Electrothermal IA9000 SERIES User manual

Page 1 of 40 M8144 Issue 2.0

IA 9000 SERIES.

Digital Melting Point

INSTRUCTION BOOK.

Page 2 of 40 M8144 Issue 2.0

Please take your time to read your IA 9000 Digital Melt Point Apparatus Instruction

book in order to understand the safe and correct use of your new Electrothermal

product.

It is recommended the Responsible Body for the use of this equipment reads this

Instruction book and ensures the user(s) are suitably trained in its operation.

CONTENTS

Section 1

Introduction

Page 3

Section 2

Symbols and using this Instruction book

Page 4

Section 3

Safety Information.

Page 5

Section 4

Unpacking and contents

Page 7

Section 5

Installation

Page 8

Section 6

Environmental Protection.

Page 9

Section 7

Product Operation.

Page 10

Section 8

Technical Specification.

Page 31

Section 9

Maintenance

Page 33

Section 10

Customer Support

Page 35

Section 11

Spares and Accessories

Page 36

Section 12

Notes

Page 38

Section 13

EC declaration of Conformity Notes

Page 40

Appendix A

Decontamination Certificate.

Page 37

©The copyright of this Instruction book is the property of Electrothermal. This instruction book is supplied by

Electrothermal on the express understanding that it is to be used solely for the purpose for which it is supplied. It

may not be copied, used or disclosed to others in whole or part for any purpose except as authorized in writing by

Electrothermal. Electrothermal reserve the right to alter, change or modify this instruction book without prior

notification.

In the interest of continued development Electrothermal reserve the right to alter or modify the design

and /or assembly process of their products without prior notification.

This product is manufactured in Great Britian by Electrothermal. Part of the Bibby Scientific Group of

companies. Registered address:

Electrothermal.

Electrothermal House.

Unit12A, Purdeys Way.

Purdeys Industrial Estate.

Rochford,

Essex. SS4 1ND

Great Britain.

Tel +44(0)1702 303350

Fax+44(0)1702 468731

Page 3 of 40 M8144 Issue 2.0

1. INTRODUCTION.

Your Electrothermal IA9000 series Digital Melting Point Apparatus has been designed for general

purpose laboratory use in which samples submitted for analysis are enclosed in a glass capillary

tube and brought to a melt point condition under strick controlled parrameters of time and

temperature.

All of the models with in the IA9000 range are operated in a simular manor. An advanced

Micorcontroller and step through menu system accuratly controll oven temperature and ramp rate.

Melt temperatures can be recorded using the new ergonomicly designed keypad using a single

touch keypad entry and ‘One Touch’ enty / storage.

The IA9200 and IA9300 models contain an internal memory which can be used for storage of run

data. These units are able to output data information via the printer, USB flash drive or direct to a

host PC using Hyperterminal.

In addition the IA9200 and IA9300 units contain the facility to support the following features:-

Start of ramp temperature and ramp rate can be touch keypad selected for different test

standards.

The operating menu system permits batch serial numbers to be allocated via the touch

keypad.

All stored data enables the reproduction of hard copies which contain the date, time and

batch number associated with a built in ‘real time’ clock.

Ceiling temperatures may be set in order to preserve chemicals for analysis should they

failed to perform as anticipated

Daylight balanced LED oven illumination assists in the clear viewing of melt points.

All IA 9000 series Digital Melting Point Apparatus from Firmware version V0.30 will support

Electrothermal’s ECO mode power saving facility which gives the user the option of setting time

out for the oven on/off facility together with the display back light and oven illumination LED’s.

Page 4 of 40 M8144 Issue 2.0

2. SYMBOLS AND USING THIS INSTRUCTION BOOK

2.1. Throughout this Instruction book the following symbols are shown to identify conditions which

pose a hazard to the user, or to identify actions that should be observed. These symbols are

also shown on the product, or its packaging. When a symbol is shown next to a paragraph or

statement it is recommended the user takes particular note of that instruction in order to

prevent damage to the equipment or to prevent injury to one’s self or other people.

To prevent injury or equipment damage it is the manufacturer’s recommendation that

all persons using this equipment are suitably trained before use.

