Hardi Commander Twin Force Plus User manual

1

GB 01 06

Illustrations, technical information and data in this book are to the best of our belief correct at the time of printing. As

it is HARDI INTERNATI NAL A/S policy permanently to improve our products, we reserve the right to make

changes in design, features, accessories, specifications and maintenance instructions at any time and without

notice. HARDI INTERNATI NAL A/S is without any obligation in relation to implements purchased before or after

such changes.

HARDI INTERNATI NAL A/S cannot undertake any responsibility for possible omissions or inaccuracies in this

publication, although everything possible has been done to make it complete and correct.

As this instruction book covers more models and features or equipment, which are available in certain countries

only, please pay attention to paragraphs dealing with precisely your model.

Published and printed by HARDI INTERNATI NAL A/S

We congratulate you for choosing a HARDI plant protection product. The reliability and

efficiency of this product depend upon your care. The first step is to carefully read and

pay attention to this instruction book. It contains essential information for the efficient

use and long life of this quality product.

As the instruction book covers all OMMANDER plus models with HAY boom or HAZ

boom, please pay attention to the paragraphs dealing with precisely your model.

This book is to be read in conjunction with the Spray Technique book.

More information about the OMMANDER plus can be found on the products own web-

site at: http//www.commander-plus.com

COMMANDER

TWIN FORCE

Instruction book

670747-GB-2000/01

2

3

TT

TT

Taa

aa

abb

bb

ble ofle of

le ofle of

le of Contents Contents

Contents Contents

Contents

Declaration of Conformity ........................................................ 4

Operator safety ........................................................................ 5

COMMANDER plus .................................................................. 6

Sprayer use ............................................................................. 8

Unloa ing the sprayer from the truck ....................................... 8

Before putting the sprayer into operation ................................. 8

Connecting the sprayer ............................................................ 9

Drawbars ..................................................................... 9

Fixe rawbar ...............................................................10

STEERING rawbar ..................................................... 10

SELF TRACK for COMMANDER 2200/2800 ................ 10

TRAIL CONTROL ......................................................... 10

Transmission shaft ................................................................... 11

Operator safety ............................................................ 11

Installation of transmission shaft ...................................11

Track gauge ............................................................................. 13

Altering the track gauge ................................................13

A justment ranges - track wi th ....................................14

Permitte rim positions ................................................. 15

Hy raulic systems .................................................................... 16

Tractor Operate Hy raulics ......................................... 16

Direct Acting Hy raulic system ..................................... 16

Loa Sensing ............................................................... 16

Control boxes an power supply ............................................... 17

Brakes ......................................................................................18

Emergency an parking brake (if fitte ) ........................ 18

Hy raulic activate brakes (if fitte ) .............................. 18

Air activate brakes (if fitte ) ........................................ 18

Single-line brakes (if fitte ) ........................................... 19

Dual-line brakes (if fitte ) .............................................. 19

Counter weight (TRACKER mo els only) ................................. 20

Transport ................................................................................. 21

Roa worthiness ........................................................... 21

Rear lights (if fitte ) ...................................................... 21

Transport brackets, height setting ................................ 21

Transport lock .............................................................. 22

Driving Technique ..................................................................... 23

STEER TRACK an SELF TRACK ............................. 23

STEER TRACK ........................................................... 23

SELF TRACK .............................................................. 24

TRAIL CONTROL ........................................................ 24

Equipment - Stan ar an A itional ....................................... 25

La er ......................................................................... 25

Platform ....................................................................... 25

Tank level in icator ...................................................... 25

Large storage Locker (if fitte ) ..................................... 25

Small storage Locker (if fitte ) ..................................... 25

Front Locker (if fitte ) .................................................. 25

Boom an Work lights (if fitte ) ................................... 26

Crop protection Kit (if fitte ) ........................................ 27

Mu guar s (if fitte ) .................................................... 28

Disconnecting the sprayer ....................................................... 29

Operating the boom ................................................................. 30

The HAY boom ............................................................. 30

The HAZ boom ............................................................. 30

Air slot angling ............................................................. 30

Electrical fan spee a justment (if fitte ) ...................... 31

Boom suspension sensitivity ........................................ 31

Operating the liqui system ...................................................... 32

MANIFOLD SYSTEM ............................................................... 32

Use of MANIFOLD valve system ................................. 32

Electrical operate MANIFOLD valves (if fitte ) ............ 33

Quick reference ............................................................ 33

Filling of water .............................................................. 33

Filling of rinsing tank (if fitte ) ....................................... 35

Filling of clean water tank ............................................. 36

A justment of EVC operating unit ................................ 36

A justment of pressure equalisation ............................. 36

Operating the control unit while spraying ...................... 37

Remote pressure gauge (if fitte ) ................................. 37

Filters ....................................................................................... 37

Self-cleaning filter .........................................................37

Choice of correct restrictor ........................................... 37

Filling of chemicals ................................................................... 38

Filling of Liqui chemicals .............................................38

Filling of Pow er chemicals .......................................... 39

Use of rinsing tank an rinsing nozzles (if fitte ) ..................... 40

Technical Resi ue .................................................................... 41

Draining a resi ue ........................................................ 41

Using the rain valve ................................................................ 41

Using the suction quick coupler ................................................ 41

Operation of the rain valves .................................................... 41

Safety precautions ................................................................... 42

Personal protection .......................................................42

Air technique ............................................................................ 43

Air spee / Air volume ...................................................43

Blower a justment ........................................................ 43

Angling of air an liqui ................................................ 43

A justing the air assistance .......................................... 43

Setting of air spee , rules of thumb .............................. 44

Angling of air an liqui , rules of thumb ........................ 44

Water sensitive paper ................................................... 45

Maintenance - rules of thumb ................................................... 49

Cleaning the sprayer ................................................................ 49

Cleaning the tank ......................................................... 49

Cleaning an maintenance of filters ..............................50

Lubrication ............................................................................... 51

Lubricating points ......................................................... 51

Service an Maintenance intervals ........................................... 56

10 hours service ........................................................... 56

50 hours service ........................................................... 56

100 hours service ......................................................... 56

250 hours service ......................................................... 56

500 hours service ......................................................... 56

1000 hours service or yearly, whichever comes first ..... 57

Occasional maintenance .............................................. 57

Off-season storage ................................................................... 76

Off-season storage program ......................................... 76

Preparing the sprayer for use after storage ................... 76

Fault-fin ing ............................................................................. 77

Operational problems ............................................................... 77

TRACKER amping system ......................................... 77

Liqui system ............................................................... 78

EVC Operating unit ...................................................... 79

Hy raulic system (Tractor Operate Hy raulics) ........... 79

Hy raulic system (Direct Acting Hy raulic System) ....... 80

Hy raulic fan transmission ........................................... 81

Emergency operation of the sprayer ......................................... 82

The boom ..................................................................... 82

Steering rawbar (if fitte ) ............................................ 82

Technical specifications ............................................................ 83

Overall imensions ....................................................... 83

Weight ..........................................................................83

Pump capacity ............................................................. 85

Filters an nozzles ....................................................... 86

Temperature an pressure ranges................................. 86

Brakes ..........................................................................86

Materials an recycling ................................................ 86

Disposal of the sprayer ................................................ 86

Conversion factors, SI to Imperial units ........................ 86

Electrical connections 86

Rear lights .................................................................... 86

Electrical connections for EVC operating unit ............... 87

Electrical chart (EVC) .................................................. 87

Installation instruction for boom an work light ............. 88

Electrical specifications for Boom an Work light ......... 89

Boom hy raulic charts .............................................................. 90

Subject in ex ............................................................................xx

4 GB 02 01

EC Declaration

Dec Dec

Dec Dec

Declarlar

larlar

laraa

aa

ation oftion of

tion oftion of

tion of Conf Conf

Conf Conf

Conformityormity

ormityormity

ormity

Manufacturer, Importer,

HARDI INTERNATI NAL A/S

Helgeshøj Allé 38

DK 2630 Taastrup

DENMARK

declare that the following product;

_________________________________________________________________________________________

A. was manufactured in conformity with the provisions in the C UNCIL DIRECTIVE of 14 June 1989 on mutual

approximation of the laws of the Member States on the safety of machines (89/392/EEC as amended by directives

91/368/EEC and 93/368/EEC) with special reference to Annex 1 of the Directive on essential safety and health

requirements in relation to the construction and manufacture of machines.

