Bike-Lift SA-07 User manual

Operating manual No. 057-2-6-0009-R0 Page 1

Version 2018

EN

EC Use and Maintenance Manual

SA-07 Shock absorber dismantler

Bike

BikeBike

Bike-

--

-Lift EUROPE s.r.l.

Lift EUROPE s.r.l. Lift EUROPE s.r.l.

Lift EUROPE s.r.l.

via Don Milani, 40/42

43012 anguinaro di Fontanellato (PARMA) – Italy

Web site: www.bikelifteurope.it

E-mail: info@bikelifteurope.it

Operating manual No. 057-2-6-0009-R0 Page 2

Version 2018

EN

Summary

1 Information section ............................................................................................................................. 4

1.1 Preface ................................................................................................................................................ 4

1.2 Prohibitions ........................................................................................................................................ 5

1.3 Warranty ............................................................................................................................................. 5

Warranty conditions ................................................................................................................... 5

1.3.1

Insurance .................................................................................................................................... 5

1.3.2

1.4 Manufacturer identification ............................................................................................................... 6

1.5 Technical assistance and spare parts ................................................................................................. 6

1.6 C Declaration of conformity ............................................................................................................. 7

1.7 Normative references ......................................................................................................................... 8

1.8 General regulations and conventions................................................................................................. 8

1.9 Key ...................................................................................................................................................... 9

2 Machine description ................................................................................................................... 10

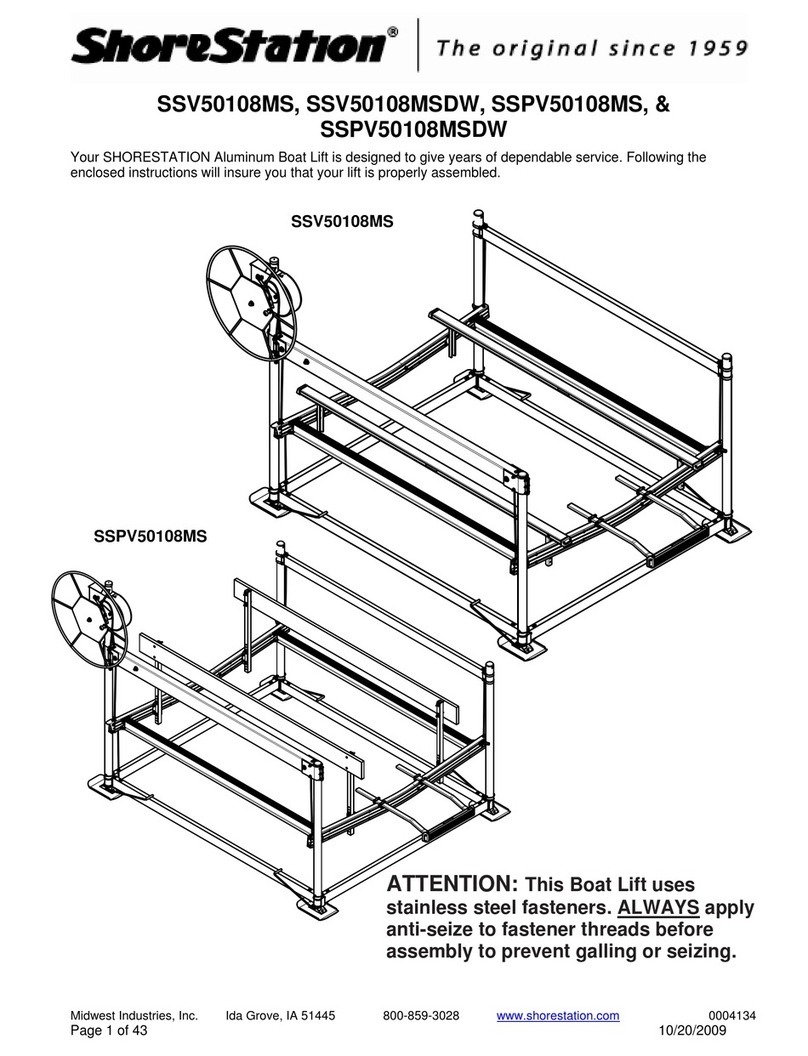

2.1 Machine name .................................................................................................................................. 10

2.2 Shock Absorber Dismantler identification ........................................................................................ 10

2.3 Intended use and reasonably foreseeable misuse ........................................................................... 11

2.4 Technical specifications .................................................................................................................... 11

Standard adapters data ............................................................................................................ 11

2.4.1

3 Safety section .................................................................................................................................... 12

3.1 nvironmental working values ......................................................................................................... 12

3.2 Sound level ....................................................................................................................................... 12

3.3 Operator protections ......................................................................................................................... 12

3.4 Pictograms ........................................................................................................................................ 12

3.5 General safety rules .......................................................................................................................... 13

4 Transport and handling section ...................................................................................................... 14