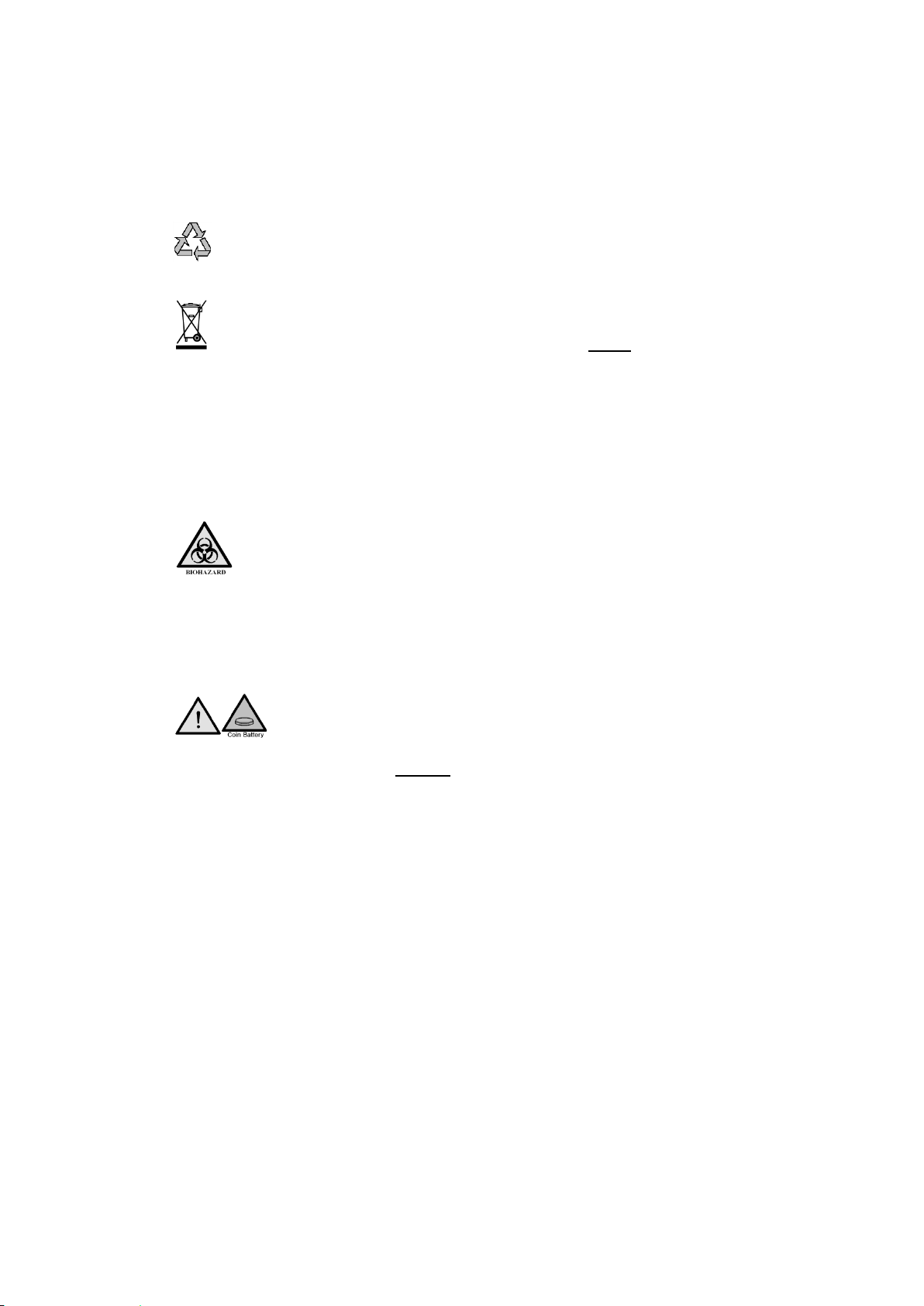

2.2. Symbols defined.

Caution, risk of danger. See note or adjacent symbol.

Recyclable Packing Material

Do not dispose of product in normal domestic waste.

Contains CR2032 button coin battery. (IA9200/IA9300 only).

(To be disposed of according to regulations- not

customer serviceable).

Refer to this Instructions book.

Bio Chemical Hazard. Caution required. Will require

decontamination.

Caution / risk of electric shock.

ECO Mode supported

Page 5 of 40 M8144 Issue 2.0

3. SAFETY INFORMATION.

This product has been designed for safe operation when used as detailed in accordance with the

Manufacturer’s instructions.

NOTE: Failure to use this equipment in accordance with the manufactures operating instructions

may compromise your basic safety protection afforded by the equipment and may invalidate the

warranty / guarantee. The warranty / guarantee does not cover damaged caused by faulty

installation or misuse of the equipment.

This equipment is classified as Class O (IEC519:part 2) with regard to over temperature

protection and should be used accordingly.

3.1. Prevention of Fire and Electric Shock.

Ensure the Mains Power Supply conforms to rating found on the

data plate located on the underside of your IA melting point

apparatus.

Do not attempt to gain access to the inside of the Power Supply.

There are no serviceable parts inside.

3.2. General Safe Operating Practice.

Always follow good laboratory practice when using this equipment.

Give due recognition to your company’s safety and legislative

health & safety procedures and all associated legislation applicable

to your areas of operation. Check laboratory procedures for

substances being heated and ensure all hazards (e.g. explosion,

implosion or the release of toxic or flammable gases) that might

arise have been suitably addressed before proceeding. (Consult

your company practice).

Ensure equipment is used on a clean, dry, non-combustible, solid

work surface with at least 300mm suitable clearance all around

from other equipment.

Do not position the IA Melting Point Apparatus so that it is

difficult to connect / disconnect from the power cable assembly.

Do not position the IA Melting Point Apparatus so that it is

difficult to connect / disconnect data and communication cables.

Do not immerse any part of this equipment in water / fluid.

It is not recommended to leave any heating apparatus unattended

during operation.

Only use Original Equipment Manufacture’s Parts and Accessories.

Ref Section 11.

Page 6 of 40 M8144 Issue 2.0

The equipment is not spark, flame or explosion proof and has not

been designed for use in hazardous areas in terms of BSEN 60079-

14:1997. Keep flammable, low flash point substances away from

the apparatus.

Do not operate or handle any part of this product with wet hands.

Do not lean or stretch over the unit when in operation.

Do not to look directly at the LED oven illumination light source

while turned on.

