LinMot E1100 Series User manual

Motion Control SW

Documentation of the Motion Control SW

-E1100 / B1100 Drive Series

Motion Control SW

User Manual

L

i

n

M

o

t

Motion Control SW

© 2013 NTI AG

This work is protected by copyright.

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying,

recording, microfilm, storing in an information retrieval system, not even for didactical use, or translating, in whole or in

part, without the prior written consent of NTI AG.

LinMot® is a registered trademark of NTI AG.

Note

The information in this documentation reflects the stage of development at the time of press and is therefore without obligation.

NTI AG. reserves itself the right to make changes at any time and without notice to reflect further technical advance or product

improvement.

Document Version 3.17b / Whp, December 2013

age 2/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

TABLE OF CONTENT

SYSTEM OVERVIEW ............................................................................................................ 9

1.1 REFERENCES ......................................................................................................................... 9

1.2 DEFINITIONS, ITEMS, SHORTCUTS ............................................................................................. 9

1.3 DATA TYPES ......................................................................................................................... 9

2 MOTION CONTROL INTERFACES ............................................................................... 10

3 STATE MACHINE .............................................................................................................. 11

3.1 STATE 0: NOT READY TO SWITCH ON .................................................................................. 13

3.2 STATE 1: SWITCH ON DISABLED ........................................................................................... 13

3.3 STATE 2: READY TO SWITCH ON .......................................................................................... 13

3.4 STATE 3: SETUP ERROR STATE ............................................................................................. 13

3.5 STATE 4: ERROR STATE ....................................................................................................... 13

3. STATE 5: HW TEST ............................................................................................................ 13

3.7 STATE : READY TO OPERATE .............................................................................................. 13

3.8 STATE 8: OPERATION ENABLED ............................................................................................. 14

3.9 STATE 9: HOMING ............................................................................................................... 14

3.10 STATE 10: CLEARANCE CHECK ........................................................................................... 14

3.11 STATE 11: GOING TO INITIAL POSITION .............................................................................. 14

3.12 STATE 12: ABORTING ........................................................................................................ 14

3.13 STATE 13: FREEZING ......................................................................................................... 15

3.14 STATE 14: ERROR BEHAVIOUR QUICK STOP ......................................................................... 15

3.15 STATE 15: GOING TO POSITION .......................................................................................... 15

3.1 STATE 1 : JOGGING + ....................................................................................................... 15

3.17 STATE 17: JOGGING - ........................................................................................................ 15

3.18 STATE 18: LINEARIZING ..................................................................................................... 15

3.19 STATE 19: PHASE SEARCHING ............................................................................................. 15

3.20 STATE 20: SPECIAL MODE ................................................................................................. 15

3.21 BUILDING THE CONTROL WORD .......................................................................................... 15

3.22 CONTROL WORD ............................................................................................................... 1

3.23 STATUS WORD .................................................................................................................. 17

3.24 WARN WORD ................................................................................................................... 18

4 MOTION COMMAND INTERFACE ............................................................................... 19

4.1 MOTION COMMAND INTERFACE ............................................................................................. 19

4.1.1 Command Header .................................................................................................... 19

4.1.1.1 Master ID .......................................................................................................... 19

4.1.1.2 Sub ID ............................................................................................................... 19

4.1.1.3 Command Count ............................................................................................... 19

4.2 OVERVIEW MOTION COMMANDS ........................................................................................... 20

4.3 DETAILED MOTION COMMAND DESCRIPTION ........................................................................... 25

4.3.1 No Operation (000xh) .............................................................................................. 25

4.3.2 Write Interface Contro Word (001xh) .................................................................... 25

4.3.3 Write Live Parameter (002xh) ................................................................................. 25

4.3.4 Write X4 Intf Outputs with Mask (003xh) ................................................................ 25

4.3.5 Write X6 Intf Outputs with Mask (004xh) ................................................................ 25

4.3.6 C ear Event Eva uation (008xh) .............................................................................. 26

4.3.7 Master Homing (009xh) ........................................................................................... 26

4.3.8 VAI Go To Pos (010xh) ........................................................................................... 26

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 3/91

L

i

n

M

o

t

Motion Control SW

4.3.9 VAI Increment Dem Pos (011xh) ............................................................................. 26

4.3.10 VAI Increment Target Pos (012xh) ........................................................................ 27

4.3.11 VAI Go To Pos From Act Pos And Act Ve (013xh) .............................................. 27

4.3.12 VAI Go To Pos From Act Pos Starting With Dem Ve = 0 (014xh) ...................... 27

4.3.13 VAI Increment Act Pos (015xh) ............................................................................. 27

4.3.14 VAI Increment Act Pos Starting With Dem Ve = 0 (016xh) ................................. 28

4.3.15 VAI Stop (017xh) ................................................................................................... 28

4.3.16 VAI Go To Pos After Actua Command (018xh) .................................................... 28

4.3.17 VAI Go To Ana og Pos (019xh) ............................................................................. 28

4.3.18 VAI Go To Pos On Rising Trigger Event (01Axh) ................................................. 29

4.3.19 VAI Increment Target Pos On Rising Trigger Event (01Bxh) ............................... 29

4.3.20 VAI Go To Pos On Fa ing Trigger Event (01Cxh) ............................................... 29

4.3.21 VAI Increment Target Pos On Fa ing Trigger Event (01Dxh) ............................. 29

4.3.22 VAI Change Motion Parameters On Positive Position Transition (01Exh) .......... 29

4.3.23 VAI Change Motion Parameters On Negative Position Transition (01Fxh) ........ 30

4.3.24 Predef VAI Go To Pos (020xh) .............................................................................. 30

4.3.25 Predef VAI Increment Dem Pos (021xh) ............................................................... 30

4.3.26 Predef VAI Increment Target Pos (022xh) ............................................................ 30

4.3.27 Predef VAI Go To Pos From Act Pos and Act Ve (023xh) ................................... 30

4.3.28 Predef VAI Go To Pos From Act Pos Starting With Dem Ve = 0 (024xh) ........... 31

4.3.29 Predef VAI Stop (027xh) ........................................................................................ 31