B. was manufactured in conformity with the current standards implementing harmonised standards in accordance

with Article 5 (2) and other relevant standards.

Taastrup, January 2000

_____________________________________________

Erik Holst

Managing Director

HARDI INTERNATI NAL A/S

Adhere extra shipping package labels in the Product Identification Certificate.

5 GB 03 01

Safety notes

OperOper

OperOper

Operaa

aa

ator saftor saf

tor saftor saf

tor safetyety

etyety

ety

Watch for this symbol .

It means WARNING, CAUTI N,

N TE. Your safety is involved so be

alert!

Note the following recommended precautions and safe

operating practices.

Read and understand this instruction book

before using the equipment. It is equally

important that other operators of this equip-

ment read and understand this book.

Local law may demand that the operator be

certified to use spray equipment. Adhere to

the law.

Pressure test with clean water prior to filling

with chemicals.

Wear protective clothing.

Rinse and wash equipment after use and

before servicing.

Depressurize equipment after use and before

servicing.

Never service or repair the equipment whilst it

is operating.

Disconnect electrical power before servicing.

Always replace all safety devices or shields

immediately after servicing.

If an arc welder is used on the equipment or

anything connected to the equipment, discon-

nect power leads before welding. Remove all

inflammable or explosive material from the

area.

Do not eat, drink or smoke whilst spraying or

working with contaminated equipment.

Wash and change clothes after spraying.

Wash tools if they have become contaminated.

In case of poisoning, immediately seek medi-

cal advice. Remember to identify chemicals

used.

Keep children away from the equipment.

Do not attempt to enter the tank.

Do not go under any part of the sprayer unless

it is secured. The boom is secure when

placed in the transport brackets.

If any portion of this instruction book remains unclear

after reading it, contact your HARDI dealer for further

explanation before using the equipment.

6GB 04 06

Description

COMMANDER plusCOMMANDER plus

COMMANDER plusCOMMANDER plus

COMMANDER plus

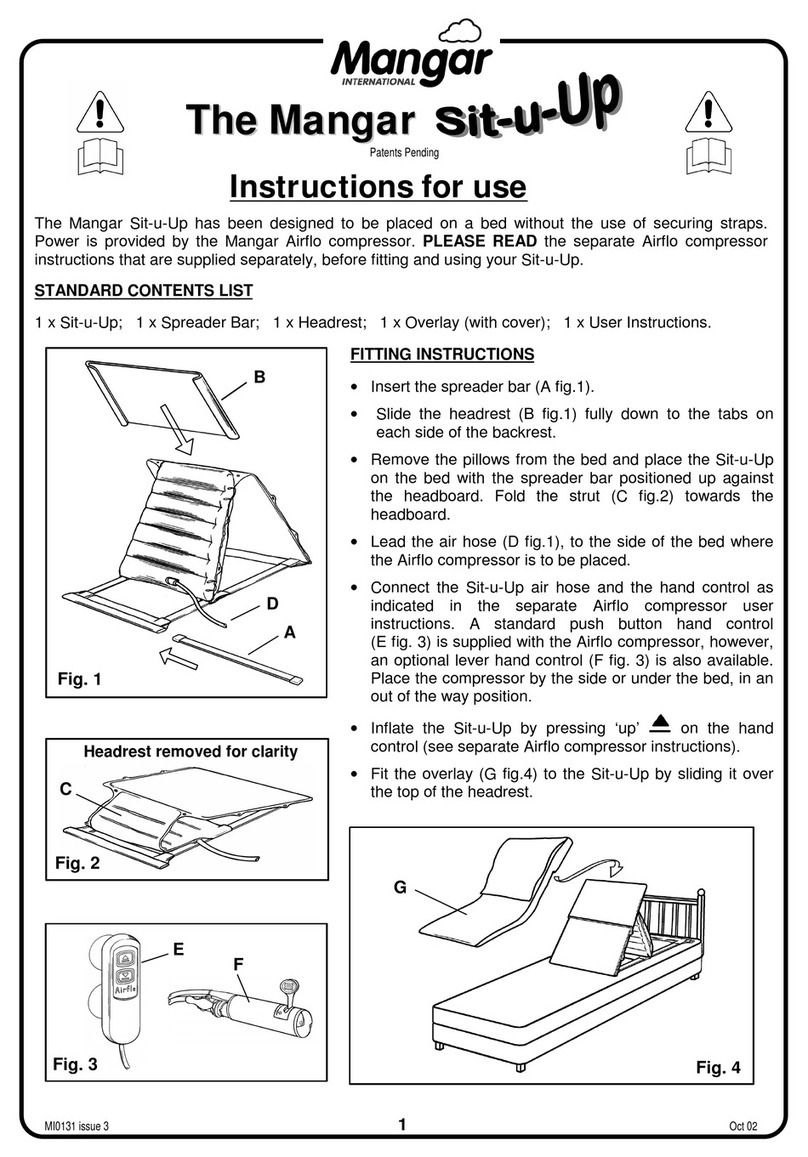

The C MMANDER plus is divided into three zones: a Clean zone, a Working zone and an Application zone, refer-

ring to the level of possible pesticide contamination.

CLEAN ZONE WORKING ZONE APPLICATION ZONE

Please note that some of the features are optional equipment

Locker for protective gear

Clean water tank

Tap for hand washing

Support leg

Pump

P.T. . shaft

Tank level indicator

MANIF LD valves

Couplers for fast filling

Working platform with

ladder

Hydraulic and electric

components

Boom and Work lights

HARDI FILLER

Lockers for pesticide

containers and equip-

ment

PARALIFT boom lift system

Boom

Nozzles

Mudguards

Suspension

Crop Protection Kit

T271-0010x

7

GB 04 06

Description

DescriptionDescription

DescriptionDescription

Description

Frame

Strong and compact frame with several options of

drawbars and wheel sizes. The frame has a strong

chemical and weather resistant electrostatic lacquer

coat. Screws, nuts, etc. have been DELTA-MAGNI

treated to be resistant to corrosion.

Tank

UV-resistant Polyethylene in a suitable design with no

sharp corners for easy agitation, emptying and cleaning.

Nominal contents 2200, 2800, 3200 or 4200 l.

Pump

Diaphragm pump with 6 diaphragms, model 363 or 463,

depending on boom width, with easily accessible valves

and diaphragms. Standard = 540 r.p.m. (6 splines)

ptional = 1000 r.p.m. (21 splines).

MANIFOLD SYSTEM

All functions of the spray circuits are operated via the

centrally situated MANIF LD valves with colour coded

plates and pictorial symbols for easy operation.

Operating unit

The system is based on EVC - Electrical Valve Control.

The on/off is linked to the section valves, which is

resulting in a very quick response to on/off.

The operating unit is constructed of modules and is

electrically controlled via a remote control box.

The built-in HARDI-MATIC ensures a constant volume

per hectare of the liquid (l/ha) at varying forward speed

within the same gear when the number of P.T. . revolu-

tions are between 300-600 r.p.m. (pump 540 r.p.m) or

650-1100 r.p.m. (pump 1000 r.p.m.).

Filters

With the self-cleaning filter the impurities that exist in the

spray liquid will bypass the filter and be recirculated back

to the tank via the return flow. Also suction filter and

nozzle filters are standard. In-line pressure filters can be

fitted as option.

Boom

All booms are suspended in a strong, stable parallelo-

gram boom lift.

The HAY/HAZ booms are trapeze/pendulum suspended

and fully hydraulically operated, including boom slanting

control and air slot angling. HAZ models have Direct

Acting Hydraulics (D.A.H.) and individual boom tilt

function as well.

The TWIN blowers are driven by a built-in hydrostatic

transmission powered via the tractor P.T. . Blower

speed can be adjusted stepwise from the tractor cabin.

The HAY/HAZ booms are available in 18, 20, 21, 24, 27

and 28 m working width.

