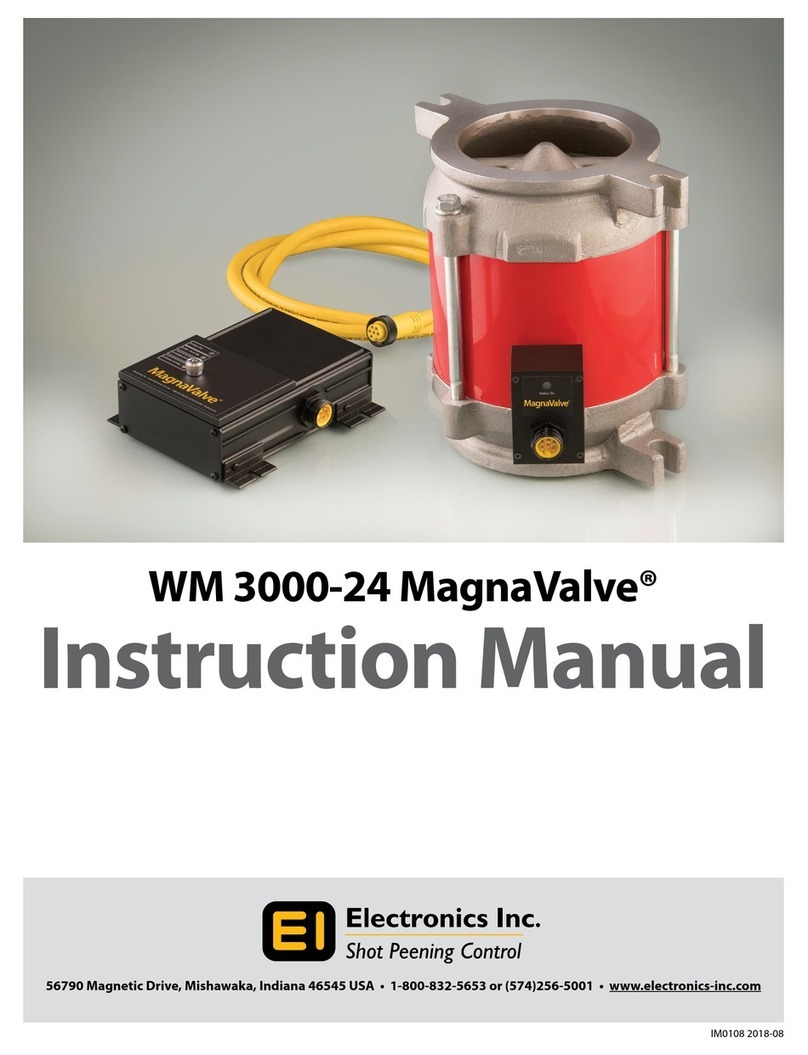

Electronics 250-N User manual

Instruction Manual

Standard Accuracy Series MagnaValves™

Standard Accuracy Series MagnaValves

IM:0072 Revision: G Date: 2/13/13

For the Following

MagnaValve Models

250-N 1578

500-N 579

577 1579

1577 580

578 590

Hybrid Installations

VLP+599-5.0

LP+599-5.0

*Added 1500 Series

16 July, 2002

Made in the USA

Electronics Inc.

56790 Magnetic Drive

Mishawaka, Indiana 46545

1-800-832-5653 (Toll Free)

Phone: 1-574-256-5001

Fax: 1-574-256-5222

Website: www.electronics-inc.com

2

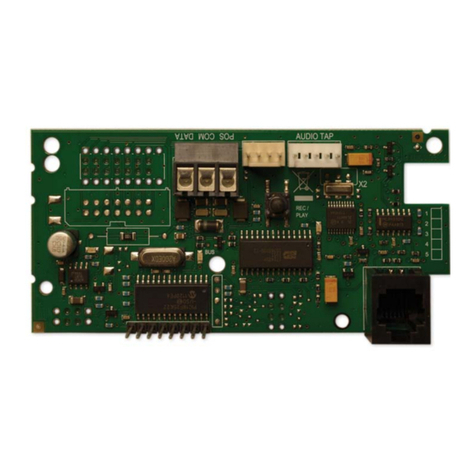

Wiring Diagram

3

Factory MagnaValve Connections

Sensor wires Power Coils

White (clear) Black Orange Brown

Two LED’s indicate the

presence of ±12Vdc.

