Electrolux Professional EFTD052E User manual

Flight Type dishwasher

EFTD052E-EFTD064E-EFTD082E-

EFTD108E-EFTD052S-EFTD064S-

EFTD082S-EFTD108S

EN User manual *

*Original instructions PM00510- 2020.03

2

Foreword

The installation, use and maintenance manual (hereinafter Manual) provides the user with information necessary for correct

and safe use of the machine (or “appliance“).

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable for improving

machine performance in every respect and, above all, preventing injury to persons and animals and damage to property due to im-

proper operating procedures.

All persons involved in machine transport, installation, commissioning, use and maintenance, repair and disassembly must con-

sult and carefully read this manual before carrying out the various operations, in order to avoid wrong and improper actions that

could compromise the machine's integrity or endanger people. Make sure to periodically inform the user regarding the safety regu-

lations. It is also important to instruct and update personnel authorised to operate on the machine, regarding its use and

maintenance.

The manual must be available to operators and carefully kept in the place where the machine is used, so that it is always at hand

for consultation in case of doubts or whenever required.

If, after reading this manual, there are still doubts regarding machine use, do not hesitate to contact the Manufacturer or the au-

thorised Service Centre to receive prompt and precise assistance for better operation and maximum efficiency of the machine.

During all stages of machine use, always respect the current regulations on safety, work hygiene and environmental protection. It

is the user's responsibility to make sure the machine is started and operated only in optimum conditions of safety for people, ani-

mals and property.

IMPORTANT

• The manufacturer declines any liability for operations carried out on the appliance without respecting the instructions

given in this manual.

• The manufacturer reserves the right to modify the appliances presented in this publication without notice.

• No part of this manual may be reproduced.

• This manual is available in digital format by:

– contacting the dealer or reference customer care;

– downloading the latest and up to date manual on the web site;

• The manual must always be kept in an easily accessed place near the machine. Machine operators and mainte-

nance personnel must be able to easily find and consult it at any time.

3

Contents

A WARNING AND SAFETY INFORMATION...................................................................................................4

A.1 General information ......................................................................................................................4

A.2 General safety .............................................................................................................................4

A.3 Personal protection equipment ........................................................................................................ 5

A.4 Water connection..........................................................................................................................5

A.5 Electrical connection .....................................................................................................................5

A.6 Machine cleaning and maintenance..................................................................................................6

A.7 Machine disposal..........................................................................................................................6

B WARRANTY .........................................................................................................................................6

B.1 Warranty terms and exclusions........................................................................................................ 6

C GENERAL SAFETY RULES.....................................................................................................................7

C.1 Introduction .................................................................................................................................7

C.2 Mechanical safety characteristics, hazards......................................................................................... 7

C.3 Guards.......................................................................................................................................7

C.4 Emergency switch ........................................................................................................................7

C.4.1 Emergency switch reinstatement ............................................................................................7

C.5 Safety signs to be placed on the machine or near its area...................................................................... 7

C.6 Instructions for use and maintenance................................................................................................ 8

C.7 Reasonably foreseeable improper use ..............................................................................................8

C.8 End of use ..................................................................................................................................8

C.9 Residual risks ..............................................................................................................................8

D GENERAL INFORMATION ......................................................................................................................9

D.1 Introduction .................................................................................................................................9

D.2 Definitions...................................................................................................................................9

D.3 Machine and Manufacturer‘s identification data ................................................................................... 9

D.4 Appliance identification ................................................................................................................ 10

D.4.1 How to identify the technical data.......................................................................................... 10

D.4.2 How to interpret the factory description .................................................................................. 10

D.5 Responsibility ............................................................................................................................ 10

D.6 Copyright.................................................................................................................................. 11

D.7 Keeping the manual .................................................................................................................... 11

D.8 Recipients of the manual .............................................................................................................. 11

E NORMAL USE .................................................................................................................................... 11

E.1 Correct use ............................................................................................................................... 11

E.2 Characteristics of personnel enabled to operate on the machine ........................................................... 11

E.3 Characteristics of personnel trained for normal machine use ................................................................ 11

E.4 Operator qualified for normal machine use ....................................................................................... 11

F PRODUCT OVERVIEW ........................................................................................................................ 11

F.1 Modules list............................................................................................................................... 11

G TECHNICAL DATA............................................................................................................................... 14

G.1 Main technical characteristics........................................................................................................ 14

H CONTROL PANEL DESCRIPTION .......................................................................................................... 16

H.1 Control panel description.............................................................................................................. 16

H.2 Basic Controls ........................................................................................................................... 16

I NORMAL MACHINE USE...................................................................................................................... 17

I.1 Fitting of filters and overflows ........................................................................................................ 17

I.2 Fitting of wash and rinse arms ....................................................................................................... 17

I.3 Starting .................................................................................................................................... 18

I.4 Washing phase .......................................................................................................................... 18

I.5 Operation ................................................................................................................................. 19

I.5.1 Loading/unloading tableware ............................................................................................... 19

I.5.2 Change the conveyor speed ................................................................................................ 20

I.5.3 Start/stop washing cycle ..................................................................................................... 20

I.6 Type of tableware ....................................................................................................................... 20

I.6.1 Plastic or metal baskets ..................................................................................................... 20

I.6.2 Plastic or ceramic dishes .................................................................................................... 20

J DAILY CLEANING AND MAINTENANCE .................................................................................................. 20

J.1 Machine cleaning ....................................................................................................................... 20

J.2 Daily internal cleaning ................................................................................................................. 21

J.3 Maintenance ............................................................................................................................. 22

J.3.1 Repair and extraordinary maintenance .................................................................................. 22

J.3.2 Parts and accessories ........................................................................................................ 22

J.3.3 Prolonged period of inactivity ............................................................................................... 22

J.4 Machine disposal........................................................................................................................ 22

K TROUBLESHOOTING.......................................................................................................................... 22

K.1 Alarms ..................................................................................................................................... 22

K.2 Common faults.......................................................................................................................... 23

4

A WARNING AND SAFETY INFORMATION

A.1 General information

To ensure safe use of the machine and a proper understanding of the manual it is

necessary to be familiar with the terms and typographical conventions used in the

documentation. The following symbols are used in the manual to indicate and identify the

various types of hazards:

WARNING

Danger for the health and safety of operators.

