Electrolux Professional NHT8 User manual

Hood dishwasher

EN Installation manual *

*Original instructions 59566WM00- 2022.06

2

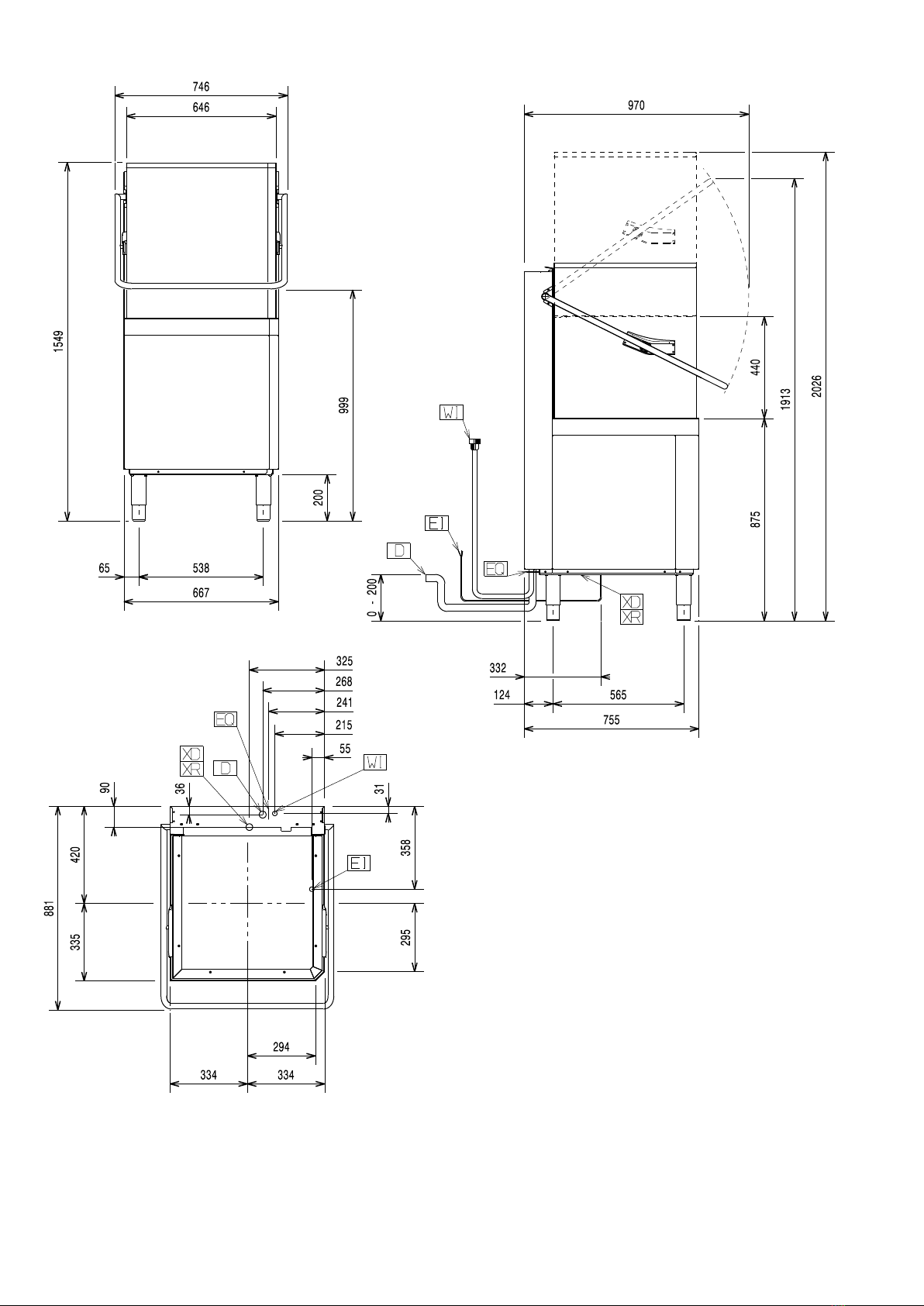

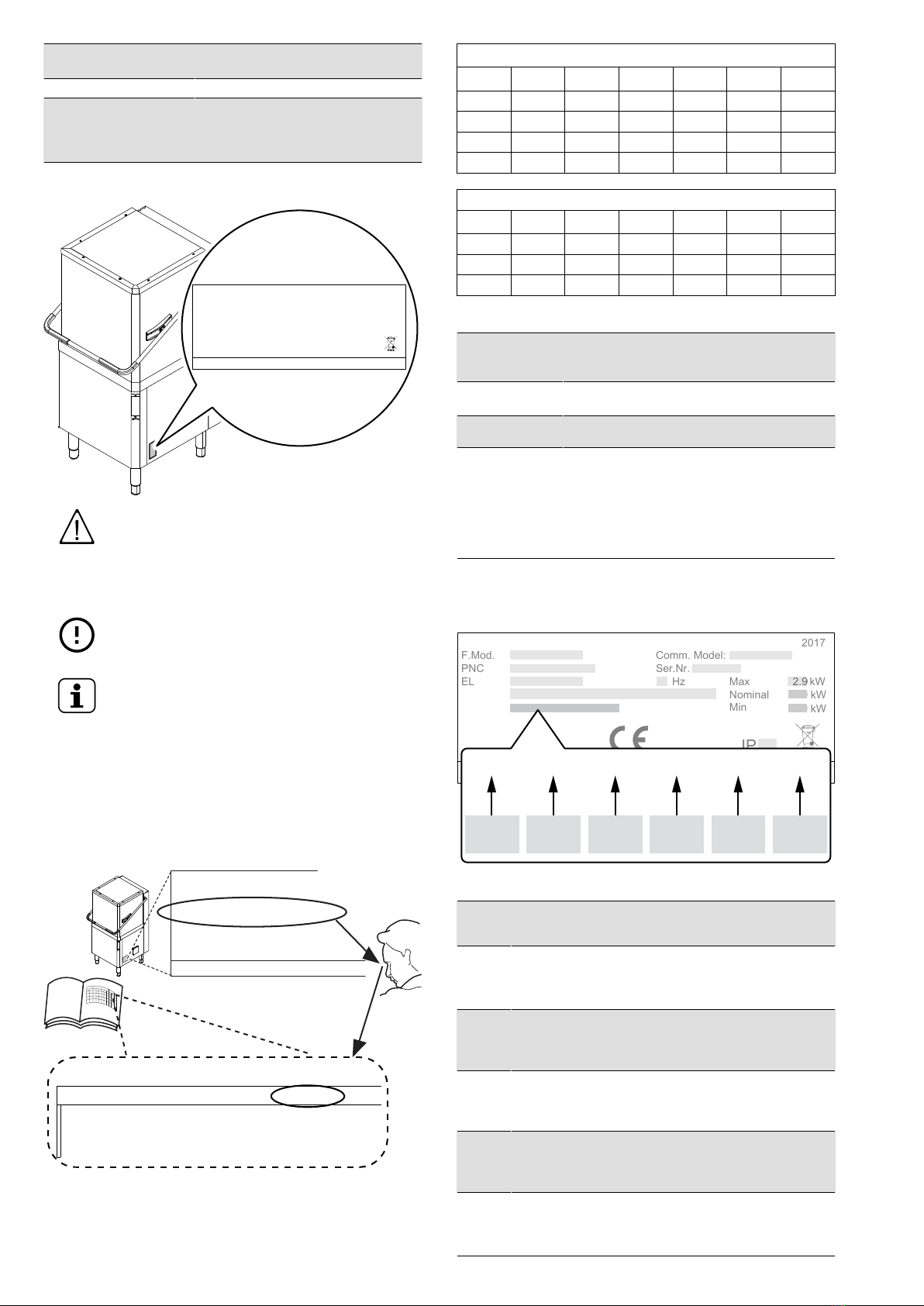

Installation diagram Manual hood type (single skin) without drain

pump and without Energy Saving Device (ESD)