4.1 Transport, handling and storage ...................................................................................................... 14

4.2 Unpacking ......................................................................................................................................... 14

4.3 Disposal of the packaging ................................................................................................................. 14

4.4 Packaging and transport ................................................................................................................... 15

4.5 Warnings for handling and transport ............................................................................................... 15

5 Installation section .......................................................................................................................... 16

5.1 Filling ............................................................................................................................................... 17

Operating manual No. 057-2-6-0009-R0 Page 3

Version 2018

EN

6 Dismantling/scrapping section ........................................................................................................ 18

6.1 Storage .............................................................................................................................................. 18

6.2 Scrapping and disposal ..................................................................................................................... 18

6.3 Scrapping materials .......................................................................................................................... 18

6.4 Instructions for a suitable waste treatment ....................................................................................... 18

6.5 lectrical and electronic equipment waste ...................................................................................... 19

7 Operation section ............................................................................................................................. 20

7.1 Use .................................................................................................................................................... 21

8 Maintenance section ........................................................................................................................ 23

8.1 Maintenance ..................................................................................................................................... 23

8.2 Cleaning ............................................................................................................................................ 23

Cleaning of the work areas ....................................................................................................... 23

8.2.1

8.3 Problems and remedies .................................................................................................................... 24

9 Technical diagrams and components section .................................................................................. 25

Machine maintenance sheet ........................................................................................................................... 26

Operating manual No. 057-2-6-0009-R0 Page 4

Version 2018

EN

1 Information section

1.1 Preface

The EC Use and Maintenance Manual is a document issued by Bike-Lift Europe s.r.l. as an

integral part of the Machine.

The purpose of this publication is to provide the operator with efficient and safe instructions

regarding the use and maintenance.

This Manual must be read entirely before starting any operation concerning the

installation, use, maintenance and putting out of service of the machine; therefore it

is necessary to be kept intact over time.

In order to properly store the Manual it is recommended to:

•

Use the manual without deteriorating it;

•

Do not remove, add, change or rewrite any part of the Manual; any modifications must

be made only by Bike-Lift-Europe s.r.l.;

•

Keep the Manual in areas protected against humidity in order not to compromise its

durability over time;

•

Deliver the Manual to any other user or subsequent owner of the Machine.

Workers in charge of using this machine must have all the necessary information and

must receive proper training.

The manual and relative documentation are confidential by law with the prohibition of

reproduction or transmission to third parties without receiving the explicit authorization of the

manufacturer.

As a partial exception to the above mentioned, a copy of this Manual kept in the vicinity of the

Machine is allowed for prompt reference, in case the original document is stored in a different

place, in order to guarantee better keeping over time.

Drawings, data and specifications contained in this manual can be modified at any time by the

company, without prior notice.

In case of significant changes of the machine due to the installation of new parts, Bike-Lift

Europe s.r.l. will compile an updated Manual that will be sent to the Customer together with

the purchased part.

Operating manual No. 057-2-6-0009-R0 Page 5

Version 2018

EN

1.2 Prohibitions

The installation, use, maintenance and putting out of service of the device with means, objects,

actions and anything else not provided for in this manual is considered improper and therefore

the manufacturer declines all responsibility for the consequences that may occur regarding

people, animals and objects.

It is expressly FORBIDDEN the use of the Machine by Operators who do not

know the regulation and procedures described in the Manual and by unauthorized

people (hereinafter referred to as "non-operators").

It is also forbidden the use of the machine by children and the non-operators or children must

not stand near the machine during all phases of the machine's life.

The putting out of service of the protection systems or anything else provided by the

manufacturer to protect the operators is the sole responsibility of the Purchaser or the

Machine's User.

Any mechanical, electrical or functional change of the Machine (not provided for in this

Manual) regarding the control systems, the logic of controls, the circuits present and the safety

systems is prohibited without the prior written authorization of the manufacturer.

1.3 Warranty

Bike-Lift Europe s.r.l. will not be held responsible for inconveniences, breakages, accidents,

etc. due to lack of knowledge or failure to apply the procedures specified in this Manual. The

same applies to the execution of modifications, changes or for the installation of accessories

not previously authorized.

Warranty conditions

1.3.1

Bike-Lift Europe s.r.l guarantees its products for 12 months, except for the commercial

components that are guaranteed by the manufacturers.

All worn parts are excluded from the warranty.

The warranty is limited to the replacement, ex-works Bike-Lift Europe s.r.l, of those parts that

are recognized as defective by Bike-Lift Europe s.r.l due to a material or manufacturing defect

and do not include labor or travel expenses required for their replacement.

The recognition of the warranty is void if the anomaly is due to an inappropriate use of the

product, if the installation was not carried out according to the provisions of the company or if

non-genuine parts were installed.

It also becomes void if the product has been submitted to performances exceeding those

indicated by Bike-Lift Europe s.r.l.