4.3.30 Predef VAI Go To Pos After Actua Command (028xh) ........................................ 31

4.3.31 Predef VAI Go To Pos On Rising Trigger Event (02Axh) ..................................... 31

4.3.32 Predef VAI Increment Target Pos On Rising Trigger Event (02Bxh) ................... 31

4.3.33 Predef VAI Go To Pos On Fa ing Trigger Event (02Cxh) ................................... 31

4.3.34 Predef VAI Go To Pos On Fa ing Trigger Event (02Dxh) ................................... 31

4.3.35 Predef VAI Infinite Motion Positive Direction (02Exh) ........................................ 32

4.3.36 Predef VAI Infinite Motion Negative Direction (02Fxh) ....................................... 32

4.3.37 P Stream With S ave Generated Time Stamp (030xh) ........................................... 32

4.3.38 PV Stream With S ave Generated Time Stamp (031xh) ......................................... 32

4.3.39 P Stream With S ave Generated Time Stamp and Configured Period Time (032xh)

.......................................................................................................................................... 32

4.3.40 Stop Streaming (03Fxh) ......................................................................................... 33

4.3.41 Time Curve With Defau t Parameters (040xh) ...................................................... 33

4.3.42 Time Curve With Defau t Parameters From Act Pos (041xh) ............................... 33

4.3.43 Time Curve To Pos With Defau t Speed (042xh) ................................................... 33

4.3.44 Time Curve To Pos With Adjustab e Time (043xh) ............................................... 33

4.3.45 Time Curve With Adjustab e Offset, Time Sca e & Amp itude Sca e (044xh) ....... 34

4.3.46 Time Curve With Adjustab e Offset, Time & Amp itude Sca e (045xh) ................. 34

4.3.47 Time Curve With Adjustab e Offset, Time & Amp itude Sca e On Rising Trigger

Event (046xh) .................................................................................................................... 34

4.3.48 Time Curve With Adjustab e Offset, Time & Amp itude Sca e On Fa ing Trigger

Event (047xh) .................................................................................................................... 34

4.3.49 Time Curve To Pos With Defau t Speed On Rising Trigger Event (04Axh) .......... 35

4.3.50 Time Curve To Pos With Defau t Speed On Fa ing Trigger Event (04Cxh) ........ 35

4.3.51 Time Curve To Pos With Adjustab e Time On Rising Trigger Event (04Exh) ...... 35

4.3.52 Time Curve To Pos With Adjustab e Time On Fa ing Trigger Event (04Fxh) ..... 35

4.3.53 Modify Curve Start Address in RAM (050xh) ........................................................ 35

4.3.54 Modify Curve Info B ock 16 Bit Va ue in RAM (051xh) ........................................ 36

4.3.55 Modify Curve Info B ock 32 Bit Va ue in RAM (052xh) ........................................ 36

age 4/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

4.3.56 Modify Curve Data B ock 32 Bit Va ue in RAM (054xh) ...................................... 37

4.3.57 Modify Curve Data B ock 64 Bit Va ue in RAM (055xh) ...................................... 37

4.3.58 Modify Curve Data B ock 96 Bit Va ue in RAM (056xh) ...................................... 38

4.3.59 Setup Encoder Cam On Rising Trigger Event With De ay Counts (069xh) .......... 38

4.3.60 Setup Encoder Cam On Rising Trigger Event With De ay Counts, Target Pos and

Length (06Axh) ................................................................................................................. 38

4.3.61 Setup Encoder Cam On Fa ing Trigger Event With De ay Counts (06Bxh) ........ 39

4.3.62 Setup Encoder Cam On Fa ing Trigger Event With De ay Counts, Target Pos

and Length (06Cxh) .......................................................................................................... 39

4.3.63 Setup Encoder Cam On Rising Trigger Event With De ay Counts, Amp itude sca e

and Length (06Dxh) .......................................................................................................... 39

4.3.64 Setup Encoder Cam On Fa ing Trigger Event With De ay Counts, Amp itude

sca e and Length (06Exh) ................................................................................................. 40

4.3.65 Start VAI Encoder Position Indexing (070xh) ....................................................... 40

4.3.66 Start Predef VAI Encoder Position Indexing (071xh) ........................................... 40

4.3.67 Stop Position Indexing and VAI Go To Pos (07Exh) ............................................. 40

4.3.68 Stop Position Indexing and VAI Go To Pos (07Fxh) ............................................. 41

4.3.69 VAI 16 Bit Go To Pos (090xh) .............................................................................. 41

4.3.70 VAI 16 Bit Increment Dem Pos (091xh) ................................................................ 41

4.3.71 VAI 16 Bit Increment Target Pos (092xh) ............................................................. 41

4.3.72 VAI 16 Bit Go To Pos From Act Pos And Act Ve (093xh) .................................... 42

4.3.73 VAI 16 Bit Go To Pos From Act Pos Starting With Dem Ve = 0 (094xh) ............ 42

4.3.74 VAI 16 Bit Increment Act Pos (095xh) .................................................................. 42

4.3.75 VAI 16 Bit Increment Act Pos Starting With Dem Ve = 0 (096xh) ...................... 42

4.3.76 VAI 16 Bit Stop (097xh) ......................................................................................... 42

4.3.77 VAI 16 Bit Go To Pos After Actua Command (098xh) ......................................... 43

4.3.78 VAI 16 Bit Go To Pos On Rising Trigger Event (09Axh) ...................................... 43

4.3.79 VAI 16 Bit Increment Target Pos On Rising Trigger Event (09Bxh) .................... 43

4.3.80 VAI 16 Bit Go To Pos On Fa ing Trigger Event (09Cxh) .................................... 43

4.3.81 VAI 16 Bit Increment Target Pos On Fa ing Trigger Event (09Dxh) .................. 44

4.3.82 VAI 16 Bit Change Motion Parameters On Positive Position Transition (09Exh)

.......................................................................................................................................... 44

4.3.83 VAI 16 Bit Change Motion Parameters On Negative Position Transition (09Fxh)

.......................................................................................................................................... 44

4.3.84 Predef VAI 16 Bit Go To Pos (0A0xh) ................................................................... 44

4.3.85 Predef VAI 16 Bit Increment Dem Pos (0A1xh) .................................................... 45

4.3.86 Predef VAI 16 Bit Increment Target Pos (0A2xh) ................................................. 45

4.3.87 Predef VAI 16 Bit Go To Pos From Act Pos And Act Ve (0A3xh) ....................... 45

4.3.88 Predef VAI 16 Bit Go To Pos From Act Pos Starting With Dem Ve = 0 (0A4xh)

.......................................................................................................................................... 45