WARNING

Danger of electrocution - dangerous voltage.

CAUTION

Risk of damage to the machine or the product.

IMPORTANT

Important instructions or information on the product

Equipotentiality

Read the instructions before using the appliance

Clarifications and explanations

A.2 General safety

• The appliance must not be used by people (including children) with limited physical,

sensory or mental abilities or without experience and knowledge of it, unless instructed

in its use and supervised by those responsible for their safety.

– Do not let children play with the appliance.

– Keep all packaging and detergents away from children.

– Cleaning and user maintenance shall not be made by children without supervision.

• For suitable personal protection equipment, refer to chapter “A.3 Personal protection

equipment“.

• Several illustrations in the manual show the machine, or parts of it, without guards or

with guards removed. This is purely for explanatory purposes. Do not install the machine

without the guards or with the protection devices deactivated.

• Do not remove, tamper with or make illegible the safety, danger and instruction signs

and labels on the machine.

• Do not remove, tamper with or make the labels on the machine illegible.

• Do not remove or tamper with the machine’s safety devices.

• Unauthorized personnel must not enter the work area.

• Remove any flammable products or items from the work area.

5

A.3 Personal protection equipment

Summary table of the Personal Protection Equipment (PPE) to be used during the various stages of the machine's

service life.

Stage Protective

garments

Safety

footwear

Gloves Glasses Safety

helmet

Transport —● ○ —○

Handling ● ● ○ — —

Unpacking ○ ● ○ — —

Installation ○ ● ●1— —

Normal use ● ● ●2○—

Adjustments ○ ● — — —

Routine

cleaning

○ ● ●1ˉ3○—

Extraordi-

nary

cleaning

○ ● ●1ˉ3○—

Maintenance ○ ● ○ — —

Dismantling ○ ● ○ ○ —

Scrapping ○ ● ○ ○ —

Key:

●PPE REQUIRED

○PPE AVAILABLE OR TO BE USED IF NECESSARY

—PPE NOT REQUIRED

1. During these operations, gloves must be cut-resistant. Failure to use the personal protection equipment by

operators, specialized personnel or users can involve exposure to damage to health (depending on the

model).

2. During these operations, gloves must be heatproof and suitable for contact with water and the substances

used (refer to the safety data sheet of the substances used for the information regarding the required PPE).

Failure to use the personal protection equipment by operators, specialised personnel or users can involve

exposure to chemical risk and cause possible damage to health (depending on the model).

3. During these operations, gloves must be suitable for contact with chemical substances used (refer to the

safety data sheet of the substances used for information regarding the required PPE). Failure to use the

personal protection equipment by operators, specialized personnel or users can involve exposure to

chemical risk and cause possible damage to health (depending on the model).

A.4 Water connection

• The operating water pressure (minimum and maximum) must be between:

– 100 kPa [1 bar] and 600 kPa [6 bar];

• Make sure that there are no visible water leaks during and after the first use of the

machine.

A.5 Electrical connection

• Work on the electrical systems must only be carried out by a specialised personnel.

• If the power cable is damaged it must be replaced by the Customer Care Service or in

any case by specialised personnel, in order to prevent any risk.

6

A.6 Machine cleaning and maintenance

• Refer to “A.3 Personal protection equipment“ for suitable personal protection equipment.

• Put the machine in safe conditions before starting any maintenance operation.

Disconnect the machine from the power supply and carefully unplug the power supply

cable, if present.

• Depending on the model and type of electric connection, during maintenance operations,

the cable and plug must be kept in a visible position by the operator carrying out the work.

• Do not touch the machine with wet hands or feet or when barefoot.

• Do not remove the safety guards.

• Use a ladder with suitable protection for work on machines with high accessibility.

• Respect the requirements for the various routine and extraordinary maintenance

operations. Non compliance with the instructions can create risks for personnel.

• Extraordinary maintenance, checking and overhaul operations must only be carried out

by a specialised personnel or the Customer Care Service, provided with suitable

personal protection equipment (safety shoes and gloves), tools and ancillary means.

Ordinary maintenance

• Do not clean the machine with jets of water.

• Contact with chemical substances (e.g. detergent, rinse aid, scale remover, etc.) without

taking appropriate safety precautions (e.g. personal protection equipment) can involve

exposure to chemical risk and possible damage to health. Therefore always refer to the

safety cards and labels on the products used.

Repair and extraordinary maintenance

• Repair and extraordinary maintenance have to be carried out by specialised authorised

personnel. The manufacturer declines any liability for any failure or damage caused by

the intervention of an unauthorized technician by the Manufacturer and the original

manufacturer warranty will be invalidated.

A.7 Machine disposal

• Work on the electrical equipment must only be carried out by a specialised personnel,

with the power supply disconnected.

• Dismantling operations must be carried out by specialised personnel.

• Make the appliance unusable by removing the power cable and any compartment

closing devices, to prevent the possibility of someone becoming trapped inside.

• Refer to “A.3 Personal protection equipment“ for suitable personal protection equipment.

• When scrapping the machine, the “CE“ marking, this manual and other documents

concerning the appliance must be destroyed.

IMPORTANT

Save these instructions carefully for further consultation by the various

operators.

B WARRANTY

B.1 Warranty terms and exclusions

If the purchase of this product includes warranty coverage,

warranty is provided in line with local regulations and subject to

the product being installed and used for the purposes as

designed, and as described within the appropriate equipment

documentation.

Warranty will be applicable where the customer has used only

genuine spare parts and has performed maintenance in

accordance with Electrolux Professional user and mainte-

nance documentation made available in paper or electronic

format.

Electrolux Professional strongly recommends using Electrolux

Professional approved cleaning, rinse and descaling agents to

obtain optimal results and maintain product efficiency over

time.

