake winch handle

1. Unscrew locking nut (A) on brake winch.

2. Place brake winch handle onto bolt.

3. Screw locking nut into place to secure brake

winch handle.

Slew Handle

4. Unscrew the nut and remove the small bolt (B)

on the slew.

5. Attach slew handle by sliding it onto the slew,

aligning the bolt hole.

A

B

6

Operating instructions

Safety check

Before using the Strong Arm, the operator should complete the following check:

1. Retaining pins are locked correctly and the unit is secured to the base plate.

2. Boom support is in correct position and that it rmly holds the boom.

3. Boom locking pin is secure, preventing the boom from sliding.

Using the Strong Arm

1. Rotate winch handle anti-clockwise to lower hook.

2. Secure load to the hook.

Prior to lifting, check that the clip on the hook is locked in place and

that the hook has a proper lift point.

3. Rotate handle clockwise slowly to raise the load in a safe manner.

4. Rotate slew handle to turn the boom in a circular arc either clockwise or anti-

clockwise.

Adjusting the boom

Extending the boom

Remove boom locking pin and slowly slide boom to desired length and reattach locking

pin to secure the boom.

Adjusting the boom height

Have a rm grip on the boom and boom support and slowly raise until desired angle is

reached. Placing boom support into holder, make sure it is safely secured.

See Appendix 3 for boom length and weight guidelines.

Boom is not to be extended or raised while the weight is attached.

All changes must be done prior to operation.

Strong Arm—Operating Manual

7

Maintenance

§Always check cable and hook for signs of damage, wear and fraying.

§Check for any structural damage.

§Check that the winch locks correctly and winch cogs and teeth are suciently

lubricated with CRC TAC2 (or equivalent) adhesive lubricant. Check that the roller

pins are free of damage and moving correctly.

§Check that all pins, washers and clips aren’t damaged or missing.

8

Warranty

Electrodrive Pty Ltd warrants that this product is free from defects in materials and

workmanship for a period of twelve months from the date of dispatch from the

Electrodrive plant.

If a defect is reported, Electrodrive will repair or replace the defective part, at its own

discretion. This warranty does not apply if this unit has been misused, damaged, or

modied in any way.

Please be aware that modications and misuse will void your warranty. The following

activities (including, but not limited to) are examples of these:

Unauthorised maintenance

§There are modications to the body or frame of the machine

§Use of non-specied parts

§The machine is serviced by an unauthorised service agent

Misuse

§Overloading the unit during lifting

§Carrying people or other foreign objects

§Exposed to rain or other precipitation, unless weatherproof option is installed

§Exposed to a corrosive environment

General wear items not covered under warranty

§Tyres, tubes and castors

Strong Arm—Operating Manual

9

Appendix 1: Specications

The Strong Arm has been load tested in accordance with Test Specication Clause

12.2/AS4991-2004 (Certicate Number ALS31085).

See Appendix 3 for boom length and weight guidelines.