Insurance

1.3.2

All Bike-Lift Europe s.r.l products are insured with an RCP policy with a price ceiling of €

3.000.000. Damages caused by negligence or tampering are excluded.

Operating manual No. 057-2-6-0009-R0 Page 6

Version 2018

EN

1.4 anufacturer identification

Bike-Lift EUROPE s.r.l. via Don Milani, 40/42, 43012 Sanguinaro di Fontanellato (PARMA)

– Italy

Website: www.bikelifteurope.it

E-mail:

info@bikelifteurope.it

Tel: 0039-0521-827091

Fax: 0039-0521-827064

1.5 Technical assistance and spare parts

To order spare parts, it is recommended to specify exactly the following data:

•

Model and serial number of the machine;

•

Code number and part name;

•

Required quantity;

•

Shipping means, address and telephone number;

For replacements use only genuine spare parts.

Do not wait until the components are completely worn before replacing them.

CAUTION: THE RECIPIENT WILL BE CHARGED FOR THE REPLACEMENT

TOGETHER WITH THE SHIPPING COSTS.

We recommend that you always contact Bike-Lift Europe s.r.l. for all those Assistance and

maintenance operations that are not described or indicated in this Manual.

Operating manual No. 057-2-6-0009-R0 Page 7

Version 2018

EN

1.6 EC Declaration of conformity

I FR B D E NL

Dichiarazione di

conformità

Declaration de

conformité

Declaration of

conformity

Konformitäts

-

erklärung

Declaración de

conformidad

Declaratie van

conformiteit

Io sottoscritto Je soussigné The undersigned

Der

Unterzeichnete

im name der

l abajo firmante

Ondergetekende

Bike-Lift EUROPE s.r.l. via Don Milani, 40/42, 43012 Sanguinaro di Fontanellato (PARMA) –

Italy

Dichiara sotto la

propria

responsabilità,

che la smonta

ammortizzatori

Déclare sous sa

propre

responsabilité

que la machine

Declares under its

own

responsibility

that the machine

rklärt auf eigene

Verantwortung

dass die

Maschine

Declara bajo su

responsabilidad

que la máquina

Verklaart op eigen

verantwoordelijkh

eid dat de machine

Marca

Marque

Trademark

Marke

Marca

Merk

Modello:

Modèle:

Model:

Modell:

Modelo:

Model:

Numero di serie

Numéro de

série

Serial number

Serien Nummer

Numero de serie

Serienummer

Conforme alla

direttiva

st conforme

aux

spécifications

de la directive

Complies with the

requirements

established by

directive

Die

Bestimmungen

des rlasses

Cumple los

requisites de la

directiva

Overeenkomt met

het gestelde in

MD 2006/42/CE

successive

modifiche ed

integrazioni,

secondo le

norme

et compris les

modifications et

les intégrations,

selon la norme

And subsequent

modifications and

supplements,

according to

standard

Und den

nachfolgenden

Änderungen

entspricht,

entsprechend den

Richtlinien

Y succesivas

modificacions e

integracions,

según la norma

n aanvullingen en

modificaties

hiervan, volgens

richtlijn

EN ISO 12100:2010; EN 349; EN 982

Bike Lift urope

s.r.l

Alessandro Tozzi

Operating manual No. 057-2-6-0009-R0 Page 8

Version 2018

EN

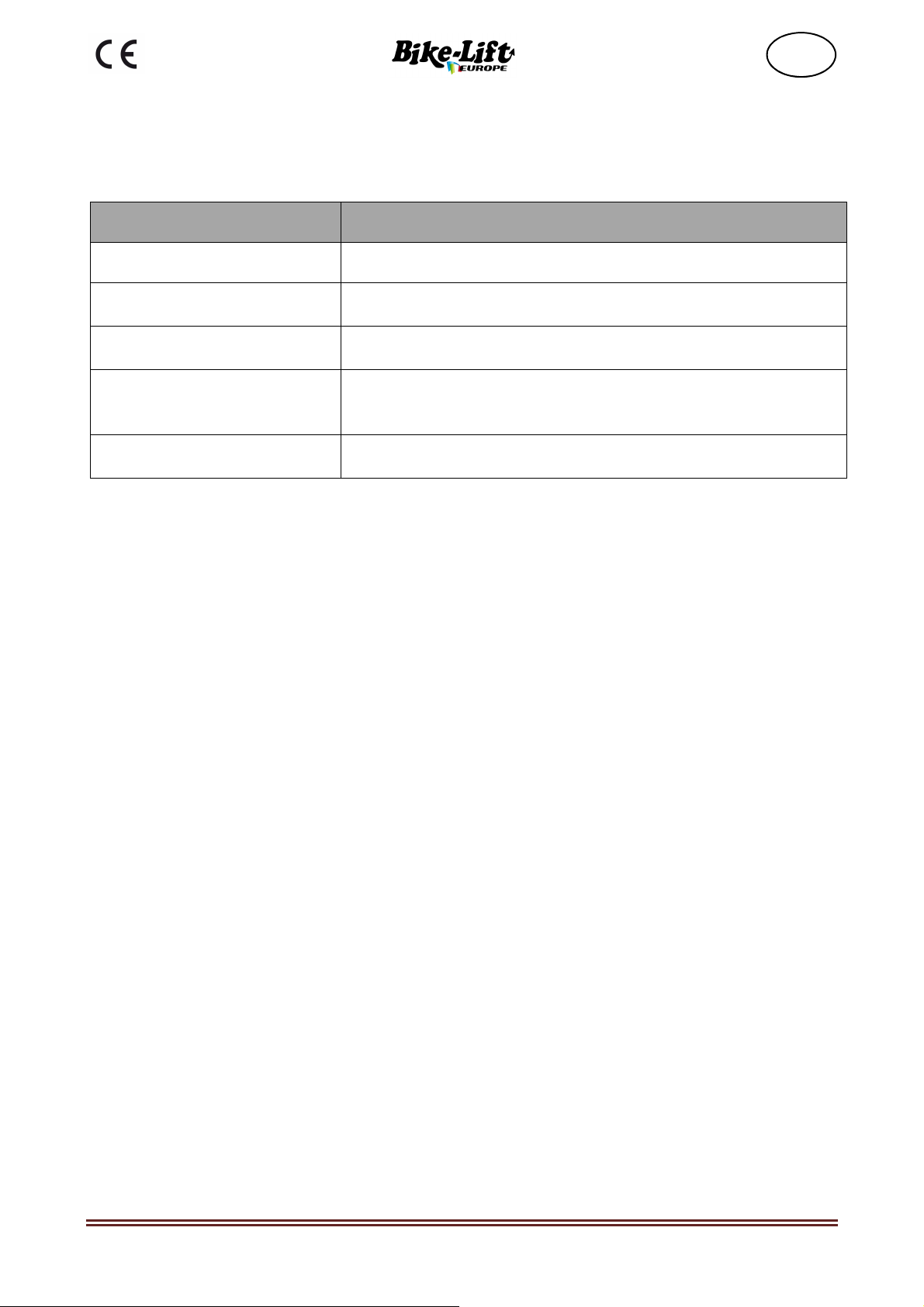

1.7 Normative references

The machine is identified by the CE marking drawn up according to the specifications of the

Machinery Directive 2006/42/EC and subsequent updates.

Reference

Title

2006/42/EC

Machinery Safety Directive

EN ISO 12100 (2010)

Safety of machinery - General principles of design - Risk

assessment and risk reduction.

UNI EN 349 (1993+A1:

2008)

Safety of machinery - Minimum spaces to avoid the crushing

of body parts.

EN 982 (2009)

Safety of machinery - Safety requirements related to systems

and their components for hydraulic fluid and pneumatic

transmissions - Hydraulic fluid

UNI 1285-68

Calculation of metal pipes resistance subject to internal

pressure

1.8 General regulations and conventions

This manual is an integral part of the product and MUST be kept for further reference.

FOR ANY REQUEST FOR CLARIFICATION, CONTACT THE EMPLOYER OR THE

BIKE-LIFT EUROPE S.R.L TECHNICAL SERVICE, AVOIDING PERSONAL

INITIATIVES THAT COULD CAUSE VERY SERIOUS OR FATAL ACCIDENTS.

Read the warranty carefully before using the machine.

CONVENTIONS:

In this manual "right side", "left side", "forward", "backwards", "top" and "bottom"

refer to the operator located in front of the machine with the hydraulic pump on his right

side.

In this manual the measurement units are expressed in the SI international system (e.g.

the capacity of liquids is expressed in liters).

Operating manual No. 057-2-6-0009-R0 Page 9

Version 2018

EN

1.9 Key

SHOCK ABSORBER DISMANTLER: spring compression system for the replacement of

shock absorbers and fork gaskets.

OPERATOR: In compliance with Directive 2006/42/EC and subsequent updates, it is specified

that the term "operator" means the person (s) in charge of installing, operating, adjusting and

cleaning the machine. The maintenance and repair operations of the machine are the

responsibility of competent personnel.

SYMBOLS

MEANIN

Yellow triangle pictogram generally indicates a Warning /Risk, e.g. risk of high

temperatures, risk of crushing the hands, ...

BLUE round pictogram generally indicates an Obligation, for example the

obligation to wear certain PPE (goggles ...) or the Obligation to read the User

Manual.

Round red Prohibition pictogram indicates in general a Prohibition, for example,

person access prohibition, prohibition of hand access while the vehicle is moving.

Indicates that the operation can be performed by specialized personnel authorized

by the Employer.

Particular importance indication that requires attention.

Specifies an operation that can only be performed by trained personnel, or after

having read and consulted specific operating instructions.

