10

Contents

A SAFETY INFORMATION....................................................................................................................... 11

A.1 General information .................................................................................................................... 11

A.2 General safety ........................................................................................................................... 11

A.3 Personal protection equipment ...................................................................................................... 12

A.4 Transport, handling and storage .................................................................................................... 13

A.5 Installation and assembly ............................................................................................................. 13

A.6 Electrical connection ................................................................................................................... 13

A.7 Service..................................................................................................................................... 14

A.8 Disposal of packing..................................................................................................................... 14

A.9 Machine disposal........................................................................................................................ 14

B GENERAL INFORMATION .................................................................................................................... 14

B.1 Introduction............................................................................................................................... 14

B.2 Definitions................................................................................................................................. 14

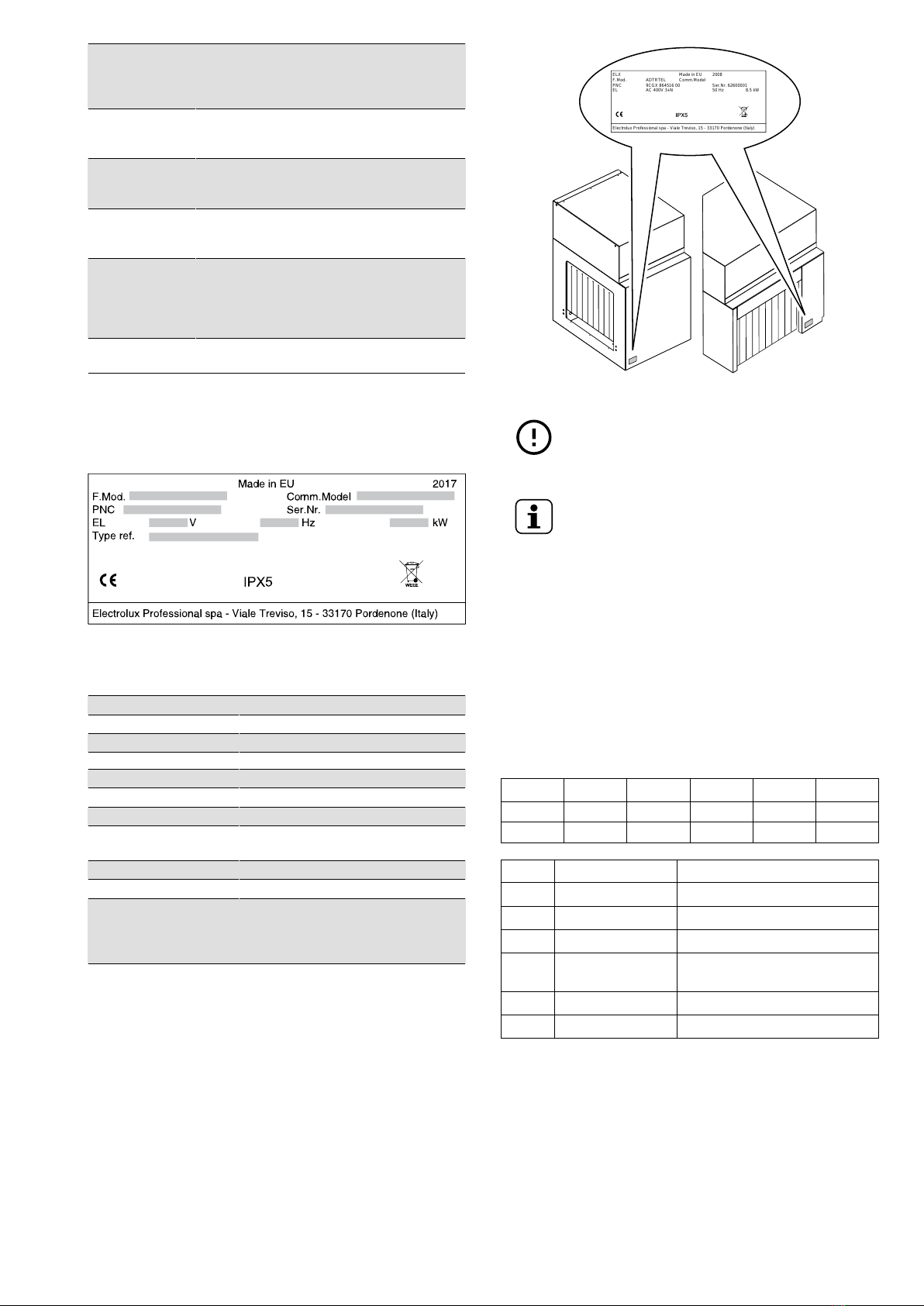

B.3 Appliance and manufacturer's identification data ............................................................................... 15

B.4 Additional indications................................................................................................................... 15

B.4.1 How to interpret the factory description .................................................................................. 15

B.5 Responsibility ............................................................................................................................ 15