Page 7 of 40 M8144 Issue 2.0

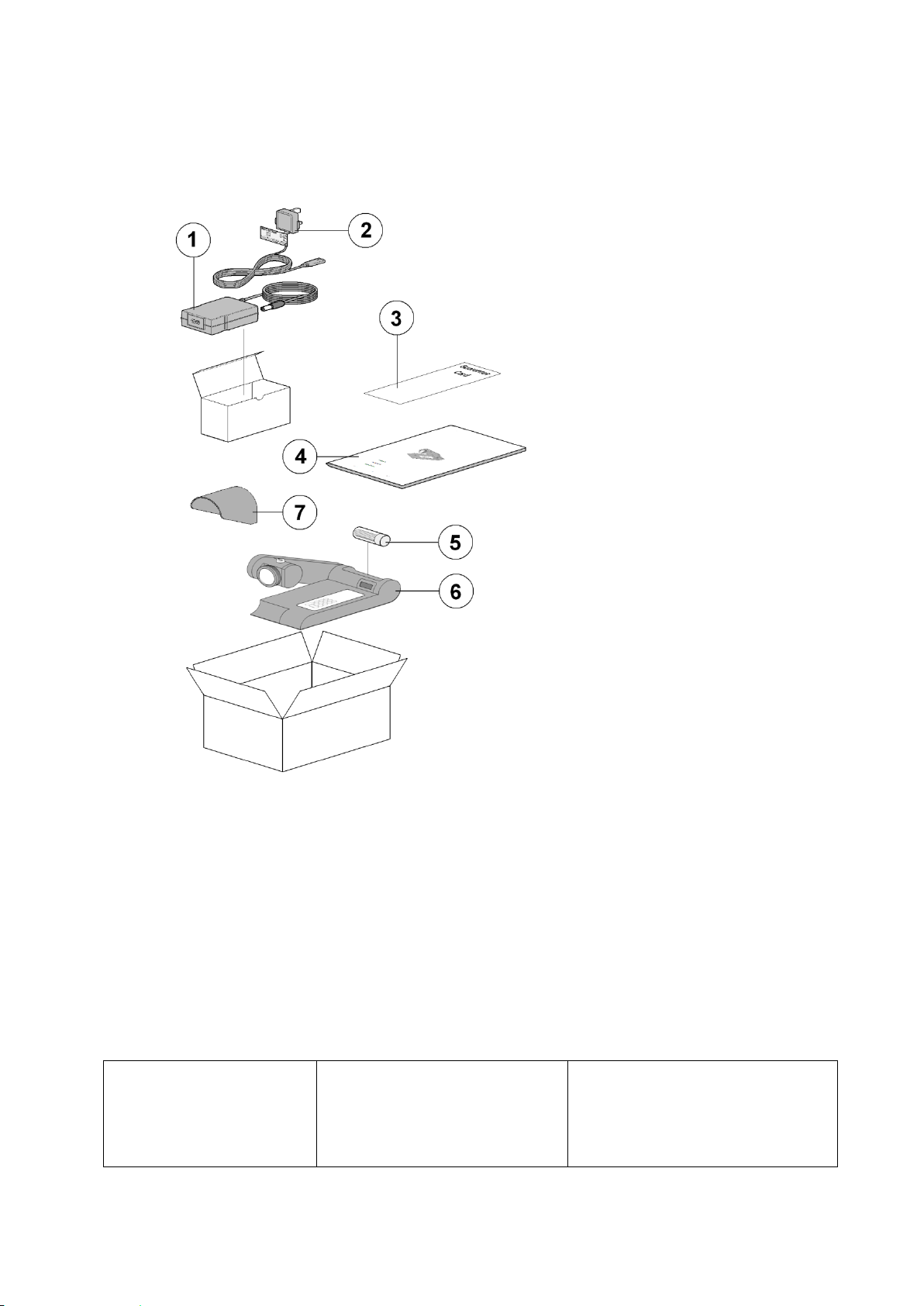

4. UNPACK AND CONTENTS.

4.1. Please check the contents of your carton against the diagram.

For your future reference

please record your products

Serial and Model numbers.

Unit Serial Number

Unit Model/Cat Number.

Item

Description

Qty

1

Power supply

1

2

Power Supply mains lead

(illustration only)

1

3

Guarantee card

1

4

Operating and safety

Instructions book

1

5

Capillary tubes

1

6

IA Melting point product

1

7

Lens Hood

1

Note: Additional Packing material may be

present.

Page 8 of 40 M8144 Issue 2.0

5. INSTALLATION.

5.1. Electrical Safety and Installation.

5.1.1.This equipment is designed to safe under the following conditions:-

Indoor use.

Altitude up to 2000 meters.

Temperatures between 5C and 40C.

Maximum relative humidity 80% for temperatures up to 31C decreasing linearly to

50% relative humidity at 40C.

Mains supply voltage fluctuations up to 10% of the nominal voltage.

Transient overvoltage’s typically present on the mains supply.

Applicable rated pollution degree 2.

5.1.2.Check the voltage on the product data label on this product unit and those of any

accompanying electrical accessory. Ensure the rating conforms to your local supply.

Page 9 of 40 M8144 Issue 2.0

6. ENVIRONMENTAL PROTECTION.

6.1. Electrothermal has given due consideration to environmental issues within the design and

manufacturing process of this product without compromising product performance and value.

6.2. Packaging materials have been selected such that they may be sorted for recycling.

6.3. At the end of your product and accessories life, it must not be discarded as domestic

waste. Ref: EU Directive 2002/96/EC on Waste Electrical and Electronic Equipment Directive

(WEEE).

Please contact your distributor / supplier for further information. For end users outside of the

EU consult applicable regulations. (*)

6.4. This product should only be dismantled for recycling by an authorized recycling company.

This product and accessories must be accompanied by a completed

Decontamination Certificate prior to any disposal. Copies of the Certificate are

available from your distributor of Electrothermal products, alternatively you may copy

and enlarge from ‘Appendix A’ of this instruction book.

6.5. Battery Disposal.

IA9200 / IA9300 contain a Lithium Cell button Battery (CR2032) on the

control PCB located on the master control PCB. The battery must be disposed of in

accordance with regulations. Do Not dispose of product in a fire as batteries may

explode.

Electrothermal is registered as Electrothermal Engineering Limited with the Environment Agency as a producer of WEEE through B2B, an authorized compliance Scheme.