3

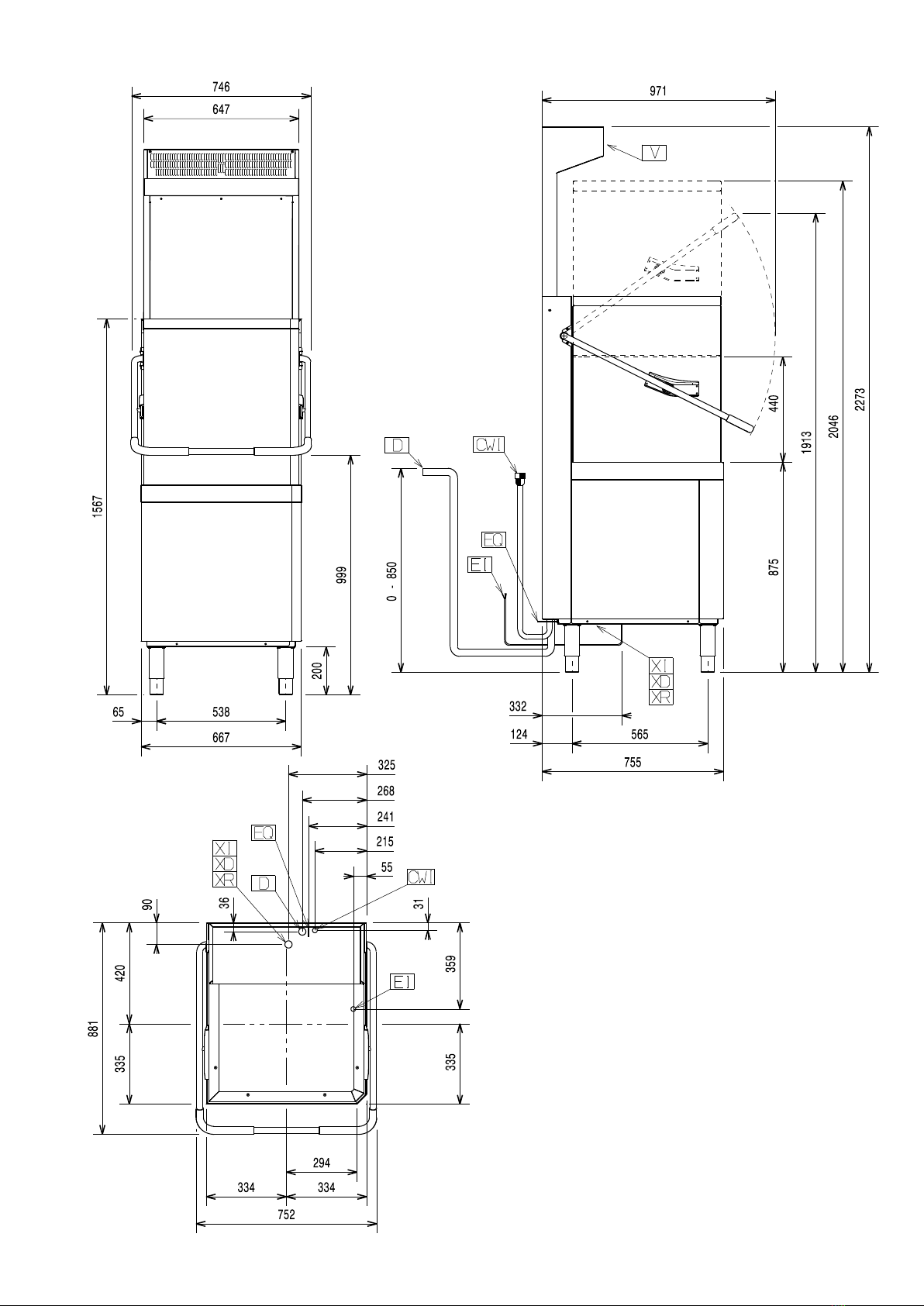

Installation diagram Manual hood type (single skin) without drain

pump and with Energy Saving Device (ESD)

4

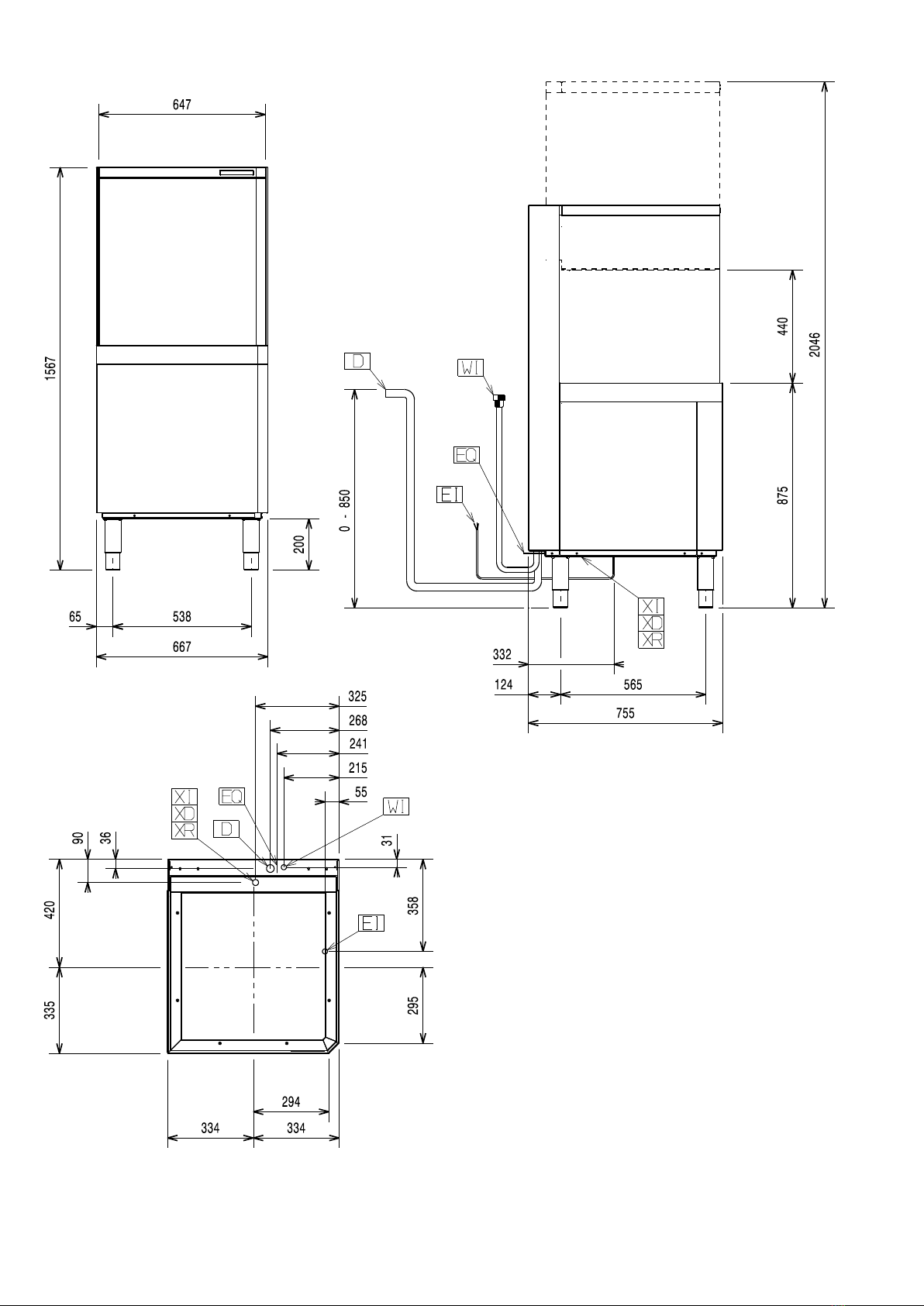

Installation diagram Manual hood type (single skin) with drain

pump and without Energy Saving Device (ESD)

