Electronics MagnaValve WM 3000-24 User manual

2

Table of Contents

Product Overview and Principle of Operation........................................................................... 3

Installation.................................................................................................................................................. 4

Adjustments ..............................................................................................................................................4

Operation - MagnaValve...................................................................................................................... 4

Operation - Remote Valve Driver .....................................................................................................5

Specifications ............................................................................................................................................6

Dimensions ................................................................................................................................................7

Remote Valve Drive Cable Connection ......................................................................................... 8

AC-24 Controller Cable Connection ............................................................................................... 8

Troubleshooting ......................................................................................................................................9

Maintenance............................................................................................................................................10

Spare Parts List........................................................................................................................................10

Contacting Electronics Inc.................................................................................................................10

Limited Warranty...................................................................................................................................11

Read this manual completely before installing the MagnaValve.

WARNING!

The MagnaValve emits magnetic elds and can be harmful to pacemaker wearers.

3

Product Overview and

Principle of Operation

MagnaValve® Description

The MagnaValve® WM 3000-24 is a normally closed valve that regulates the ow

of steel shot or grit in wheel-blast machines for blast cleaning applications. It is a

powerful valve with a ow rate capacity of up to 3,000 lb/min (1,361 kg/min) for

wheels up to 125 hp. The Remote Valve Driver for the MagnaValve comes with a 6-ft

cable for installation in the customer’s electrical panel, making it an ideal valve for

blast machines in high-temperature environments.

The MagnaValve reduces media usage, energy costs, machine downtime, and wear

and tear on equipment.

How It Works

The MagnaValve’s maintenance-free construction includes a rare earth permanent

magnet for normally closed operation and an electromagnet for controlling shot ow

rates. With power applied, the magnetic eld is neutralized and shot is allowed to

ow through the valve.When no power is applied to the MagnaValve, the permanent

magnet stops all ow. If the power is interrupted for any reason, the permanent

magnet securely holds the shot.

The MagnaValve is factory tested and results are supplied upon request.

MagnaValve Controllers for Closed-Loop Operation

For an “automatic” closed-loop operation, an Electronics Inc. AC-24 Controller will

detect the current load on the wheel motor and regulate the ow of media to the

WM 3000-24. The WM 3000-24 MagnaValve, with the AC-24 Controller, provides

reliable, repetitive, and consistent media ow rates for blast cleaning applications.

The MagnaValve system makes it easy to document ow rates and establish or repeat

a good set-up.

AC-24 Controller Data Sheet

http://www.electronics-inc.com/uploads/AC-24Controller(1).pdf

AC-24 Controller Instruction Manual

http://www.electronics-inc.com/data_sheets_and_instruction_manuals_for_wheel_blast_machine_products2.html

4

Installation

MagnaValve

The MagnaValve must be mounted in a vertical position with an adequate supply of

media above it.

Remote Valve Driver

The Remote Valve Driver should be mounted in an electrical panel that conforms to

the temperature range of 50˚- 120˚ F (10˚- 49˚ C).

Adjustments

MagnaValve

No adjustments are required or recommended. The valve has been tested at the

factory prior to shipment.

Remote Valve Driver

Adjustments to the Remote Valve Driver can be made from the front of the driver;

however, the factory settings should not be changed.The output signal is 10 Vdc. See

page 5 for additional information on the Remote Valve Driver.

Operation

MagnaValve

Signals used to operate the MagnaValve originate at the AC-24 Controller. There are

three conditions necessary for correct operation.

1) Power. 24 Vdc power must be continuously applied to the valve. The valve

requires 2 Amps for operation and a power supply rated at 50 Va. The voltage

should be 24 ±2 Vdc.

2) Enable Signal. The 24 Vdc Enable Signal is used to activate the valve.

3) Input Signal. The analog 0-10 Vdc input signal must be above 0.25 Vdc as a

minimum ow command signal.

AC-24 Controller Operation

Please download the AC-24 Instruction Manual

http://www.electronics-inc.com/data_sheets_and_instruction_manuals_for_wheel_blast_machine_products2.html

5

830500830500

Valve Pulse

▼

620 Hz

Program Port Test Connector

0-10 V IN

NA

NA

24 V

Pulse Hz

GND

Valve On

Vin > 0.25 Vdc

Enable (24 Vdc)

Power (24 Vdc)

è

ç

é

Valve Pulse

Rate at which the valve dispenses shot. The Valve Pulse

is factory set to match the best ow characteristics of

the media (cast steel or cut wire). The typical operation

rate is 8 Hertz.