Page 10 of 40 M8144 Issue 2.0

7. PRODUCT OPERATION.

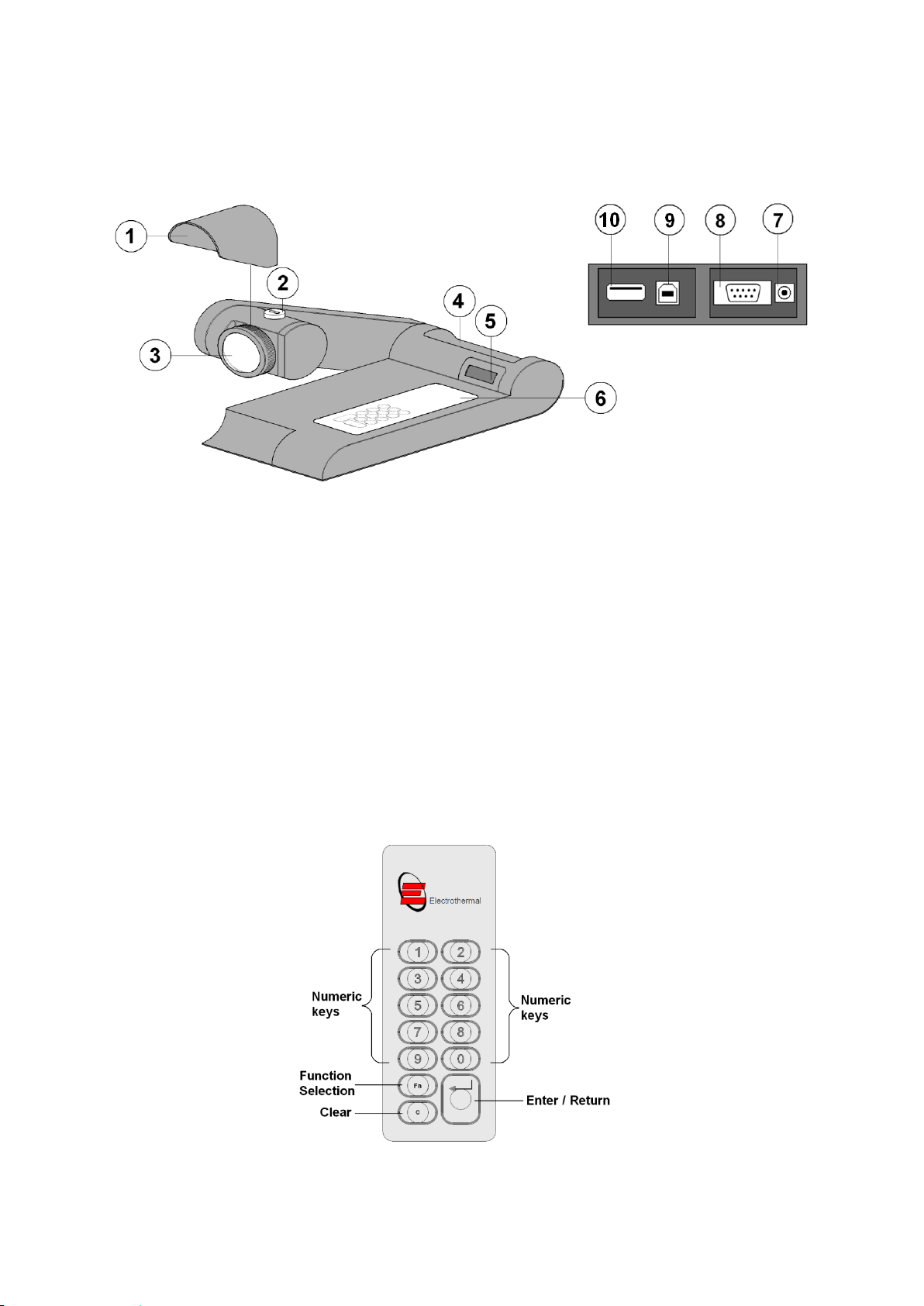

7.1. Overview.

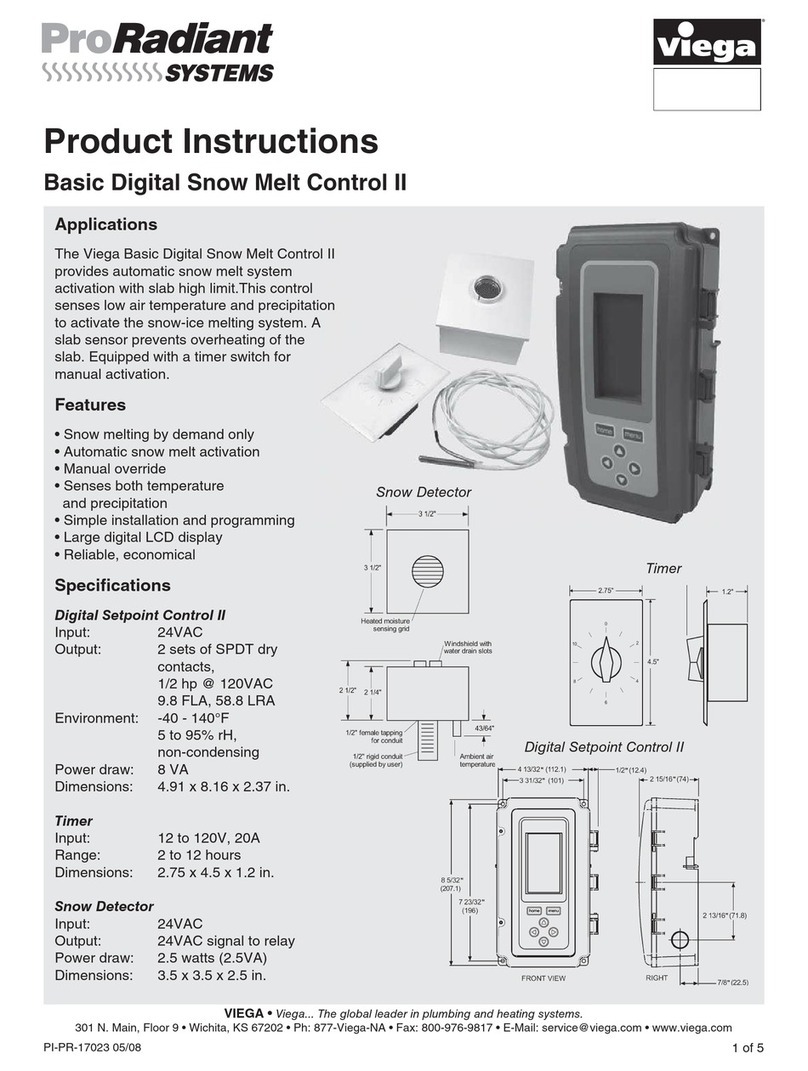

Front view

Rear view

Number

Description

1

Lens hood

2

Capillary Guide

3

Lens

4

Capillary tube holder

5

2 x 12 digit display

6

Keypad

7

Power input

8

RS232 serial printer connection socket

9

USB socket type B (Slave)

10

USB socket type A (Master)

Keypad layout

Page 11 of 40 M8144 Issue 2.0

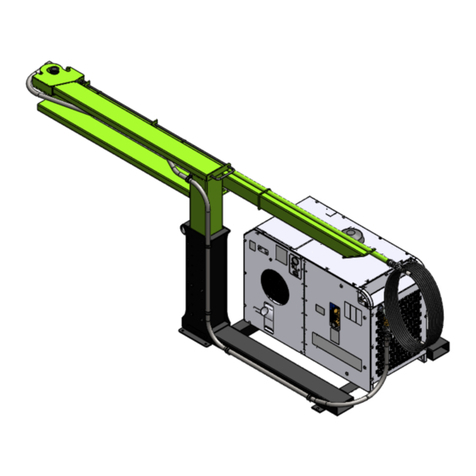

7.1.1. Connect the mains supply lead and power supply to your IA as illustrated.

7.1.2. The lense hood attachment is optional It’s purpose is to assis in viewing the sample

when using the IA in direct light. Slide the lense hood over the threaded back section of

the lense as illustrated.

7.1.3.Adjust the arm height and oven head angle to suit by loosening the clamp screws and

adjusting as required. Retighten the clamp screws after making adjustments. Always

loosen the clamp screws before making adjustments.

7.1.4. Turn on at the mains electical supply and observe the IA goes through a warm up and

self check routine which include a diplay of the Model type, the firmware issue release

number. Once the clock and date have been set the 9200 and 9300 models will display

the real time and date during the warm up procedure.

Page 12 of 40 M8144 Issue 2.0

7.2. Principals of Operation.

7.2.1.During operation the various parameters of the sample analysis are shown on the liquid

crystal display, and all the stages of the process are indicated by the L.E.D. illumination