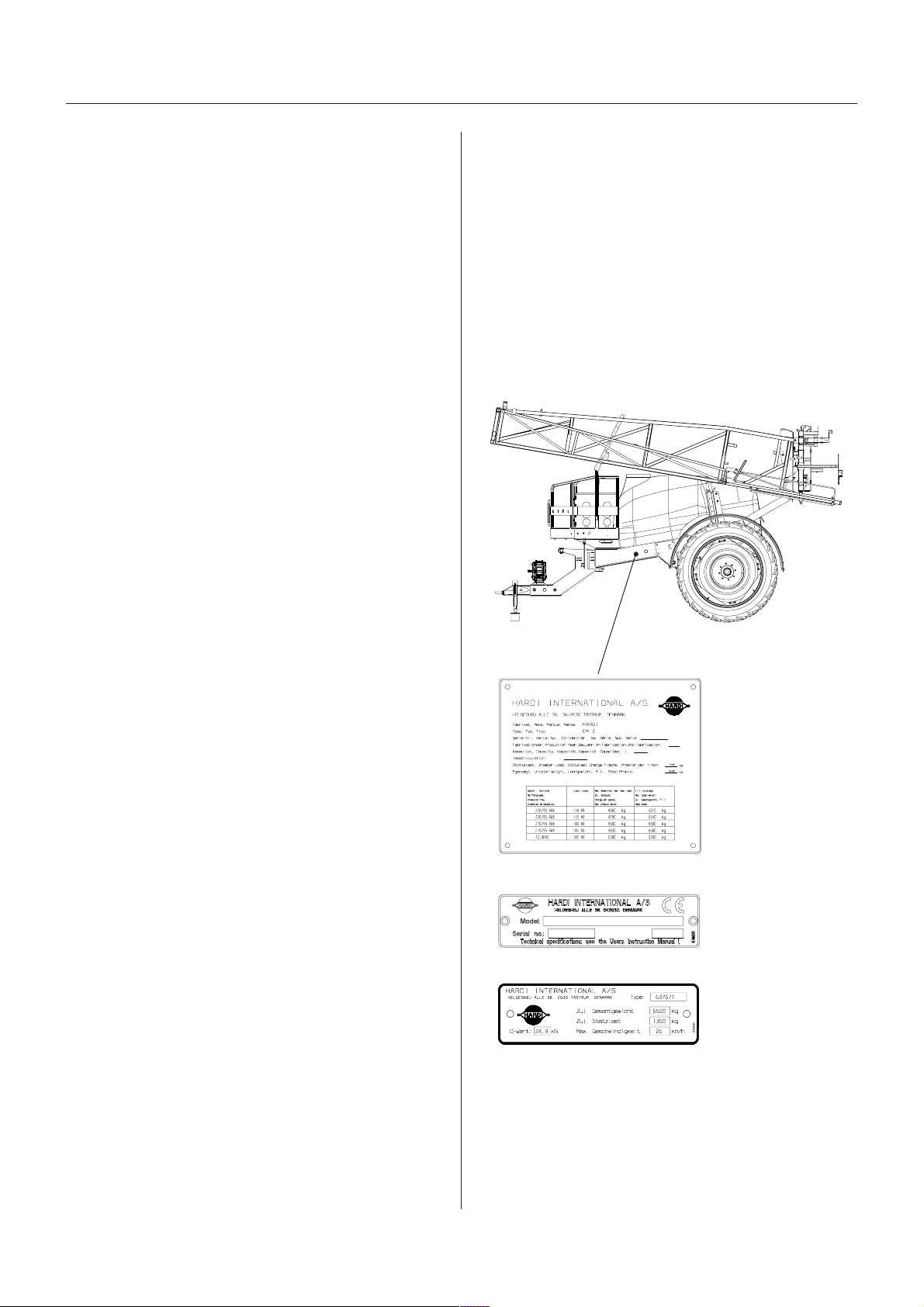

Identifi ation plates

An identification plate fitted on the frame indicates

producer name, model, own weight, max. weight, max.

pressure of the hydraulic system, and max. pressure of

the spray liquid system. Frame, boom centre frame, and

inner/outer sections also have identification plates

indicating boom type and part number of spare parts. If

ordering spare parts, inform your dealer of these, so the

right model and version are described.

T271-0010x

T279-0005

T279-0002

T279-0006

(Certain countries only)

8GB 04 06

Description

SprSpr

SprSpr

Spraa

aa

ayy

yy

yer useer use

er useer use

er use

The HARDI C MMANDER sprayer is for the application

of crop protection chemicals and liquid fertilisers.

The equipment must only be used for this purpose. It is

not allowable to use the sprayer for other purposes.

If no local law demands that the operator must be

certified to use the spray equipment, it is strongly recom-

mended to be trained in correct plant protection and in

safe handling of plant protection chemicals to avoid

unnecessary risk for persons and the environment when

doing the spray job.

Unloading the sprUnloading the spr

Unloading the sprUnloading the spr

Unloading the spraa

aa

ayy

yy

yer frer fr

er frer fr

er from the trom the tr

om the trom the tr

om the trucuc

ucuc

uc

For the unloading of the sprayer a crane or a fork lift is

needed. When loading with a crane please observe the

lifting points as shown on the illustration, and make sure

that the straps or belts used for lifting are strong enough.

BefBef

BefBef

Beforor

oror

ore putting the spre putting the spr

e putting the spre putting the spr

e putting the spraa

aa

ayy

yy

yer intoer into

er intoer into

er into

operoper

operoper

operaa

aa

ationtion

tiontion

tion

Although the sprayer has been applied with a strong and

protective surface treatment on steel parts, bolts etc. in

the factories, it is recommended to apply a film of

anticorrosion oil (e.g. CASTR L RUSTILL or SHELL

ENSIS FLUID) on all metal parts in order to avoid

chemicals and fertilisers discolouring the enamel.

If this is done before the sprayer is put into operation for

the first time, it will always be easy to clean the sprayer

and keep the enamel shiny for many years.

This treatment should be carried out every time the

protection film is washed off.

T021-0003

9

GB 05 02 01

Sprayer setup

Connecting the sprConnecting the spr

Connecting the sprConnecting the spr

Connecting the spraa

aa

ayy

yy

yerer

erer

er

DrDr

DrDr

Draa

aa

awbarwbar

wbarwbar

wbarss

ss

s

Mounted on the chassis in a centre pivot, the drawbar

can be either standard fixed or optionally steered.

Steering can be hydraulically operated or it can be

automatically controlled (TRAIL C NTR L).

Following drawbar extensions are available. The draw-

bar extensions are available - steering or fixed - for both

high and low tractor hitch points. Each drawbar is

available in a long or a short version.

Mounting the drawbar extension

The extension piece is inserted into

the opening of the drawbar,

fastened by two main bolts

through the two holes A and

secured by two linch pins.

Support leg

The support leg is stored in the bracket on the sprayers

right side when the sprayer is attached to the tractor.

To remove the support leg: Lift the leg, remove the linch

pin and pull out the support leg.

The support leg can then

be mounted to the drawbar

extension and secured by

linch pin.

T251-0014x

Swivel type

Zugmaul

Hitch (IS 5692)

REDNAMMOC

ZPL/YPL

DEXIF

RABWARD

GNIREETS

RABWARD

LIART

LORTNOC

FLES

KCART

0082/0022seYseYseYseY

0024/0023seYseYseYoN

Overview - Drawbar systems

035

rabwarD

snoisnexe

REDNAMMOC

0082/0022

REDNAMMOC

0024/0023

WOLdnaHGIH

hcih

WOLdnaHGIH

hcih

33ØepytleviwSoNseY

63ØepytleviwSseYoN

04ØluamguZseYseY

)2965OSI05ØhctiHseYseY

noisrevtrohsadnagnolanielbaliavaerasrabwardllA

Overview - Drawbar extensions

034

A

T251-0012x

T142-0028x

T251-0012x

10 GB 05 02 01

Sprayer setup

FF

FF

Fixix

ixix

ixed dred dr

ed dred dr

ed draa

aa

awbarwbar

wbarwbar

wbar

Make sure the drawbar points straight ahead from its

position on the trailer. If not, the two turn buckles A can

be adjusted till the drawbar is centred.

STEERING drSTEERING dr

STEERING drSTEERING dr

STEERING draa

aa

awbarwbar

wbarwbar

wbar

Transport lo k (if fitted)

The transport lock is a safeguard that will keep the

drawbar in a centred position in case of hydraulic

leakage during transport on public roads.

The transport lock is fixed by linch pins.

If necessary, the transport lock can be adjusted by

turning the turnbuckle.