The Electrolux Professional warranty does not cover:

7

• service trips cost to deliver and pick up the product;

• installation;

• training on how to use/operate;

• replacement (and/or supply) of wear and tear parts unless

resulting from defects in materials or workmanship reported

within one (1) week from the failure;

• correction of external wiring;

• correction of unauthorized repairs as well as any damages,

failures and inefficiencies caused by and/or resulting from;

– insufficient and/or abnormal capacity of the electrical

systems (current/voltage/frequency, including spikes

and/or outages);

– inadequate or interrupted water supply, steam, air, gas

(including impurities and/or other that does not comply

with the technical requirements for each machine);

– plumbing parts, components or consumable cleaning

products that are not approved by the manufacturer;

– customer’s negligence, misuse, abuse and/or non-com-

pliance with the use and care instructions detailed within

the appropriate equipment documentation;

– improper or poor: installation, repair, maintenance

(including tampering, modifications and repairs carried

out by third parties not authorized third parties) and

modification of safety systems;

– Use of non-original components (e. g.: consumables,

wear and tear, or spare parts);

– environment conditions provoking thermal (e. g. over-

heating/freezing) or chemical (e. g. corrosion/oxidation)

stress;

– foreign objects placed in- or connected to- the product;

– accidents or force majeure;

– transportation and handling, including scratches, dents,

chips, and/or other damage to the finish of the product,

unless such damage results from defects in materials or

workmanship and is reported within one (1) week of

delivery unless otherwise agreed;

• product with original serial numbers that have been

removed, altered or cannot be readily determined;

• replacement of light bulbs, filters or any consumable parts;

• any accessories and software not approved or specified by

Electrolux Professional.

Warranty does not include scheduled maintenance activities

(including the parts required for it) or the supply of cleaning

agents unless specifically covered within any local agreement,

subject to local terms and conditions.

Check on Electrolux Professional website the list of authorized

customer care.

C GENERAL SAFETY RULES

C.1 Introduction

The machines are provided with electric and/or mechanical

safety devices for protecting workers and the machine itself.

Therefore the user must not remove or tamper with such

devices. The Manufacturer declines any liability for damage

due to tampering or their non-use.

C.2 Mechanical safety characteristics,

hazards

The machine does not have sharp edges or protruding parts.

The guards for the moving and live parts are fixed to the

cabinet with screws, to prevent accidental access.

C.3 Guards

The guards on the machine are:

• fixed guards (e.g. casings, covers, side panels, etc.), fixed

to the machine and/or frame with screws or quick-release

connectors that can only be removed or opened with tools;

• interlocked movable guards (door) for access inside the

machine;

• machine electrical equipment access top panel, made from

a panel openable with tools. The panel must not be opened

when the machine is connected to the power supply.

IMPORTANT

Several illustrations in the manual show the

machine, or parts of it, without guards or with

guards removed. This is purely for explanatory

purposes. Do not use the machine without the

guards or with the protection devices deactivated.

C.4 Emergency switch

The emergency switches installed do not exempt operators

from diligent and careful use of the machine.

The function of these devices guarantees prompt intervention

in case of emergency.

• Operators must know the position of the emergency

switches installed on the machine.

• The paths to reach and operate them must be kept free of

obstacles.

• Anyone detecting a danger for persons must immediately

operate one of the emergency stops. The same applies in

case of operation anomalies and/or damage to parts of the

machine requiring it to be stopped immediately.

C.4.1 Emergency switch reinstatement

When an emergency switch is operated, restart the machine

only after making sure that:

• the cause requiring operation of the emergency switch has

been eliminated;

• restarting machine operation does not involve any hazard.

If the EMERGENCY SWITCH is operated during the use of the

machine, the entire machine is deactivated.

To reinstate machine operation, proceed as follows:

• release the previously operated red emergency button,

turning or pulling it in order to disconnect its interlock;

• restart the machine according to what is described in

paragraph “I.3 Starting“.

C.5 Safety signs to be placed on the

machine or near its area

Prohibition Meaning

do not oil, lubricate, repair and adjust

moving parts

do not remove the safety devices

do not use water to extinguish fires

(placed on electrical parts)

8

Danger Meaning

danger of crushing hands

caution, hot surface

danger of electrocution (shown on elec-

trical parts with indication of voltage)

C.6 Instructions for use and maintenance

Risks mainly of a mechanical, thermal and electrical nature

exist in the machine. Where possible the risks have been

neutralised:

• directly, by means of adequate design solutions.

• indirectly by using guards, protection and safety devices.

Any anomalous situations are signalled on the control panel

display.

During maintenance several risks remain, as these could not

be eliminated, and must be neutralised by adopting specific

measures and precautions.

Do not carry out any checking, cleaning, repair or maintenance

operations on moving parts. Workers must be informed of this

prohibition by means of clearly visible signs.

To guarantee machine efficiency and correct operation,

periodical maintenance must be carried out according to the

instructions given in this manual.

Make sure to periodically check correct operation of all the

safety devices and the insulation of electrical cables, which

must be replaced if damaged.

C.7 Reasonably foreseeable improper use

Improper use is any use different from that specified in this

manual. During machine operation, other types of work or

activities deemed improper and that in general can involve

risks for the safety of operators and damage to the appliance

are not allowed. Reasonably foreseeable improper use

includes:

• lack of machine maintenance, cleaning and periodical

checks;

• structural changes or modifications to the operating logic;

• tampering with the guards or safety devices;

• failure to use personal protection equipment by operators,

specialised personnel and maintenance personnel;

• failure to use suitable accessories (e.g. use of unsuitable

equipment or ladders);

• keeping combustible or flammable materials, or in any case

materials not compatible with or pertinent to the work, near

the machine;

• wrong machine installation;

• placing in the machine any objects or things not compatible

with its use, or that can damage the machine, cause injury

or pollute the environment;

• climbing on the machine;

• non-compliance with the requirements for correct machine

use;

• other actions that give rise to risks not eliminable by the

Manufacturer.

WARNING

The previously described actions

are prohibited!

C.8 End of use

When the appliance is no longer to be used, make it unusable

by removing the mains power supply wiring.