or audible warning. The principles of the operation are as follows:-

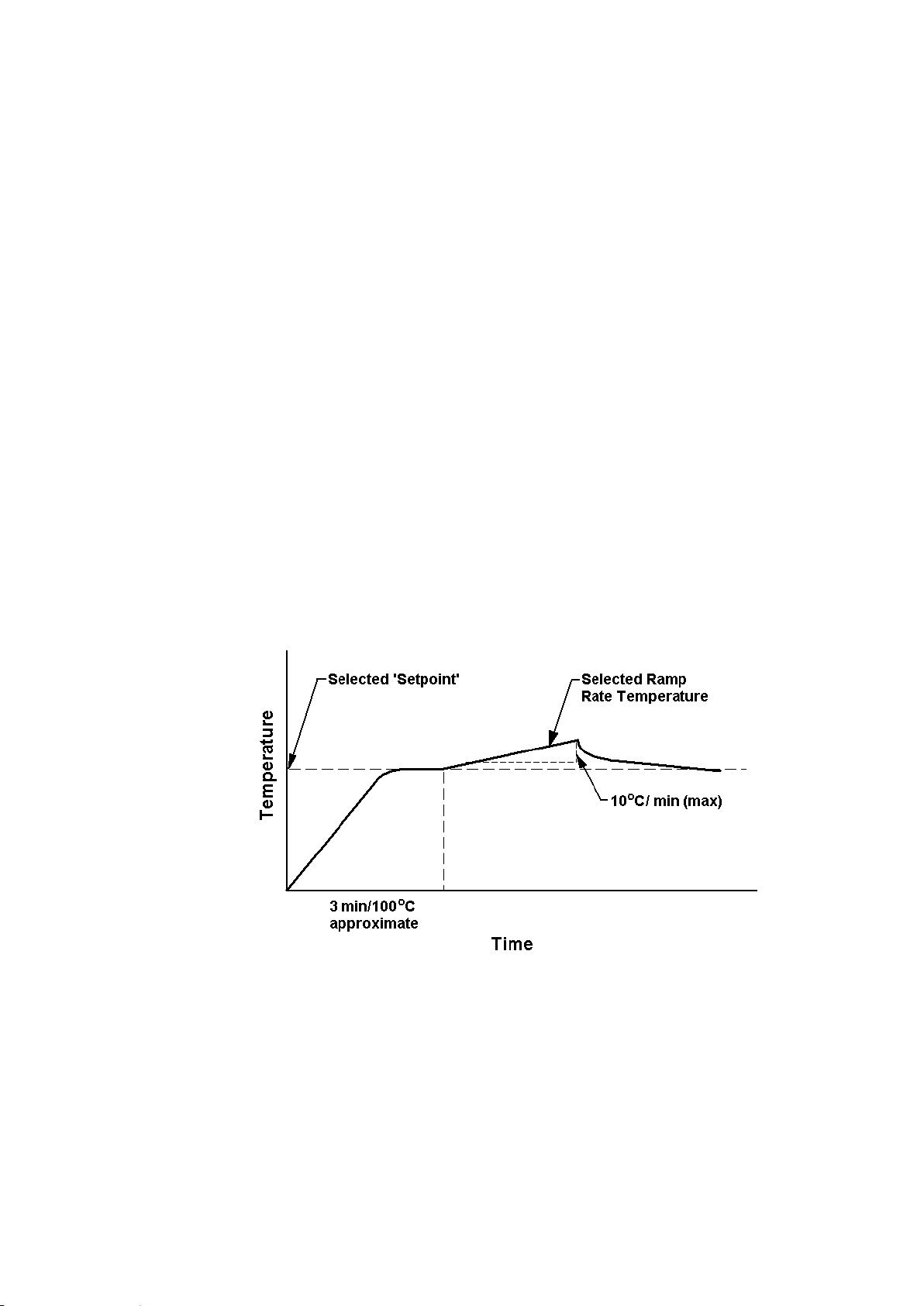

Guided by knowledge of the expected melting temperatures of the sample, a ‘Set

Point’ is established and its value keyed in.

The oven temperature is driven to meet the ‘Set Point’ at maximum rate.

After a short delay for the oven temperature to stabilize at the ‘Set Point’, the ramp

is activated and the temperature now increases linearly at the much slower ramp

rate, during which time the melt analysis takes place.

The melting of the sample is observed and the temperatures registered via the

keypad at the appropriate time.

The temperatures (and for the IA9200 / IA9300 also the measuring parameters) are

now available for review on the display (and for the IA9300 & 9200 a hard copy

printed print out, output to USB flash drive or direct down load to a PC may be

selected).

The oven temperature may now be directed to a new ‘Set Point’ if required for the

next analysis.

Page 13 of 40 M8144 Issue 2.0

7.2.2. Preparation of Samples.

To obtain the best results the samples under melt should be perfectly dry. Drying is best

accomplished by storing the samples in vacuum desiccators over a suitable drying

agent such as phosphorus pent oxide. Always dry hygroscopic samples.

Provided the sample is dry there is usually little difficulty in introducing a small amount

of sample into the capillary tube. Insert the tube into your sample to gather material.

Stand the tube upright and then tap the tube on the bench to compact the material at

the tube base. It is important not to use too large a sample, a quantity occupying no

more than 1-2 mm of the bottom of the tube is ample. If this is exceeded accurate and

sharp melt reading points may not be obtained. Care should be taken to see the sample

beds down to the bottom of the tube as large air pockets can cause false melt

observations.

Please not sample preparation should be undertaken independently of the IA

apparatus.

7.2.3.Determination of Melting point.

In recording melting points, the operator may wish to observe four distinct phases:

a) First signs of change (darkening, shriveling, sintering, etc). These changes may be

due to loss of solvent or crystallization. Occasionally one can see the solvent

condensing on the cooler portion of the tube.

b) First signs of liquid formation.

c) Formation of meniscus.

d) Formation of a completely clear liquid.

Not all compounds will behave in this manner however. With many, especially where

the material is in a high state of purity, no change may be seen before any liquid

appears. Some materials will be seen to sublime, rather than melt above 300°C

Decomposition may often be accompanied by evolution of gas.

Pure compounds will be expected to pass through the 3 stages a) c) and d), within a

range of 1°C.

7.2.4.Interpretation of Results.

It is generally accepted the formation of a meniscus should be regarded as the figure to

be recorded for a single temperature melting point. Where a range is quoted, it can

generally be assumed reference is being made to stages b) to d) inclusive. The range

will generally cover no more than 1°C for pure compounds, but may well extend to 3 or

4°C for others. The range will often be greater when decomposition or sublimation is

experienced. When using the equipment to determine the melting point of more than

one sample of the same compound at a time, the average of the meniscus temperature

(onset of melt) should be taken.

Page 14 of 40 M8144 Issue 2.0

7.3. Setting the Time and Date (9200 & 9300 models only).

Date and time settings may also be accessed via the (F3) function facility.

Note: The time clock has no daylight saving facility. You may wish to re-set the time when

daylight saving takes place.