10

Appendix 2: Mounting plate

Strong Arm—Operating Manual

11

Appendix 3: Boom length and weight

guidelines

12

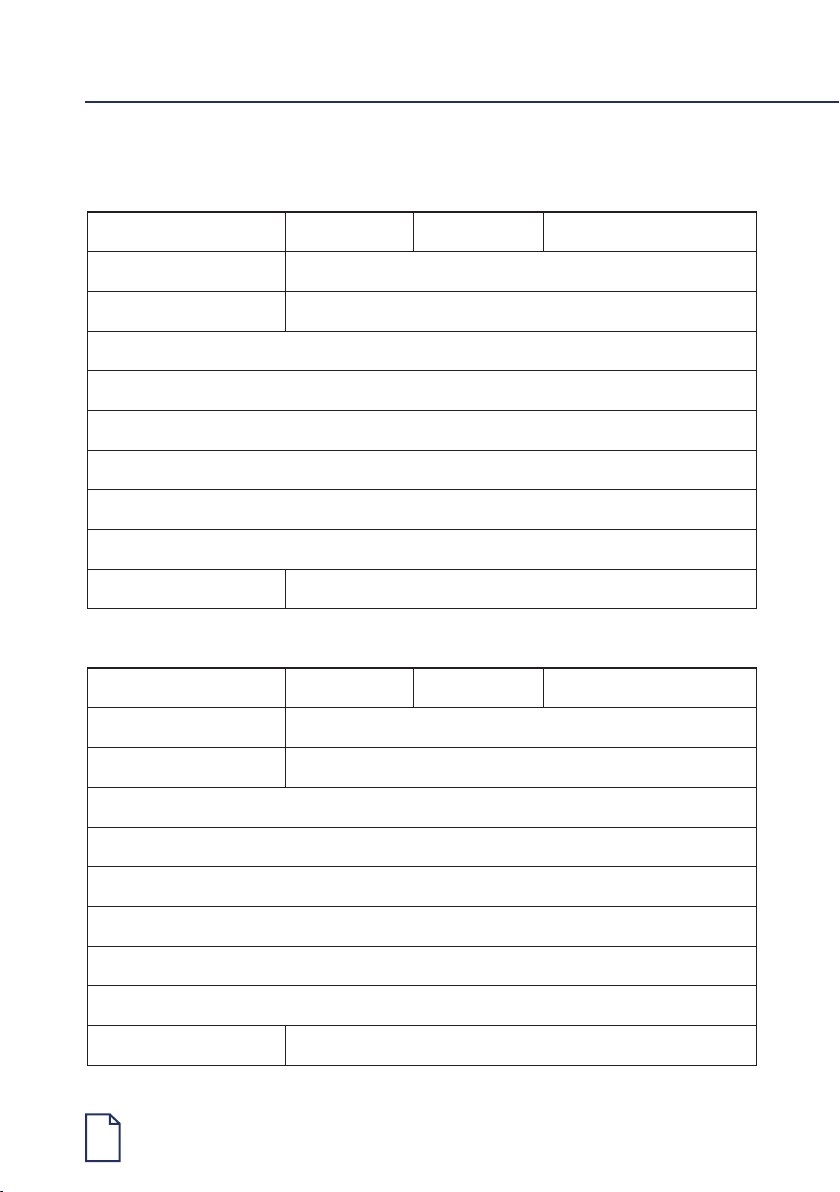

Service log

Service recommendations

To ensure this equipment is kept in a safe and reliable condition, it is important to

follow a preventative maintenance program. Maintain a log of the service work on the

cards below, and always use an approved Electrodrive service agent to conduct the

works. Approved service personnel will be provided with all necessary documents and

components in service repair, including but not limited to, circuit diagrams, component

part lists, descriptions, service checklists and spare parts.