5

Installation diagram Manual hood type (single skin) with drain

pump and with Energy Saving Device (ESD)

6

Installation diagram Manual hood type (double skin) with drain

pump and without Energy Saving Device (ESD)

7

Installation diagram Manual hood type (double skin) with drain

pump and with Energy Saving Device (ESD)

8

Installation diagram Automatic hood type with drain pump and

without Energy Saving Device (ESD)

9

Installation diagram Automatic hood type with drain pump and with

Energy Saving Device (ESD)

10

CWI = Cold water Inlet pipe ⌀=3/4″ G

WI = Water Inlet pipe ⌀=3/4″ G

D = Drain pipe internal ⌀=40 mm(ʌ) - 20 mm(*)

(ʌ) Only for model with free-fall drainage

(*) Only for model with drain pump

EI = Electrical Inlet

EQ = Equipotential screw

XD = Inlet pipe for detergents

XR = Inlet pipe for rinse-aid

XI = Inlet pipe for delime

11

Foreword

Read the following instructions, including the warranty terms before installing and using the appliance.

Visit our website www.electroluxprofessional.com and open the Support section to:

Register your product

Get hints & tips of your product, service and repair information

The installation, use and maintenance manual (hereinafter Manual) provides the user with information necessary for correct and

safe use of the appliance.

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable for improving ap-

pliance performance in every respect and, above all, preventing injury to persons and animals and damage to property due to im-

proper operating procedures.

All persons involved in appliance transport, installation, commissioning, use and maintenance, repair and disassembly must con-

sult and carefully read this manual before carrying out the various operations, in order to avoid wrong and improper actions that

could compromise the appliance's integrity or endanger people. Make sure to periodically inform the user regarding the safety reg-

ulations. It is also important to instruct and update personnel authorised to operate on the appliance, regarding its use and

maintenance.

The manual must be available to operators and carefully kept in the place where the appliance is used, so that it is always at hand

for consultation in case of doubts or whenever required.

If, after reading this manual, there are still doubts regarding appliance use, do not hesitate to contact the Manufacturer or the au-

thorised Service Centre to receive prompt and precise assistance for better operation and maximum efficiency of the appliance.

During all stages of appliance use, always respect the current regulations on safety, work hygiene and environmental protection. It

is the user's responsibility to make sure the appliance is started and operated only in optimum conditions of safety for people, ani-

mals and property.

IMPORTANT

• The manufacturer declines any liability for operations carried out on the appliance without respecting the instructions

given in this manual.

• The manufacturer reserves the right to modify the appliances presented in this publication without notice.

• No part of this manual may be reproduced.

• This manual is available in digital format by:

– contacting the dealer or reference customer care;

– downloading the latest and up to date manual on the web site;

• The manual must always be kept in an easily accessed place near the appliance. Appliance operators and mainte-

nance personnel must be able to easily find and consult it at any time.

12

Contents

A SAFETY INFORMATION ....................................................................................................................... 13

A.1 General information .................................................................................................................... 13

A.2 General safety ........................................................................................................................... 13

A.3 Personal protection equipment ...................................................................................................... 14

A.4 Transport, handling and storage .................................................................................................... 14

A.5 Installation and assembly ............................................................................................................. 15

A.6 Water connection........................................................................................................................ 15

A.7 Electrical connection ................................................................................................................... 15

A.8 Machine cleaning and maintenance................................................................................................ 16

A.9 Service..................................................................................................................................... 16

A.10 Disposal of packing..................................................................................................................... 17

A.11 Machine disposal........................................................................................................................ 17

B GENERAL INFORMATION .................................................................................................................... 17

B.1 Introduction ............................................................................................................................... 17

B.2 Definitions................................................................................................................................. 17

B.3 Machine and Manufacturer‘s identification data ................................................................................. 17

B.4 Appliance identification ................................................................................................................ 18

B.4.1 How to identify the technical data.......................................................................................... 18

B.4.2 How to interpret the factory description .................................................................................. 18

B.4.3 How to interpret the type reference ....................................................................................... 18

B.5 Responsibility ............................................................................................................................ 19

B.6 Copyright.................................................................................................................................. 19

B.7 Keeping the manual .................................................................................................................... 19

B.8 Recipients of the manual .............................................................................................................. 19

C TECHNICAL DATA............................................................................................................................... 19

C.1 Main technical characteristics........................................................................................................ 19

C.2 Characteristics of power supply ..................................................................................................... 20

D TRANSPORT, HANDLING AND STORAGE .............................................................................................. 20

D.1 Introduction ............................................................................................................................... 20

D.2 Transport: Instructions for the carrier............................................................................................... 21

D.3 Handling................................................................................................................................... 21

D.3.1 Procedures for handling operations....................................................................................... 21

D.3.2 Shifting ........................................................................................................................... 21

D.3.3 Placing the load................................................................................................................ 21

D.4 Storage .................................................................................................................................... 21

D.5 Unpacking ................................................................................................................................ 21

E INSTALLATION AND ASSEMBLY ........................................................................................................... 21

E.1 Introduction ............................................................................................................................... 21

E.2 Customer responsibilities ............................................................................................................. 21

E.3 Characteristics of the installation place............................................................................................ 21

E.4 Appliance space limits ................................................................................................................. 21

E.5 Positioning ................................................................................................................................ 21

E.6 Extraction hood.......................................................................................................................... 22

E.7 Disposal of packing..................................................................................................................... 22

E.8 Plumbing connections ................................................................................................................. 23

E.9 Plumbing circuits ........................................................................................................................ 23

E.10 Electrical connections.................................................................................................................. 24

E.10.1 Connections provided for energy control ................................................................................ 25

E.11 Safety devices ........................................................................................................................... 25

E.12 “HACCP“ arrangement ................................................................................................................ 25

E.13 Detergent/rinse aid dispensers and prearrangements ......................................................................... 25

E.13.1 Electrical connections for automatic detergent and rinse-aid dispensers........................................ 26

F CONTROL PANEL DESCRIPTION .......................................................................................................... 26

F.1 Control panel description.............................................................................................................. 26

F.2 Basic Controls ........................................................................................................................... 27

G COMMISSIONING ............................................................................................................................... 27

G.1 Preliminary checks, adjustments and operational tests ....................................................................... 27

H BASIC MACHINE SETUP...................................................................................................................... 28

H.1 Manual activation ....................................................................................................................... 28

H.2 Setting the dispensers ................................................................................................................. 28

H.3 Note for external dispenser ........................................................................................................... 29

I DISHWASHER WITH INCORPORATED CONTINUOUS WATER SOFTENER.................................................. 30

I.1 Hood type dishwasher with incorporated continuous water softener....................................................... 30

I.1.1 Salt container................................................................................................................... 30

I.1.2 How to fill the salt container ................................................................................................. 30

J TROUBLESHOOTING .......................................................................................................................... 31

J.1 Alarms ..................................................................................................................................... 31

13

A SAFETY INFORMATION

A.1 General information

These appliance is intended to be used for commercial applications, for example in

kitchens of restaurant, canteens, hospitals. It must be used for washing plates, dishes,

glassware, cutlery and similar articles.

To ensure safe use of the machine and a proper understanding of the manual it is

necessary to be familiar with the terms and typographical conventions used in the

documentation. The following symbols are used in the manual to indicate and identify the

various types of hazards:

WARNING

Danger for the health and safety of operators.