SELF TRASELF TRA

SELF TRASELF TRA

SELF TRACK fCK f

CK fCK f

CK for COMMANDER 2200/2800or COMMANDER 2200/2800

or COMMANDER 2200/2800or COMMANDER 2200/2800

or COMMANDER 2200/2800

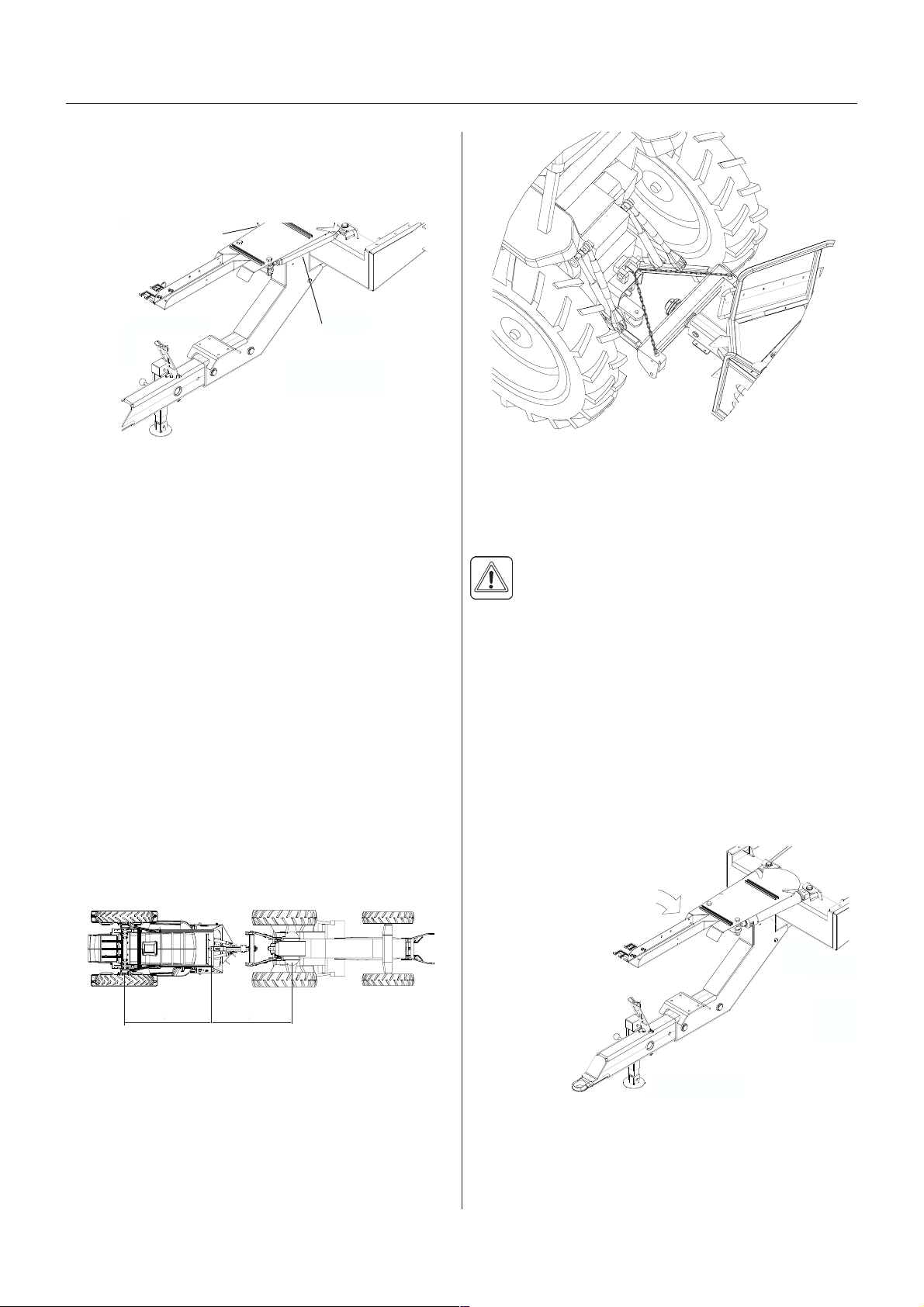

SELF TRACK is connected as follows:

1. Attach the tractor lower links in the two mountings of

the SELF TRACK. Adjust the length of the drawbar if

necessary - to obtain the best tracking, choose the

setting where the distance X is equal to distance Y.

Secure with linch pins.

2. Attach safety chains to top link clevis. The chain will

prevent the transmission shaft from being damaged if

the lift arms are lowered too far. Adjust the chain

length so the chains are tight when the tractor P.T. .

and pump shaft are in a horizontal line.

A

A

T251-0012x

xyT251-0015x

T251-0016x

NOTE! If possible, lock the tractor hydraulic lever when

the lift arms are in the correct position to avoid the

sprayer weight resting on the stabiliser chains.

3. Tighten the lift arm stabiliser chains.

WARNING! Do not stand in the area around the

drawbar during manoeuvring.

TRAIL CONTROLTRAIL CONTROL

TRAIL CONTROLTRAIL CONTROL

TRAIL CONTROL

Please refer to separate instruction book.

ose pacose pac

ose pacose pac

ose packk

kk

kaa

aa

agg

gg

ge suppore suppor

e suppore suppor

e support t

t t

t

To prevent hoses and wiring from being damaged by the

tractor wheels, all hoses, cables and wires are held by

the hose bracket A fitted to the drawbar.

Check that the length of the hoses and cables are

sufficient by tight turns.

T251-0012x

A

11

GB 05 03 01

Sprayer setup

TT

TT

Trr

rr

ransmission shaftansmission shaft

ansmission shaftansmission shaft

ansmission shaft

OperOper

OperOper

Operaa

aa

ator saftor saf

tor saftor saf

tor safetyety

etyety

ety

To avoid accidents and personal injuries, note the

following recommended precautions and safe operation

practices.

1. Always ST P ENGINE before attaching the transmis-

sion shaft to tractor P.T. . - most tractor P.T. . shafts

can be rotated by hand to facilitate spline alignment,

when engine is stopped.

2. When attaching the shaft, make sure that the snap

lock is FULLY ENGAGED - push and pull shaft until it

locks.

WARNING! R TATING TRANSMISSI N

SHAFTS WITH UT PR TECTI N GUARDS

ARE FATAL.

3. Always keep protection guards and chains intact and

make sure that it covers all rotating parts, including

CV-joints at each end of the shaft. Do not use without

protection guard.

4. Do not touch or stand on the transmission shaft when

it is rotating - safety distance: 1.5 meter.

5. Prevent protection guards from rotating by attaching

the chains allowing sufficient slack for turns.

6. Make sure that protection guards around tractor

P.T. . and implement shaft are intact.

7. Always ST P ENGINE and remove the ignition key

before carrying out maintenance or repairs to the

transmission shaft or implement.