Operating manual No. 057-2-6-0009-R0 Page 10

Version 2018

EN

2 Machine description

2.1 achine name

The Shock Absorber Dismantler described in this manual has been specifically designed for

use in the dismantling and assembly operations of shock absorbers and gaskets for motorcycle

forks.

2.2 Shock Absorber Dismantler identification

The machine has an identification plate fixed in a visible way as indicated in the following

picture.

Figure 1- example of a plate affixed to the machine

Refer to these details for ordering spare parts and for any kind of contact with the manufacturer

It is absolutely forbidden for the user to remove or alter this plate. Any modification or

removal of the plate will void any warranty.

The machines can be subject to updates or small aesthetic changes and therefore have different

details than those shown, without prejudice to the descriptions and procedures contained by

this Manual.

Operating manual No. 057-2-6-0009-R0 Page 11

Version 2018

EN

2.3 Intended use and reasonably foreseeable misuse

The shock absorber dismantler is intended exclusively for disassembly and/or assembly of

shock absorbers and/or gaskets for motorcycle forks.

The following operations are not permitted:

• use for industrial shock absorbers is prohibited

• use in potentially explosive atmospheres environments is forbidden

• it is forbidden to use the device for applications other than those indicated

THIS MACHINE IS DESIGNED ONLY FOR THE INTENDED USE

DESCRIBED IN THIS MANUAL; ANY OTHER USE IS TO BE

CONSIDERED IMPROPER AND THEREFORE THE MANUFACTURER

CANNOT BE HELD LIABLE FOR ANY DAMAGES CAUSED BY USE

CONSIDERED INAPPROPRIATE OR NOT EXPRESSLY MENTIONED IN

THIS USER MANUAL.