WARNING

Danger of electrocution - dangerous voltage.

CAUTION

Risk of damage to the appliance or the product.

IMPORTANT

Important instructions or information on the product

Equipotentiality

Read the instructions before using the appliance

Clarifications and explanations

A.2 General safety

• The machine must not be used by people (including children) with limited physical,

sensory or mental abilities or without experience and knowledge of it, unless instructed

in its use and supervised by those responsible for their safety.

– Do not let children play with the machine.

– Keep all packaging and detergents away from children.

– Cleaning and user maintenance shall not be made by children without supervision.

• For suitable personal protection equipment, refer to chapter “A.3 Personal protection

equipment“.

• Several illustrations in the manual show the machine, or parts of it, without guards or

with guards removed. This is purely for explanatory purposes. Do not install the machine

without the guards or with the protection devices deactivated.

• Do not remove, tamper with or make illegible the safety, danger and instruction signs

and labels on the machine.

• Do not remove or tamper with the machine’s safety devices.

• Before carrying out any machine installation, always consult the installation manual,

which gives the correct procedures and contains important information on safety.

• Unauthorized personnel must not enter the work area.

14

• Remove any flammable products or items from the work area.

• Machine positioning, installation and disassembly must be carried out by the specialised

personnel in conformity with the current safety regulations, regarding the equipment

used and the operating procedures.

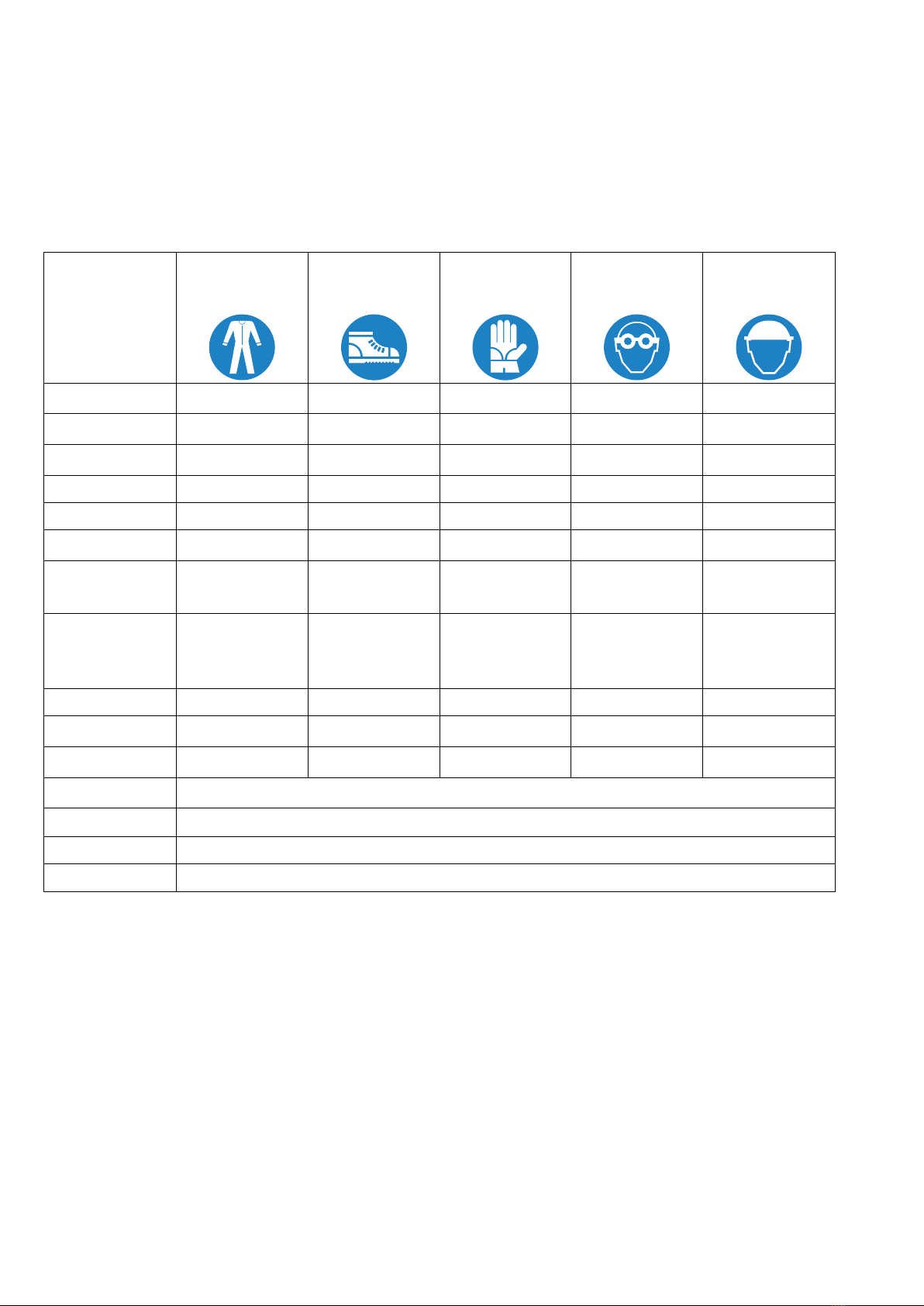

A.3 Personal protection equipment

Summary table of the Personal Protection Equipment (PPE) to be used during the various

stages of the appliance's service life.

Stage Protective

garments

Safety

footwear

Gloves Glasses Safety

helmet

Transport —● ○ —○

Handling ● ● ○ — —

Unpacking ○ ● ○ — —

Installation ○ ● ●1— —

Normal use ● ● ●2○—

Adjustments ○ ● — — —

Routine

cleaning

○ ● ●1ˉ3○—

Extraordi-

nary

cleaning

○ ● ●1ˉ3○—

Maintenance ○ ● ○ — —

Dismantling ○ ● ○ ○ —

Scrapping ○ ● ○ ○ —

Key:

●PPE REQUIRED

○PPE AVAILABLE OR TO BE USED IF NECESSARY

—PPE NOT REQUIRED

1. During these operations, gloves must be cut-resistant. Failure to use the personal protection equipment by

operators, specialized personnel or users can involve exposure to damage to health (depending on the model).

2. During these operations, gloves must be heatproof and suitable for contact with water and the substances

used (refer to the safety data sheet of the substances used for the information regarding the required PPE).

Failure to use the personal protection equipment by operators, specialised personnel or users can involve

exposure to chemical risk and cause possible damage to health (depending on the model).

3. During these operations, gloves must be suitable for contact with chemical substances used (refer to the

safety data sheet of the substances used for information regarding the required PPE). Failure to use the

personal protection equipment by operators, specialized personnel or users can involve exposure to chemical

risk and cause possible damage to health (depending on the model).

A.4 Transport, handling and storage

• Due to their size, the machines cannot be stacked on top of each other during transport,

handling and storage; this eliminates any risks of loads tipping over due to stacking.

• Do not stand under suspended loads during loading or unloading operations.

Unauthorized personnel must not enter the work area.

• The weight of the appliance alone is not sufficient to keep it steady.

15

• For machine lifting and anchoring, do not use movable or weak parts such as: casings,

electrical raceways, pneumatic parts, etc.

• Do not push or pull the machine to move it, as it may tip over. Use proper tool to lift the

machine.

• Machine transport, handling and storage personnel must be adequately instructed and

trained regarding the use of lifting systems and personal protection equipment suitable

for the type of operation carried out.

A.5 Installation and assembly

• Follow the installation instruction supplied with the machine.

• Do not install a damaged machine. Any missing or faulty parts must be replaced with

original parts.