InstallaInstalla

InstallaInstalla

Installation oftion of

tion oftion of

tion of tr tr

tr tr

transmission shaftansmission shaft

ansmission shaftansmission shaft

ansmission shaft

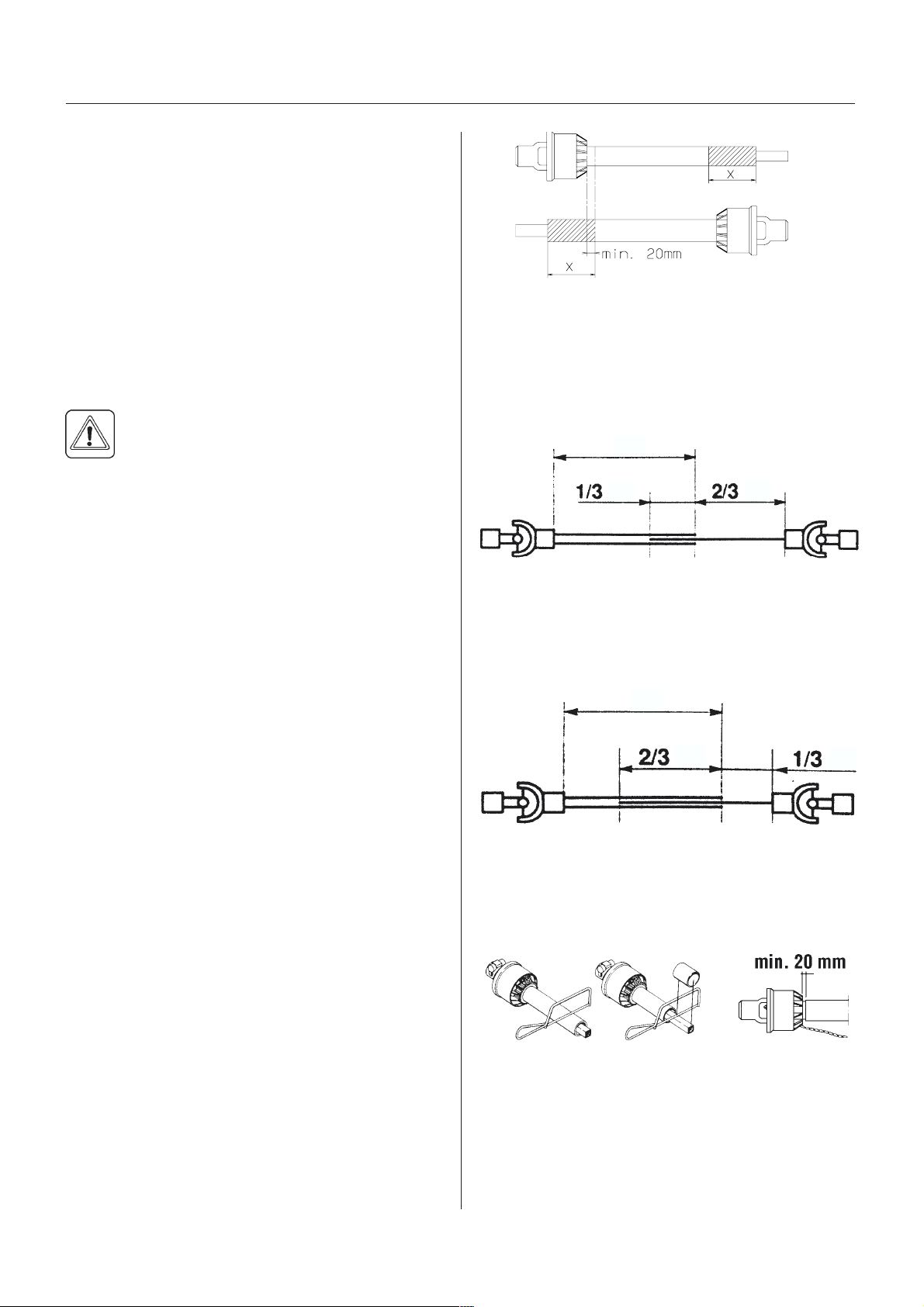

First installation of the transmission shaft is done in the

following way:

1. Attach sprayer to tractor and set sprayer height in the

position with shortest distance between the tractor

and sprayer pump P.T. . shafts.

2. Stop engine and remove ignition key.

3. If transmission shaft must be shortened, the shaft is

pulled apart.

Fit the two shaft parts at tractor and sprayer pump

and measure how much it is necessary to shorten the

shaft.

Mark the protection guards.

NOTE! The shaft must always have a minimum overlap.

The size of this overlap depends on the pump model:

Pump with 6 splines/540 r.p.m.

The shaft must always have an overlap of minimum 1/3

of the length.

Pump with 21 splines/1000 r.p.m.

The shaft must always have an overlap of minimum 2/3

of the length.

4. The two parts are shortened equally. Use a saw, and

file the profiles afterwards to remove burrs.

5. Grease the tractor P.T. . and pump shafts.

6. Fit the shaft to tractor P.T. . and sprayer pump shaft.

NOTE: Female part marked with a tractor towards

tractor!

T259-0004

T259-0005 T259-0007

T259-0011

T259-0011

12 GB 05 03 01

Sprayer setup

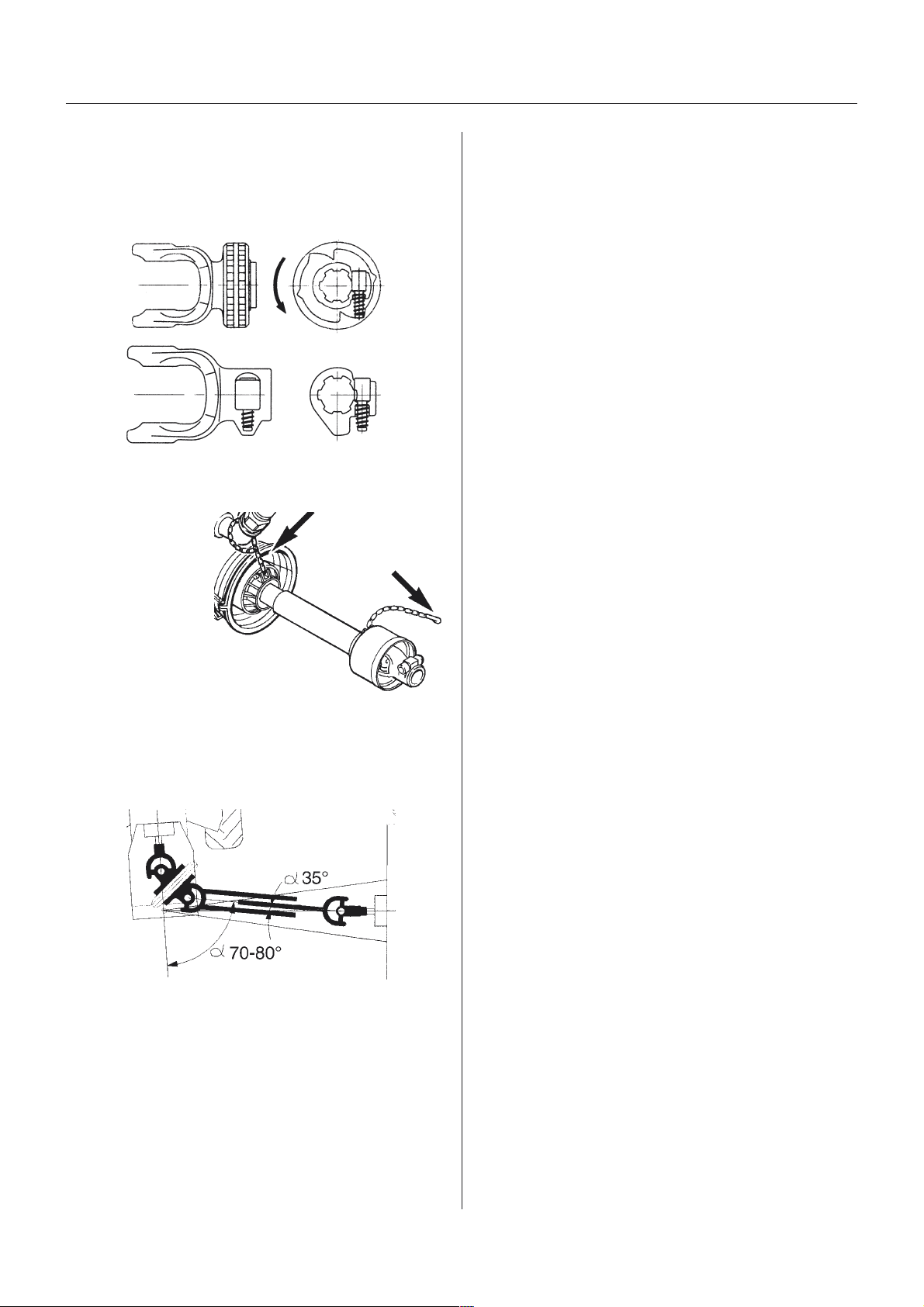

8. Twist the collar and slide the yoke onto the P.T. .

shaft.

Make sure that the lock engages by pushing and

pulling the shaft forwards and backwards.

9. Fit the chains to prevent the protection guards from

rotating with the shaft.

NOTE!To ensure long life of the transmission shaft try to

avoid working- angles greater than 35°. The wide angle

shaft with Constant Velocity Joint works in angles up to

70°- 80° for short periods (during turning etc.).

