Doc. No.: 560001 EG

Page:4 Ed.1" 08-2014

From ser. no.:

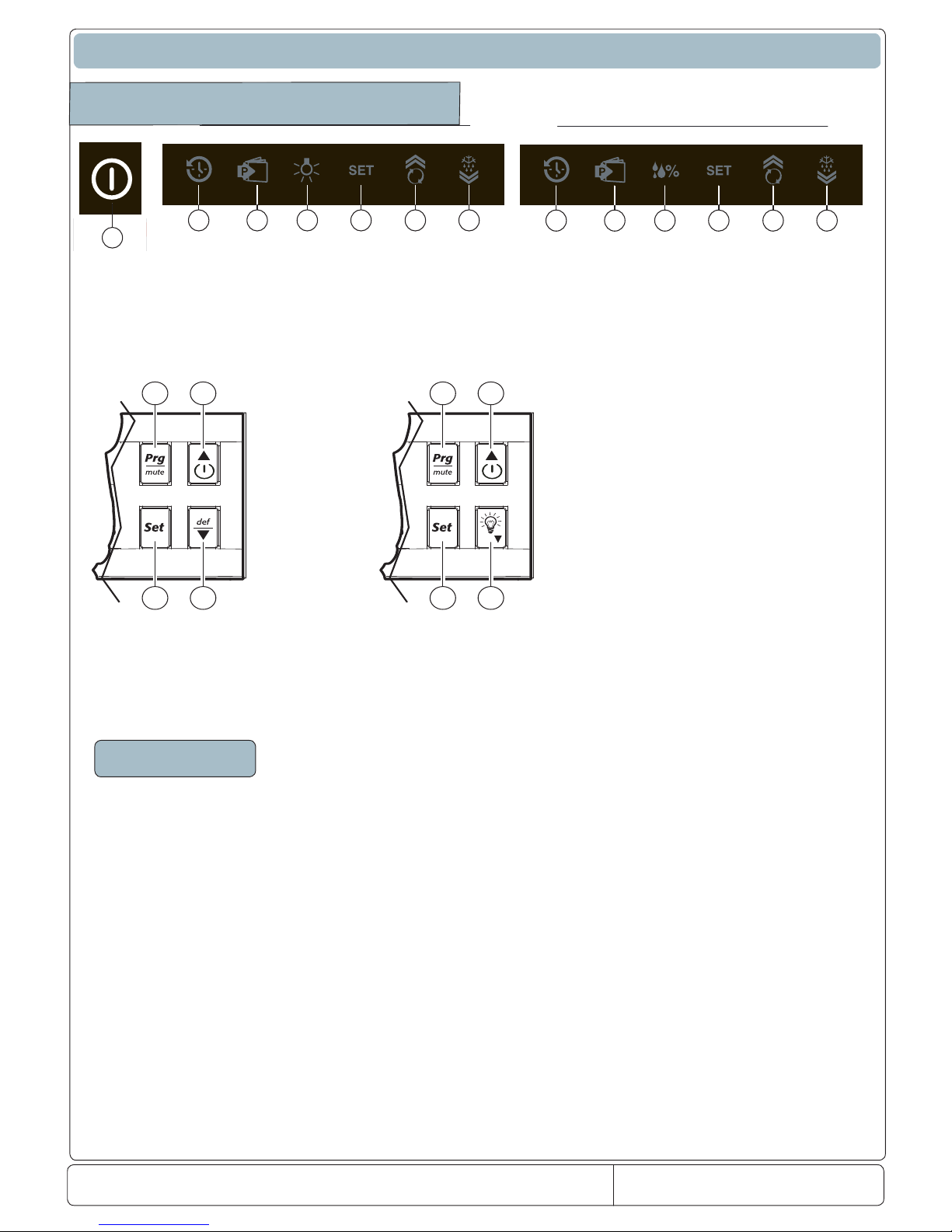

INSTRUMENT PROGRAMMING

Operation parameters, completely modiable from front keypad. Access to these is protected by a password that prevents random changes or modications by

unauthorised persons.

Accessing parameters (configuration):

1. press the PRG and SET buttons together for more than 5 seconds and the display will show "00", password required;

2. use the buttons or to scroll the numbers until displaying "11" (Password for accessing parameters);

3. conrming with SET, the rst modiable parameter will appear on the display.