• Do not make any modifications to the parts supplied with the machine.

• Disconnect the machine from the power supply before carrying out any installation

procedure. Connect the machine to the power supply only at the end of the installation.

• The machine is not suitable for installation outdoors and/or in places exposed to

atmospheric agents (rain, direct sunlight, freeze, humid and dusty location, etc.).

• Do not install the machine over 2000 meters above sea level.

• Make sure that the floor where you install the machine is flat, stable, heat resistant and

clean.

• If available, make sure to install the accessory to fix the machine to the floor.

• Use a ladder with suitable protection for work on machines with high accessibility.

A.6 Water connection

• The plumbing connections must be carried out by a specialised personnel.

• The machine is to be connected to the water mains using the new supplied hose-sets.

Do not use old hose sets.

• Always use a new set of joints if you remove and re-install the water inlet pipe to the

machine.

• Before connection to new pipes, pipes not used for a long time, where repair work has

been carried out or new devices fitted (water meters, etc.), let the water flow until it is

clean and clear.

• The operating water pressure (minimum and maximum) must be between:

– 0.5 bar [50 kPa] and 7 bar [700 kPa];

• Make sure that there are no visible water leaks during and after the first use of the

machine.

• Install an approved dual check valve upstream according to the regulation of the

installation country.

A.7 Electrical connection

• Work on the electrical systems must only be carried out by a specialised personnel.

• Make sure that the electrical information on the rating plate agrees with the power supply.

• Make sure to install the machine in accordance with the safety regulations and local

laws of the country where used.

• If the power cable is damaged it must be replaced by the Customer Care Service or in

any case by specialised personnel, in order to prevent any risk.

• The machine must be correctly earthed. The manufacturer is not responsible for the

consequences of an inadequate earthing system.

• If present, connected the machine to the equipotential protection circuit .

16

• To protect the power supply of the machine against short circuits and/or overloads,

install a thermal fuse or a suitable automatic thermal magnetic circuit breaker, ADS

(Automatic Disconnection of Supply).

• To protect the power supply of the machine against current leakages, install a high-

sensitivity manual reset RCD (Residual Current Device), suitable for overvoltage

category III.

• For protection against indirect contacts (depending on the type of supply provided for

and connection of earths to the equipotential protection circuit ) refer to point 6.3.3 of

EN 60204-1 (IEC 60204-1) with the use of protection devices that ensure automatic cut-

off of the supply in case of isolation fault in the TN or TT systems or, for IT systems, the

use of isolation controllers or differential current protection devices to activate automatic

power disconnection (an isolation controller must be provided for indicating a possible

first earth fault of a live part, unless a protection device is supplied for switching off the

power in case of a such a fault. This device must activate an acoustic and/or visual

signal which must continue for the entire duration of the fault). For example: in a TT

system, a residual current device with cut-in current (e.g. 30 mA) coordinated with the

earthing system of the building where the machine is located must be installed ahead of

the supply.

• On all rack type dishwasher, make sure to install an emergency switch at the infeed and

outfeed. For all additional modules installed later, move the emergency switch at the

ends of the equipment.

• For all the additional modules installed later, make sure that the power cable supply is

properly sized.

A.8 Machine cleaning and maintenance

• Refer to “A.3 Personal protection equipment“ for suitable personal protection equipment.

• Put the machine in safe conditions before starting any maintenance operation.

Disconnect the machine from the power supply and carefully unplug the power supply

cable, if present.

• Depending on the model and type of electric connection, during maintenance operations,

the cable and plug must be kept in a visible position by the operator carrying out the work.

• Do not touch the machine with wet hands or feet or when barefoot.

• Do not remove the safety guards.

• Use a ladder with suitable protection for work on machines with high accessibility.

• Respect the requirements for the various routine and extraordinary maintenance

operations. Non compliance with the instructions can create risks for personnel.

• Contact with chemical substances (e.g. detergent, rinse aid, scale remover, etc.) without

taking appropriate safety precautions (e.g. personal protection equipment) can involve

exposure to chemical risk and possible damage to health. Therefore always refer to the

safety cards and labels on the products used.

Repair and extraordinary maintenance

• Repair and extraordinary maintenance have to be carried out by specialised authorised

personnel. The manufacturer declines any liability for any failure or damage caused by

the intervention of an unauthorized technician by the Manufacturer and the original

manufacturer warranty will be invalidated.

A.9 Service

• Only original spare parts can ensure the safety standards of the appliance.

17

A.10 Disposal of packing

• Dispose of each packaging items respecting the current regulation in the country of

installation.

A.11 Machine disposal

• Work on the electrical equipment must only be carried out by a specialised personnel,

with the power supply disconnected.

• Dismantling operations must be carried out by specialised personnel.

• Make the appliance unusable by removing the power cable and any compartment

closing devices, to prevent the possibility of someone becoming trapped inside.

• Refer to “A.3 Personal protection equipment“ for suitable personal protection equipment.

• When scrapping the machine, the “CE“ marking, this manual and other documents

concerning the appliance must be destroyed.

IMPORTANT

Save these instructions carefully for further consultation by the various

operators.

B GENERAL INFORMATION

B.1 Introduction

Given below is some information regarding the intended use of

this appliance, its testing, and a description of the symbols

used (that identifies the type of warning), the definitions of

terms used in the manual and useful information for the

appliance user.

B.2 Definitions

Listed below are the definitions of the main terms used in the

manual. It is advisable to read them carefully before use.

Operator machine installation, adjustment, use,

maintenance, cleaning, repair and trans-

port personnel.

Manufacturer Electrolux Professional SpA or any other

service centre authorised by Electrolux

Professional SpA.

Operator for

normal

machine use

an operator who has been informed and

trained regarding the tasks and hazards

involved in normal machine use.

Customer

Care service

or specialised

technician

an operator instructed/trained by the

Manufacturer and who, based on his

professional and specific training, experi-

ence and knowledge of the accident-

prevention regulations, is able to appraise

the operations to be carried out on the

machine and recognise and prevent any

risks. His professionalism covers the

mechanical, electrotechnical and elec-

tronics fields.

Danger source of possible injury or harm to health.

Hazardous

situation

any situation where an operator is

exposed to one or more hazards.

Risk a combination of probabilities and risks of

injury or harm to health in a hazardous

situation.

Protection

devices

safety measures consisting of the use of

specific technical means (guards and

safety devices) for protecting operators

against risks.

Guard an element of a machine used in a specific

way to provide protection by means of a

physical barrier.

Safety device a device (other than a guard) that elimi-

nates or reduces the risk; it can be used

alone or in combination with a guard.

Customer the person who purchased the machine

and/or who manages and uses it (e. g.

company, entrepreneur, firm).

Emergency

stop device

a group of components intended for the

emergency stop function; the device is

activated with a single action and pre-

vents or reduces damage to persons/

machines/property/animals.

Electrocution an accidental discharge of electric current

on a human body.