C.9 Residual risks

The machine has several risks that were not completely

eliminated from a design standpoint or with the installation of

adequate protection devices. Nevertheless, through this

manual the Manufacturer has taken steps to inform operators

of such risks, carefully indicating the personal protection

equipment to be used by them. In order to reduce the risks,

provide for sufficient spaces while installing the unit. To

preserve these conditions, the areas around the machine

must always be:

• kept free of obstacles (e.g. ladders, tools, containers, boxes,

etc.);

• clean and dry;

• well lit.

For the Customer's complete information, the residual risks

remaining on the machine are indicated below: such situations

are deemed improper and therefore strictly forbidden.

Residual risk Description of hazardous

situation

Slipping or falling The operator can slip due to water

or dirt on the floor

Catching, dragging or

crushing

Catching or dragging of the oper-

ator or other persons in the drive,

during the machine work phase,

due to improper actions, such as:

• placing an arm inside the

machine to remove a stuck rack

without stopping the machine

by operating an emergency

switch;

• accessing the rack handling

system without stopping the

machine by operating an emer-

gency switch.

Use of improper clothing with

loose parts (e.g. necklaces,

scarves, shawls, ties, etc.) or long

hair not gathered, which could get

caught up in moving parts.

Burns/abrasions (e.g.

heating elements,

cold pan, cooling cir-

cuit plates and pipes)

The operator deliberately or unin-

tentionally touches some

components inside the machine

without using protective gloves.

Stab wounds The operator deliberately or unin-

tentionally touches some

components with sharp edges

during the machine cleaning with-

out using protective gloves.

Burns The operator deliberately or unin-

tentionally touches some

components inside the machine or

dishes at the outfeed without using

gloves or without allowing them to

cool.

Shearing of upper

limbs

The operator violently closes the

front panels.

Electrocution Contact with live parts during

maintenance operations carried

out with the electrical panel

powered

Falling from above The operator intervenes on the

machine using unsuitable systems

to access the upper part (e.g. rung

ladders, or climbs on it)

9

Residual risk Description of hazardous

situation

Crushing or injury The specialised personnel may

not correctly fix the control panel

when accessing the technical

compartment. The panel could

close suddenly.

Crushing or shearing Possible risk of injury to upper

limbs during the hood closing

operation.

Residual risk Description of hazardous

situation

Tipping of loads When handling the machine or the

packing containing it, using unsuit-

able lifting systems or accessories

or with the unbalanced load

Chemical Contact with chemical substances

(e.g. detergent, rinse aid, scale

remover, etc.) without taking

adequate safety precautions.

Therefore always refer to the

safety cards and labels on the

products used.

IMPORTANT

In case of a significant anomaly (e.g. short circuits,

wires coming out of the terminal block, motor

breakdowns, worn electrical cable sheathing, etc.)

the operator must immediately deactivate the

machine.

D GENERAL INFORMATION

D.1 Introduction

Given below is some information regarding the intended use of

this appliance, its testing, and a description of the symbols

used (that identifies the type of warning), the definitions of

terms used in the manual and useful information for the

appliance user.

D.2 Definitions

Listed below are the definitions of the main terms used in the

manual. It is advisable to read them carefully before use.

Operator machine installation, adjustment, use,

maintenance, cleaning, repair and trans-

port personnel.

Manufacturer Electrolux Professional SpA or any other

service centre authorised by Electrolux

Professional SpA.

Operator for

normal

machine use

an operator who has been informed and

trained regarding the tasks and hazards

involved in normal machine use.

Customer

Care service

or specialised

technician

an operator instructed/trained by the

Manufacturer and who, based on his

professional and specific training, experi-

ence and knowledge of the accident-

prevention regulations, is able to appraise

the operations to be carried out on the

machine and recognise and prevent any

risks. His professionalism covers the

mechanical, electrotechnical and elec-

tronics fields.

Danger source of possible injury or harm to health.

Hazardous

situation

any situation where an operator is

exposed to one or more hazards.

Risk a combination of probabilities and risks of

injury or harm to health in a hazardous

situation.

Protection

devices

safety measures consisting of the use of

specific technical means (guards and

safety devices) for protecting operators

against risks.

Guard an element of a machine used in a specific

way to provide protection by means of a

physical barrier.

Safety device a device (other than a guard) that elimi-

nates or reduces the risk; it can be used

alone or in combination with a guard.

Customer the person who purchased the machine

and/or who manages and uses it (e. g.

company, entrepreneur, firm).

Emergency

stop device

a group of components intended for the

emergency stop function; the device is

activated with a single action and pre-

vents or reduces damage to persons/

machines/property/animals.

Electrocution an accidental discharge of electric current

on a human body.