4.3.89 Predef VAI 16 Bit Stop (0A7xh) ............................................................................. 45

4.3.90 Predef VAI 16 Bit Go To Pos After Actua Command (0A8xh) ............................. 45

4.3.91 Predef VAI 16 Bit Go To Pos On Rising Trigger Event (0AAxh) .......................... 46

4.3.92 Predef VAI 16 Bit Increment Target Pos On Rising Trigger Event (0ABxh) ........ 46

4.3.93 Predef VAI 16 Bit Go To Pos On Fa ing Trigger Event (0ACxh) ........................ 46

4.3.94 Predef VAI 16 Bit Increment Target Pos On Fa ing Trigger Event (0ADxh) ...... 46

4.3.95 VAI Predef Acc Go To Pos (0B0xh) ...................................................................... 46

4.3.96 VAI Predef Acc Increment Dem Pos (0B1xh) ....................................................... 46

4.3.97 VAI Predef Acc Increment Target Pos (0B2xh) ..................................................... 46

4.3.98 VAI Predef Acc Go To Pos From Act Pos And Act Ve (0B3xh) ........................... 47

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 5/91

L

i

n

M

o

t

Motion Control SW

4.3.99 VAI Predef Acc Go To Pos From Act Pos Starting With Dem Ve = 0 (0B4xh) . . 47

4.3.100 VAI Predef Acc Go To Pos After Actua Command (0B8xh) ............................... 47

4.3.101 VAI Predef Acc Go To Pos On Rising Trigger Event (0BAxh) ............................ 47

4.3.102 VAI Predef Acc Increment Target Pos On Rising Trigger Event (0BBxh) .......... 47

4.3.103 VAI Predef Acc Go To Pos On Fa ing Trigger Event (0BCxh) .......................... 48

4.3.104 VAI Predef Acc Increment Target Pos On Fa ing Trigger Event (0BDxh) ........ 48

4.3.105 VAI Dec=Acc Go To Pos (0C0xh) ....................................................................... 48

4.3.106 VAI Dec=Acc Increment Dem Pos (0C1xh) ....................................................... 48

4.3.107 VAI Dec=Acc Increment Target Pos (0C2xh) ..................................................... 48

4.3.108 VAI Dec=Acc Go To Pos From Act Pos And Act Ve (0C3xh) ........................... 49

4.3.109 VAI Dec=Acc Go To Pos From Act Pos Starting With Dem Ve = 0 (0C4xh) . . . 49

4.3.110 VAI Dec=Acc Go To Pos With Max Curr (0C5xh) ............................................. 49

4.3.111 VAI Dec=Acc Go To Pos From Act Pos And Ve With Max Curr (0C6xh) ........ 50

4.3.112 VAI Dec=Acc Go To Pos From Act Pos And Ve = 0 With Max Curr (0C7xh) .. 50

4.3.113 VAI Dec=Acc Go To Pos After Actua Command (0C8xh) ................................. 50

4.3.114 VAI Dec=Acc Go To Pos On Rising Trigger Event (0CAxh) .............................. 50

4.3.115 VAI Dec=Acc Increment Target Pos On Rising Trigger Event (0CBxh) ............ 51

4.3.116 VAI Dec=Acc Go To Pos On Fa ing Trigger Event (0CCxh) ............................ 51

4.3.117 VAI Dec=Acc Increment Target Pos On Fa ing Trigger Event (0CDxh) .......... 51

4.3.118 VAI Increment Captured Pos (0D0xh) ................................................................ 51

4.3.119 VAI 16 Bit Dec=Acc Go To Pos (0D1xh) ............................................................ 51

4.3.120 VAI Go To Cmd Tab Var1 Pos (0D4xh) .............................................................. 51

4.3.121 VAI Go To Cmd Tab Var2 Pos (0D5xh) .............................................................. 52

4.3.122 VAI Go To Cmd Tab Var1 Pos From Act Pos And Act Ve (0D6xh) ................... 52

4.3.123 VAI Go To Cmd Tab Var2 Pos From Act Pos And Act Ve (0D7xh) ................... 52

4.3.124 VAI Start Trig Rise Config VAI Command (0DExh) ........................................... 53

4.3.125 VAI Start Trig Rise Config VAI Command (0DFxh) ........................................... 53

4.3.126 Encoder Cam Enab e (100xh) ............................................................................. 53

4.3.127 Encoder Cam Disab e (101xh) ............................................................................ 53

4.3.128 Encoder Cam Go To Sync Pos (102xh) ............................................................... 53

4.3.129 Encoder Cam Set Va ue (104xh) .......................................................................... 53

4.3.130 Encoder Cam y Define Curve With Defau t Parameters (1y0xh) ........................ 53

4.3.131 Encoder Cam y Define Curve From Act Pos (1y1xh) .......................................... 54

4.3.132 Encoder Cam y Define Curve To Pos (1y2xh) ..................................................... 54

4.3.133 Encoder Cam y Define Curve From Pos To Pos In Counts (1y3xh) ................... 54

4.3.134 Encoder Cam y Define Curve To Pos In Counts (1y4xh) .................................... 54

4.3.135 Encoder Cam y Define Curve With Amp itude Sca e In Counts (1y5xh) ............ 55

4.3.136 Encoder Cam y Enab e (1y6xh) ........................................................................... 55

4.3.137 Encoder Cam y Disab e (1y7xh) .......................................................................... 55

4.3.138 Encoder Cam y Change Amp itude Sca e and Length (1y8xh) ............................ 55

4.3.139 Encoder Winding Start With Defau t Parameters (300xh) .................................. 55

4.3.140 Encoder Winding Start With Defau t Parameters At Revo utions (301xh) ......... 55

4.3.141 Start Command Tab e Command (200xh) ........................................................... 56

4.3.142 Start Command Tab e Command On Rising Trigger Event (201xh) ................... 56

4.3.143 Start Command Tab e Command On Fa ing Trigger Event (202xh) ................. 56

4.3.144 Modify Command Tab e 16 bit Parameter in RAM (208xh) ............................... 56

4.3.145 Modify Command Tab e 32 bit Parameter in RAM (209xh) ............................... 56

4.3.146 Wait Time (210xh) ............................................................................................... 57