Test Connector

Provides access to

diagnostic voltages.

• 0 - 10 Vdc input

• 24 Vdc “Enable” input

• 6 - 20 Hertz pulse rate

• 0 Vdc common

Operation

Remote Valve Driver

Valve Driver Panel (behind the cover plate)

*Diagnostic LEDs

Valve On. Indicates when power is being sent to the MagnaValve’s electromagnet. When the

LED is on, the valve is on for full capacity ow rate. When the LED is o, the MagnaValve’s

permanent magnet has stopped the media ow. When the LED is blinking, the shot ow is

being regulated.

Vin > 0.25 Vdc. Indicates that an analog signal input greater than 0.25 Vdc has been received.

When this LED is o, no media ow is allowed. The input signal range is 0 -10 Vdc. At 10 Vdc,

the MagnaValve will open to full capacity. The relationship between the 0 -10 Vdc input signal

and actual ow rate is non-linear.

24 Vdc Enable. Indicates that the 24 Vdc Enable Signal has been received. When the LED is

o, the MagnaValve is inhibited and no shot will ow. This feature is provided as an on-o

action so the 0-10 Vdc input signal does not have to be disabled or removed.

24 Vdc Power. Indicates that 24 Vdc is available to operate the electromagnet for media ow.

It should always be available and able to supply 2 Amps.

All four LEDs must be on in order to have media ow.

Diagnostic LEDs*

The large knurled screw on the front cover of the Remote Valve Driver can be removed to gain

access to the factory adjustments. Please refer all adjustments to qualied personnel.

6

Specifcations

MagnaValve

Power +24 Vdc @ 2A (50 VA)

Media Steel Shot and Grit

Weight 32 lb (14.5 kg)

Mode Normally Closed

Temperature Range Valve: 50˚- 230˚ F (10˚-110˚ C)

Signal Input 0 - 10 Vdc

Flow Output 0 - 3,000 lb/min (0 - 1,361 kg/min)*

Display LEDs Valve On

0 - 10 Vdc Command Input Available

24 V Flow Enable

+24 Vdc Power

Cable: 2 Conductor shielded 18 AWG or equivalent.

Connect shield at control only.

* Flow rate based on S230 cast steel shot

Remote Valve Driver

Temperature Range 50˚- 120˚ F (10˚- 49˚ C)

7

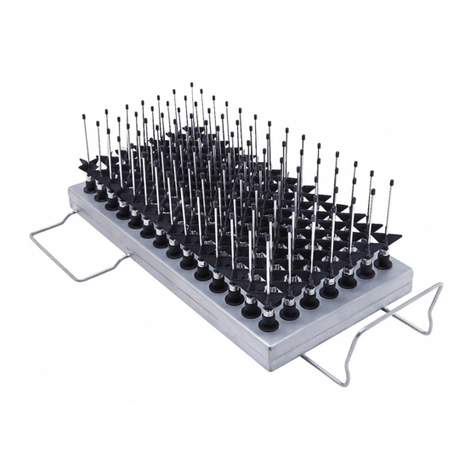

Dimensions

.91”

(23 mm)

9.30”

(236 mm)

4.50”

(114 mm)

1.50”

(38 mm)

1.50”

(38 mm)

.56”

(14 mm)

10.00”

(254 mm)

9.00”

(229 mm)

2.87”

(73 mm)

4.29”

(109 mm)

7.13”

(181 mm)

5.00”

(127 mm)

ValveOn

MagnaValve®

For stability, the MagnaValve should be located as close as possible (within at least 3 ft / 1 m) to the blast machine wheel.

Panel spacing for the Remote Valve Driver: 5” on cable side, 0.5”on top and bottom.

5.460” (138.7 mm)

4.890” (124.2 mm)

6.62”

(168.1 mm)

4.739”

(120.4 mm)

2.032”

(51.6 mm)

.886”

(22.5 mm)

3.772”

(95.8 mm)

8

Maximum

Temperature:

212˚ F / 100˚ C

Place valve within

3 ft/1 m of wheel

feedspout media

inlet

Cable #1

White

Green 24 Vdc

0 Vdc

Enable Input

24 Vdc Enable Output 24 Vdc

Flow Command

Input 0 -10 Vdc Flow Command

Output 0 - 10 Vdc

Blue

Orange

Cable #2

Red

Black

Maximum

Temperature:

100˚ F / 37˚ C

Place driver module in

electrical control panel

24 Vdc

0 Vdc

Signal

Ground

Earth

Customer

Power

Supply

Shunt

0.05 Ω

Remote Setpoint

(if used) 0 - 10 Vdc

Recorder output

(if used) 0 - 10 Vdc

Remote Enable

(if used) 24 Vdc

Customer’s

100:5 Current Transformer

Pass one loop through

center 0-100 Amps

current transformer

Cable #1- A six-foot

cable and plug are

supplied with the

MagnaValve and only

the green and white

wires need to be

connected. Do not use

the other wires in the

cable. Wiring from

the MagnaValve to the

Remote Valve Driver

should be in a private

conduit (no adjacent

motor leads, etc).