T259-0003

T259-0008

T259-0002

13

GB 05 04 04

Sprayer setup

T251-0005

TT

TT

Trr

rr

racac

acac

ac g g

g g

gaugaug

augaug

augee

ee

e

Altering the trAltering the tr

Altering the trAltering the tr

Altering the tracac

acac

ack gk g

k gk g

k gaugaug

augaug

augee

ee

e

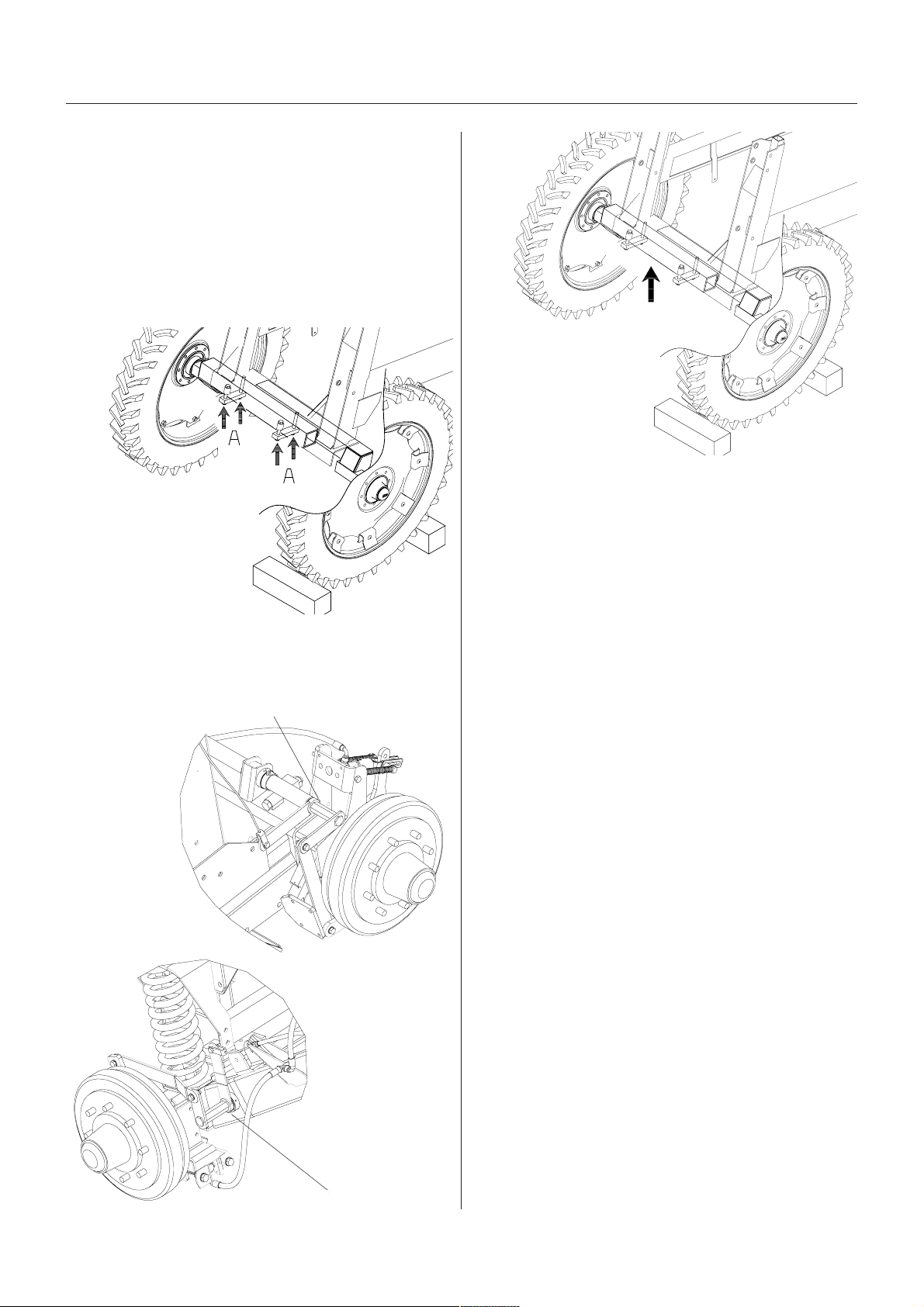

The track gauge of the C MMANDER can be altered

stepless as follows,

1. Measure the current track gauge (centre RH tyre to

centre LH tyre). Each side must be extended or

retracted half the desired alteration.

2. Attach the sprayer to tractor and engage tractor

parking brake.

3. Place stop wedges in front

of and behind RH wheel.

Jack up LH wheel, support

and secure sprayer body.

4. Loosen clamp bolts

for LH wheel axle.

5. Loosen the nut B on the brake operating arm.

Extend/retract this arm according to the adjustment of

the axle.

T251-0006

T112-0005x

T112-0005x

COMMANDER

without suspension

COMMANDER

with suspension

B

B

6. Extend or retract the axle.

A sack barrow and a

rod will facilitate the

operation.

7. If the rim position must be changed, do this first and

fine adjust by extending or retracting the axles.

Remember to tighten the wheel nuts to the specified

torque:

Rim plate to rim: 280 + 30 Nm (207 + 22 lbft)

Rim plate to hub: 490 Nm (288 lbft)

8. Tighten the clamp bolts to a torque of:

280 Nm (207 lb.ft) for 2200/2800

390 Nm (289 lbft) for 3200/4200.

9. Tighten nut B again.

IMPORTANT! Place the jack under the axle and lift the

wheel to remove load from the clamps before tightening

the clamp bolts to the specified torque.

10. Repeat the procedure on RH wheel.

11. Check the distance from centre tyre to centre of tank

frame is equal at RH and LH.

12. Retighten clamp bolts and wheel bolts to specified

torque after 8 hours of work.