Conduit Ports

Red Black Orange Brown

Valve Driver Connections

SPAN Adjustment – Used to cali-

brate the maximum flow

ZERO Adjustment – Used to set

0 Volts for a no flow condition

Pair 1 White 1. 0-5VDC out

Black 2. 0VDC

Pair 2 Green 3. +12VDC

Black 4. –12VDC

Pair 3 Red 5. (+) MagnaValve

Black 6. (-) MagnaValve

Typical Customer wiring connections

Notes:

1. The Magna valve is calibrated at the factory. A catch and weigh test is recommended during

installation. Make any adjustments for maximum flow using the Span at the Magnavalve only.

2. All cable shields at the valve must be isolated from any part of the valve and machine. The

shields should be terminated at the controller only.

3. A separate conduit for MagnaValve cables must be used to prevent and interference from oth-

er equipment. Multiple MagnaValve cables may be routed in the same conduit.

4

1. Introduction

This instruction manual covers the MagnaValve models listed in Table 1. A pre-Amp is used

to provide a flow rate signal and transmit it back to the FC Controller as a 0-5 Vdc analog sig-

nal with ±10% accuracy.

Custom calibrations may be used when special conditions prevail; however, we recommend

the standard ranges listed above be used whenever possible because all production valves

are pre-calibrated to the standard ranges shown. An emergency request for a spare Magna-

Valve calibrated to standard range is usually handled within 24 hours. A non-standard cali-

bration may require one week to allow access to the calibration.

2. Theory of Operation

The MagnaValve is a magnetic valve used to control the flow rate of steel shot used in shot

peening and abrasive blast cleaning machines. There are no moving parts in the Magna-

Valve. A strong permanent magnetic field holds the shot. Application of power from the Model

FC controller will cancel the magnetic field and allow shot to flow. The valve is pulsed at eight

times per second (8 Hz) to modulate the flow rate. A special sensor is located in the lower

section of the MagnaValve (or in the 599-5.0 sensor mounted below the MagnaValve for hy-

brid installations) to detect the actual shot flow rate. The sensor signal is processed by the

pre-amp and then sent to the FC controller for feedback information.

A valve driver module is used at each valve to precisely regulate the cancellation current to

assure zero residual magnetic field. The valve driver module is factory set at an amperage

value listed on the valve driver module and does not require any customer adjustment.

Valve Model Maximum Flow

Rate (Lb./min) Operating

Range (Lb./min)

250-N 700 70-700

500-N 1200 120-1200

577 2 .2-2

578 20 3-30

579 100 10-100

580 200 20-200

590 300 30-300

VLP

599-5.0 Sensor 1,000 100-1000

LP

599-5.0 Sensor 1,999 200-2000

1577 2 .2-2

1579 100 10-100

Table 1 MagnaValve Models

5

The Pre-Amp is factory calibrated and should not require any customer attention. The full-

scale output voltage feedback signal of the Pre-Amp is 5.00 Vdc. The pre-amp uses an oscil-

lator circuit and inductive sensor to detect metal density (shot flow) and converts this frequen-

cy into a 0-5 Vdc output feedback signal.

3. Calibration

SUMMARY –

Set MagnaValve Pre-amp zero output

Set Pre-Amp span to achieve full-scale flow

Confirm accuracy (perform catch & weigh tests)

Full-scale flow range is the maximum flow, in pounds per minute, required for your installation.

See Table 2. The MagnaValve pre-amp has been factory calibrated and should not need ad-

justment. In the event re-calibration is desired the following steps should be followed.

A. With no shot flowing, adjust the zero trimpot to achieve 0VDC output feedback signal.

B. Perform a catch and weigh test to ascertain flow rate at maximum capacity.

C. Adjust the span trimpot if required. Repeat the catch test to confirm accuracy.

D. You must also match the Model FC Controller display to the MagnaValve pre-amp out-

put signal. The Model FC Control display is used for many different size MagnaValves

and therefore many display ranges are used. The FC Control display range can be

changed as required for any particular MagnaValve. For example, to change the model

FC Control display to 0-700 lbs/min full scale range.