Use 16 AWG. For runs

longer than 98 ft/30 m,

use larger wire such as

14 AWG.

4

8

20

19

2

18

9

5

7

WM 3000-24

REMOTE

VALVE DRIVER

AC-24 CONTROLLER

Cable #2 - A six-foot

cable and plug are

supplied for Cable #2.

Do not use green and

white wires. Connect

red (+) and black (–)

wires directly to 24 Vdc

power source. Connect

blue and orange to

AC-24 Controller

terminals 9 and 8.

(+)

(-)

▼ ▼

▼

1

3

1

3

5

2

6

4

Note #1

Note #2

Note #1 Do not attach Red and Black wires to

terminals 19 and 20. Connect Red and Black

wires directly to power supply — this prevents

ground noise interference.

Note #2 Shunt is supplied with AC-24 Controller

and is attached to terminals 5 and 7.

AC-24 Controller Cable Connection

Remote Valve Driver Cable Connection

The Remote Valve Driver should be installed in customer’s electrical panel. The 6-pin plug and cable wires connect

to customer’s wiring per the following:

White MagnaValve power signal - connect to valve driver, White only

Green MagnaValve power signal - connect to valve driver, Green only

Red Customer Power Supply in control panel - Power bus hot +24 Vdc

Black Customer Power Supply in control panel - Power bus common 0 Vdc

Blue 24 Vdc Enable Input - connect to AC-24 Controller Screw terminal #9, Enable Output

Orange 0-10 Vdc Flow Command Input - connect to AC-24 Controller Screw terminal #8, Flow Command Output

9

Troubleshooting

If all of the LEDs are on but there is no media ow, please check the following:

1) Is the mechanical slide gate valve above the MagnaValve fully open?

2) Is media available from the hopper?

3) Is there a blockage above or below the MagnaValve?

4) Is the magnetic eld completely cancelled when the “Valve On” LED is on? Check this by

removing the valve from the machine and applying the proper signals for 100% ow. Did all

of the shot fall from the valve?

If the problem can’t be identied or if you detect a problem with the magnetic eld,

contact Electronics Inc. Please have the following information ready.

1) Number of valves on the machine ___________________________________

2) Controller model _________________________________________________

3) Valve model____________________Valve serial number_________________

4) Media type ocast steel ocut wire ogrit oother___________________

5) Media size ______________________________________________________

6) Wheel size (hp)_______________ Wheel size (diameter) _________________

7) Desired wheel amperage (Amps) ____________________________________

8) Wheel speed (cpm) _______________________________________________

9) Blasting cycle time________________________________________________

10) Time between cycles ______________________________________________

Make note of LED indicators on the MagnaValve:

How do the MagnaValve LED indicators react during the blast cycle?

__________________________________________________________________________

Make note of LED indicators on the AC-24 Controller (if used):

How do the AC-24 Controller LED indicators react during the blast cycle?

__________________________________________________________________________

What does the AC-24 Controller display at the end of the blast cycle? _____________________

To expedite a solution, please send images of your valve installation,

the valve’s ID label and/or a video of the controller and valve driver during operation.

Troubleshooting with Skype is also recommended.

Electronics Inc.

Telephone: (574) 256-5001 or 1-800-832-5653 (USA and Canada)

Fax: (574) 256-5222

10

Maintenance

The MagnaValve has no moving parts and is thereby maintenance free.

Spare Parts List

The MagnaValve has no moving parts to replace.

Contacting Electronics Inc.

Electronics Inc.

56790 Magnetic Drive

Mishawaka, Indiana 46545 USA

Telephone: (574) 256-5001 or 1-800-832-5653 (USA and Canada)

Fax: (574) 256-5222

Email: [email protected]

Website: www.electronics-inc.com

Electronics Inc. makes no representations or warranties, either expressed

or implied, with respect to the contents of this publication or the products

that it describes, and specically disclaims any implied warranties of

merchantability or tness for any particular purpose. Electronics Inc. reserves

the right to revise this publication and to make changes and improvements to

the products described in this publication without the obligation of Electronics

Inc. to notify any person or organization of such revisions,

changes or improvements.