B.6 Copyright.................................................................................................................................. 16

B.7 Keeping the manual .................................................................................................................... 16

B.8 Recipients of the manual .............................................................................................................. 16

B.9 Coupling to the rack-type dishwasher.............................................................................................. 16

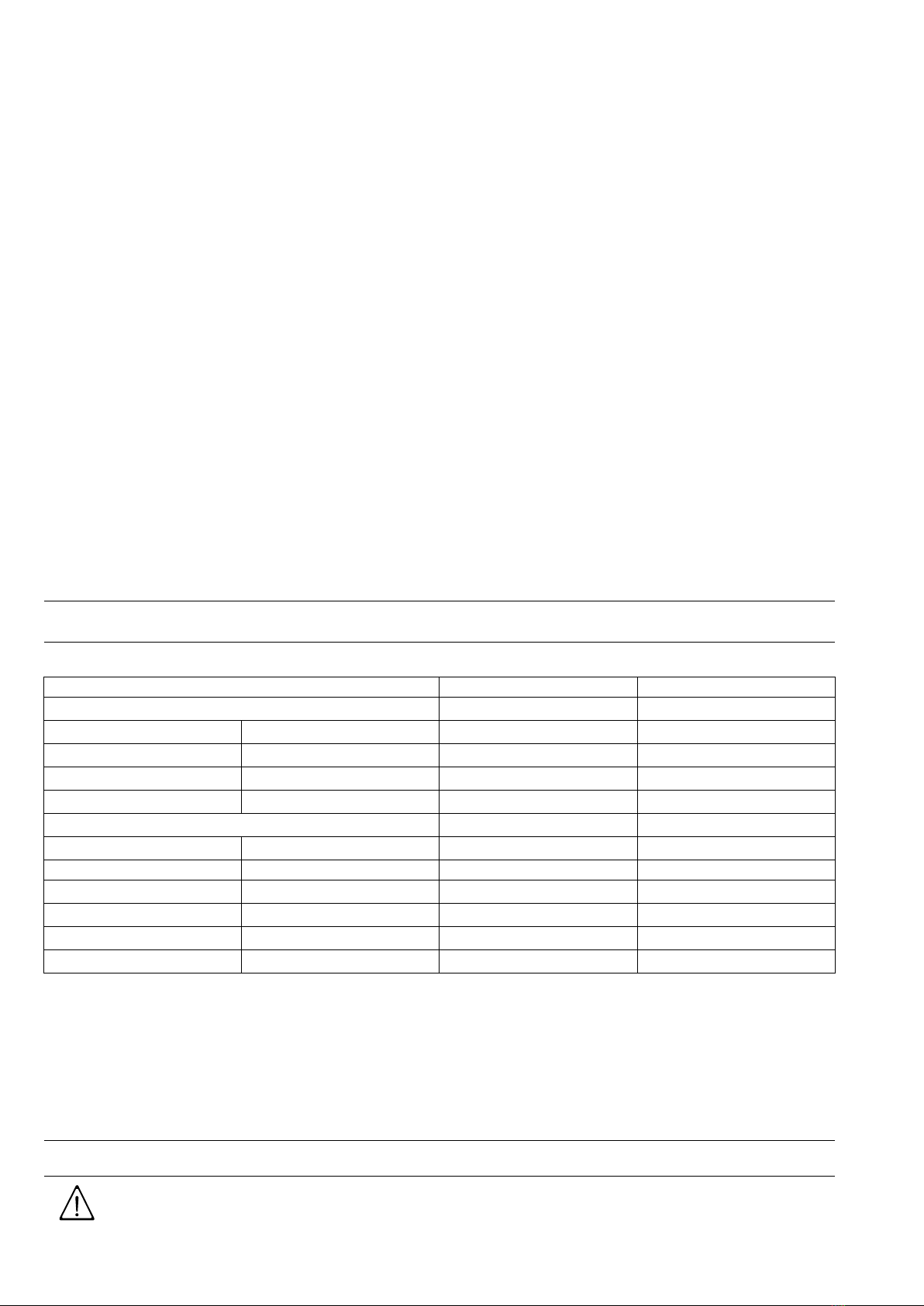

C TECHNICAL DATA............................................................................................................................... 16

C.1 Main technical characteristics........................................................................................................ 16

C.2 Characteristics of power supply ..................................................................................................... 16

D TRANSPORT, HANDLING AND STORAGE .............................................................................................. 16

D.1 Introduction............................................................................................................................... 16

D.2 Handling................................................................................................................................... 17

D.2.1 Procedures for handling operations....................................................................................... 17

D.2.2 Shifting ........................................................................................................................... 17

D.2.3 Placing the load................................................................................................................ 17

D.3 Storage .................................................................................................................................... 17

D.4 Customer packaging checks ......................................................................................................... 17

E INSTALLATION AND ASSEMBLY ........................................................................................................... 17

E.1 Introduction............................................................................................................................... 17