D.3 Machine and Manufacturer‘s

identification data

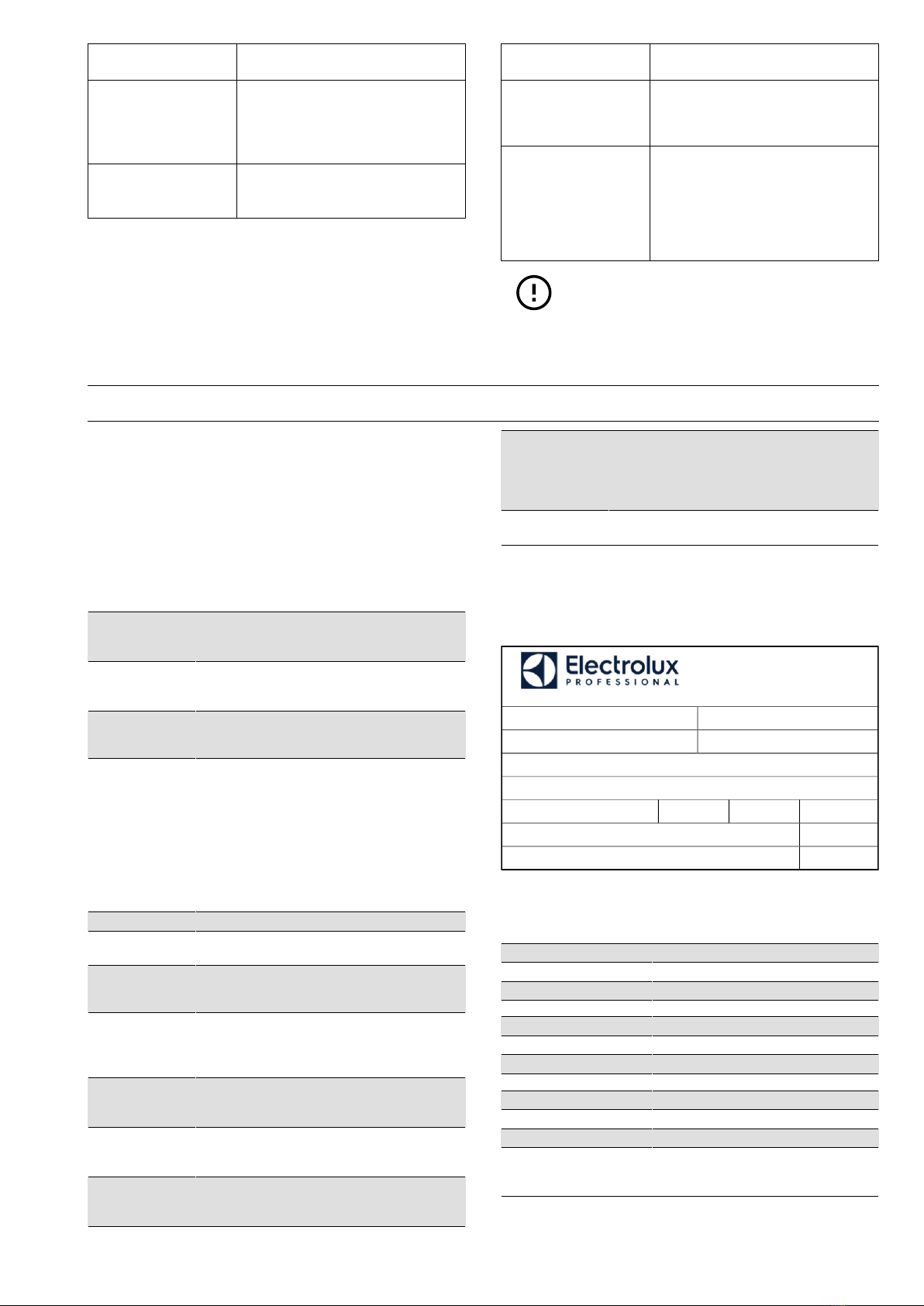

An example of the marking or dataplate on the machine is

given below:

The dataplate gives the product identification and technical

data; listed below is the meaning of the various information

given on it.

F.Mod. factory description of product

Comm.Model commercial description

PNC production number code

Ser.No. serial number

380-415V 3N~ power supply voltage

—electric convertibility

50 or 60 power supply frequency

44.5 kW max. power

60℃max water temperature

600 kPa [6 bar] max water pressure

IPX4 dust and water protection rating

Shanghai Veetsan

Electrical Appliance

Co., Ltd

manufacturer

The dataplate is located in front panel of the equipment.

Dishwasher

F.Mod. EFTD064E2 Type EFT064HO

PNC 520138 IPX4

Comm.Model EFTD064EL3U1D2FER38

Serial 85100001

EL. 380V 3N 50 Hz 46.5 KW Class I

Max. permissible water pressure 600 kPa

Max. permissible water temperature 60 °C

10

WARNING

Do not remove, tamper with or

make the machine marking

illegible.

IMPORTANT

When scrapping the machine, the marking must be

destroyed.

NOTE!

Refer to the data given on the machine marking for

relations with the Manufacturer (e.g. when ordering

spare parts, etc.).

D.4 Appliance identification

D.4.1 How to identify the technical data

• Read the factory description of the product (F. Mod.) on the

dataplate;

• identify the main machine data;

• consult G.1 Main technical characteristics paragraph.

D.4.2 How to interpret the factory description

The factory description on the dataplate has the following

meaning (some examples are given below):

(1) (2) (3) (4) (5)

E FTD 052 E 1

E FTD 082 S 1

E FTD 1081 E 1

E FTD 108 E 1

E FTD 1081 S 1

E FTD 108 S 1

Variable description

(1) Brand E = Electrolux

(2) Machine type FTD = Flight Type Dishwasher

(3) Dishes/hour 052 = 5200 dishes/hour

064 = 6400 dishes/hour

082 = 8200 dishes/hour

108 = 10800 dishes/hour

(4) Supply E = electric

S = steam

(5) Drying unit 1 = one dryer

2 = two dryers

D.5 Responsibility

The Manufacturer declines any liability for damage and

malfunctioning caused by:

• non-compliance with the instructions contained in this

manual;

• repairs not carried out in a workmanlike fashion, and

replacements with parts different from those specified in

the spare parts catalogue (the fitting and use of non-original

spare parts and accessories can negatively affect machine

operation and invalidates the original manufacturer

warranty);

• operations carried out by non-specialised personnel;

• unauthorized modifications or operations;

• missing, lack or inadequate maintenance;

• improper machine use;

• unforeseeable extraordinary events;

• use of the machine by uninformed and / or untrained

personnel;

• non-application of the current provisions in the country of

use, concerning safety, hygiene and health in the workplace.

The Manufacturer declines any liability for damage caused by

arbitrary modifications and conversions carried out by the user

or the Customer.

The employer, workplace manager or service technician are

responsible for identifying and choosing adequate and suitable

personal protection equipment to be worn by operators, in

compliance with regulations in force in the country of use.

11

The Manufacturer declines any liability for inaccuracies con-

tained in the manual, if due to printing or translation errors.

Any supplements to the installation, use and maintenance

manual the Customer receives from the Manufacturer will form

an integral part of the manual and therefore must be kept

together with it.

D.6 Copyright

This manual is intended solely for consultation by the operator

and can only be given to third parties with the permission of

Shanghai Veetsan Electrical Appliance Co., Ltd.