6 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

Strong Arm—Operating Manual

13

12 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

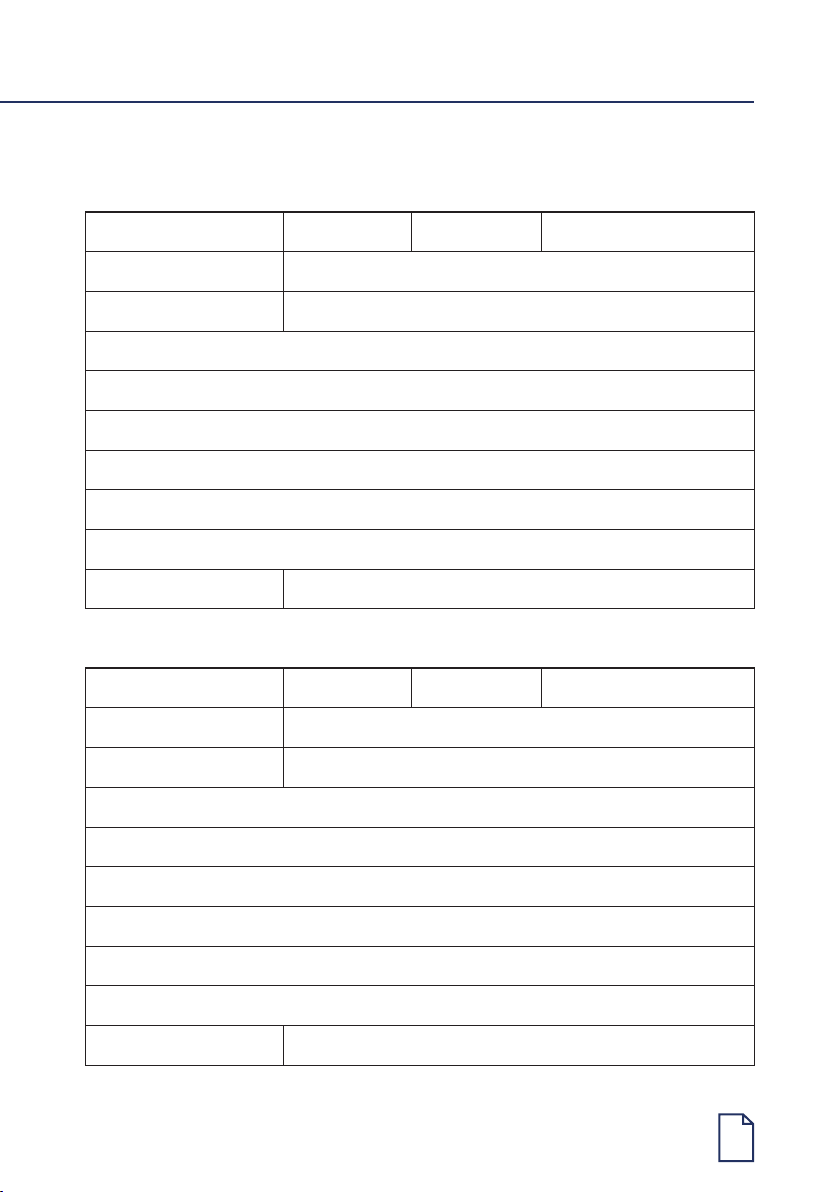

18 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

14

24 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

30 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

Strong Arm—Operating Manual

15

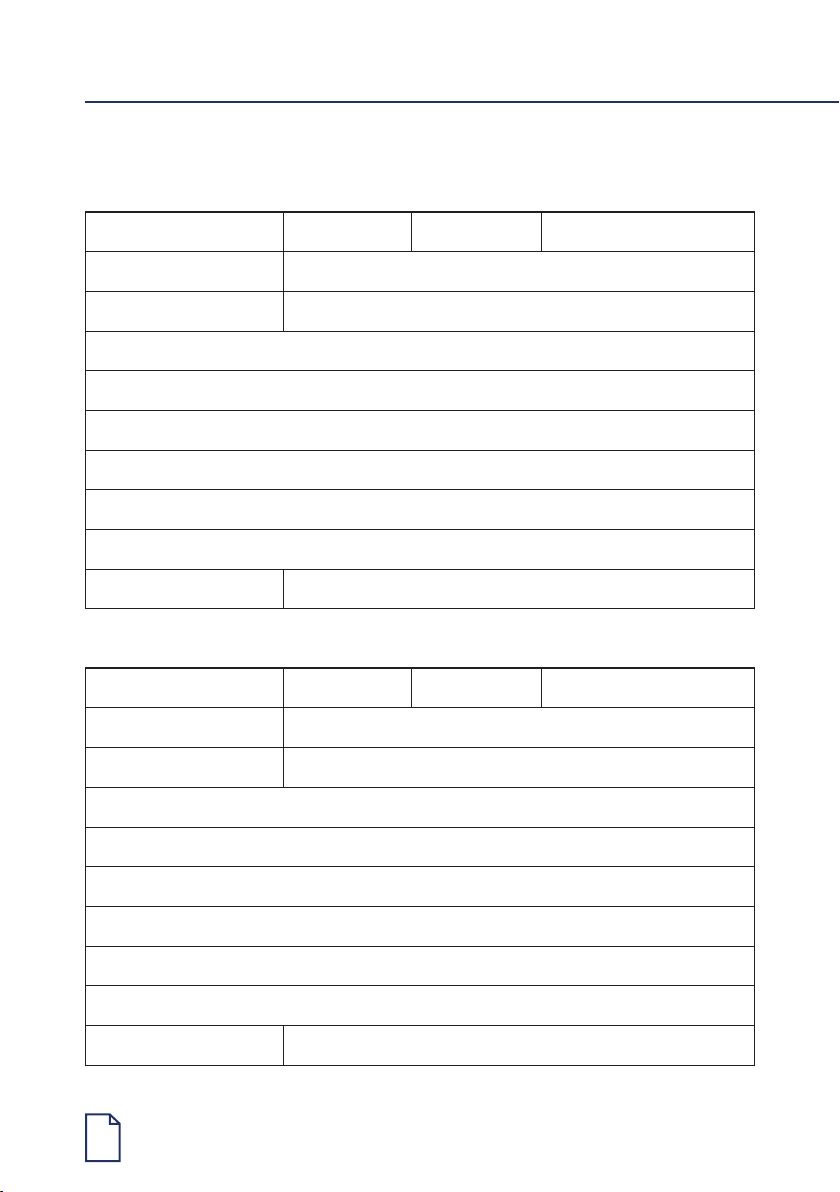

36 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