11

Limited Warranty

The warranty obligations of Electronics Inc. for this product are limited to the terms set forth

below.

Length of Warranty Period

This limited warranty lasts one (1) year from the shipping date of this product.

What is Covered

This limited warranty covers defects in materials and workmanship in this product.

What is Not Covered

This limited warranty does not cover any damage, deterioration or malfunction resulting from

any alteration, modication, improper or unreasonable use or maintenance or use of a media for

which the MagnaValve was not calibrated, misuse, abuse, accident, neglect, exposure to excess

moisture, re, improper packing and shipping (such claims must be presented to the carrier),

lightning, power surges, or other acts of nature.This limited warranty does not cover any damage,

deterioration or malfunction resulting from the installation or removal of this product from any

installation, any unauthorized tampering with this product, any repairs attempted by anyone

unauthorized by Electronics Inc. to make such repairs, or any other cause which does not relate

directly to a defect in materials and/or workmanship of this product. This limited warranty does

not cover equipment enclosures, cables or accessories used in conjunction with this product.

How to Obtain a Remedy Under this Limited Warranty

To obtain a remedy under this limited warranty, contact Electronics Incorporated by letter, email,

fax or telephone with the following information:

• Product name and model

• Product serial number

• Original shipping date (see label on product)

• Company name and location

• Name of contact person for description of symptoms

• Return shipping address and any special instructions

If it is determined that the product must be returned under this limited warranty, a Returned

Goods (RG) number, obtained from Electronics Inc., will be required. This product should be

properly packed to prevent damage in transit. Cartons not bearing a RG number will require

additional processing time and repair service may be delayed.

What Electronics Inc. Will Do Under This Limited Warranty

Electronics Inc. will, at its sole discretion, provide one of the following remedies to whatever

extent it shall deem necessary to satisfy a proper claim under this limited warranty:

1.) Elect to repair or facilitate the repair of any defective parts within a reasonable period of time,

free of any charge for the necessary parts and labor to complete the repair and restore this

product to its proper operating condition. Electronics Inc. will pay the shipping costs necessary

to return this product once the repair is complete.

2.) If the defective product cannot be repaired, it will be replaced with a new unit and the original

warranty period will be extended by six (6) months. Electronics Inc. will pay the shipping costs

necessary to replace this product.

12

If this product is returned to Electronics Inc., the product must be insured during shipment, with

the insurance and shipping charges prepaid. If this product is returned uninsured, Electronics

Inc. does not assume any risk of loss or damage during shipment. Electronics Inc. will not be

responsible for any costs related to the removal or re-installation of this product.

Out-of-Warranty Product

Product that is out-of-warranty will be repaired at customer’s request and the cost of repair will be

disclosed prior to proceeding with the repair. A purchase order must be received prior to repair. If

the product cannot be repaired, Electronics Inc. will provide one of the following remedies:

1) New unit at current pricing with a one (1) year Limited Warranty from the shipping date of

product.

2) Refurbished unit (if available) at a discounted price with a six (6) month Limited Warranty from

the shipping date of product.

Limitation on Liability

The maximum liability of Electronics Inc. under this limited warranty shall not exceed the actual

purchase price paid for the product. Electronics Inc. is not responsible for direct, special, incidental

or consequential damages resulting from any breach of warranty or condition, or under any other

legal theory to the maximum extent permitted by law.

Exclusive Remedy

To the maximum extent permitted by law, this limited warranty and the remedies set forth above

are exclusive and in lieu of all other warranties, remedies and conditions, whether oral or written,

express or implied.To the maximum extent permitted by law, Electronics Inc. specically disclaims

any and all implied warranties, including, without limitation, warranties of merchantability and

tness for a particular purpose. If Electronics Inc. cannot lawfully disclaim or exclude implied

warranties under applicable law, then all implied warranties covering this product, including

warranties of merchantability and tness for a particular purpose, shall apply to this product as

provided under applicable law.

Rights Under State Law

This warranty denes specic legal rights relative to these products provided by Electronics Inc.

Legal rights may also vary from state to state.

Table of contents

Other Electronics Control Unit manuals

Popular Control Unit manuals by other brands

Miele professional

Miele professional A 304 operating instructions

Hunter

Hunter I-40 manual

National Instruments

National Instruments NI USB-9264 USER GUIDE AND SPECIFICATIONS

eks

eks d-light DL-485MBP Description and manual

Veethree

Veethree VeeCAN 320 instructions

PAW

PAW SolarBloC mega Installation and operation instruction