D.7 Keeping the manual

The manual must be carefully kept for the entire life of the

machine, until scrapping. The manual must stay with the

machine in case of transfer, sale, hire, granting of use or

leasing.

D.8 Recipients of the manual

This manual is intended for:

• the employer of machine users and the workplace manager

• operators for normal machine use

• specialised technicians - Customer Care service (see

service manual).

E NORMAL USE

E.1 Correct use

Our machines are designed and optimized in order to obtain

high performance and efficiency.

This equipment must only be used for its expressly designed

purpose, i. e. washing dishes with water and specific deter-

gents. Any other use is to be deemed improper.

E.2 Characteristics of personnel enabled to

operate on the machine

The Customer is responsible for ensuring that persons

assigned to the various duties:

• read and understand the manual;

• receive adequate training and instruction for their duties in

order to perform them safely;

• receive specific training for correct machine use.

E.3 Characteristics of personnel trained for

normal machine use

The Customer must make sure the personnel for normal

machine use are adequately trained and skilled in their duties,

as well as ensuring their own safety and that of other persons.

The Customer must make sure his personnel have understood

the instructions received and in particular those regarding work

hygiene and safety in use of the machine.

E.4 Operator qualified for normal machine

use

Must have at least:

• knowledge of the technology and specific experience in

operating the machine;

• adequate general basic education and technical knowledge

for reading and understanding the contents of the manual,

including correct interpretation of the drawings, signs and

pictograms;

• sufficient technical knowledge for safely performing his

duties as specified in the manual;

• knowledge of the regulations on work hygiene and safety.

In case of a significant anomaly (e. g. short circuits, wires

coming out of the terminal block, motor breakdowns, worn

electrical cable sheathing, etc.) the operator for normal

machine use must:

• immediately deactivate the machine by turning the switch

disconnector to “O“ or operating the main emergency switch

on the equipment;

• close the machine water supply by shutting off the water.

F PRODUCT OVERVIEW

F.1 Modules list

The excellent modular design includes:

A. inlet module;

B. pre-wash module;

C. wash module;

D. rinse module;

E. drying module;

F. outlet module.

(the maximum configuration has one pre-wash module, three

wash modules, two rinse modules and a drying module.

The composition can be selected as required. (Make sure to

specify when ordering).

Stainless steel insulated wash tank, wash chambers and low-

flow rotating rinse system, efficiently save energy and reduce

operating costs.

The standard large insulated door provides easy access to

clean and maintain the inside.

Two conveyor speed are available for operators to adjust the

transporting speed depending on the dirt degree and variety of

cutlery and tableware.

Steam heating and electric heating are available for “EFTD“

series dishwasher. (Make sure to specify when ordering).

Equipped with a built-in electric or steam heating device (27

KW or 18 KW) to help you select according to feeding water

temperature and energy conditions (Make sure to specify

when ordering).

12

Modules composition

4.150

E

300

750

800

800

800

1.000

250

A

C

F

D

EFT052D...1

4.150

E

300

750

800

800

800

1.000

250

A

C

F

D

EFT052D...1

5150

300

950

800

800

800

1000

250250

800

A

E

F

CB

D

EFT062D...1

5150

300

950

800

800

800

1000

250

800

A

E

F

CB

D

EFT062D...1

13

Modules composition (cont'd.)

Modules descriptions

AInlet 3 optional lengths 1 750 mm

2 950 mm

3 1100 mm

BPrewash section Optional module P 800 mm

6.250

300

950

800

800

800

1.300

250250

800800

A

E

F

CB

DC

EFT082D...1

6.250

300

950

800

800

800

1.300

250

800800

A

E

F

CB

DC

EFT082D...1

F

950

800

800

800 1.600

7.350

800

800800

250

300

A

F

ECB

EFT108D...1

DC

C

F

950

800

800

800 1.600

7.350

800

800800

250

300

A

F

ECB

EFT108D...1

DC

C

14

Modules descriptions (cont'd.)

CWash section 3 optional lengths 1 800 mm

2 1600 mm

3 2400 mm

DRinse section Rinse module R 800 mm

DRinse section Rinse module R 800 mm

EDryer section Optional module D 800 mm

FOutlet section 5 optional lengths 1 1000 mm

2 1300 mm

3 1600 mm

4 1900 mm

5 2200 mm

G TECHNICAL DATA

G.1 Main technical characteristics

Electrical models

Model EFTD052E1 EFTD064E1 EFTD082E1 EFTD108E1

Three phases voltage V 380-415V 3N~ 380-415V 3N~ 380-415V 3N~ 380-415V 3N~

Convertible to V — — — —

Frequency Hz 50 or 60150 or 60150 or 60150 or 601

Maximum absorbed power

[NO ESD]2KW 46.5 48.5 76 93.5

Maximum absorbed power

[ESD]3KW 42.7 44.7 66.7 87.7

Boiler heating power KW 9x249x249x349x34

Boiler heating power KW 7x247x249x247x34

Wash tank heating power KW 8x2

[1 tank]

8x2

[1 tank]

8x2

[2 tanks]

8x2

[3 tanks]

Prewash pump power KW -2 2 2

Wash pump power KW 2

[1 tank]

4

[2 tanks]

6

[3 tanks]

8

[4 tanks]

Dryer heating power KW 9 9 9 9

Inlet water pressure Kpa

[bar]

100 kPa [1 bar]

600 kPa [6 bar]

100 kPa [1 bar]

600 kPa [6 bar]

100 kPa [1 bar]

600 kPa [6 bar]

100 kPa [1 bar]

600 kPa [6 bar]

Inlet water hardness °fH

[°dH]

14

[8]

14

[8]

14

[8]

14

[8]

Concentration of chlorides in

water ppm <20 <20 <20 <20

Inlet water conductivity mS/cm <400 <400 <400 <400

Cold water supply temper-

ature for model without ESD ℃10-65 10-65 10-65 10-65

Cold water supply temper-

ature for model with ESD ℃10-65510-65510-65510-655

Hot water supply

temperature ℃10-65610-65610-65610-656

Rinse water consumption l/h 210 210 280 320

Boiler capacity l 23 23 23 23

Tank capacity l92

1 tank

196

2 tanks

294

3 tanks

392

4 tanks

Speed 1 m/min

1.0 1.4 2.0 2.7

Speed 2 1.6 2.0 2.6 3.3

Noise level dB(A) <70 <70 <70 <70

Protection level IPX4 IPX4 IPX4 IPX4

1. Appliances with 50 Hz or 60 Hz power frequency can be selected.

2. For appliance without Energy Saving Device

3. For appliance with Energy Saving Device

15

Electrical models (cont'd.)

