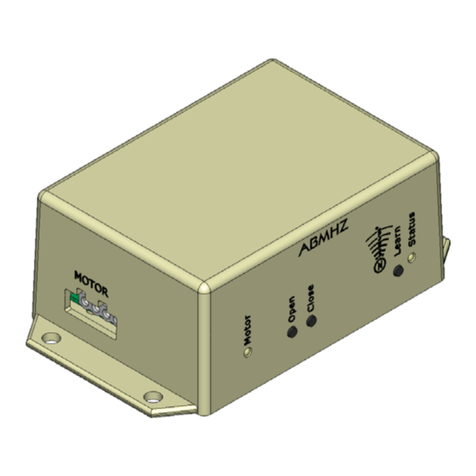

Electronic Solutions ABMHZ Assembly instructions

ABMHZ Version 1+1

Advanced User Manual

20 November 2007 Rev. B ©2007, Electronic Solutions, Inc. page 1 of 5

1355 Horizon Avenue, Lafayette, CO 80026-9304 USA

voice: +1.303.469.9322 fax: +1.303.469.5129 www.elec-solutions.com

Electronic

Solutions, Inc.

1. Introduction

This document is for the advanced user who has knowledge of the Z-Wave™

Command Classes and is able to initiate Z-Wave commands programmatically.

When the ABMHZ sends a Node Info Report, it reports itself as a Basic Slave

device with generic support for Multilevel switch, specifically supporting the Multi-

position motor class. In addition to the mandatory command classes, it also

supports Manufacturer Specific, Version, All Switch, Configuration, and Power level

command classes (details and examples on how to utilize these classes below).

2. Status LED

On power-up, LED blinks GREEN once indicating Z-Wave processor Version 1.

This LED will blink green on reception of a valid Z-Wave command.

This LED will blink red if an error has occurred.

3. Motor LED

On power-up, this LED will blink RED once indicating motor processor Version 1.

This LED will stay red after power-up if the unit is not calibrated.

This LED will be green when ready for calibration (please see Calibration section).

4. COMMAND_CLASS_CONFIGURATION Commands

There are 3 configuration parameters accessible via the

COMMAND_CLASS_CONFIGURATION. Each parameter is a single byte, and can

only contain the value of 1 or 0.

Sample commands:

To check unit calibration state, send CONFIGURATION_GET, 1. Return is a 0 or 1.

To check unit motor direction state, send CONFIGURATION_GET, 2. Return is a 0

or 1.

To check unit tilt feature state, send CONFIGURATION_GET, 3. Return is a 0 or 1.

To initiate calibration sequence, send CONFIGURATION_SET, 1, 1, 1.

To set motor direction to reversed and calibrate, send CONFIGURATION_SET, 2, 1,

1 (if already reversed, then no action).

To return all settings to factory default, send CONFIGURATION_SET, 1, 129, 1.

ABMHZ Version 1+1

Advanced User Manual

20 November 2007 Rev. B ©2007, Electronic Solutions, Inc. page 2 of 5

Configuration

parameter #

Length

(bytes)

Read values

Write values

Description

1

1

0 = Not calibrated

1 = Calibrated

0 = No Action

1 = Begin calibration

sequence

Unit calibration state.

2

1

0 = Motor direction

normal

1 = Reversed motor

direction

0 = Set direction to

“normal” and begin

calibration sequence

1 = Set direction to

reverse and begin

calibration sequence

Unit calibrated for normal

or reversed motor

direction.

3

1

0 = Tilt feature not

enabled

1 = Tilt feature

enabled

0 = Disable tilt

1 = Enable tilt

Allows precision

positioning of wood blinds.

1,2, or 3

129

n/a

0 or 1 = Return to factory

defaults

Unit uncalibrated, motor

direction normal, tilt

disabled

5. COMMAND_CLASS_BASIC Commands

A BASIC_GET will return a motor position value between 0 and 99, or 255. A

value of 255 means the motor is not calibrated, and cannot report a valid position.

(The Motor LED will also be red)

A BASIC_SET 0 will move the shade of a properly calibrated motor to the fully

closed position. A BASIC_SET 99 or 255 will move the shade to the fully open

position. Sending BASIC_SET 255 to an un-calibrated motor will also cause it to

move to a limit. Sending a BASIC_SET X (where X is 1 to 99) command to an

uncalibrated motor will result in no motion. The Status LED will blink red to

indicate an error condition.

Sample commands:

To move shade to 50%, send BASIC_SET 50.

To check current shade position, send BASIC_GET. The return value is 0 to 99.

ABMHZ Version 1+1

Advanced User Manual

20 November 2007 Rev. B ©2007, Electronic Solutions, Inc. page 3 of 5

6. COMMAND_CLASS_SWITCH_MULTILEVEL Commands

A MULTILEVEL_SWITCH_GET will return a motor position value between 0 and 99,

or 255. A value of 255 means the motor is not calibrated, and cannot report a

valid position. (The Motor LED will also be red)

A MULTILEVEL_SWITCH_SET 0 will move the shade of a properly calibrated motor

to the fully closed position. A MULTILEVEL_SWITCH_SET 99 or 255 will move the

shade to the fully open position. Sending MULTILEVEL_SWITCH_SET 255 to an

uncalibrated motor will also cause it to move to a limit.