42 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

16

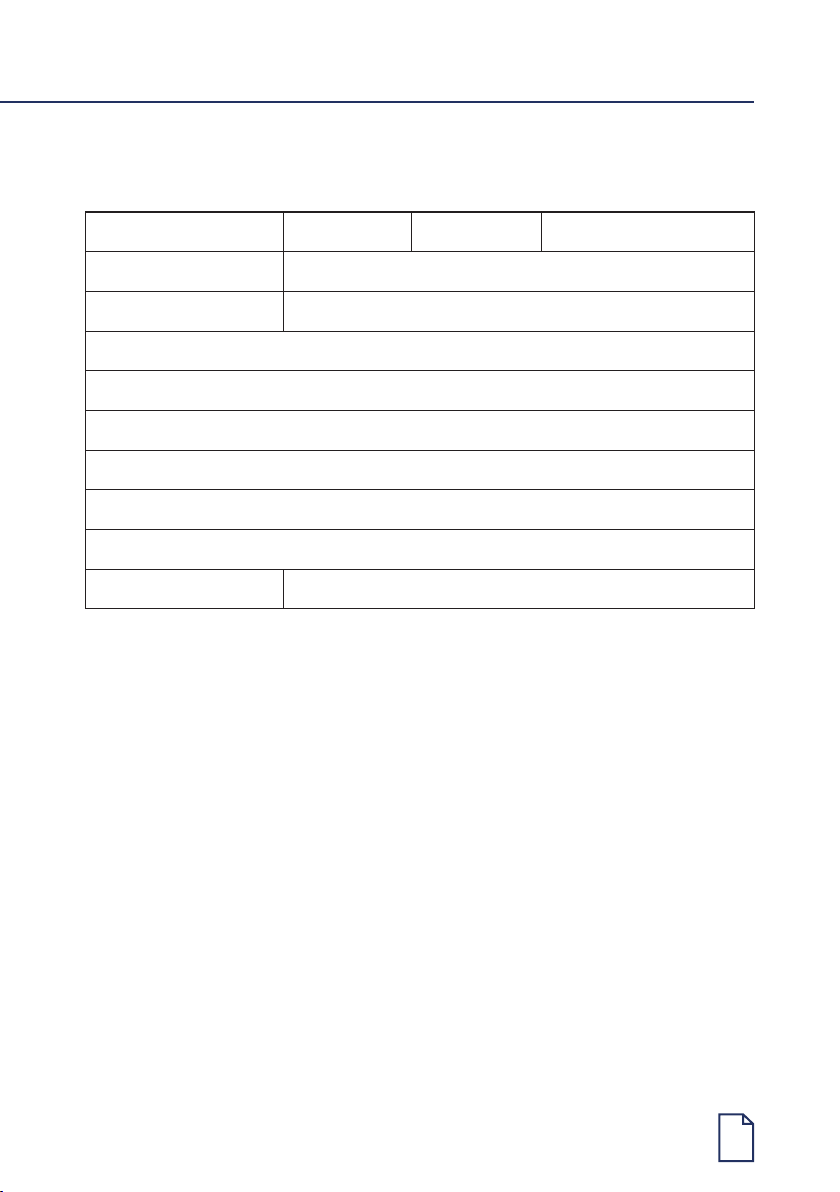

48 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

54 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

Strong Arm—Operating Manual

17

60 month service

Date of service Service agent

Machine serial number

Summary of works

Next service due

Mobility solutions to help you push, pull & lift with ease

www.electrodrive.com.au

This manual suits for next models

1