4.3.147 Wait Unti Motion Finished (211xh) .................................................................... 57

4.3.148 Wait Unti In Target Position (212xh) ................................................................. 57

age 6/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

4.3.149 Wait Unti Rising Trigger Event (213xh) ............................................................. 57

4.3.150 Wait Unti Fa ing Trigger Event (214xh) ........................................................... 57

4.3.151 Wait Unti Demand Position Greater Than (220xh) ........................................... 57

4.3.152 Wait Unti Demand Position Less Than (221xh) ................................................. 57

4.3.153 Wait Unti Actua Position Greater Than (222xh) .............................................. 58

4.3.154 Wait Unti Actua Position Less Than (223xh) .................................................... 58

4.3.155 Wait Unti Difference Position Greater Than (224xh) ........................................ 58

4.3.156 Wait Unti Difference Position Less Than (225xh) .............................................. 58

4.3.157 Wait Unti Difference Position Unsigned Greater Than (226xh) ........................ 58

4.3.158 Wait Unti Difference Position Unsigned Less Than (227xh) ............................. 58

4.3.159 Wait Unti Demand Ve ocity Greater Than (228xh) ............................................ 59

4.3.160 Wait Unti Demand Ve ocity Less Than (229xh) ................................................. 59

4.3.161 Wait Unti Actua Ve ocity Greater Than (22Axh) .............................................. 59

4.3.162 Wait Unti Actua Ve ocity Less Than (22Bxh) .................................................... 59

4.3.163 Wait Unti Current Greater Than (22Exh) .......................................................... 59

4.3.164 Wait Unti Current Less Than (22Fxh) ................................................................ 59

4.3.165 Set Cmd Tab e Var 1 To (240xh) ......................................................................... 60

4.3.166 Add To Cmd Tab e Var 1 (241xh) ....................................................................... 60

4.3.167 Set Cmd Tab e Var 2 To (242xh) ......................................................................... 60

4.3.168 Add To Cmd Tab e Var 2 (243xh) ....................................................................... 60

4.3.169 Write Cmd Tab e Var 1 To UPID RAM va ue (248xh) ........................................ 60

4.3.170 Write Cmd Tab e Var 2 To UPID RAM va ue (249xh) ........................................ 60

4.3.171 Write UPID RAM Va ue To Cmd Tab e Var 1 (24Cxh) ...................................... 60

4.3.172 Write UPID RAM Va ue To Cmd Tab e Var 2 (24Dxh) ...................................... 60

4.3.173 IF Cmd Tab e Var 1 Less Than (250xh) .............................................................. 61

4.3.174 IF Cmd Tab e Var 1 Greater Than (251xh) ......................................................... 61

4.3.175 IF Cmd Tab e Var 1 Less Than (252xh) .............................................................. 61

4.3.176 IF Cmd Tab e Var 1 Greater Than (253xh) ......................................................... 61

4.3.177 IF Demand Position Less Than (258xh) .............................................................. 61

4.3.178 IF Demand Position Greater Than (259xh) ........................................................ 61

4.3.179 IF Actua Position Less Than (25Axh) ................................................................ 62

4.3.180 IF Actua Position Greater Than (25Bxh) ........................................................... 62

4.3.181 IF Difference Position Less Than (25Cxh) .......................................................... 62

4.3.182 IF Difference Position Greater Than (25Dxh) .................................................... 62

4.3.183 IF Current Less Than (25Exh) ............................................................................. 62

4.3.184 IF Current Greater Than (25Fxh) ....................................................................... 62

4.3.185 IF Ana og Va On X4.4 Less Than (260xh) ......................................................... 63

4.3.186 IF Masked X4 Input Va ue Equa Than (262xh) .................................................. 63

4.3.187 IF Masked X6 Input Va ue Equa Than (263xh) .................................................. 63

4.3.188 IF Masked Status Word Equa Than (264xh) ...................................................... 63

4.3.189 IF Masked Warn Word Equa Than (265xh) ....................................................... 63

4.3.190 Encoder Winding Stop Adaptation Of Left/Right Position and Disturbance

(304xh) .............................................................................................................................. 63

4.3.191 Encoder Winding Restart Adaptation Of Left/Right Position and Disturbance

(305xh) .............................................................................................................................. 64

4.3.192 Encoder Curve Winding Start With Defau t Parameters (310xh) ....................... 64

4.3.193 Encoder Curve Winding Start With Defau t Parameters At Revo utions (311xh)

.......................................................................................................................................... 64

4.3.194 VAI Go To Pos With Higher Force Ctr Limit (380xh) ....................................... 64

4.3.195 VAI Go To Pos From Act Pos And Reset Force Contro (381xh) ....................... 64

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 7/91

L

i

n

M

o

t

Motion Control SW

4.3.196 Force Ctr Change Target Force (382xh) ........................................................... 65

4.3.197 VAI Go To Pos With Higher Force Ctr Limit and Target Force (383xh) .......... 65

4.3.198 VAI Go To Pos With Lower Force Ctr Limit (384xh) ........................................ 65

4.3.199 VAI Go To Pos With Lower Force Ctr Limit and Target Force (385xh) ........... 66

5 SETPOINT GENERATION ............................................................................................... 67

5.1 VA-INTERPOLATOR ............................................................................................................. 7

5.1.1.1 Parameters and Output ...................................................................................... 7

5.2 P(V)-STREAM .................................................................................................................... 8

5.3 CAM MOTIONS .................................................................................................................... 9

5.3.1 Triggered Cam Motions ........................................................................................... 69

5.3.2 Repeated Cam Motions with the Modu o CamMode ............................................... 69

5.4 WINDING ............................................................................................................................ 70

5.4.1 Winding disturbance ................................................................................................ 70

6 COMMAND TABLE ........................................................................................................... 71

7 DRIVE CONFIG RATION ............................................................................................... 72

7.1 POWER BRIDGE ................................................................................................................... 72

7.2 X4 I/O DEFINITIONS ........................................................................................................... 72

7.2.1 X4.3 Brake ............................................................................................................... 72