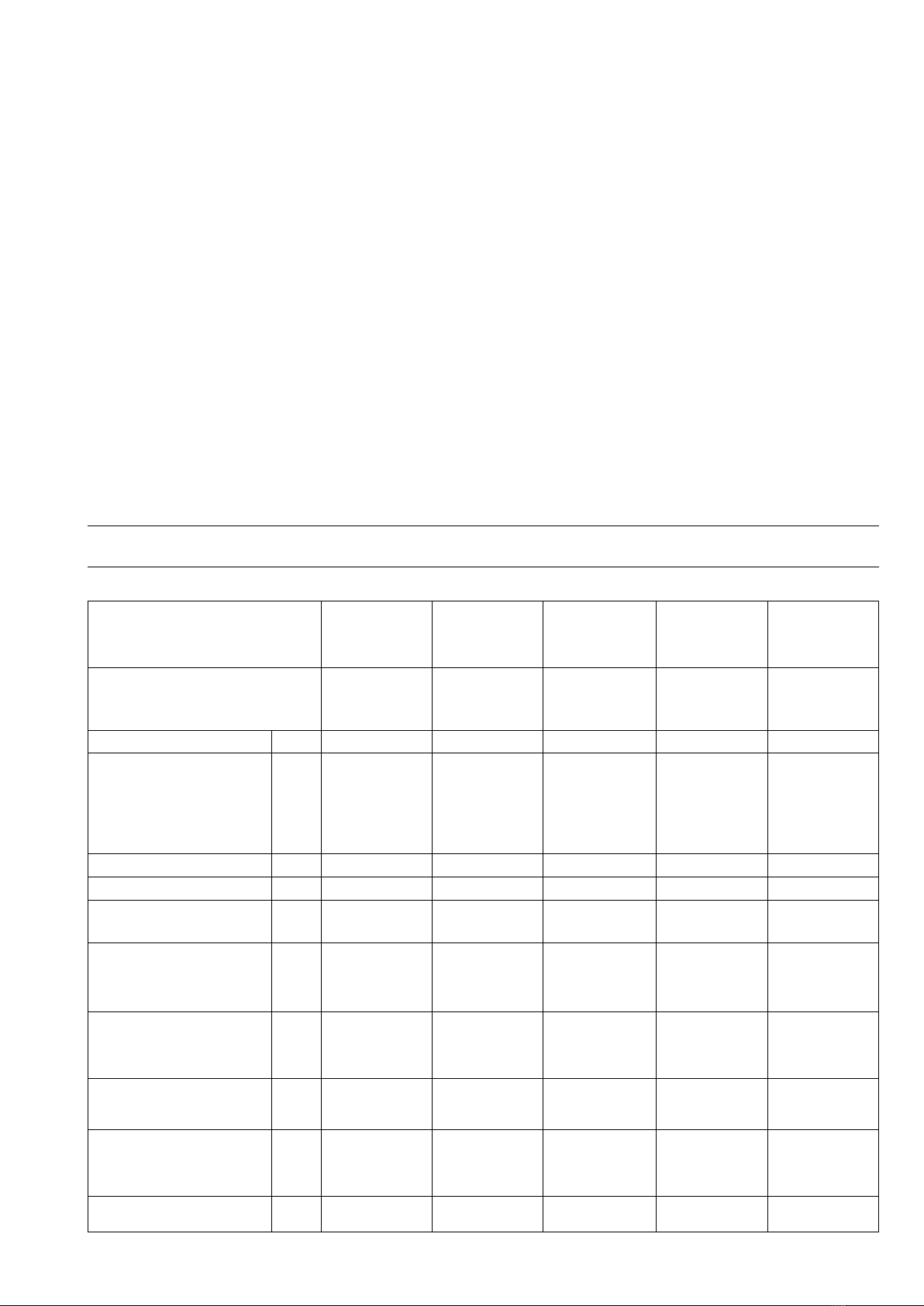

B.3 Machine and Manufacturer‘s

identification data

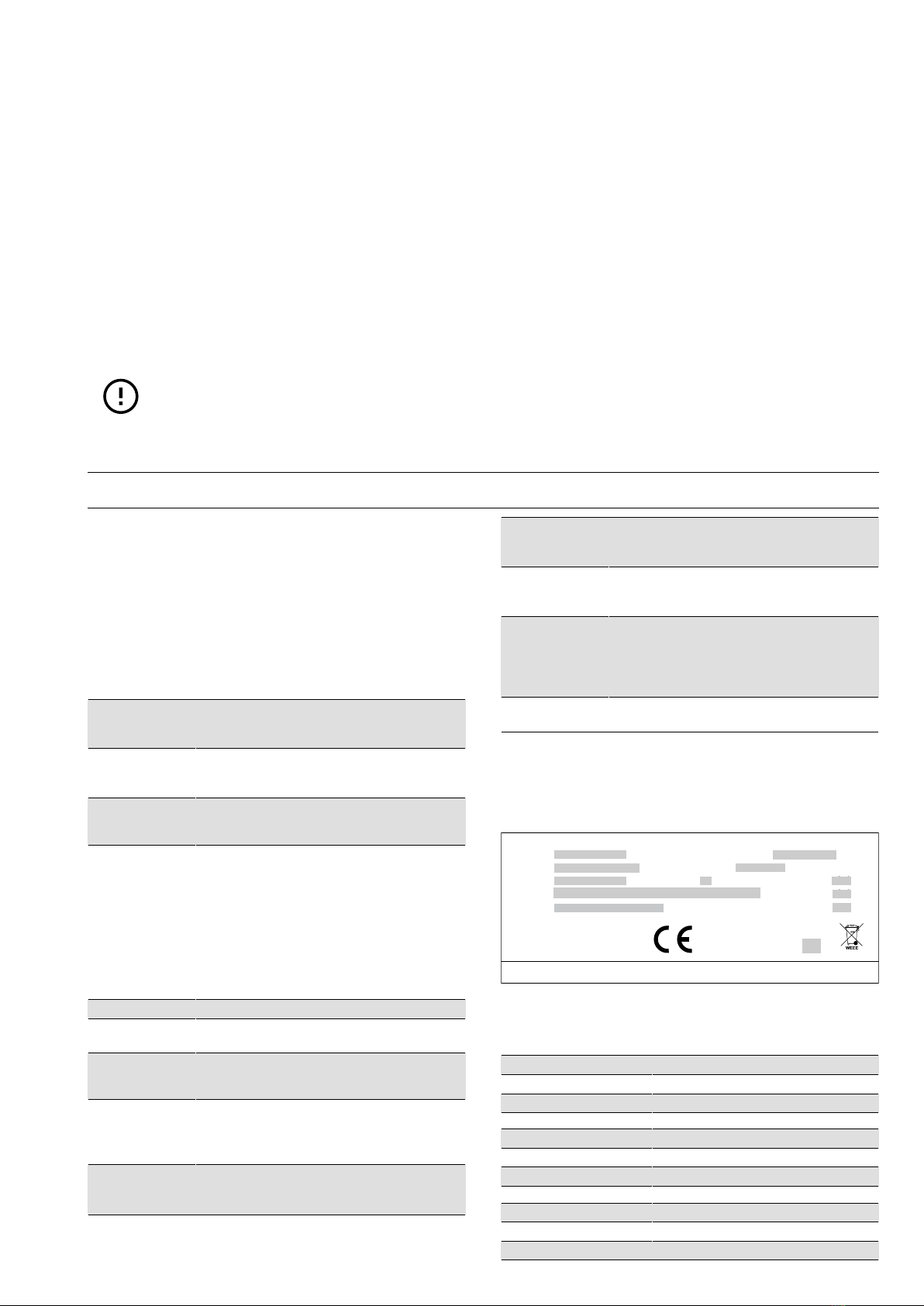

An example of the marking or dataplate on the machine is

given below:

The dataplate gives the product identification and technical

data; listed below is the meaning of the various information

given on it.

F.Mod. factory description of product

Comm.Model commercial description

PNC production number code

Ser.No. serial number

400V 3N~ power supply voltage

230V 3~ - 230V 1N~ electric convertibility

Hz power supply frequency

12.9 kW max. power

9.9 kW nominal power

6.9 kW min. power

IPX25 dust and water protection rating

2017F.Mod.

Comm. Model: PNC Ser.Nr. EL Hz Max 12.9 kW Nominal 9.9 kW

6.9 kWMin

Eletrolux Professional spa - Viale Treviso, 15 - 33170 Pordenone (Italy)

IP

Type ref.