THE MACHINE IS DESIGNED EXCLUSIVELY FOR SINGLE

OPERATOR USE

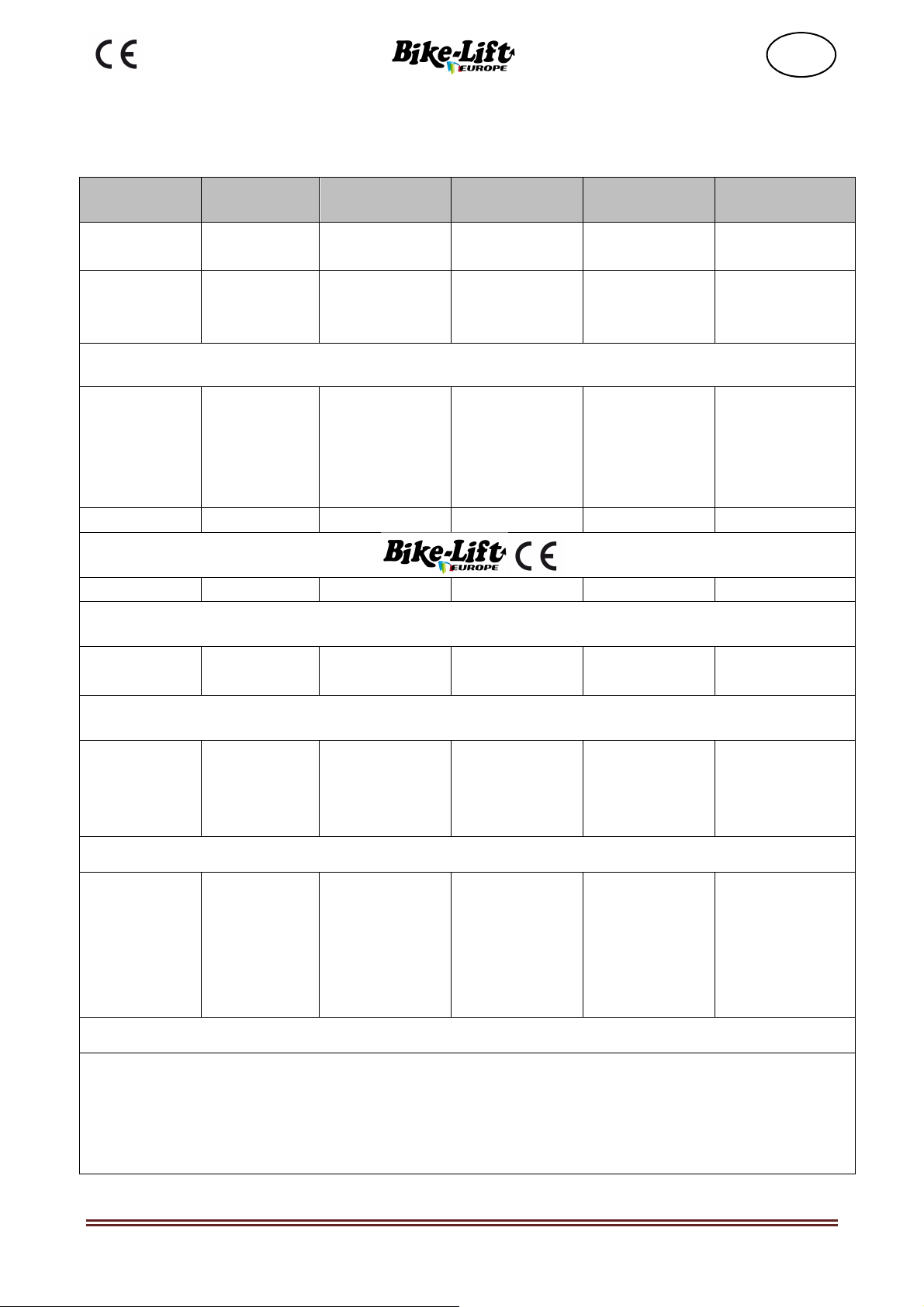

2.4 Technical specifications

Model

SA 07

Weight

Kg

15

General sizes mm

length "L"

height "H"

depth “D”

210 mm

1040 mm

245 mm

Standard adapters data

2.4.1

Diameter

Diameter

Diameter

45 mm

59 mm

75 mm

47 mm

62 mm

77 mm

50 mm

66 mm

80 mm

53 mm

68 mm

83 mm

56 mm

71 mm

87 mm

Operating manual No. 057-2-6-0009-R0 Page 12

Version 2018

EN

3 Safety section

3.1 Environmental working values

The use environment of the machine must be well lit, must not present explosion hazards of

any kind and must be protected from atmospheric precipitations.

The machine works properly within the following values:

•

Ambient temperature between 5° and 40° C;

•

Ambient humidity between 30% and 90% without condensation;

STORAGE: if the machine has been unpacked, store it in a closed space protected from bad

weather conditions.

3.2 Sound level

During the normal conditions of use some measurements were made at the workplace at a

distance of 1 meter and at a height of 1.6 meters above the ground.

The survey was carried out with a sound level meter, complying with IEC 651 standard, class 1

and the result of the assessment was lower than the minimum limit of action required by the

regulations in force.

3.3 Operator protections

Before starting any type of work using the shock absorber dismantler, the

operator must wear appropriate personal protective equipment (PPE),

such as gloves and safety footwear.

Always wear work clothing normally used in the mechanical workshop

activity.

3.4 Pictograms

Hands crushing hazard.

The machine must always be operated by only one Operator

Operating manual No. 057-2-6-0009-R0 Page 13

Version 2018

EN

3.5 General safety rules

•

The shock absorber dismantler must only be operated by trained and authorized

personnel.

•

Before using the shock absorber dismantler, check that it has not been damaged, that

there are no air leaks or worn parts.

•

Do not overload the shock absorber dismantler. Overloading can damage or break the

shock absorber dismantler.

•

Make sure that the brackets have been positioned and fixed correctly depending on the

spring to be disassembled.

•

Periodically carry out a complete check of the shock absorber dismantler, making sure

that each of its components is intact and fully functional.

ACCURATE USE OF THE SHOCK ABSORBER DISMANTLER:

•

Do not subject the shock absorber dismantler to overloads; always check the integrity of

the machine.

•

Make sure that the spring is correctly held in the respective bracket so as to avoid any

sudden slippage.

•

Do not allow the shock absorber dismantler to be used by people who have not read

these instructions.

•

The shock absorber dismantler must not be modified. Modifications can reduce or

cancel the effectiveness of security measures and increase risks for the operator.

•

Carefully check the shock absorber dismantler, making sure that the moving parts of the

machine work perfectly, that they do not jam and there are no broken or damaged parts

that could jeopardize their operation.

•

Have the shock absorber repaired only and exclusively by specialized personnel and

only using genuine spare parts.

•

Remove the dirt and dust accumulated on the sliding parts (column) with a dry cloth,

every 200 cycles of use or about every 3 months.

The machine must always be operated by only one Operator.

THE MANUFACTURER DECLINES ANY RESPONSIBILITY FOR DAMAGES TO

THINGS OR PEOPLE CAUSED BY FAILURE TO COMPLY WITH THE SAFETY

REGULATIONS DESCRIBED IN THIS MANUAL, INCLUDING THE LAWS IN FORCE

AT THE WORKPLACE.

IT IS EXTREMELY IMPORTANT THAT THE OPERATOR UNDERSTANDS ALL THE

SAFETY RULES LISTED BELOW IN ORDER TO AVOID PERSONAL INJURY OR

DAMAGE TO PROPERTY OR THE OTHERS.

A machine that is not subject to regular maintenance is a hazard source to the operator and to

people working nearby. To ensure the safe and efficient operation of the machine, make sure

that the maintenance schedule is correctly followed.

It is strictly forbidden to tamper with, modify or change the parts of the machine that will

alter its regular operation.

Operating manual No. 057-2-6-0009-R0 Page 14

Version 2018

EN

4 Transport and handling section

4.1 Transport, handling and storage

CAUTION: Disseminate the instructions described in this chapter to all personnel

involved in the transport and handling of the machine.