7.2.1.1 X4.3 Brake Operation Enabled Behavior ......................................................... 73

7.2.1.2 X4.3 Brake Operation /Abort Behavior ............................................................ 73

7.2.1.3 X4.3 Brake Operation Quick Stop Behavior .................................................... 74

7.2.2 X4.6 Trigger ............................................................................................................. 74

7.2.2.1 Direct Trigger Mode ......................................................................................... 74

7.2.2.2 Inhibited Trigger Mode ..................................................................................... 75

7.2.2.3 Delayed Trigger Mode ...................................................................................... 75

7.2.2.4 Inhibited & Delayed Trigger Mode .................................................................. 7

7.2.3 X4.8 and X4.9 Limit Switches .................................................................................. 76

7.2.4 X4.10 and X4.11 PTC 1 and PTC 2 ......................................................................... 76

7.2.5 X4.12 SVE (Safety Vo tage Enab e) ......................................................................... 77

7.3 MASTER ENCODER .............................................................................................................. 77

7.4 MONITORING ...................................................................................................................... 79

7.4.1 Logic Supp y Vo tage ............................................................................................... 79

7.4.2 Motor Supp y Vo tage .............................................................................................. 79

7.4.2.1 Phase Switch On Test ....................................................................................... 79

7.4.3 Regeneration Resistor .............................................................................................. 80

7.4.4 Temperature Monitoring ......................................................................................... 81

7.5 POSCTRLSTRUCTURE ........................................................................................................... 82

8 MOTOR CONFIG RATION ............................................................................................ 83

8.1 GENERIC MOTOR TEMPERATURE CALCULATED ........................................................................ 83

9 STATE MACHINE SET P ................................................................................................ 84

10 ERROR CODE LIST ........................................................................................................ 85

11 CONTACT ADDRESSES ................................................................................................. 92

age 8/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

System Overview

This user Manual describes the Motion Control SW functionality of the LinMot E1100 /

B1100 drives.

1.1 References

Ref Title Source

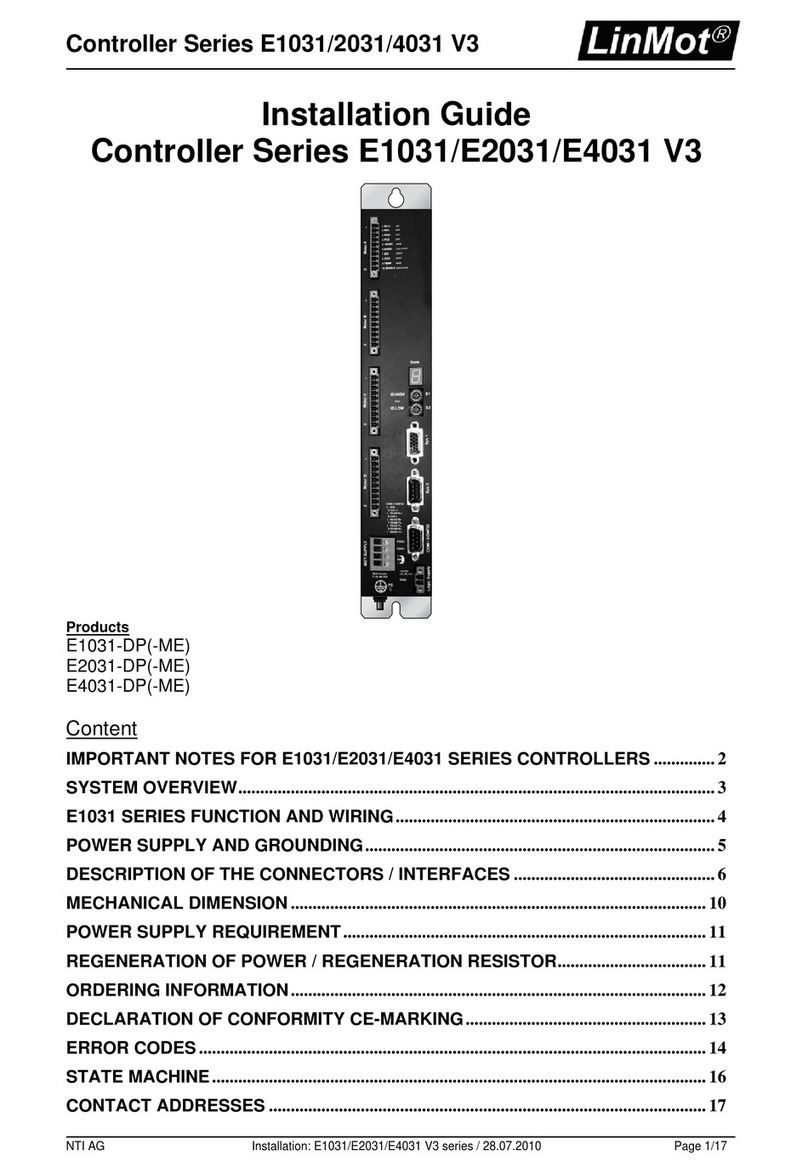

1 Installation_Guide_E1100.pdf www.linmot.com

2 Installation_Guide_B1100.pdf www.linmot.com

3 Usermanual_LinMot-Talk_4.pdf www.linmot.com

4 QuickStartGuide_B1100-VF.pdf www.linmot.com

The documentation is distributed with the LinMot-Talk configuration software or can be

downloaded from the Internet from the download section of our homepage.

1.2 Definitions, Items, Shortcuts

Shortcut Meaning

LM LinMot linear motor

OS Operating system (Software)

MC (SW) Motion Control (Software)

Intf Interface (Software)

Appl Application (Software)

VAI VA-Interpolator (Max velocity limited acceleration position interpolator)

os osition

Vel Velocity

Acc Acceleration

Dec Deceleration

U ID Unique arameter ID (16 bit)

1.3 Data types

Type Range/Format Num of bytes

Bool Boolean, False/True 1/8

Byte 0..255 1

Char ASCII 1

String Array of char last char = 00h X

SInt16 -32768..32767 2

UInt16 0..65535 2

SInt32 -2147483648..2147483647 4

UInt32 0..4294967295 4

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 9/91

Realtime Machine Control Monitoring, Testing, Simulating

L

i

n

M

o

t

Motion Control SW

2 Motion Control Interfaces

For controlling the behavior of the motion control SW, two different Interfaces are available.