E. Turn setpoint knob to 100% (Full CW).

F. Be sure the FC Control is in local mode, not remote mode. See the LED indicators on

the front panel and use the local/remote slide switch if necessary.

G. Push and hold display toggle until the FC Control display reads 700.

H. The Model FC Control front panel span adjustment is factory set so that a 5.00 VDC

signal input will display the proper full scale signal, such as 700.

To check this feature you may inject a precision 5.00VDC calibration control signal

from any suitable DC source. If the Model FC Controller display does not show the de-

The FC Controller span should not need adjustment.

Model 250-N 700 lb./min.

Model 500-N 1200 lb./min.

Model 577 2 lb./min.

Model 578 20 lb./min.

Model 579 100 lb./min.

Model 580 200 lb./min.

Model 590 300 lb./min.

Model VLP + 599-5.0 Sensor 1,000 lb./min.

Model LP + 599-5.0 Sensor 1,999 lb./min.

Model 1577 2 lb./min.

Model 1579 100 lb./min.

Table 2. Maximum Flow Rate

6

sired value then adjust the Model FC Front panel span adjustment until it does.

I. A catch test can be run to verify the accuracy of the maximum flow rate of the Magna-

Valve. If necessary, Adjust the Pre-Amp span adjustment ( not the FC controller span

adjustment) and repeat the catch and weigh tests until the correct amount of shot is

caught. Adjust the span once at any desired flow rate for proper flow then fill in the

chart to check performance.

J. Confirm the accuracy by filling in the table column marked “Actual lbs/min” in the table

corresponding to the desired maximum flow rate. Correct discrepancies by making ad-

justments to the compensation trimpots as necessary.

The Tables are located at the end of this document.

4. Trouble shooting

For additional troubleshooting information see the model FC installation manual IM0056.

For assistance call or fax the factory for help

Phone 1-(574)-256-5001

FAX 1-(574)-256-5222

www.shotpeener.com

7

Set Point Ideal lb/min. Actual lb/min.

100% 700

95% 665

85% 595

75% 525

65% 455

55% 385

45% 315

35% 245

25% 175

15% 105

Set Point Ideal lb/min. Actual lb/min.

100% 1200

95% 1140

85% 1020

75% 900

65% 780

55% 660

45% 540

35% 420

25% 300

15% 180

Set Point Ideal lb/min. Actual lb/min.

100% 200

95% 190

90% 180

85% 170

80% 160

75% 150

70% 140

65% 130

60% 120

55% 110

50% 100

45% 90

40% 80

35% 70

30% 60

25% 50

20% 40

15% 30

Set Point Ideal lb/min. Actual lb/min.

100% 300

95% 285

90% 270

85% 255

80% 240

75% 225

70% 210

65% 195

60% 180

55% 165

50% 150

45% 135

40% 120

35% 105

30% 90

25% 75

20% 60

15% 45

Catch and Weigh Tables

1200 lb/min Max 700 lb/min Max

300 lb/min Max 200 lb/min Max

8

Set Point Ideal Lb./min. Actual lb/min.

100% 20.0

95% 19.0

85% 17.0

75% 15.0

65% 13.0

55% 11.0

45% 9.0

35% 7.0

25% 5.0

15% 3.0

Set Point Ideal Lb./min. Actual Lb./min.

100% 2.00

95% 1.90

85% 1.70

75% 1.50

65% 1.30

55% 1.10

45% .90

35% .70

25% .50

15% .30

Set Point Ideal Lb./min. Actual lb/min.

100% 100

95% 95

85% 85

75% 75

65% 65

55% 55

45% 45

35% 35

25% 25

15% 15

100 lb/min Max 20 lb/min Max

2 lb/min Max

This manual suits for next models

9

Other Electronics Control Unit manuals

Popular Control Unit manuals by other brands

UTC Fire and Security

UTC Fire and Security Interlogix NX-535N installation manual

Compac

Compac OPT SCR200 installation manual

Compaq

Compaq KN310 Installation Card

TE Connectivity

TE Connectivity FORTIS Zd Series Assembly

claber

claber Elettra Evolution user manual

Maple Armor

Maple Armor NOU FW337 installation manual