For safety reasons, the moving parts must be locked before transport.

4.2 Unpacking

If the machine is supplied wrapped in nylon cloth, any accessories, spare parts and

consumables will be packed in cardboard boxes and positioned above the work surface.

To remove the packaging, cut the nylon tape, taking care not to damage the machine or its

parts.

Remove any accessories located above the work surface, and make sure that the contents

comply with the order and the accompanying documentation.

4.3 Disposal of the packaging

N.B.

Disposal of the packaging must be done by the purchaser in compliance with the laws in

force.

N.B.

The components of the packaging (e.g. cardboard, plastic, polystyrene, nails, nylon, etc.)

MUST NOT be left within the reach of children, as they are a source of hazard.

NO COMPLAINTS WILL BE ACCEPTED IF THE GOODS DO NOT COMPLY WITH

THE ORDER OR THE ACCOMPANYING DOCUMENTS IF THEY ARE NOT

REPORTED WITHIN FIVE DAYS FROM THE RECEIPT DATE OF THE GOODS.

Operating manual No. 057-2-6-0009-R0 Page 15

Version 2018

EN

4.4 Packaging and transport

You can manually handle the packaged machine, as previously described (see section 4.2), but

it is recommended to use lifting means such as a pallet jack whose maximum lifting capacity

must not be less than the total weight of the shock absorber dismantler.

N.B. THE TOTAL WEIGHT OF THE MACHINE IS SHOWN ON THE IDENTIFICATION

PLATE AFFIXED TO THE MACHINE.

The machine is tested and in perfect condition.

4.5 Warnings for handling and transport

The loading or unloading is recommended to be carried out manually or using lifting

equipment (e.g. pallet jack). Also take into account:

•

It is strictly forbidden for things and/or people to be near the machine, the unloading or

loading area and the means of transport during the loading and unloading operations.

•

Do not carry out sudden maneuvers when lifting or lowering the load.

•

Pay the utmost attention during all handling operations, to make sure that the machine

will not be damaged.

•

Follow the internal and legal provisions concerning lifting and transport.

•

IT IS FORBIDDEN TO APPROACH OR PASS UNDER SUSPENDED LOADS.

N.B. THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR ANY DAMAGE

CAUSED BY ANY ACTION DURING THE UNLOADING, LOADING AND HANDLING

OPERATIONS OF THE MACHINE.

Operating manual No. 057-2-6-0009-R0 Page 16

Version 2018

EN

5 Installation section

The machine must be installed in compliance with the safety regulations and instructions

included in this chapter. The machine must be positioned in such a way as to allow the

Operator to easily replace the shock absorbers or the gaskets of the bike fork.

The shock absorber dismantler must therefore be installed by taking into account the minimum

distances from walls or other possible boundaries (boundaries are imaginary lines that delimit

the work or safety areas of other machines or structures).

Simple precautions are necessary for the positioning of the shock absorber dismantler.

Always consider the safety aspect not only in relation to the work performed with the machine

but also to the hazards caused by other machines present in the workplace.

Before positioning the machine make sure that:

•

The flooring is suitable for placing the machine, i.e. without holes, yielding parts, and

its capacity is sufficient to support the weight of the press plus the weight of the

accessory parts and any large work piece, considering an adequate safety factor.

•

If the positioning must be performed on lofts, upper floors or elevated areas, make sure

that the maximum capacity of the lofts or flooring is higher than the weight of the

machine and any accessory weights, considering also an adequate safety factor.

•

Do not place the machine on yielding or non-compact surfaces (e.g. on gravel or

crushed stone, sand, etc.).

•

PAY CLOSE ATTENTION TO THE OVERHEAD POWER LINES.

•

Check in advance the position of any overhead power line and signal them with

appropriate warning signs.

•

Always consider an adequate distance from the sliding ways of the means of transport,

elevators, pallet jacks, etc. Sources of unpredictable and sudden hazard.

•

Make sure that the identified position is always equipped with adequate lifting systems.

•

Pay the utmost attention to the handling of lifting systems (e.g. gantry cranes, hoists,

pallet jacks, forklift trucks, cranes, jib cranes, etc.)

Operating manual No. 057-2-6-0009-R0 Page 17

Version 2018

EN

5.1 Filling

N.B. When the oil level in the tank drops, generally following:

volume absorption by the cylinder

volume absorption by the system

the discharge of air bubbles left in the pipes

it is necessary to fill up the oil level by bringing it to the correct level and checking it with the

level indicator.

Operating manual No. 057-2-6-0009-R0 Page 18

Version 2018

EN

6 Dismantling/scrapping section

6.1 Storage

In case of prolonged storage, protect the machine from rain and wind and possibly store it in a

dry place.

Protect the electrical parts from dust and external agents.