Table of contents

Other ELECTRODRIVE Lifting System manuals

Popular Lifting System manuals by other brands

Hardi

Hardi Commander Twin Force Plus Instruction book

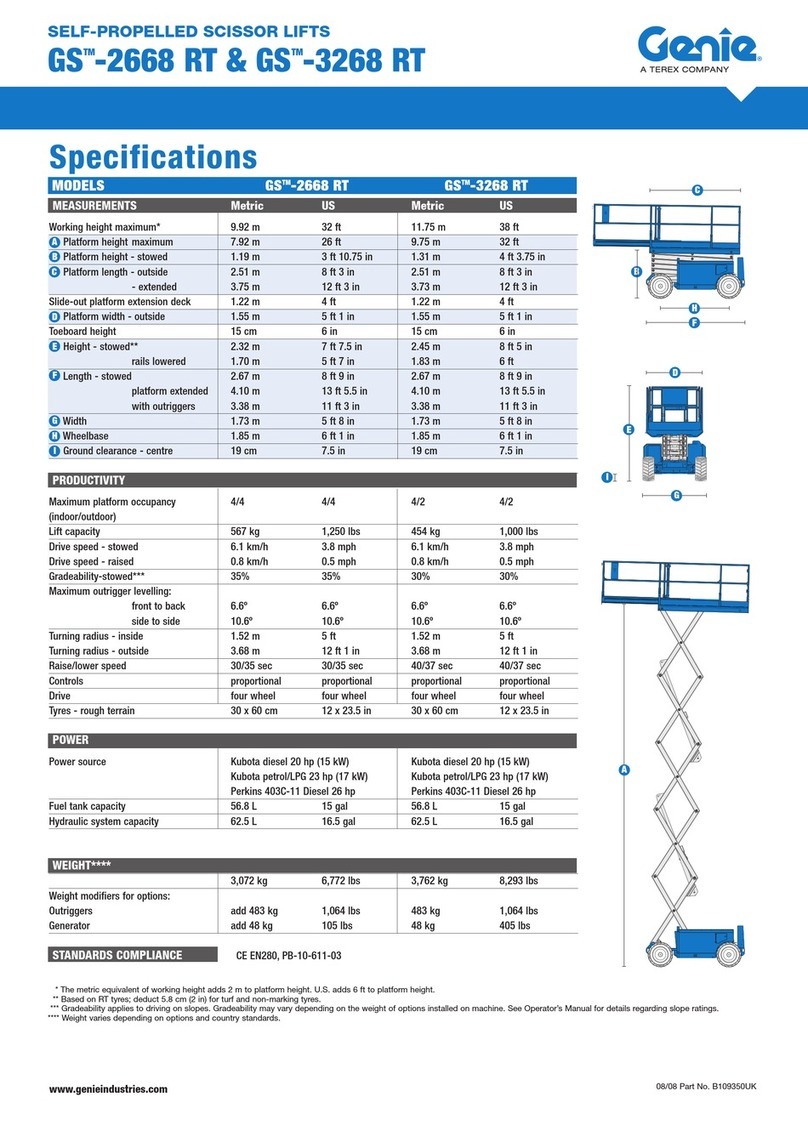

Genie

Genie GTH-2506 Stage A Operator's manual

WITTUR

WITTUR safety in motion CORE CD installation manual

Viessmann

Viessmann V AH-300 Installation and service instructions for contractors

Haulotte

Haulotte STAR 6 Operator's manual

Sinoboom

Sinoboom TB28J Plus Operation manual