18

Type ref. list of acronyms used to identify the

type of machine, uniquely

CE CE marking

Electrolux Professio-

nal SpA Viale Treviso

15 33170 Pordenone

Italy

manufacturer

The dataplate is located on the right side panel of the

equipment.

WARNING

Do not remove, tamper with or

make the machine marking

illegible.

IMPORTANT

When scrapping the machine, the marking must be

destroyed.

NOTE!

Refer to the data given on the machine marking for

relations with the Manufacturer (e.g. when ordering

spare parts, etc.).

B.4 Appliance identification

B.4.1 How to identify the technical data

To identify the technical data, read the factory description of

the product (F. Mod.) on the dataplate, identify the main

machine data and consult “Main technical characteristics,

performance and consumption”.

B.4.2 How to interpret the factory description

The factory description on the dataplate has the following

meaning (some examples are given below):

Single-Skin version

(1) (2) (3) (4) (5) (6) (7)

N HT 8 WS G

E HT 8 M

Z HT 8 L G UK

V HT 7 G

Double-Skin version

(1) (2) (3) (4) (5) (6) (7)

Z HT 8 I E L G

E HT 8 T I E L

V HT 7 I G

Variable description

(1) Brand E = Electrolux, Z = Zanussi, N = To brand,

K = Kipro, A = Alpeninox, H = Hakpro, KXT

= Klumaier X Tanner, V = Veetsan

(2) Machine

type

HT = Hood Type

(3) Racks/

hour

8 = 80 racks/hour

7 = 72 racks/hour

(4...7) Appli-

ance

equipment

T = automatic, I = double skin hood, E =

Energy Saving Device, L = delime cycle, G

= detergent pump + rinse aid pump + drain

pump, DD = detergent pump, WS = water

softener, M = marine, USPH = marine-

USPH, 6 = 60 Hz, UK = UK market, S =

solid detergent.

B.4.3 How to interpret the type reference

The type reference description on the dataplate has the

following meaning.

Legend

AType of appliance

• Hood type dishwasher

BType of rinsing

• 0 = without rinse pump

• 1 = with rinse pump

CWater treatment

• 0 = without water softener

• 1 = with water softener

DType oh hood

• 0 = manual hood

• 1 = automatic hood

EEnergy Saving Device [ESD]

• 0 = without ESD

• 1 = with ESD

FHeating element in the boiler

• 0 = single heating element

• 1 = double heating element

2012F.Mod. EHT8I Comm. Model EHT8IPNC 9CGX 504259 00 Ser.Nr. 22006001EL AC 400V 3N 50 Hz Max 12.9 kW

(AC 230 V / 1+N / 50 Hz; 230 V / 3 / 50 Hz )

Nominal 9.9 kW Min 6.9 kW

Eletrolux Professional spa - Viale Treviso, 15 - 33170 Pordenone (Italy)

IP25

Main technical characteristics

MODEL

EHT8I

Supply Electric

Power supply voltage V 400 3 N~

Frequency Hz 50 or 60

F.Mod. EHT8I

Eletrolux Professional spa - Viale Treviso, 15

2017

F.Mod.

Comm. Model:

PNC Ser.Nr.

EL Hz Max 12.9 kW

Nominal 9.9 kW

6.9 kWMin

Electrolux Professional spa - Viale Treviso, 15 - 33170 Pordenone (Italy)

IP

Type ref.

NHT

* * * * *

A B C D E F

19

B.5 Responsibility

The Manufacturer declines any liability for damage and

malfunctioning caused by:

• non-compliance with the instructions contained in this

manual;

• repairs not carried out in a workmanlike fashion, and

replacements with parts different from those specified in

the spare parts catalogue (the fitting and use of non-original

spare parts and accessories can negatively affect machine

operation and invalidates the original manufacturer

warranty);

• operations carried out by non-specialised personnel;

• unauthorized modifications or operations;

• missing, lack or inadequate maintenance;

• improper machine use;

• unforeseeable extraordinary events;

• use of the machine by uninformed and / or untrained

personnel;

• non-application of the current provisions in the country of

use, concerning safety, hygiene and health in the workplace.

The Manufacturer declines any liability for damage caused by

arbitrary modifications and conversions carried out by the user

or the Customer.

The employer, workplace manager or service technician are

responsible for identifying and choosing adequate and suitable

personal protection equipment to be worn by operators, in

compliance with regulations in force in the country of use.

The Manufacturer declines any liability for inaccuracies con-

tained in the manual, if due to printing or translation errors.

Any supplements to the installation, use and maintenance

manual the Customer receives from the Manufacturer will form

an integral part of the manual and therefore must be kept

together with it.

B.6 Copyright

This manual is intended solely for consultation by the operator

and can only be given to third parties with the permission of

Electrolux Professional company.

B.7 Keeping the manual

The manual must be carefully kept for the entire life of the

machine, until scrapping. The manual must stay with the

machine in case of transfer, sale, hire, granting of use or

leasing.

B.8 Recipients of the manual

This manual is intended for:

• the carrier and handling personnel;

• installation and commissioning personnel;

• specialised personnel - Customer Care service (see service

manual).

C TECHNICAL DATA

C.1 Main technical characteristics

Model NHT8/EHT8/

KHT8/HHT8/

XHT8/ZHT8/

VHT7/

ZHT8I/AHT8I/

EHT8I/NHT8I/

HHT8I/XHT8I/

VHT7I/

EHT8M/

EHT8IUSPH5

EHT8M6/

EHT8IUSPH6

EHT8TIL/

ZHT8TIL

Supply voltage:

convertible to

single-phase version

400V 3N~

230V 3~

230V 1N~

400V 3N~1

230V 3~1

230V 1N~1

400V 3~

—

—

440V 3~

—

—

400V 3N~

230V 3~

230V 1N~

Frequency Hz 50 50 or 60 50 60 50

Max. power

kW

12.9212.9212.9212.9212.92

Power absorbed as factory

setting 9.9 9.9 9.9 9.9 9.9

Power absorbed with water

supply at 65℃[149℉]6.936.93— — 6.93

Boiler heating elements kW 9.0 9.0 9.0 9.0 9.0

Tank heating elements kW 3.0 3.0 3.0 3.0 3.0

Water supply pressure kPa

[bar]

50 - 700

[0.5 - 7]

50 - 700

[0.5 - 7]

50 - 700

[0.5 - 7]

50 - 700

[0.5 - 7]

50 - 700

[0.5 - 7]

Water supply temperature: ℃

[℉]

— for models without ESD 10-65 [50-149] 10-65 [50-149] 10-65 [50-149] 10-65 [50-149] 10-65 [50-149]

— for models with ESD —10-20 [50-68] — — 10-20 [50-68]

Water supply hardness for

models without incorpo-

rated continuous water

softener

°f/°d/

°e 14/8/10 max 14/8/10 max 14/8/10 max 14/8/10 max 14/8/10 max

Water supply hardness for

models with incorporated

water softener

°f/°d/

°e

53.4/30/

35.7 max

53.4/30/

35.7 max

53.4/30/

35.7 max

53.4/30/

35.7 max

53.4/30/

35.7 max

Electric conductivity of

water for models without

incorporated continuous

water softener

μS/

cm <400 <400 <400 <400 <400

Concentration of chlorides

in water ppm <20 <20 <20 <20 <20

20

Model NHT8/EHT8/

KHT8/HHT8/

XHT8/ZHT8/

VHT7/

ZHT8I/AHT8I/

EHT8I/NHT8I/

HHT8I/XHT8I/

VHT7I/

EHT8M/

EHT8IUSPH5

EHT8M6/

EHT8IUSPH6

EHT8TIL/

ZHT8TIL

Rinse cycle water

consumption l 2.042.042.0 2.0 2.0

Boiler capacity l 12 12 12 12 12

Tank capacity l 24 24 24 24 24

Cycle duration in “High

Productivity“ mode5sec.