14 GB 05 04 04

Sprayer setup

Adjustment rAdjustment r

Adjustment rAdjustment r

Adjustment rangang

angang

anges - tres - tr

es - tres - tr

es - tracac

acac

ack widthk width

k widthk width

k width

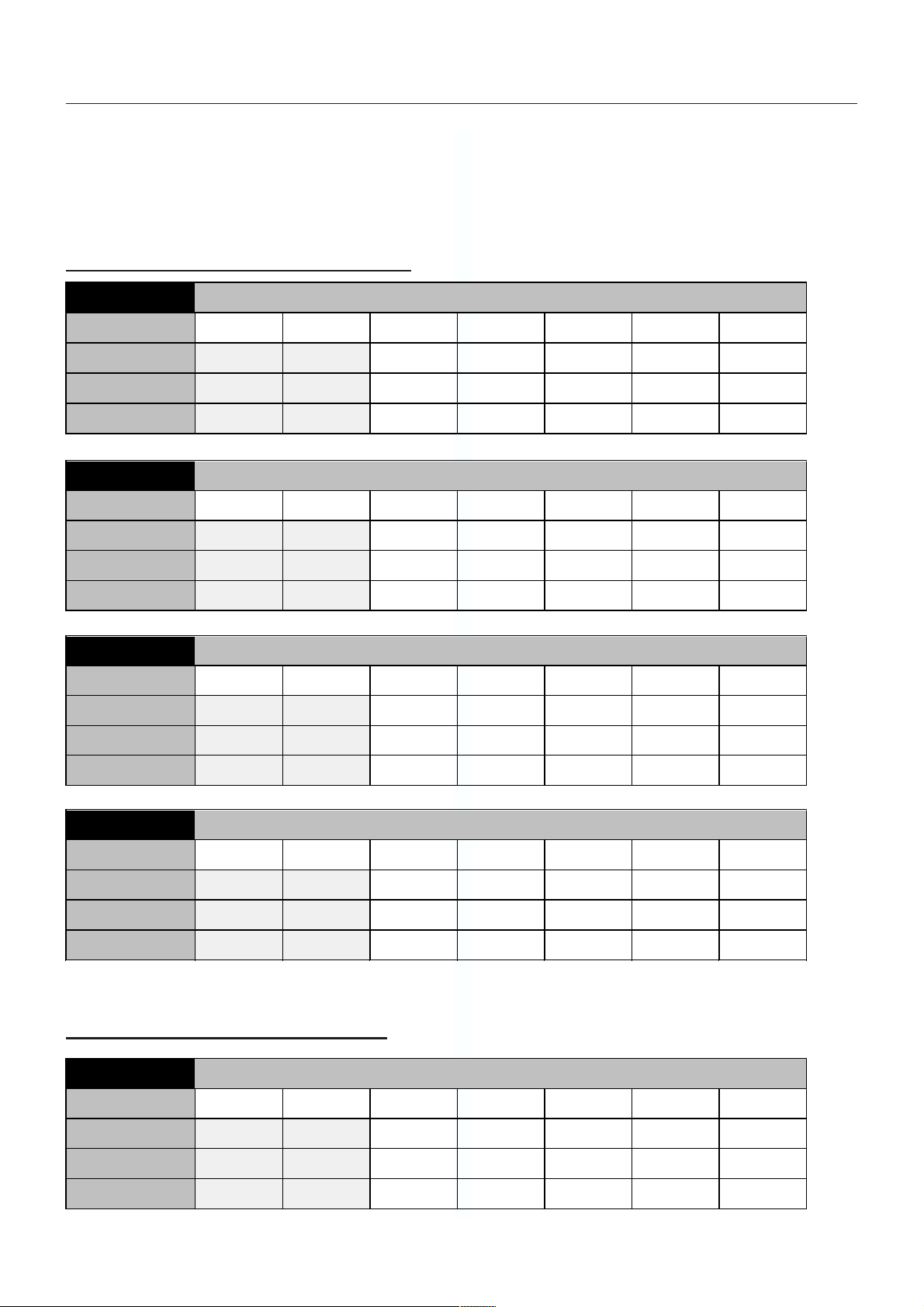

The maximum track width for all models is 2250 mm.

The minimum track width depends on the parameters in the charts beneath and whether the sprayer is equipped

with suspended axle or not. Please refer to the following charts (all figures are in mm).

Min. track width - Sprayers without suspension

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

Min. track width - Sprayers with suspension

15

GB 05 04 04

Sprayer setup

T251-0003

T251-0004

PP

PP

Permitted rim positionsermitted rim positions

ermitted rim positionsermitted rim positions

ermitted rim positions

WARNING! When altering track gauge by turning

rims and rim plates the maximum permitted

offset between centre wheel and hub flange must

be observed:

Max offset, hub flange and centre rim:

IMPORTANT! Tyre sizes 18.4 x 38 and 20.8 x 38

are not permitted in any + position, only use the

- positions.

M Min. rim offset Max. rim offset

2200/2800 -45 +55

3200/4200 -33 +33

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

&0SOXV 7\UHVL]H

Sprayer with: [ [ [ [ [ [ [

)ODQJHKXE

UDNHKXE

0XGJXDUGV

It is not permitted to fit dual wheels!

IMPORTANT! n TRACKER models a minimum track gauge of 1800 mm is strongly recommended to ensure

stability and to avoid the sprayer tipping over.

NOTE! The wider the track gauge, the better the stability of the sprayer and boom.

16 GB 05 06 06

Sprayer setup

Load Sensing

Please consult your tractor dealer for correct setup and

correct connection.

Certain tractor models are able to use Load Sensing

without connecting an external sensing line (setting 1 in

scheme). But if optimal sensing control pressure cannot

be obtained, an external sensing line needs to be

mounted (setting 2 in scheme).

Requirements - Load Sensing hose:

1/4 Standard hose

Max. rated working pressure = 200 bar.

IMPORTANT! It is of essential importance that connec-

tors on sensing line are kept totally clean. Failure to do

so will cause impurities entering the pump and thereby

cause damages to vital pump parts.

029

ciluardyh/rocarT

mesys evlavegdirraC roalugerwolF

dradnaS

)rotcartwolftnatsnoc nepOnepO

ernecdesolC

)srotcartDJniatrec desolCdesolC

gnisnesdaoL

.1 tuohtiW lanretxe

enilgnisnes

nepOnepO

gnisnesdaoL

.2 htiW lanretxe

enilgnisnes

desolCnepO

Valve open

Valve closed

T112-0004x

Flow regulator

Cartri ge valve

T112-0004x

LS

Connect hose to

LS on the

distribution block

T112-0007x

HyHy

HyHy

Hydrdr

drdr

draulic syaulic sy

aulic syaulic sy

aulic systemsstems

stemsstems

stems

yy

yy

ydrdr

drdr

draulics COMMANDER- Aaulics COMMANDER- A

aulics COMMANDER- Aaulics COMMANDER- A

aulics COMMANDER- AYY

YY

Y

Tra tor Operated Hydrauli s

Connection requirements for C MMANDER-HAY are

one double acting and one single acting spool valve.

Single acting valve: Boom lift, up/down

Double acting valve: Boom folding and unfolding

Ensure the snap couplers are clean before connection!

If hydraulic slanting control is fitted another double acting

spool valve on the tractor is required.

NOTE! The hydraulic system requires a minimum oil

pressure of 130 bar, max. oil pressure of 210 bar and an

oil capacity of approx. 5 litres. After having operated the

boom and the system has been filled with oil, check

tractors hydraulic oil level and top up if necessary.

yy

yy

ydrdr

drdr

draulics COMMANDER- AZaulics COMMANDER- AZ

aulics COMMANDER- AZaulics COMMANDER- AZ

aulics COMMANDER- AZ

Dire t A ting Hydrauli system

The D.A.H. system requires a double acting hydraulic

outlet. The hydraulic hoses are marked with arrows to

indicate direction of oil flow.

The D.A.H. system requires an oil flow between 10 and

90 l/min (19.8 Imp. gal/min.) and a min. pressure of 130

bar (1886 p.s.i.) The system has a built-in flow regulator

that maintains constant speed on hydraulic movements.

The hydraulic distribution block is situated underneath

the platform floor.

The valves on the block are operated by means of

manual override and each valve can be regulated to be

open or closed.

Before operating the hydraulics, the valves on the

sprayers hydraulic distribution block should be adjusted

according to the specific tractor model (please refer to

scheme later in this part).

If you have doubt about which type of hydraulic system

your tractor is equipped with, please ask your tractor

dealer.

17

GB 05 06 06

Sprayer setup

ContrContr

ContrContr

Control bool bo

ol bool bo

ol boxx

xx

xes and powes and pow

es and powes and pow

es and power supplyer supply

er supplyer supply

er supply

Power requirement is 12V DC.

Note Polarity!

For EVC: Brown pos. (+), Blue neg. (-).

For D.A.H.: White pos. (+), Black neg. (-).

The control boxes for EVC-operating unit and D.A.H. are

fitted in the tractor cabin at a convenient place. Tapping

screws can be used for mounting.

The wires must have a cross sectional area of at least

4.0 mm to ensure sufficient power supply. For the EVC-

operating unit the tractor circuit should have an 8 Amp

fuse and for the D.A.H. an 16 Amp fuse.

Control box for Polarity (wire colour) Require Fuse, Amp

Positive + Negative -

EVC operating

unit Brown Blue 8

D.A.H. Hy raulic White Black 16

MANIFOLD valve Brown Blue 8

Use the HARDI Electric distribution box (No. 817925) if

the tractor has a doubtful power supply.

T165-0013

18 GB 05 05 02

Sprayer setup

WARNING! Do not connect the brakes directly to

the tractor hydraulics without the brake valve. The

trailer brake power cannot be controlled, and

braking will therefore be hazardous.

IMPORTANT! Max. oil pressure is 150 bar (2175 p.s.i.)

in the brake line.

Relieve parking brake before driving.

Air activAir activ

Air activAir activ

Air activaa

aa

ated brted br

ted brted br

ted brakak

akak

akes (ifes (if

es (ifes (if

es (if f f

f f

fitted)itted)

itted)itted)

itted)

This system requires a tractor with

compressor and air brake system with

out-let(s) for trailer brakes.

IMPORTANT! The load apportioning

valve must be set at the position

corresponding to the load on the

trailer, for obtaining optimal air pres-

sure to the trailer brakes.

= Relieved = Half full tank

= Empty tank = Full tank

WARNING! Driving with wrong load apportioning

valve setting, will make the brakes under- or over-

apply, which can cause hazardous situations.

NOTE! If the air hose(s) are disconnected with air in the

brake air tank, control pressure

will be dumped and the brakes

will engage fully. If the sprayer

must be moved with air in the

tank and without the air hose(s)

connected to the tractor, the load

apportioning valve must be set

at relieved to disengage the

brakes. Remember to reset the

handle to brake position again

afterwards. When parking the

sprayer, always engage the parking brake, as the air

brakes will only be engaged as long as there is air in the

tank! Cover the couplings with the dust flaps when

hoses are disconnected.