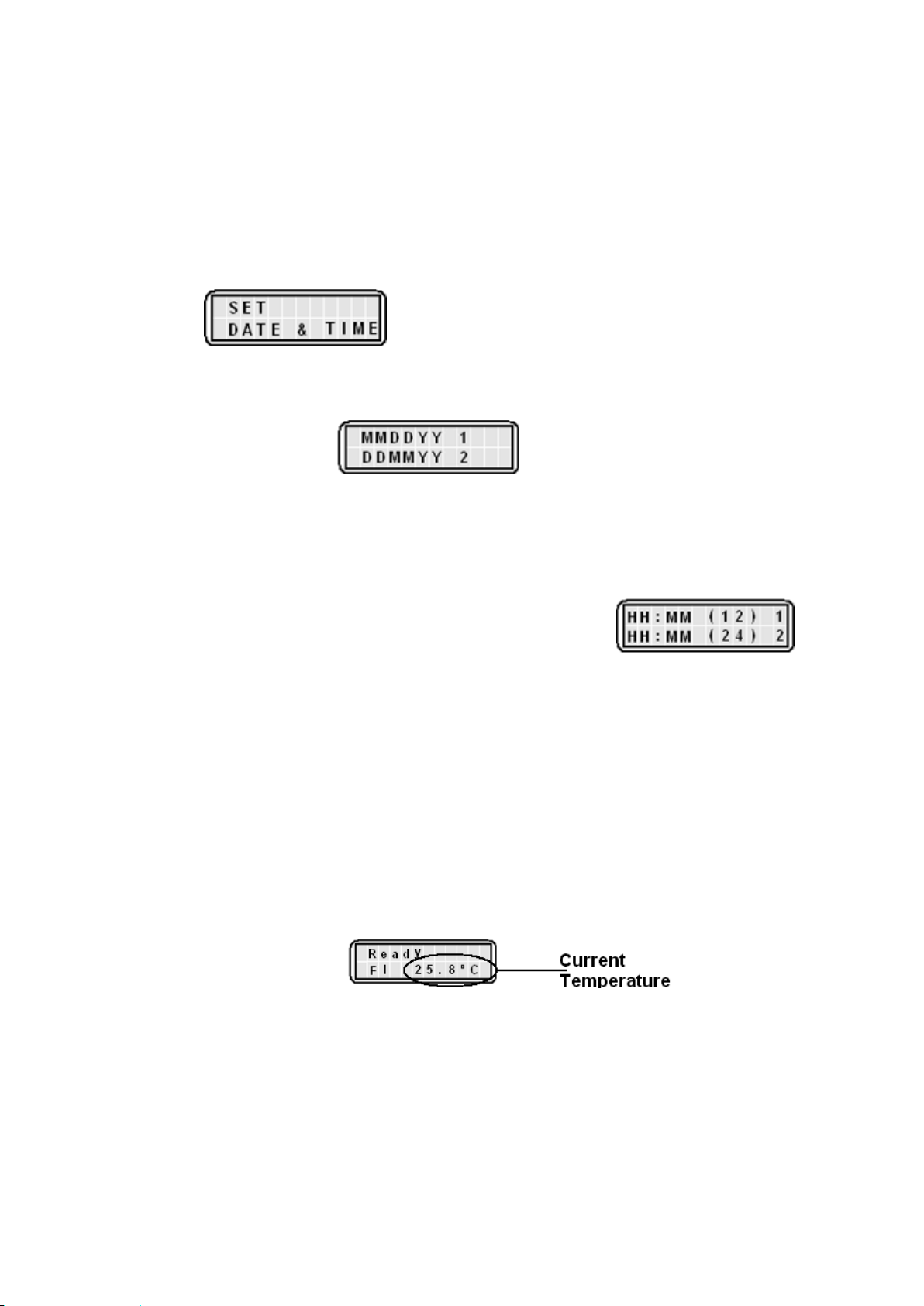

7.3.1.When either the IA9200 / IA9300 is plugged in and powered up for the first time the time

and date may require setting. After the unit has displayed the firmware version and

model type you will be asked to set the date and the time.

press the return key to take you to the setting functions.

7.3.2.You are now asked to select the date format. Select the required format by pressing

either key 1 or key 2.

7.3.3.Enter the characters of the date for the format selected. For date selection 1 enter the

following as an example. To enter 14th July 2010 press 071410. For date selection 2

enter the following using the same example. 140710.

7.3.4.You will now be prompted to select the date format of either 12 or 24 hour format. Press

key 1 for 12 hour format or press key 2 for 24 hour format.

7.3.5.Enter the time characters for the time in your time zone as directed by the screen

followed by the return key.

7.3.6.If you have selected the 12 hour time format you will now be asked to select whether

your time is set in AM or PM mode. Select the prompt key 1 or 2 as applicable.

7.3.7.Your IA will return to the user screen.

7.4. IA9100 Operation.

7.4.1.Connect the IA to the power supply. It will perform a self check while displaying the

model and firmware version. The display will then turn to the Home screen which says

‘Ready’ and shows the IA ovens current temperature.

7.4.2.F1 is the Home screen for setting temperatures and running the IA. Press ‘Fn’ key to

enter the F2 screen. The F2 screen will display the details of the last performed melt

sequence. To toggle between F1 home screen and F2 Melt recall screen press the ‘Fn’

key.

7.4.3.To commence melt setup and perform a melt sequence, ensure the unit is in the F1

home screen.

Page 15 of 40 M8144 Issue 2.0

Press the return key.

7.4.4.You are now asked to ‘Set the Temperature’. Use the key pad to enter the required set

point temperature. Refer to paragraph 7.2.1 Principals of Operation. Once the desired

set point temperature has been entered press the return key.

7.4.5. You are now asked to select your preferred ramp rate. Press 1 for 1.0°C/min or 2 for

10.0°C/min. Note:- The default ramp rate is set at 1.0°C/min.

7.4.6. You are now given the option to set the ceiling temperature. The ceiling temperature

should only be set if it is critical to your sample so that it must not be heated above a

certain temperature. The default is 400°C. If there is no requirement for setting a ceiling

temperature press the return key. The IA oven will commence heating to the set point

temperature.

Note: The last used ceiling setting will be remembered and recalled for subsequent

melts. If the IA is powered down and then powered up again the default value of 400°C

will be reinstated.

Note: The ceiling temperature cannot be set to less than 5°C of the set point

temperature. If you attempt to make an illegal setting the IA will automatically default to

5°C above the set point temperature.

7.4.7.As the IA heats up to the set point temperature you will see asterisk appear across the

low half of the display screen indicating the closeness of the oven temperature to the

set point temperature. When the set point temperature has been reached the IA will

beep three times. It is recommended the user allows a short time of a couple of minutes

for the oven temperature to stabilize before commencing with the ramp heating.

7.4.8. Insert you chemicals sample and allow the IA9100 and chemicals to stabilize once

more. Press the return key to commence ramping.

7.4.9.When the first melt is observed press the return key. Up to four melts may be performed

as described in Paragraph 7.2.3 ‘Determining melt’. Press the return key every time a

melt is observed. If less than four melts are required press the ‘Fn’ to move out of melt

record mode.