The machine can be seriously damaged if, while pending for the installation, it is kept in a

critical temperature environment. Do not expose the machine to temperatures below -10° C or

above + 60° C.

It is forbidden to store the machine or its parts on structures that have not

been specially designed

It is forbidden to store material or equipment on the machine

6.2 Scrapping and disposal

To dismantle the machine, proceed according to the following general disassembly procedure:

•

Empty the tanks of the hydraulic system.

•

Disconnect the mechanical parts.

WARNING: When handling waste it is necessary to have the appropriate

Personal Protective Equipment

6.3 Scrapping materials

These are non-hazardous special waste that can be recovered, according to M.D. of February

5

th

, 1998:

•

Ferrous materials, aluminum, stainless steel, copper

•

Plastic materials

•

Hydraulic oil

6.4 Instructions for a suitable waste treatment

Proper management of special waste includes:

Storage in suitable locations avoiding the mixing of hazardous and non-hazardous waste.

Make sure that the transport and disposal/recovery of the waste is done by authorized carriers

and recipients.

The transport of waste to authorized collection centers is allowed only if you are registered at

the Environmental Managers Register.

Operating manual No. 057-2-6-0009-R0 Page 19

Version 2018

EN

6.5

Electrical and electronic equipment waste

According Legislative Decree no. 151 of 25

th

of July 2005, the Italian Government has

implemented the European Parliament directives on the disposal of electrical and electronic

equipment waste (WEEE) (Directive 2002/95/EC and 2003/108/EC).

The decree specifically establishes measures and procedures aimed to:

1.

prevent WEEE production;

2.

promote reuse, recycling and other ways of WEEE recovery, in order to reduce the

amount to be disposed of;

3.

improve, from an environmental point of view, the intervention of the subjects

participating in the life cycle of these devices (producers, distributors, consumers and

operators directly involved in the WEEE treatment);

4.

reduce the use of hazardous substances in electrical and electronic equipment.

The decree requires the limitation and elimination of some substances present in WEEE:

banned lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and

polybrominated diphenyl.

The machine has been designed and manufactured in compliance with this directive. Follow

the instructions below.

This symbol, showing a crossed-out garbage wheeled bin, indicates the

separate collection of electrical and electronic equipment of the machine.

The user of this machine may contact the collection centers set up by the

Municipalities or ask for waste collection by the retailer, in order to dispose

of it correctly.

Operating manual No. 057-2-6-0009-R0 Page 20

Version 2018

EN

7Operation section

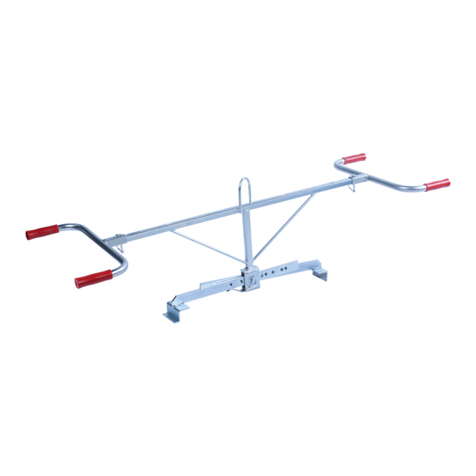

Before starting any maneuver, make sure that there are no other people in the immediate

vicinity of the machine.

Before starting to use the shock absorber dismantler, make sure that it has been well fixed to

the ground using the four holes in the base of the structure (Figure 2-holes in the base of the

structure

)

Check the correct operation of the shock absorber dismantler by carrying out a series of

maneuvers with no load, using the control lever.

The shock absorber dismantler is equipped with a safety hook; in order to carry out

any type of maneuver by using the control lever, it must be tightened to the ferrule

located on the back of the hook, by screwing the ferrule in order to activate the

pneumatic safety system.

Figure 2-holes in the base of the structure

Table of contents

Other Bike-Lift Lifting System manuals

Bike-Lift

Bike-Lift Master 504 Gate User manual

Bike-Lift

Bike-Lift LEVANTE-50 User manual

Bike-Lift

Bike-Lift Racing 350 Operator's manual

Bike-Lift

Bike-Lift HQL 400 User manual

Bike-Lift

Bike-Lift Racing 350 User manual

Bike-Lift

Bike-Lift PSB-20 User manual

Bike-Lift

Bike-Lift Kodiak 500 User manual

Bike-Lift

Bike-Lift Master 504 User manual

Bike-Lift

Bike-Lift CFL-500 User manual

Popular Lifting System manuals by other brands

MW TOOLS

MW TOOLS SL300U manual

ShoreStation

ShoreStation Manual SSV50108MS manual

Titan Lifts

Titan Lifts HD2P-10000AC-D Installation, operation & maintenance manual

Mec

Mec TITAN Boom 40-S Operator's manual

probst

probst VZ-I operating instructions

HADEF

HADEF 147/05 Installation, Operating and Maintenance Instruction