For controlling the main state machine, a bit coded control wor can be used. For

controlling the motion functionality a memory mapped motion comman interface can be

used. These two instances are mapped via an interface SW to an upper control system

( LC, I C, C, ..). The interfacing is done with digital I/Os or a serial link like rofibus D ,

CAN bus (DeviceNet, CANopen), RS485, RS422 or RS232 (LinRS protocol).

With LinMot-Talk the control over the control word can be taken bit by bit, for testing and

debugging. Unused control word bits can be forced by parameter value.

Also the control of the motion command interpreter can be switched to the control panel of

the LinMot-Talk software for testing.

All this can be done while the system is running, so be careful using this features on a

running machine!

age 10/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

PLC

with serial bus

Control Word Intf

Copy Mask

Status Word

Control Word

Parameter Force Mask

Motion

Command

Registers

Motion

Command

Registers

Control Word

Parameter Force Values

Event

Handler

Control Word

Interface Control

Word

Command

Registers

Response

Registers

LinMot-Talk1100

Control Panel

Motion Command

Interface Selector

State Machine Control Motion Command

Interpreter

Axle Control

Motion Control SW

L

i

n

M

o

t

3 State Machine

The main behavior of the axles is controlled with the control word, it is shown in the following

state diagram.

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 11/91

Enabled (8)

Ready to

Operate ( )

Ready to

Switch On (2)

Error (4)

Bit 3=1

Switch On

Disabled (1)

Bit 0=1

Not Ready to

Switch On (0)

Bit 0=0

Control Word

xxxx xxxx xxxx x110

Bit 0=0

I=0

Switch Off

Bit 2=0

Jogging - (17)

Going To Initial

Position (11)

Clearance

Checking (10) Jogging + (1 )

Homing (9)

QuickStop

Freezing (13)

Special Mode (20)

Phase Searching (19)

Aborting (12)

Bit 1=0

Going To Position (15)

Linearizing (18)

Bit 7

Power On

Setup Error (3)

Error Behavior

Quick Stop (14)

HW Tests (5)

Disable

Voltage

L

i

n

M

o

t

Motion Control SW

The state machine can be followed in the LCs with fieldbus using the the StateVar. This

response word can be configured for any supported fieldbus.

State Var

Main State Sub State

15 14 13 12 11 10 9 8 7 5 4 3 2 1 0

The State Var is divided into two sections: the Main State section (high byte) contains directly

the number of the state machine, the content of the Sub State (low byte) is state depending.

State Var

Main State Sub State

00: Not Ready To Switch On 0

01: Switch On Disabled 0

02: Ready To Switch On 0

03: Setup Error Error Code which will be logged

04: Error Logged Error Code

05: HW Tests 0 (Not yet defined)

06: Ready To Operate 0 (Not yet defined)

07: -

08: Operation Enabled Bits 0..3: Motion Command Count

Bit 4: Event Handler Active

Bit 5: Motion Active

Bit 6: In Target Position

Bit 7: Homed

09: Homing 0Fh: Homing Finished

10: Clearance Check 0Fh: Clearance Check Finished

11: Going To Initial Position 0Fh: Going To Initial Position Finished

12: Aborting Not yet defined

13: Freezing Not yet defined

14: Quick Stop (Error Behaviour) Not yet defined

15: Going To Position 0Fh: Going To Position Finished

16: Jogging + 01h: Moving positive

0Fh: Jogging +Finished

17: Jogging - 01h: Moving negative

0Fh: Jogging -Finished

18: Linearizing Not yet defined

19: Phase Search Not yet defined

20: Special Mode Not yet defined

age 12/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

3.1 State 0 Not Ready To Switch On

In this state the release of control word bit 0 switch on is awaited. As soon as this bit is

cleared a change to state 1 is performed. This behavior avoids self starting if all necessary

bits for a start are set correctly in the control word.

3.2 State 1 Switch On Disabled

The state machine rests in this state as long as the bits 1 or 2 of the control word are

cleared.

3.3 State 2 Ready To Switch On

The state machine rests in this state as long as the bit 0 is cleared.

3.4 State 3 Setup Error State

The state machine rests in this state as long the bits 0 is cleared.

3.5 State 4 Error State

The error state can be acknowledged with a rising edge of the control word bit 7 ‘Error

Acknowledge’. If the error is fatal, bit 12 ‘Fatal Error’ in the status word is set, no error

acknowledgment is possible.

In the case of a fatal error, the error has to be checked, and the problem has to be solved

before a reset or power cycle is done for resetting the error.

3.6 State 5 HW Test

The HW Test state is an intermediate state before turning on the power stage of the drive. If

everything seems to be ok the drive changes to state 6 without any user action. The test

takes about 300ms.

3.7 State 6 Ready to Operate

In this state the motor is either position controlled or with demand current = 0 and under

voltage, but no motion commands are accepted. The mode is configurable with U ID 6300h.

Sending motion commands in this state will generate the error ‘Motion command sent in

wrong state’ and a state change to the error state will be performed.

Clearing the control word bit 3 ‘Enable Operation’ in state 8 or higher will stop immediately

the set point generation and a state transition to 6 is performed. Clearing the bit while a

motion is in execution a following error might be generated.

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 13/91

L

i

n

M

o

t

Motion Control SW

3.8 State 8 Operation Enabled

This is the state of the normal operation in which the motion commands are executed. It is

strongly recommended to use the State Var for the motion command synchronization with

any fieldbus system.

State Var

Main State = 8

Homed

In Target osition

Motion Active

Event Handler

Motion Command

Count

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

In the high byte stands the number of the main state = 8. In the low byte stands in the lowest

4 bits the actual interpreted ‘Motion Command Count’, bit 4 indicates if the event handler is

active, in bit 5 stands the status word bit ‘Motion Active’, in bit 6 the status word bit ‘In Target

osition’ and in bit 7 the status word bit ‘Homed’. Because the ‘Motion Command Count’

echo and this status word bits are located in the same byte no data consistency problem is

possible with any fieldbus.

A new motion command can be setup when the Motion Command Count has changed to the

last sent an the ‘Motion Active’ bit is 0 or the ‘In Target osition’ bit is 1 if an exact

positioning is required.

3.9 State 9 Homing

The homing state is used to define the position of the system according a mechanical

reference, a home switch or an index.