7.4.10. You are now asked if you wish to turn off the oven. Press key 1 for yes or key 2 for

no. If you are going to perform subsequent melts then leave the oven on. It will reset

back to the previous set point temperature.

7.4.11. Reading the recorded melt data. From the home screen press the ‘Fn’ key to enter

F2 Melt recall screen. Press the return key to display the melt point data of the first date.

Press the return key to display the temperature the second melt recorded and so on for

the third and fourth melts. To exit the screen press ‘Fn’ twice to return to the Home

screen.

Note: Only the last recorded batch may be viewed. Previous melt data will be over

written.

Note: Data will be lost if the 9100 is turned off or disconnected from the electrical

supply.

Page 16 of 40 M8144 Issue 2.0

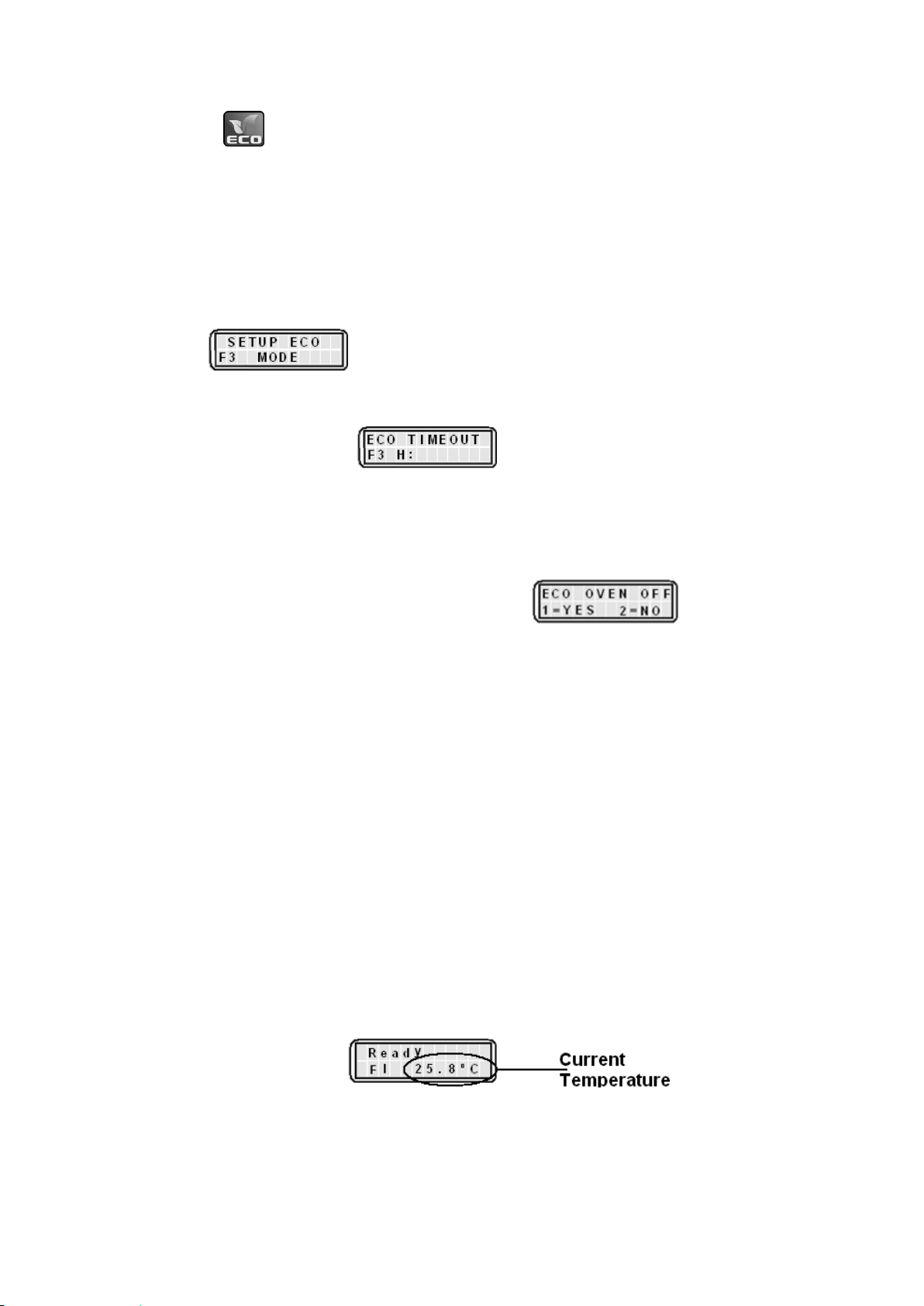

7.4.12. ECO Mode settings. IA9100.

Eco Mode is provided to save on power when the IA keypad remains untouched for a

pre specified length of time. The default setting is one hour unless adjustments are

made. Upon subsequent use the settings will be remembered until the IA is turned off at

the mains electrical supply. Power resumption will see the IA9100 return to the default

setting. As well as being able to select the ECO power off time the user can select

which functions of the ECO facility they wish to have operational. The default setting for

the oven on / off is always oven on.

7.4.13. From the home screen press the ‘Fn’ twice to enter F3 ECO Mode.

To accept entry to ECO mode press the ‘Enter’ Key. To decline

press the function key where you are taken back to the F1 home screen.

7.4.14. Use the key pad to set the hours and minutes the required before the ECO mode

power saving cuts in. . (To enter 1 hour 30 minutes press 0130). By

entering H00 M00, ECO mode will never be activated. Press ‘Enter’ to accept the time

setting. Press clear to re-enter a different time. Note: The minimum settable time is 1

hour. The maximum is 12 hours.

7.4.15. You are now asked if you wish for the oven to be turned off as well as display and

back light LED’s. Press 1 for yes and 2 for no. The IA display will

revert back to the F1 home screen.

7.4.16. When the IA enters ECO mode the Oven illumination LED will turn off. The display

back light will also extinguish and depending on the selection made so may the oven.

To show the IA is in ECO sleep mode the display will either display ‘ECO Sleep Oven

off’ or ‘ECO sleep Oven on’ accordingly.

7.4.17. To awaken the IA press any key on the keypad. The IA will return to its pre sleep

condition.

7.5. IA9200 Operation.

7.5.1. Connect the IA to the power supply. It will perform a self check while displaying the

model, date (see 7.3 for date and time setting or adjust from F3 screen if not already

set) and firmware version. The display will then turn to the home screen which says

‘Ready’ and shows the IA ovens current temperature.