E.2 Customer responsibilities ............................................................................................................. 17

E.3 Installation of dryer module on the rack-type dishwasher ..................................................................... 17

E.4 Characteristics of the place of machine installation ............................................................................ 17

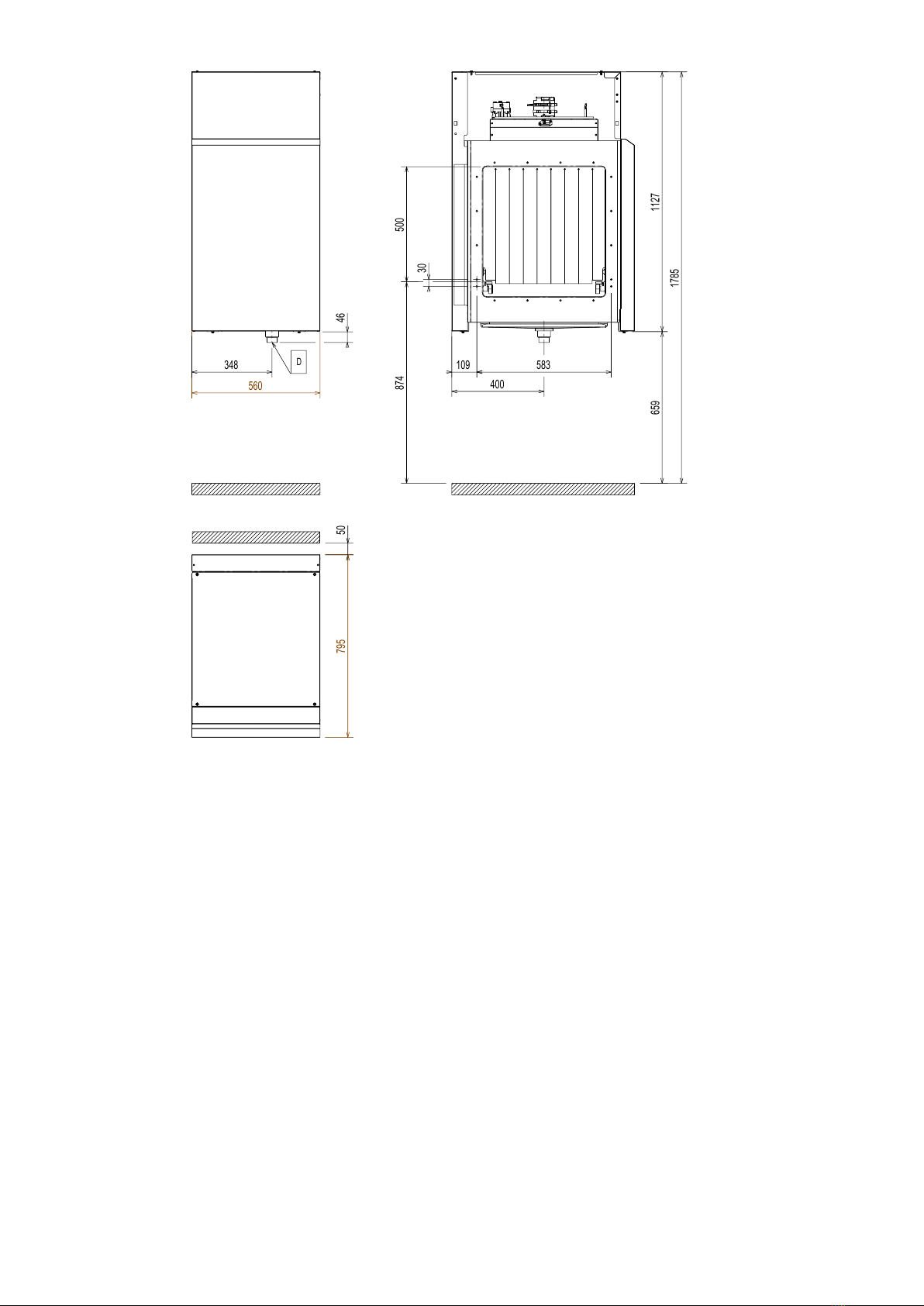

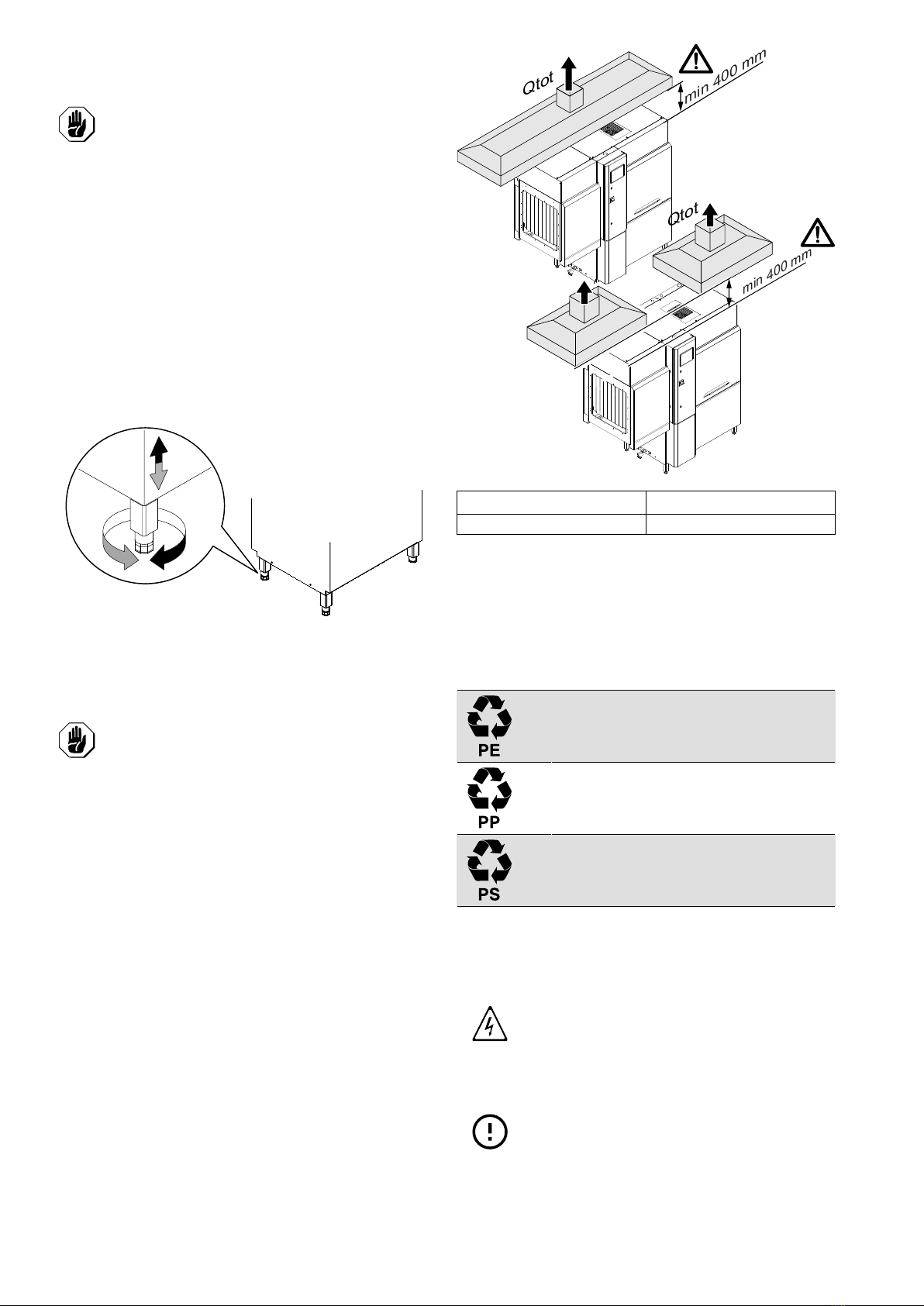

E.5 Appliance space limits ................................................................................................................. 17

E.6 Positioning ................................................................................................................................ 18

E.7 Extraction hood.......................................................................................................................... 18

E.8 Disposal of packing..................................................................................................................... 18

E.9 Mechanical connections............................................................................................................... 18

E.10 Drying tunnel 22″........................................................................................................................ 19