For LinMot motors the slider home position at this home position is taken to compensate

edge effects.

In the home sequence a position check of two positions and the motion to an initial position

can be added.

Hint: If a mechanical stop homing mode is chosen, the initial position should be a little apart

from this mechanical stop to avoid overheating of the motor.

3.10State 10 Clearance Check

Setting the Clearance Check bit in the Control Word, two positions are moved to, to check if

the whole motion range is free. Normally this action is added to the homing sequence to

ensure that the homing was done correctly.

3.11State 11 Going To Initial Position

Setting the Go To Initial osition bit in the control word, the motor moves to the initial

position, normally used to move away from the mechanical stop after homing, to protect the

motor from overheating at the mechanical stop. After an error it is also recommended to

move to a defined position again.

3.12State 12 Aborting

Clearing the /Abort bit in the control word initiates a quick stop. After the motion has stopped

the drive rests position controlled. Setting the bit again the drive rests in position until a new

motion command is executed.

age 14/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

3.13State 13 Freezing

Clearing the /Freeze bit in the control word initiates a quick stop. After the motion is stopped

the drive rests position controlled. Setting the bit again the drive will finish the frozen motion

(e.g. if it was a VAI command). Curve motion can be frozen but not restarted by releasing

this bit, setting the bit again the motor moves at the target position of the last VAI command,

if never used a VAI command it will go to the initial position.

3.14State 14 Error Behaviour Quick Stop

Most of the errors, which can occur during an active motion, cause a quick stop behavior to

stop the motion. After the quick stop is finished the motor is no longer position controlled.

3.15State 15 Going To Position

Setting the Go To osition bit in the control word, the serveo moves to the defined position,

recommendable for example, after an error, to move to a defined position again.

3.16State 16 Jogging +

Setting the Jog Move + bit in the control word, the motor moves either by a defined position

increment or to the maximal position with a limited speed. Releasing the bit will stop the

motion.

3.17State 17 Jogging -

Setting the Jog Move - bit in the control word, the motor moves either a defined position

decrement or to the minimal position with a limited speed. Releasing the bit will stop the

motion

3.18State 18 Linearizing

The linearizing state is used to correct position feedback parameters, to improve the linearity

of the position feedback.

3.19State 19 Phase Searching

The phase search is only defined for three phase EC motors with hall switches and ABZ-

sensors to find the commutation offset for to the sensor. It cannot be guaranteed that this

feature will work for all kinds of EC motors. The found offset can be found in the variable

section Calculated Commutation Offset (U ID: 1C1Bh), and has to be set manually to he

parameter hase Angle (U ID 11F2h).

3.20State 20 Special Mode

The Special Mode is available only on the B1100 drives. In this state the current command

mode over the analog input is available. For using this mode see the [4].

3.21Building the Control Word

The Control Word can be accessed bit by bit from different sources with different priorities.

The highest priorities have the bits that are forced by parameters. The second highest priority

has the control panel of the LinMot-Talk software, if logged in with the SW. The next lower

priorities have the bits that are defined on the X4 IOs as control word input bits. The lowest

priority have bits which are set over the interface (normally a serial fieldbus connection), so in

the Ctrl Word Interface Copy mask all bits can be selected, without causing any problems,

but bits which should not be accessed through the interface can be masked out.

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 15/91

L

i

n

M

o

t

Motion Control SW

3.22Control Word

With the Control Word (16Bit) the main state machine of the drive can be accessed.

Following table shows the meaning of each bit:

Bit

Name Val Meaning Remark

0

Switch On

0 OFF1 A-Stop, -> Current = 0, power switches

disabled

1 ON State change from switch on disabled to

ready to switch on

1

Voltage Enable

0 OFF2 ower switches disabled without

microcontroller action

1 Operation

2

/Quick Stop

0 OFF3 Quick Stop -> Current = 0 -> H-Bridges

disabled

1 Operation

3

Enable Operation

0 Operation disabled osition controller active Motion Commands

disabled

1 Operation enable osition controller active Motion Commands

enabled

4

/Abort

0 Abort Quick Stop position control rests active,

motion command is cleared.

1 Operation

5

/Freeze

0 Freeze motion Quick Stop position control rests active,

Target position not cleared, curves motions

are aborted

1 Operation Rising edge will reactivate motion command

6

Go To osition

0

1 Go To osition Go to fixed parameterized osition. Wait for

release of signal.

7

Error Acknowledge

0

1 Error Acknowledge Rising edge of signal acknowledges error

8

Jog Move +

0

1 Jog Move +

9

Jog Move -

0

1 Jog Move -

10

Special Mode

0

1 Special Mode Special Mode

11

Home

0 Stop Homing

1 Homing At startup bit 11 Status word is cleared, until

procedure is finished.

12

Clearance Check

0 Stop Clearance Check

1 Clearance Check Enable Clearance Check Movements

13

Go To Initial osition

0

1 Go To initial osition Rising edge will start go to initial position

14

Reserved

0

1 Reserved

15

hase Search

0 Stop hase Search

1 hase Search Enable hase Search Movements

age 16/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

3.23Status Word

Following table shows the meaning of the single bits:¬

Bit

Name Val Meaning Remark

0

Operation Enabled

0 State Nr < 8

1 Operation Enabled State Nr 8 or higher (copied to drive EN LED )

1

Switch On Active

0 Switch On Disabled Control Word Bit 0

1 Switch On Enabled

2

Enable Operation

0 Operation Disabled Control Word Bit 3

1 Operation

3

Error

0 No Error

1 Error Acknowledge with Control word Bit 7 (Reset Error)

4

Voltage Enable

0 ower Bridge Off Control Word Bit 1

1 Operation

5

/Quick Stop

0 Active Control Word Bit 2

1 Operation

6

Switch On Locked

0 Not Locked

1 Switch On Locked Release with 0 of Control word bit 0 (Switch On)

7

Warning

0 Warning not active No bit is set in the Warn Word

1 Warning active One or more bits in the Warn Word are set

8

Event Handler Active

0 Event Handler Inactive Event Handler cleared or disabled

1 Event Handler Active Event Handler setup

9

Special Motion Active

0 Normal Operation

1 Special Command runs Special motion commands (Homing, ..) runs

10

In Target osition

0 Not In os Motion active or actual position out of window

1 In os Actual position after motion in window

11

Homed

0 Motor not homed Incremental sensor not homed (referenced)

1 Motor homed osition sensor system valid

12

Fatal Error

0

1 Fatal Error A fatal error cannot be acknowledged!

13

Motion Active

0 No Motion Setpoint generation inactive

1 Motion active Setpoint generation (VAI, curve) active

14

Range Indicator 1

0 Not In Range 1 Defined U ID is not in Range 1

1 In Range1 Defined U ID is in Range 1

15

Range Indicator 2

0 Not In Range 2 Defined U ID is not in Range 2

1 In Range2 Defined U ID is in Range 2

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 17/91

L

i

n

M

o

t

Motion Control SW

3.24Warn Word

Following table shows the meaning of the single bits of the Warn Word:

Bit

Name Val Meaning

0

Motor Hot Sensor

0 Normal Operation

1 Motor Temperature Sensor On

1

Motor Short Time Overload I^2t

0 Normal Operation

1 Calculated Motor Temperature Reached Warn Limit

2

Motor Supply Voltage Low

0 Normal Operation

1 Motor Supply Voltage Reached Low Warn Limit

3

Motor Supply Voltage High

0 Normal Operation

1 Motor Supply Voltage Reached High Warn Limit

4

osition Lag Always

0 Normal Operation

1 osition Error during Moving Reached Warn Limit

5

osition Lag Standing (not on B1100)

0 Normal Operation

1 osition Error During Standing Reached Warn Limit

6

Drive Hot

0 Normal Operation

1 Temperature on Drive High

7

Motor Not Homed

0 Normal Operation

1 Warning Motor Not Homed Yet

8

TC Sensor 1 Hot

0 Normal Operation

1 TC Temperature Sensor 1 On

9

Reserved TC 2

0 Normal Operation

1 TC Temperature Sensor 2 On

10

RR Hot Calculated

0 Normal Operation

1 Regenerative Resistor Temperature Hot Calculated

11

Reserved

0

1

12

Reserved

0

1

13

Reserved

0

1

14

Interface Warn Flag

0 Normal Operation

1 Warn Flag Of Interface SW layer

15

Application Warn Flag

0 Normal Operation

1 Warn Flag Of Application SW layer

Normally the warn word bits are used to react in conditions before the drive goes into the

error state. E.g. a typical reaction on the warning ‘Motor Temperature Sensor’ would be a stop

of the machine, before the drive goes into the error state and the motor goes out of control to

avoid crashes.

age 18/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Motion Control SW

L

i

n

M

o

t

4 Motion Comman Interface

4.1 Motion Command Interface

The motion command interface consists of one word that contains the command ID, and up

to 16 command parameter words. Example: ‘VA-Interpolator 16 bit Go To Absolute osition’

Word Description Example of command

1. Command Header with ID Go To Absolute osition Immediate

2. 1. Command arameter osition

3. 2. Command arameter Maximal Speed

4. 3. Command arameter Acceleration

5. 4. Command arameter Deceleration

6.-16. 5. - Command arameter Not used

4.1.1 Comman Hea er

Master ID Sub ID Command Count

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

The header of the Motion command is split into three parts:

•Master ID

•Sub ID

•Command Count

4.1.1.1 Master ID

The master ID specifies the command group.

4.1.1.2 Sub ID

The sub ID is used to identify different commands from the same command group.

4.1.1.3 Command Count

A new command will only be executed, if the value of the command count has changed. In

the easiest way bit 0 can be toggled.

NTI AG / LinMot User Manual Motion Control SW/ 06/12/2013 age 19/91

L

i

n

M

o

t

Motion Control SW

4.2 Overview Motion Commands

Master

ID

Sub

ID

E

1

1

0

0

B

1

1

0

0

Description

00h 0h X X No Operation

1h X X Write Interface Control Word

2h X X Write Live arameter

3h X X Write X4/X14 Intf Outputs with Mask

4h X Write X6 Intf Outputs with Mask

8h X X Clear Event Evaluation

9h X X Master Homing

01h 0h X X VAI Go To os

1h X X VAI Increment Dem os

2h X X VAI Increment Target os

3h X X VAI Go To os From Act os And Act Vel

4h X X VAI Go To os From Act os Starting With Dem Vel = 0

5h X X VAI Increment Act os

6h X X VAI Increment Act os Starting with Dem Vel = 0

7h X X VAI Stop

8h X X VAI Go To os After Actual Command

9h X X VAI Go To Analog os

Ah X X VAI Go To os On Rising Trigger Event

Bh X X VAI Increment Target os On Rising Trigger Event

Ch X X VAI Go To os On Falling Trigger Event

Dh X X VAI Increment Target os On Falling Trigger Event

Eh X X VAI Change Motion arameters On ositive osition Transition

Fh X X VAI Change Motion arameters On Negative osition Transition

02h 0h X X redef VAI Go To os

1h X X redef VAI Increment Dem os

2h X X redef VAI Increment Target os

3h X X redef VAI Go To os From Act os And Act Vel

4h X X redef VAI Go To os From Act os Starting With Dem Vel = 0

7h X X redef VAI Stop With Quick Stop Deceleration

8h X X redef VAI Go To os After Actual Command

Ah X X redef VAI Go To os On Rising Trigger Event

Bh X X redef VAI Increment Target os On Rising Trigger Event

Ch X X redef VAI Go To os On Falling Trigger Event

Dh X X redef VAI Increment Target os On Falling Trigger Event

Eh X X redef VAI Infinite Motion ositive Direction

Fh X X redef VAI Infinite Motion Negative Direction

03h 0h X X Stream With Slave Generated Time Stamp

1h X X V Stream With Slave Generated Time Stamp

2h X X Stream With Slave Generated Time Stamp and Configured

eriod Time

Fh X X Stop Streaming

04h 0h X k Time Curve With Default arameters

1h X k Time Curve With Default arameters From Act os

2h X k Time Curve To os With Default Speed

3h X k Time Curve To os With Adjustable Time

4h X k Time Curve With Adjustable Offset, Time Scale & Amplitude Scale

age 20/91 User Manual Motion Control SW / 06/12/2013 NTI AG / LinMot

Other manuals for E1100 Series

3

This manual suits for next models

1

Table of contents

Other LinMot Control Unit manuals