BrBr

BrBr

Braa

aa

a eses

eses

es

EmerEmer

EmerEmer

Emergg

gg

gencenc

encenc

ency and pary and par

y and pary and par

y and parkk

kk

king bring br

ing bring br

ing brakak

akak

ake (ife (if

e (ife (if

e (if f f

f f

fitted)itted)

itted)itted)

itted)

The parking brake lever has two function modes, which

are determined by the small pawl control clip (A).

To change between the

two modes, turn the clip.

Pos. 1: The pawl control

clip must point away from

the pawl.

Pos. 2: The pawl control

clip must rest against the

pawl.

To disengage the parking

brake:

1. Set pawl control clip in pos. 1.

2. Pull the lever a little forward to release the pawl from

the ratchet and then push the lever fully backwards.

To engage the parking brake:

1. Set pawl control clip in pos. 2.

2. Pull the lever firmly forwards until parking brake is fully

engaged.

Emergency brake

1. Set pawl clip in pos. 2.

2. Attach the rope from the hole in top of the handbrake

lever (B) to e.g. the tractor top link attaching point. If

the sprayer is accidentally unhooked during transport

the rope will apply the parking brake before the rope

breaks.

IMPORTANT! To ensure safe engagement and to avoid

damages to the parking brake use rope with an ultimate

stress between 690 N (155 lb.) and 785 N (176 lb.).

yy

yy

ydrdr

drdr

draulic activaulic activ

aulic activaulic activ

aulic activaa

aa

ated brted br

ted brted br

ted brakak

akak

akes (ifes (if

es (ifes (if

es (if f f

f f

fitted)itted)

itted)itted)

itted)

This requires a special trailer brake valve attached to the

tractor hydraulic and brake system. Connect the snap

coupler to the tractor brake outlet. When the tractor

brakes are applied, the trailer brakes will work propor-

tionally to the tractor brakes, and ensure safe and

effective braking.

T021-0001

T021-0008

Tractor Trailer

Hy raulic pump

Oil

reservoir

T021-0009

T021-0010

Position

setting

Loa valve

12

A

B

Forwar Backwar

19

GB 05 05 02

Sprayer setup

SingSing

SingSing

Single-line brle-line br

le-line brle-line br

le-line brakak

akak

akes (ifes (if

es (ifes (if

es (if f f

f f

fitted)itted)

itted)itted)

itted)

Flip the snap coupler protection flap away and connect

the brake system snap coupler to the tractor outlet

(black) and let the compressor fill the sprayers air

reservoir.

Check brake circuit for leaks.

Dual-line brDual-line br

Dual-line brDual-line br

Dual-line brakak

akak

akes (ifes (if

es (ifes (if

es (if f f

f f

fitted)itted)

itted)itted)

itted)

Flip the snap coupler protection flaps away and connect

the two snap couplers for supply and control to the

tractor outlets, and check brake circuits for leaks.

The couplers are colour coded and secured against

incorrect attachment:

Red = Supply line (RH)

Yellow= Control line (LH)

Relieve parking brake before driving

20 GB 05 10

Sprayer setup

Counter wCounter w

Counter wCounter w

Counter weight eight

eight eight

eight (TRA(TRA

(TRA(TRA

(TRACKER models only)CKER models only)

CKER models only)CKER models only)

CKER models only)

To improve stability on TRACKER models, extra weight

can be added by means of liquid-filled tyres.

The standard tyre valve is an universal air-water valve.

The tyres can be filled with liquid to max. 75% of their

total volume. The table below indicates the 75% volume.

Use a mixture of water and CaCl2 to avoid frost damage

as described in table below:

CaCl2 per litre water Protection to

200 g (7.1 oz) -15°C (30.6°F)

300 g (10.6 oz) -25°C (12.6°F)

435 g (15.4 oz) -35°C (-5.4°F)

WARNING! It is very important that the CaCl2 is

added to the water and agitated until it is fully

dissolved. Never pour water on to CaCl2! If you

get CaCl2 in the eyes, flush instantly with cold water for

at least 5 minutes and seek medical advice afterwards.

IMPORTANT! The tyres must be liquid filled to max. 75

% of total tyre volume. Fill only the qty. of liquid neces-

sary to obtain sufficient stability of the sprayer. Do not fill

liquid and CaCl2 mixture in tyres without tubes!

To fill the tyres:

1. Jack up the wheel

and rotate wheel till

the valve is posi-

tioned at 12 oclock.

2. Remove the valve

body and fill liquid

until it reaches the

valve.

3. When surplus liquid

is drained through the

valve stem fit the valve body again.

4. Adjust tyre pressure and lower the wheel. (Please

refer to table for correct tyre pressure).

NOTE! When filling the tyres the valve should be posi-

tioned at 12 oclock and when adjusting the tyre pres-

sure, the valve should be positioned at 6 oclock.

To empty the tyres:

1. Rotate wheel till the

valve is positioned at

6 oclock.

2. Remove the valve

body and let out the

liquid. Retain liquid in

an appropriate

container.

3. To empty the tyre

completely the tyre is

inflated and a thin drain

tube is lead to the

bottom of the tyre. The

air pressure will now

empty the remaining

liquid.

4. Remove the drain tube,

fit the valve and inflate

the tyre to specified

pressure. See the table Tyre pressure.

NOTE! Disposal of CaCl2 has to take place according to

local legislation.

T021-0011

T021-0013

T021-0014

001

eziseryT eryrepdiuqilfoseril.xaM

"44x5.9101

"84x5.9 801

"44x2.11331

"84x2.11 441

"64x4.21871

"83x9.61 582

"83x4.81093

"83x8.02 664

1 litre = 0.264 US Gal. 1 litre = 0.22 Imp. Gal.

eziseryT

59CR

dednemmoceR

nierusserpnoialfni

).i.s.p(rab

muminiM

xednIdaoL

2A/8A

44R59/032

)44x5.9 )256.3541/431

84R59/032

)84x5.9 )256.3 741/631

44R59/072

)44x2.11 )256.3151/041

84R59/072

)84x2.11 )256.3 351/241

64x4.21)256.3851/741

83x9.61 )326.1 251/141

83x4.81)326.1441/741

83x8.02 )812.1 151/451

Recommended tyre pressure:

002

Table of contents

Popular Lifting System manuals by other brands

Wesco

Wesco EVM 206-90 Use and maintenance instructions

ARJO HUNTLEIGH

ARJO HUNTLEIGH Voyager Portable Technical manual

Big Joe

Big Joe PTE 30 Series Operation, maintenance, repair parts list

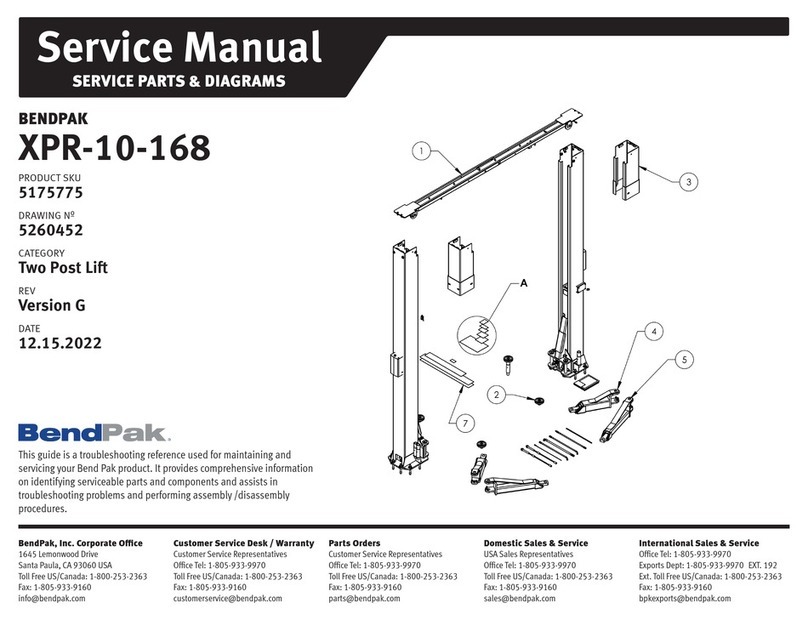

Bend-Pak

Bend-Pak XPR-10A Service manual

Bigfoot

Bigfoot PLATINUM Series Installation & owner's manual

Bend-Pak

Bend-Pak HD-9SWX Service manual