Sending a MULTILEVEL_SWITCH_START_LEVEL_CHANGE with parameter 1, bit 6

clear, causes the position value to increase and the shade opens regardless of the

calibration status.

Sending a MULTILEVEL_SWITCH_START_LEVEL_CHANGE with parameter 1, bit 6

set, causes the position value to decrease and the shade closes regardless of the

calibration status.

The values of the Ignore Start Level bit (parameter 1, bit 5) and the Start Level

parameter (parameter 2) are ignored. However, for compatibility with other Z-

Wave devices, the Ignore Start Level bit should be set to 1.

Sending a MULTILEVEL_SWITCH_STOP_LEVEL_CHANGE at any time will stop the

motor.

Sample commands:

To move shade to 50%, send MULTILEVEL_SWITCH_SET 50.

To check current shade position, send MULTILEVEL_SWITCH_GET. The return

value is 0 to 99.

To force a shade open (regardless of whether the motor control is calibrated),

send

MULTILEVEL_SWITCH_START_LEVEL_CHANGE 32.

To force a shade closed (regardless of whether the motor control is calibrated),

send MULTILEVEL_SWITCH_START_LEVEL_CHANGE 96.

7. COMMAND_CLASS_SWITCH_ALL Commands

The Factory default setting for SWITCH_ALL is ALL_ON and ALL_OFF commands

disabled.

Send SWITCH_ALL_GET to get the SWITCH_ALL_ON and SWITCH_ALL_OFF

status.

ABMHZ Version 1+1

Advanced User Manual

20 November 2007 Rev. B ©2007, Electronic Solutions, Inc. page 4 of 5

Send SWITCH_ALL_SET 0 to disable SWITCH_ALL_ON and SWITCH_ALL_OFF

commands.

Send SWITCH_ALL_SET 1 to enable SWITCH_ALL_OFF commands only.

Send SWITCH_ALL_SET 2 to enable SWITCH_ALL_ON commands only.

Send SWITCH_ALL_SET 255 to enable both SWITCH_ALL_ON and

SWITCH_ALL_OFF commands.

8. COMMAND_CLASS_POWERLEVEL Commands

Send POWERLEVEL_TEST_NODE_SET, 2, 0, 0, 100 to have this node send 100

test frames at maximum signal strength to node 2. When the test completes,

node 2 sends a POWERLEVEL_TEST_NODE_REPORT back. If a single message is

acknowledged, the test passes. The last 2 parameters represent the number of

test frames acknowledged.

It is also possible to query for the results of the last test by sending a

POWERLEVEL_TEST_NODE_GET.

Send POWERLEVEL_SET, 5, 60 to set node to power level 5 (mid-level power) for

60 seconds.

9. COMMAND_CLASS_MANUFACTURER_SPECIFIC Command

Send MANUFACTURER_SPECIFIC_GET. The return message should be 0x00,

0x33, 0x52, 0x50, 0x30, 0x31 This shows the ESI product data as Manufacturer

ID: 0033, Product Type ID: “RP”, and Product ID: “01”.

10. COMMAND_CLASS_VERSION Commands

Send VERSION_GET.

The returned message is 0x04, 0x02, 0x06, 0x01, 0x01, 0x5A.

This represents Library type 4 for basic slave device

Protocol Version 2

Protocol Sub Version 6

Application Version is the Z-Wave™ processor code version (currently 1)

Application Sub Version is the motor processor code version (currently 1)

11. Manual Buttons

The two small push-button located on the side of the unit are labeled “OPEN” and

“CLOSE”.

Pressing the OPEN button should open the shade.

ABMHZ Version 1+1

Advanced User Manual

20 November 2007 Rev. B ©2007, Electronic Solutions, Inc. page 5 of 5

If the OPEN button closes the shade instead of opening it, the motor direction

must be reversed using one of the following:

1. Use the reverse direction & calibrate button sequence

2. Set Configuration Parameter #2 to a 1

3. Swap motor directional wires on the motor connector.

Pressing the CLOSE button should close the shade. (If it does not, fix this as

described above)

A press of either button while the shade is moving will cause the shade to stop.

12. Calibration

Calibration is required before SET and GET will work correctly. Calibration is

accessed by pressing and holding down both the OPEN and CLOSE buttons

simultaneously for approximately 10 seconds, until the Motor LED turns green.

While the Motor LED is green (within 10 seconds):

Press the CLOSE button to start a calibration sequence.

- or -

Press the OPEN button to reverse the motor direction and start a calibration

sequence.

A calibration sequence consists of the shade moving between the upper and lower

limits and stopping at the fully closed position.

After the calibration sequence completes, the Motor LED turns off.

NOTE: The ABMHZ is a Z-Wave enabled device and is fully compatible with any Z-Wave enabled network. Z-Wave

enabled devices displaying the Z-Wave logo can also be used with ESI Z-Wave enabled motor controllers such as

ABMHZ regardless of the manufacturer. ESI Z-Wave enabled motor controllers can also be used in other

manufacturer’s Z-Wave enabled networks and all listening devices act as repeaters, regardless of vendor.

Other Electronic Solutions Controllers manuals