4. If the inlet water temperature is higher than 45℃, reduce the boiler heating power of 9 KW.

5. Recommended cold water supply temperature 10℃

6. Recommended hot water supply temperature 50℃.

Steam Models

Model EFTD052S1 EFTD064S1 EFTD082S1 EFTD108S1

Three phases voltage V 380-415V 3N~ 380-415V 3N~ 380-415V 3N~ 380-415V 3N~

Convertible to V — — — —

Frequency Hz 50 or 60150 or 60150 or 60150 or 601

Maximum absorbed power KW 3.5 5.5 7.5 9.5

Maximum absorbed power KW 3.7 5.43 7.7 9.68

Prewash pump power KW -2 2 2

Wash pump power KW 2

[1 tank]

4

[2 tanks]

6

[3 tanks]

8

[4 tanks]

Boiler heating power KW / / / /

Water tank heating power KW / / / /

Dryer heating power KW / / / /

Inlet water pressure Kpa [bar] 100 kPa [1 bar]

600 kPa [6 bar]

100 kPa [1 bar]

600 kPa [6 bar]

100 kPa [1 bar]

600 kPa [6 bar]

100 kPa [1 bar]

600 kPa [6 bar]

Inlet water hardness °fH

[°dH]

14

[8]

14

[8]

14

[8]

14

[8]

Concentration of chlorides in

water ppm <20 <20 <20 <20

Inlet water conductivity mS/cm <400 <400 <400 <400

Cold water supply temper-

ature for model without ESD ℃10-65 10-65 10-65 10-65

Cold water supply temper-

ature for model with ESD ℃10-65210-65210-65210-652

Hot water supply

temperature ℃10-65310-65310-65310-653

Rinse water consumption l/h 210 210 280 320

Boiler capacity l 23 23 23 23

Tank capacity l92

1 tank

196

2 tanks

294

3 tanks

392

4 tanks

Speed 2 m/min

1.0 1.4 2.0 2.7

Speed 1 1.6 2.0 2.6 3.3

Noise level dB(A) <70 <70 <70 <70

Steam consumption kg/h 75 75 88 101

Steam pressure Kpa [bar] 100-300

[1-3]

100-300

[1-3]

100-300

[1-3]

100-300

[1-3]

Protection level IPX4 IPX4 IPX4 IPX4

1. Appliances with 50 Hz or 60 Hz power frequency can be selected.

2. Recommended cold water supply temperature 10℃

3. Recommended hot water supply temperature 50℃.

Productivity table

Models EFTD052...1 EFTD064...1 EFTD082...1 EFTD108...1

Speed 1 Productivity

[dish/h]

3200 4500 6400 8600

Speed 2 5200 6400 8200 10800

Main ON/OFF switch (residual current circuit breaker)

Max power

[KW] 2-6 30-36 53-60 61-67 68-87 88-110

C220V 25A 125A 200A 225A 300A 350A

380V 16A 63A 125A 125A 160A 200A

16

Power supply cable

Max power

[KW] 2-6 36 37-42 43-69 70-85 86-108

SYJV3*2.5

+2*1.5 YJV3*6+2*4 YJV3*16+2*10 YJV3*25+2*16 YJV3*35+2*16 YJV3*50+2*25

H CONTROL PANEL DESCRIPTION

H.1 Control panel description AOFF button

BPOWER light

CON button

DSTART button

EPAUSE button

FSPEED 1 button

GSPEED 2 button

HBoiler temperature display

IWash temperature display of tank 1

LWash temperature display of tank 2

MWash temperature display of tank 3

H.2 Basic Controls

Some functions are common to all models of the range, whereas others are available only on some versions.

ON button and POWER indicator

light

Press this button to switch the appliance on. The Power indicator light

is on and the water start to fill the tanks. After some minutes also the

tank heating elements start to warm the water.

The red indicator light of the pause button blinks alternately every

second during the filling and heating phases.

When the dishwasher is ready to work the green indicator light of the

start button flashes 2 times and for 2 second is off.

OFF button Press the OFF button to switch the appliance off.

The POWER indicator light is off.

START button Press this button to start the washing cycle.

PAUSE button Press this button to stop the washing cycle.

Wash SPEED 1 button Press this button to set the conveyor belt at the low speed. It is suitable

for heavily soiled dishes.

Wash SPEED 2 button Press this button to set the conveyor belt at the high speed. It is

suitable for normally soiled dishes.

Wash tank temperature display It shows the temperature of the water inside the wash tank.

Boiler temperature display It shows temperature of the water inside the boiler.

G

HAM

B

C

L

E

FID

--- --- --- ---

17

I NORMAL MACHINE USE

I.1 Fitting of filters and overflows

CAUTION

The below operations must be performed

when the machine is cold and switched off.

Make sure that:

1. the inlet filter is correctly installed;

2. the filter of prewash and wash pump is correctly installed;

3. the prewash/wash tank overflows are correctly installed;

4. the prewash/wash tank filters are correctly installed;

5. the filter and the overflow of the rinse tank are correctly

installed.

I.2 Fitting of wash and rinse arms

Make sure that:

1. the upper and lower washing arm are correctly installed;

2. the rinsing arm is correctly installed.

1

2

3

18

I.3 Starting

• Make sure all the types of curtains, provided for the

machine model, are correctly fitted.

• Close the doors of the various machine modules.

• Check the detergent or rinse aid containers.

Refill or replace them with new ones in order to always

obtain the good washing results.

NOTE!