45-84-150

50-84-150

(VHT7G)

45-84-1506

50-84-150

(VHT7IG)

45-84-150 45-84-150 45-84-1506

Cycle duration in “NSF/

ANSI3“ compliant mode5sec. 57-84-150 57-84-150657-84-150 57-84-150 57-84-1506

Legal noise level Leq7

dB[A] LpA:68dB

KpA:1.5dB

LpA:68dB

KpA:1.5dB

LpA:68dB

KpA:1.5dB

LpA:68dB

KpA:1.5dB

LpA:68dB

KpA:1.5dB

Protection rating IPX25 IPX25 IPX25 IPX25 IPX25

Net weight for models with-

out [with] ESD kg 106 [-] 117 [150] 117 [-] 117 [-] 119 [152]

Power supply cable H07RN-F H07RN-F H07RN-F H07RN-F H07RN-F

Supply cord diameter (min.

- max. value)

mm 18 - 25 18 - 25 18 - 25 18 - 25 18 - 25

Latent heat without [with]

ESD

kWh 0.5 [-] 0.5 [0.35] 0.5 [-] 0.5 [-] 0.5 [0.35]

Sensible heat without [with]

ESD

kWh 2 [-] 2 [1.49] 2 [-] 2 [-] 2 [1.49]

1. For the model EHT8IELG6: 380-400V 3N~ convertible 220-230V 3~ or 220-230V 1N~.

2. If activated by software, coincidence of tank and boiler heating elements.

3. Activatable via software only by a specialized technician.

4. For models VHT7G and VHT7IG 2.3 liters.

5. With water supply temperature at 65℃[149℉].

6. In models with Energy Saving Device (ESD) cycle duration is extended by 11 seconds.

7. The noise emission values have been obtained according to EN ISO 11204.

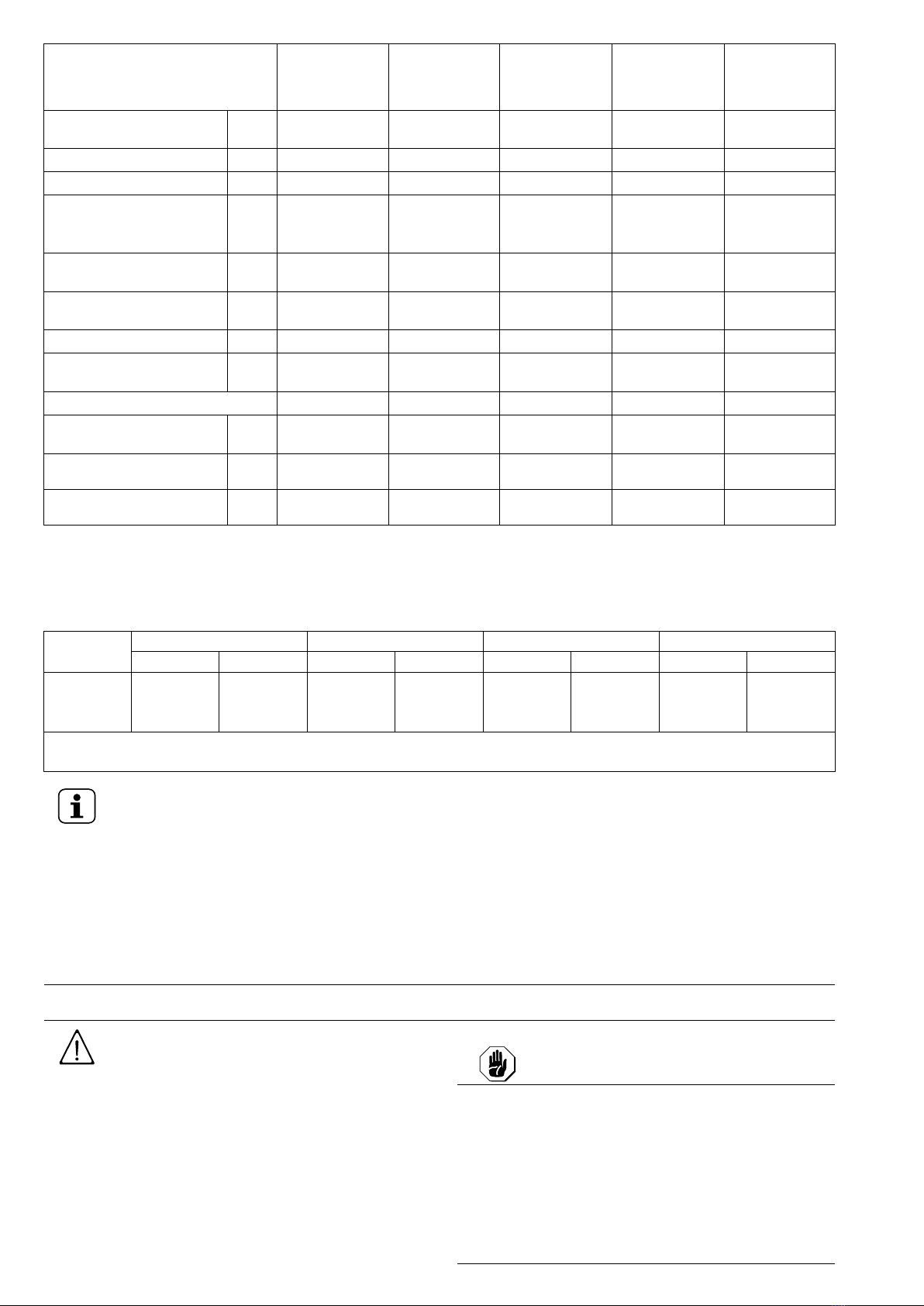

380 – 415V 3N 400 – 440V 3 220 – 240V 3 220 – 240V 1N

C S C S C S C S

6.9 kW

9.9 kW

12.9 kW

5x2.5 mm2

5x2.5 mm2

5x4 mm2

16A 3P + N

20A 3P + N

32A 3P + N

5x2.5 mm2

4x2.5 mm2

4x4 mm2

16A 3P

20A 3P

25A 3P

4x4 mm2

4x6 mm2

4x10 mm2

20A 3P

32A 3P

50A 3P

3x6 mm2

3x10 mm2

3x10 mm2

40A 1P + N

60A 1P + N

70A 1P + N

C = Power supply cable

S = On/Off switch

NOTE!

Standard cycle time may vary should the inlet water temperature and/or the boiler heating elements be different from

that indicated above.

C.2 Characteristics of power supply

The AC power supply to the machine must meet the following conditions:

• max. voltage variation ± 6%

• max. frequency variation ± 1% continuous ± 2% for a short period.

Harmonic distorsion, unbalanced three-phase supply voltage, voltage pulses, interruption, dips and the other electric character-

istics must respect the provisions of point 4.3.2 of Standard EN 60204-1 (IEC 60204-1).

D TRANSPORT, HANDLING AND STORAGE

WARNING

Refer to chapter “A SAFETY

INFORMATION“.

D.1 Introduction

Transport (i. e. transfer of the machine from one place to

another) and handling (i. e. transfer inside workplaces) must

occur with the use of special and adequate means.

CAUTION

The machine must only be transported, handled and stored

by specialised personnel, who must have:

• specific technical training and experience in the use of

lifting systems;

• knowledge of the safety regulations and applicable laws

in the relevant sectors;

• knowledge of the general safety rules;

• personal protection equipment suitable for the type of

operation carried out;

• the ability to recognize and avoid any possible hazard.

This manual suits for next models

19

Table of contents

Other Electrolux Professional Dishwasher manuals