Modifying parameters

After displaying the parameter, proceed as follows:

1. use the buttons or to scroll the parameters to the one to be modied. Scrolling is accompanied by lighting up of an icon on the display, representing the

parameter category. Alternatively, press the PRG button to display a menu of the categories or parameters for quickly accessing the family of parameters to be

changed;

2. scroll the menu with the buttons and and the codes of the various parameter categories (see "Summary of operation parameters") are displayed, together

with lighting up of the corresponding icon (if present);

3. on accessing the category, press SET to go straight to the rst parameter of the selected category (if no parameter is visible, pressing the SET button will

have no eect);

4. it is possible to continue consulting the parameters or return to the categories menu with the PRG button;

5. press SET to display the value associated with the parameter;

6. increase or decrease the value respectively with the buttons and ;

7. press SET to temporarily save the new value and return to the display of the parameter. Repeat the procedure from step 1 or step 2;

8. if the parameter has subparameters, press SET to display the rst subparameter;

9. press the buttons or to view all the subparameters;

10. press SET to display the associated value;

11. increase or decrease the value respectively with the buttons or ;

12. press SET to temporarily save the new value and return to the display of the subparameter code;

13. press PRG to return to the display of the parent parameter.

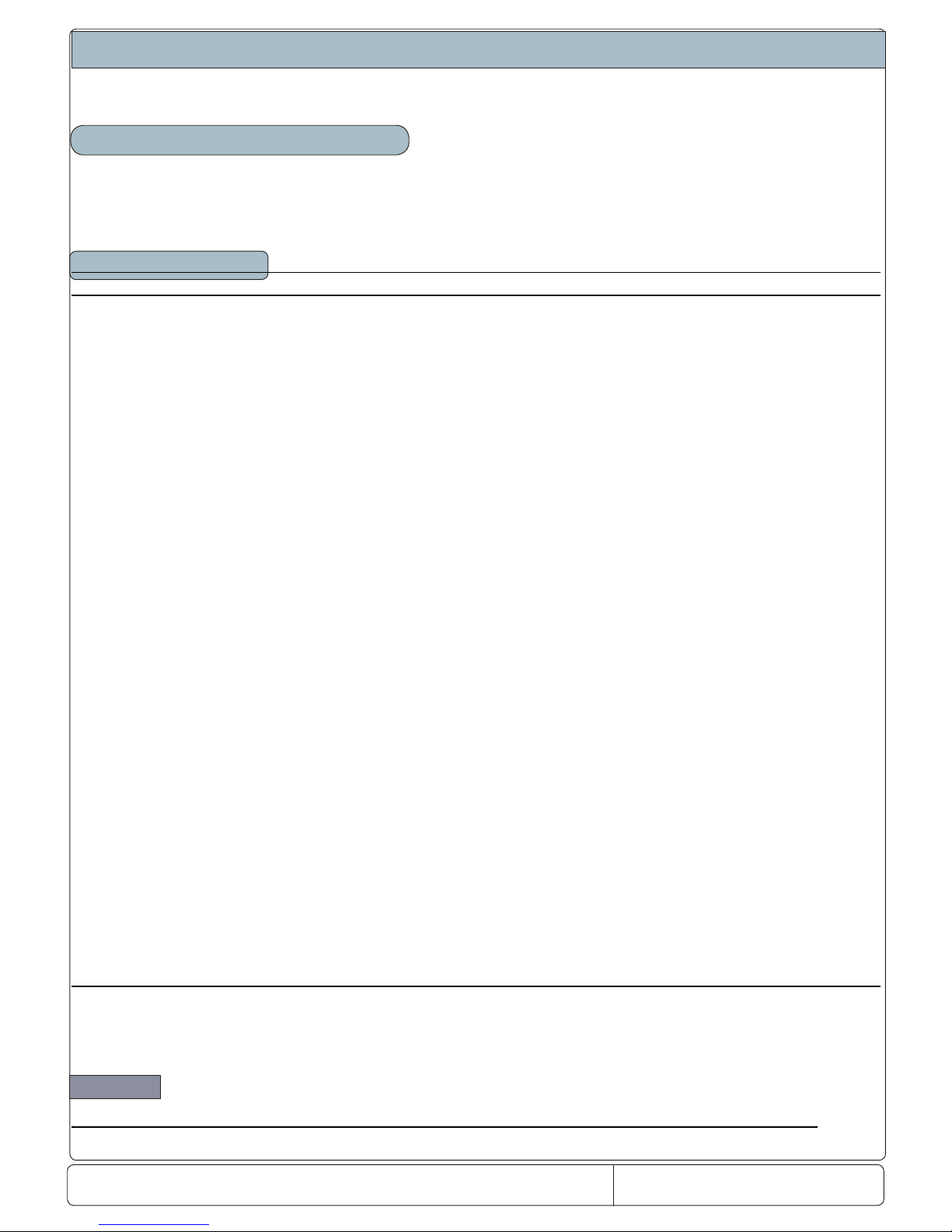

Saving new values assigned to parameters

To permanently save the values of the modied parameters, press the PRG button for more than 5 seconds, thus exiting the parameter modication proce-

dure. It is possible to cancel all the parameter modications, temporarily stored in RAM, and return to "normal operation" by not pressing any button for 60 seconds,

thus allowing the parameter modication session to expire forTIMEOUT.

Attention:If the modication session expires for timeout, the parameters will not be not restored.

If the power to the instrument is switched o before pressing the PRG button, all changes made to the parameters and temporarily saved will be lost.