To obtain excellence washing performance, use

detergent, rinse aid and descaling agent sug-

gested by Electrolux Professional. In the

Electrolux Professional web site, open the

“Accessories and Consumables“ web page and

navigate into the dishwashing equipment tab to

order most suitable detergents and accessories.

CAUTION

The use of “foaming/nonspecific“ deter-

gents or in any case detergents used in

different ways from that prescribed by the

manufacturer, can cause damage to the

dishwasher and compromise the washing

results.

WARNING

When using chemicals, comply

with the safety notes and dosage

recommendations printed on the

packaging. Refer to the chapter

A.3 Personal protection equip-

ment for handling chemical

products.

• Activate the main ON/OFF switch.

• Open the water supply tap.

• Make sure the filters, arms and the overflows are correctly

fitted in their position.

• Press the ON button to switch the dishwasher on.

• The red indicator light of the pause button blinks

alternately every second during the filling and heating

phases.

When the dishwasher is ready to work the green indicator

light of the start button flashes 2 times and for 2 second

is off and the displays of the wash tank and boiler show the

working temperature.

Tank temperature

Boiler temperature

• To shut down the dishwasher, press the OFF button.

I.4 Washing phase

The washing phase includes washing with hot water and

detergent at a temperature of 60℃and rinsing with hot water

and a rinse aid at a temperature of 82℃.

This machine can operate in 2 modes:

1. Speed 1 : low speed for heavily soiled dishes.

2. Speed 2 : high speed for normally soiled dishes.

Max

Max

L1 L2 L3 N

L1 L2 L3 N

PE

C

WI

19

Conveyor belt speed and productivity table

Model

(m/min) dish/h (m/min) dish/h

EFTD052...1 1.0 3200 1.6 5200

EFTD064...1 1.4 4500 2.0 6400

EFTD082...1 2.0 6400 2.53 8200

EFTD108...1 2.7 8600 3.4 10800

I.5 Operation

The dishwasher is ready for use when the green indicator light

of the start button flashes 2 times and for 2 second is off

and the display shows:

• the temperature of the tank is at 60℃or more;

• the boiler temperature is at 82℃or more.

I.5.1 Loading/unloading tableware

This dishwasher is suitable for washing dishes, cups, cutlery,

trays, containers and receptacles in plastic and/or steel used

for preparing, cooking and serving; as well as a wide variety of

ceramic and/or metal cooking utensils. However it is advisable

not to wash decorated dishes or place silverware in contact

with other metals.

IMPORTANT

All the dishes must be arranged in the special

conveyor belt in order to be washed. Before

arranging the dishes into the conveyor belt, clear

the dishes of any food residuals and rinse them in

order not to clog the filters. Use cold or warm water

(at a max. temperature of 35℃) with a manual

prewash spray.

CAUTION

Failure to remove the residuals of deter-

gent possibly used for manual prewash

can cause malfunctioning of the dish-

washer and compromise washing results.

• Load dishes, bowls, trays and pans neatly onto the

conveyor, avoiding collisions and damage.

NOTE!

To facilitate the flow of water leave a space of

about 100 mm between each pan.

• Avoid to arrange or overfill the conveyor belt of items too

close, because this cause a bad washing results. The

washing arms of the machine with several angled water jets

are not able to perfectly clean the dishes.

• Make sure that large utensils like pots, big plates, big trays

can be transported through smoothly before washing them.

If the large dishes can not easily pass through the machine,

please don't try again.

• Remove the tableware from the outlet module and put it into

storage boxes.

When the conveyor belt is empty for a certain period of time,

the dishwasher automatically stops. When a tableware is

loaded again, the dishwasher starts washing again.

NOTE!

It is advisable that 2 operators load and unload

tableware from the dishwasher conveyor belt.

• One operator puts the tableware neatly onto the conveyor

belt, and presses the START button.

The machine starts washing, and the tableware exits from

the outlet module after a washing cycle.

• Second operator remove the cleaned tableware. If the

tableware activates the end limit switch the dishwasher

stops immediately. Remove the tableware from the con-

veyor belt and press the start button to start the washing

cycle again.

20

WARNING

Danger of crushing.

Keep hands and arms away from

the conveyor belt entry zone.

I.5.2 Change the conveyor speed

1. Press PAUSE button to stop the dishwasher.

2. Select the required speed.

3. Press the START button to set the new speed.

NOTE!

When changing the speed while the conveyor is

running, the speed will not take effect immediately.

Always stop and re-start the dishwasher.

IMPORTANT

Call the Customer Care service to change the

default dishwasher speed of washing.

I.5.3 Start/stop washing cycle

Make sure that all doors of the dishwasher are closed.

Press the START button on the control panel or the green

START button in the inlet or outlet module to start the washing

cycle.

Press the STOP button on the control panel or the red STOP

button in the inlet or outlet module to stop the washing cycle. It

is also possible to stop the washing cycle opening a door.

I.6 Type of tableware

• Place all tableware including dishes, plates, trays on the

conveyor belt to a certain degree.

• Bowls needs to be fitted into the conveyor belt. Cups,

glasses and silverware should be placed in a rack, although

they can be directly put on conveyor belt.

• Make sure that large utensils like pots, big plates, big trays

can be transported through smoothly before washing them.

If the large dishes can not easily pass through the machine,

please don't try again.

I.6.1 Plastic or metal baskets

Plastic, or metal baskets wherein the size does not exceed 600

X 450 X 340 mm.

I.6.2 Plastic or ceramic dishes

Plastic or ceramic dishes, bowls or trays wherein the size does

not exceed 400 X 400 X 340 mm.

J DAILY CLEANING AND MAINTENANCE

WARNING

Refer to “Warning and Safety

Information“.

J.1 Machine cleaning

Cleaning must be carried out after every day of use. Use hot

water, a neutral detergent/cleaner if necessary, and a soft

brush or sponge. If another type of detergent is used, carefully

follow the producer's instructions and observe the safety rules

given in the information sheets provided with the product or

substance.

This manual suits for next models

7

Table of contents

Other Electrolux Professional Dishwasher manuals