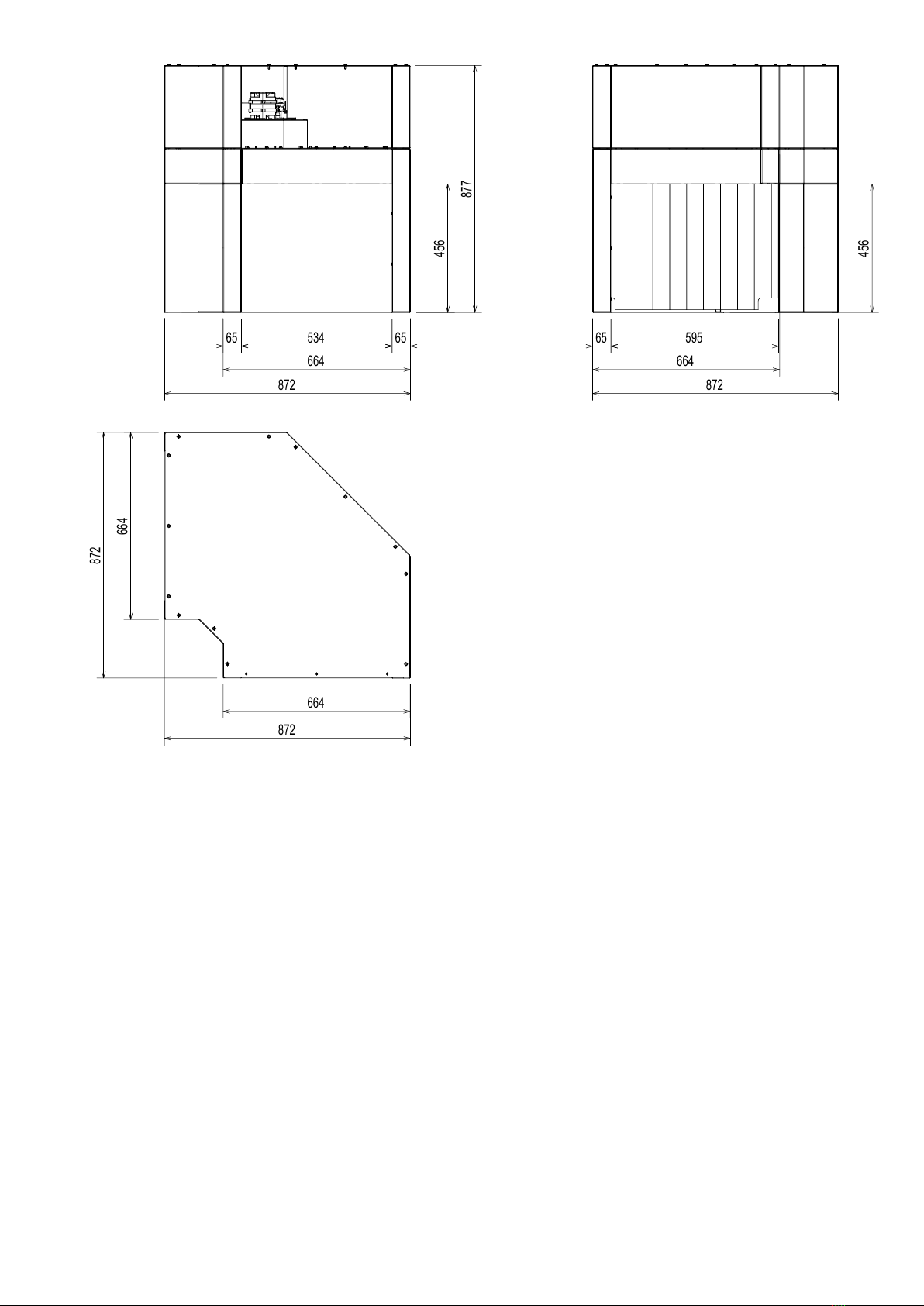

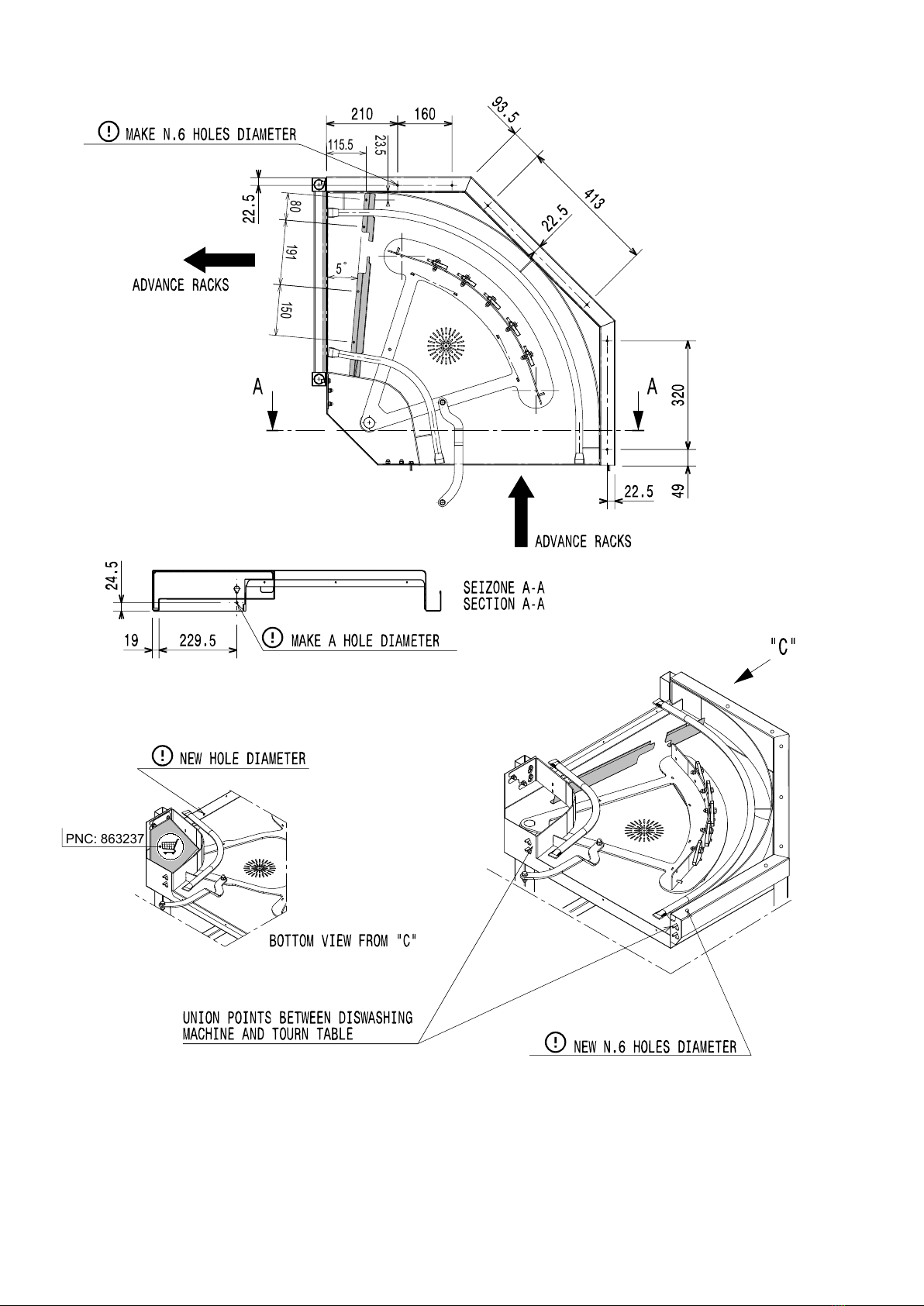

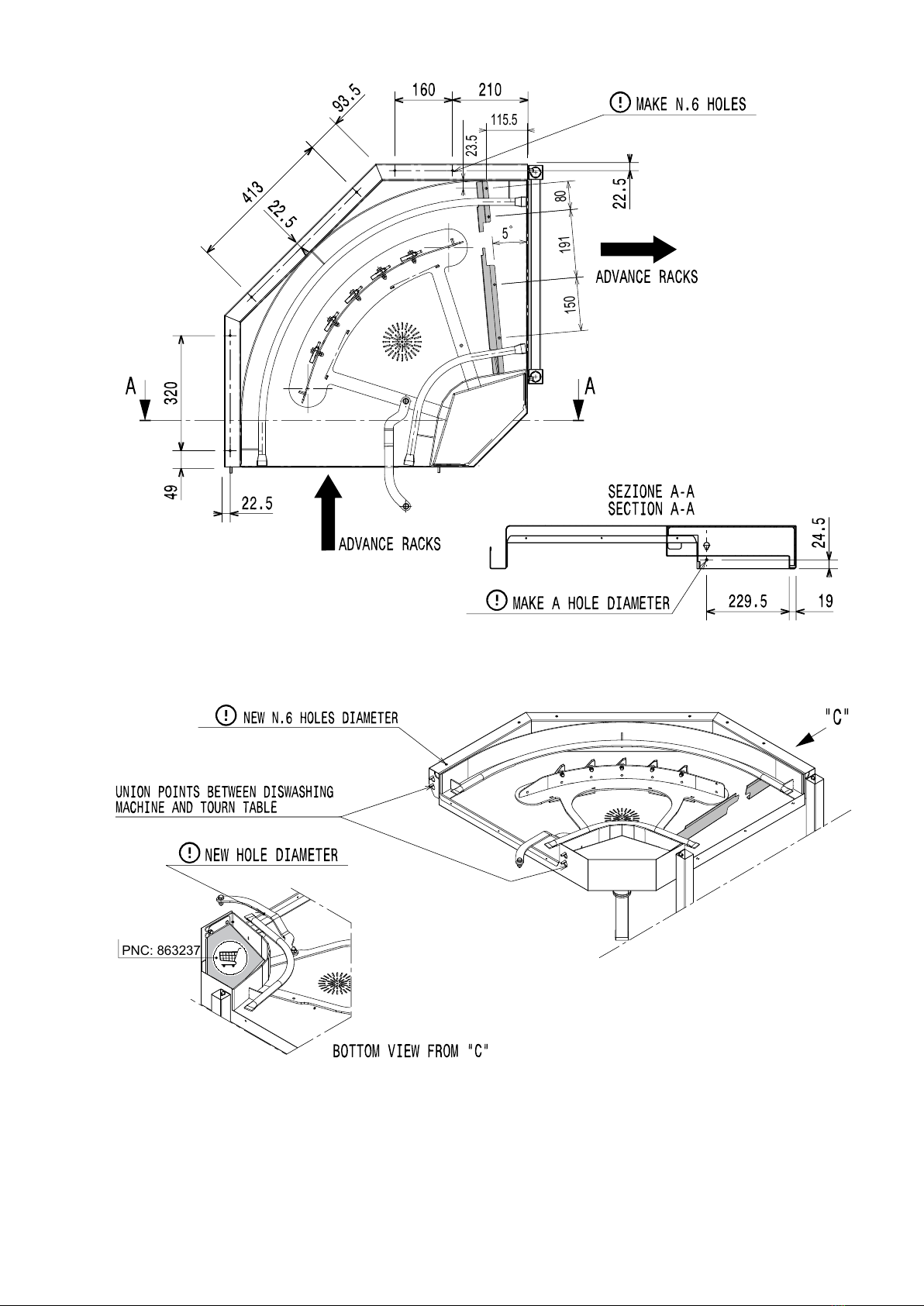

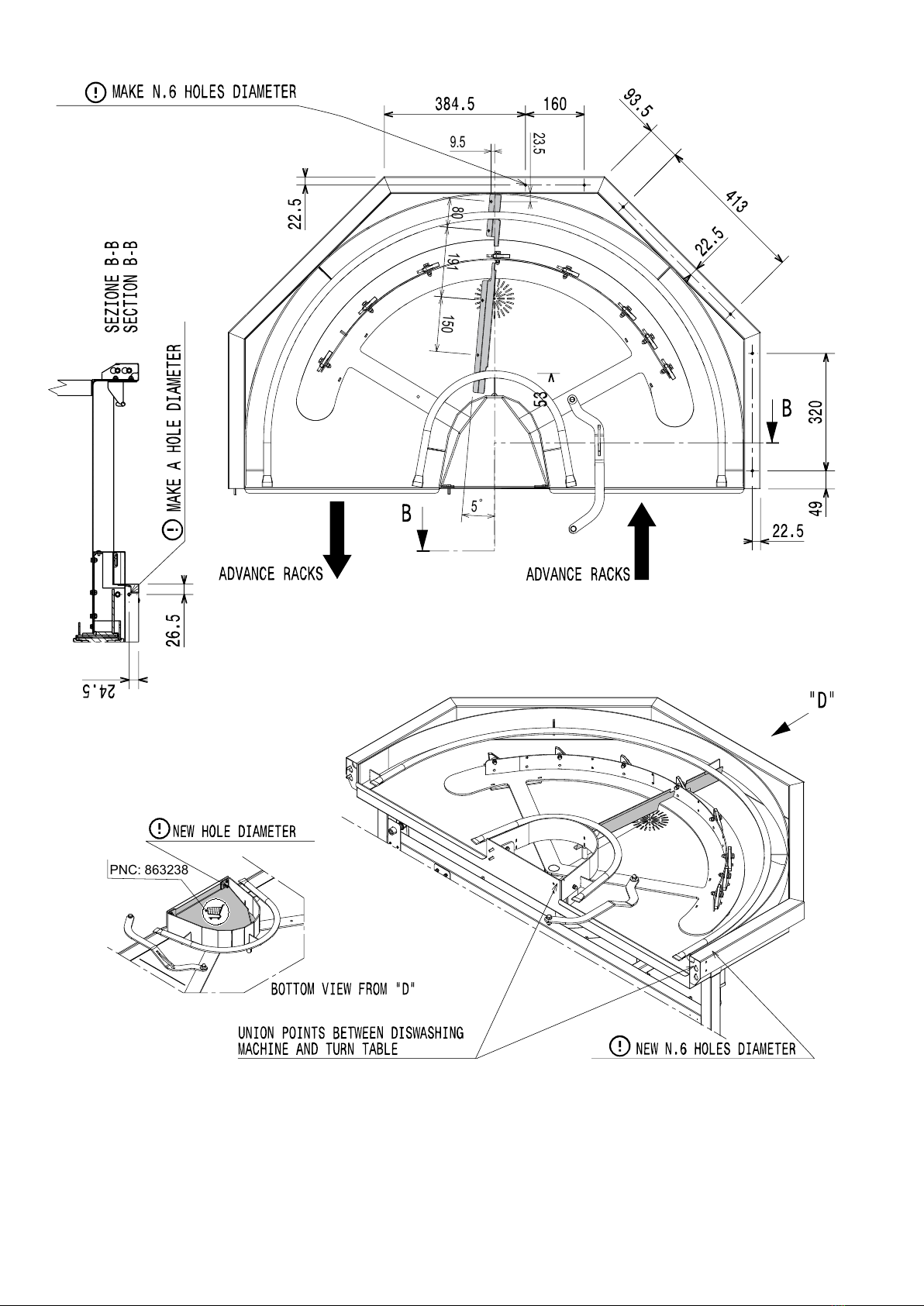

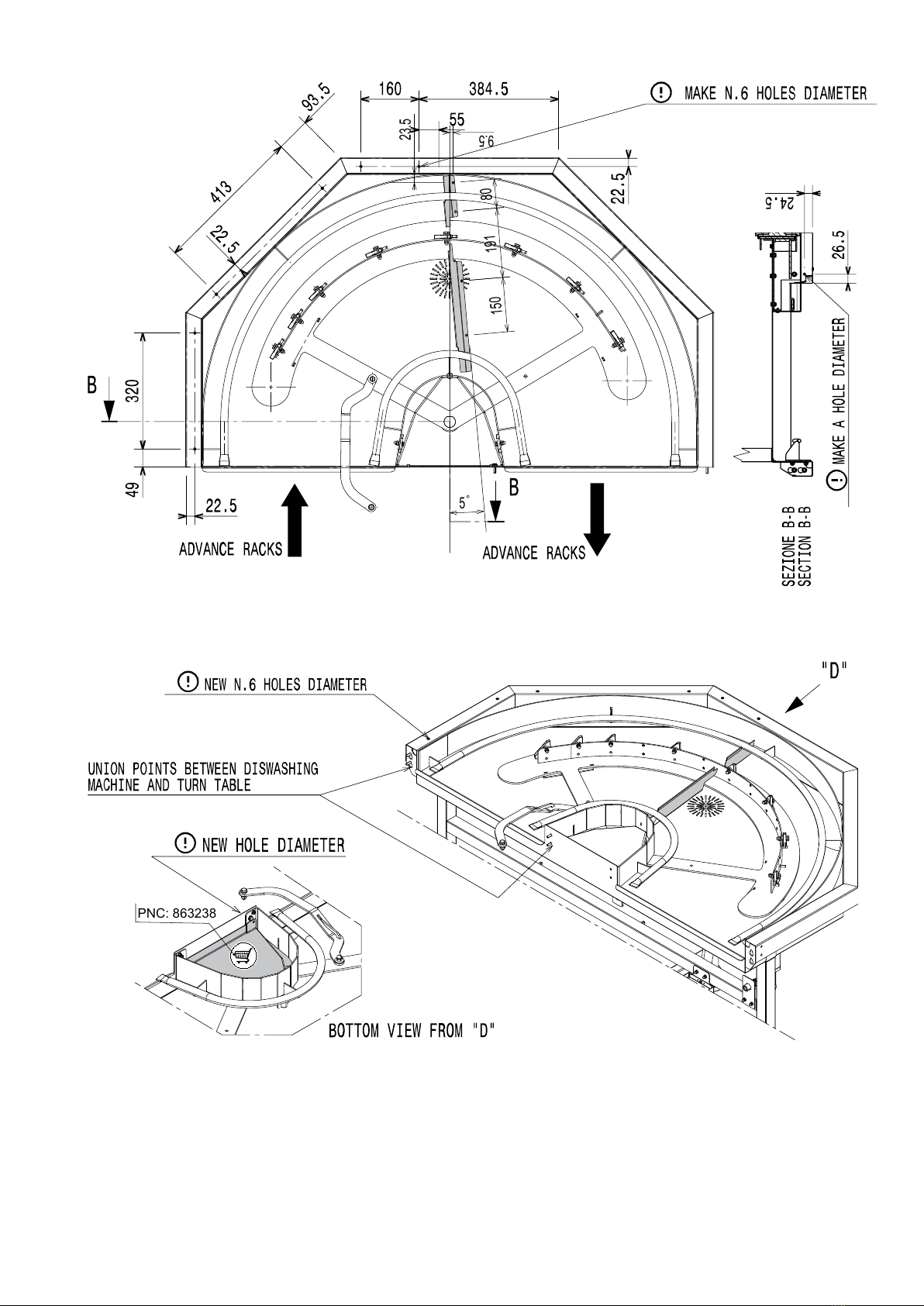

E.11 Drying tunnel corner 90°............................................................................................................... 20

E.11.1 Mechanical connection....................................................................................................... 20

E.11.2 Drilling diagrams for Electrolux rack handling system ................................................................ 22

E.12 Electrical connection ................................................................................................................... 22

E.13 Installation wizard....................................................................................................................... 22

E.14 Constructional modifications ......................................................................................................... 23

E.15 Installation of rack handling systems............................................................................................... 23

E.16 Arrangement for mechanical connection (only for Electrolux Professional rack handling system non motor

operated).................................................................................................................................. 23

E.17 Installation of the end limit switch ................................................................................................... 24

E.17.1 Prearrangement for electrical connection ............................................................................... 24

E.18 Positioning of emergency switches ................................................................................................. 24

E.18.1 Electrical connection.......................................................................................................... 25

E.19 Emergency stop reinstatement ...................................................................................................... 25

E.20 Fitting curtains ........................................................................................................................... 26

F COMMISSIONING ............................................................................................................................... 26

F.1 Preliminary checks, adjustments and operational tests ....................................................................... 26

F.2 Electrical and plumbing connection................................................................................................. 26

F.3 Positioning and fitting of the curtains ............................................................................................... 27

F.4 First starting .............................................................................................................................. 27

G NORMAL USE .................................................................................................................................... 27

G.1 For additional information, refer to manual supplied with the appliance ................................................... 27