Page 17 of 40 M8144 Issue 2.0

7.5.2. Function key operation. (Fn). The function key is used for scrolling through the sub

menus of the 9200 model. Each time the Fn key is pressed the IA will enter the next

sequential function screen. The main home screen is F1 from which settings are made

and melts are performed. From F1 press the Fn key and the sub menu F2 ‘Stored data’

appears. The F2 sub menu is used for recalling saved melt information together with

selecting data output methods. From F2 press the Fn key to access F3 the sub menu

the settings menu. Within the settings function the time clock can be access for making

time and date setting and adjustments. If you press the Clear ‘C’ key from F2 or F3 will

return you to F1 home screen.

F1 Operational mode.

7.5.3.Setting the IA9200 to perform a melt. You are now asked to ‘Set the Temperature’.

Use the key pad to set the set point temperature. Refer to paragraph 7.2.1 Principals of

Operation. Once the desired set point temperature has been entered press the return

key.

7.5.4.You are now asked to set the ramp rate. The default is 0.2°C/min. To change the ramp

rate use the keypad to enter the new ramp rate value. Press the return key to accept the

default or accept the new ramp rate value.

Note: The last used ramp rate setting will be remembered and recalled for subsequent

melts. If the IA is powered down and then powered up again the default value of

0.2°C/min will be reinstated.

7.5.5.You are now given the chance to enter a ceiling. The ceiling temperature should only be

set if it is critical to your sample so that it must not be heated above a certain

temperature. The default is 400°C. If there is no requirement for setting a ceiling

temperature press the return key. The IA oven will commence heating to the set point

temperature.

Note: The last used ceiling setting will be remembered and recalled for subsequent

melts. If the IA is powered down and then powered up again the default value of 400°C

will be reinstated.

Note: The ceiling temperature cannot be set to less than 5°C of the set point

temperature. If you attempt to make an illegal setting the IA will automatically default to

5°C above the set point temperature.

7.5.6. As the Melt Point apparatus heats up to the set point temperature you will see asterisk

appear across the low half of the display screen indicating the closeness to the set set

point temperature. When the set point temperature has been reached the Melt Point

apparatus will beep three times. It is recommended the user allows time for the oven

temperature to stabilize before commencing with the ramp heating.

7.5.7.Insert you chemicals sample and allow time for the oven to reheat back to the set point

temperature. Press the return key to commence ramping. You will notice a moving icon

indicating that the IA is in ramping condition.

7.5.8.When the first melt is observed press the return key. Up to four melts may be

performed. See paragraph 7.2.3 ‘Determination of Melt point’. Press the return key

every time a melt is observed. If less than four melts are required press the ‘Fn’ to move

out of melt storage mode.

7.5.9.You are now asked if you wish to turn off the oven. Press key 1 for yes or key 2 for no. If

you are going to perform subsequent melts then leave the oven on. It will reset back to

the previously set plateau temperature.

Page 18 of 40 M8144 Issue 2.0

7.5.10. You are now asked if you wish to store the melt data. Press 1 for yes or 2 for no. If

the answer is yes you will be asked to enter a batch number. Select a batch number

between 1 and 2000 and press the return key. After making store data decision you are

taken to the recorded data option screen.

7.5.11. You are now asked if you wish to view the recorded melt data. Press 1 for yes or 2 for

no. If you have selected yes. Press the return key to scroll through the data settings and

recorded melt data. If you pressed no you are taken straight to the printing option

screen.

7.5.12. You are now asked if you wish to print out the recorded data. Press 1 for yes or 2 for

no. Ensure a printer is connected before selecting 1 for a print. (See printer set up

paragraph 7.8).

7.5.13. You are now asked if you which to output the data via a USB Pen drive. Press 1 for

yes or 2 for no. If you press 1 for yes you are asked to insert a USB Pen drive. Your

data will be uploaded to the Pen drive device. Data written to the Pen drive can be

accessed on your PC using MS ‘Notepad’or similar application. The file name is IAxxxx

where xxxx is the batch number.

7.5.14. You are asked if you want to send the melt data direct to your PC. Press 1 for yes or

2 for no. Ensure your IA is connected to your PC using the USB slave socket. (See 7.1

over view illustration and item 9 USB socket type ‘B’ Slave). The IA is accessed via

HyperTerminal on your PC. (See paragraph 7.9 HyperTerminal set up and access).

7.5.15. Finally you are asked if you wish to retain the settings. (Only available if the oven

has not been turned off). Press key 1 for yes or key 2 for no. This feature allows the

user to return straight back to performing subsequent melt without the option of making

adjustments to the melt profile. (Returned to paragraph 7.5.6). Use this facility when

there are lots of melt to be performed and the previously set temperature, ramp rate and

ceiling temperature are required for all. This facility cuts down on key entry and assists

in speeding up the melt through put. When 1 is selected the IA will return to the plateau

temperature. The 4 asterisk will appear on the display as an indication of the closeness

to temperature plateau. When the IA beeps and four asterisks are displayed press the

return key to commence ramping. By pressing the 2 = no key the user is taken back to

the F1 home screen where upon melt profile adjustment can be made.

F2 Reviewing and Outputting Stored data.

7.5.16. From the F1 home screen press the ‘Fn’ key to enter F2 Stored data screen. Press

the return key to accept access.

7.5.17. Enter the batch number using the keypad. Press the keypad return key.

Page 19 of 40 M8144 Issue 2.0

7.5.18. The IA now says Display. This alows both settings and melt data to be viewed on the

display. Press 1 for yes or 2 for no. If 1 = yes is selected you will see the following

information. Press the return key to view the next field.

Date and first melt recorded time.

The set Ramp rate.

M1 melt temperature.

M2 melt temperature (assuming it was recorded).

M3 melt temperature (assuming it was recorded).

M4 melt tempeature (assuming it was recorded).

To exit view melt data without viewing all the stored data press the ‘Fn’ to sequence

into the printing option.

To exit viewing the melt data and return to F2 screen inorder to view another stored

batch press the ‘C’ key.

7.5.19. You are now asked if you wish to print out the recorded data. Press 1 for yes or 2 for

no. Ensure a printer is connected before selecting 1 for a print.

7.5.20. You are now asked if you which to output the data via a USB Pendrive. Press 1 for

yes or 2 for no. If you press 1 for yes you are asked to insert a USB flash drive. Your

data will be uploaded to the flash drive. It can be read on your PC using ‘Notepad’.

7.5.21. You are asked if you want to send the melt data direct to your PC. Press 1 for yes or

2 for no. Ensure your IA is connected to your PC using the slave socket.

7.5.22. You are asked if you wish to delete stored data. Press 1 for yes or 2 for no. You are

now returned to the F1 home screen.

F3 Setup Mode.

7.5.23. From the F1 home screen press the ‘Fn’ key twice to enter F3 setup mode screen.

Press the return key to accept access.

7.5.24. Time and date settings and adjustments are made here. See section 7.4.

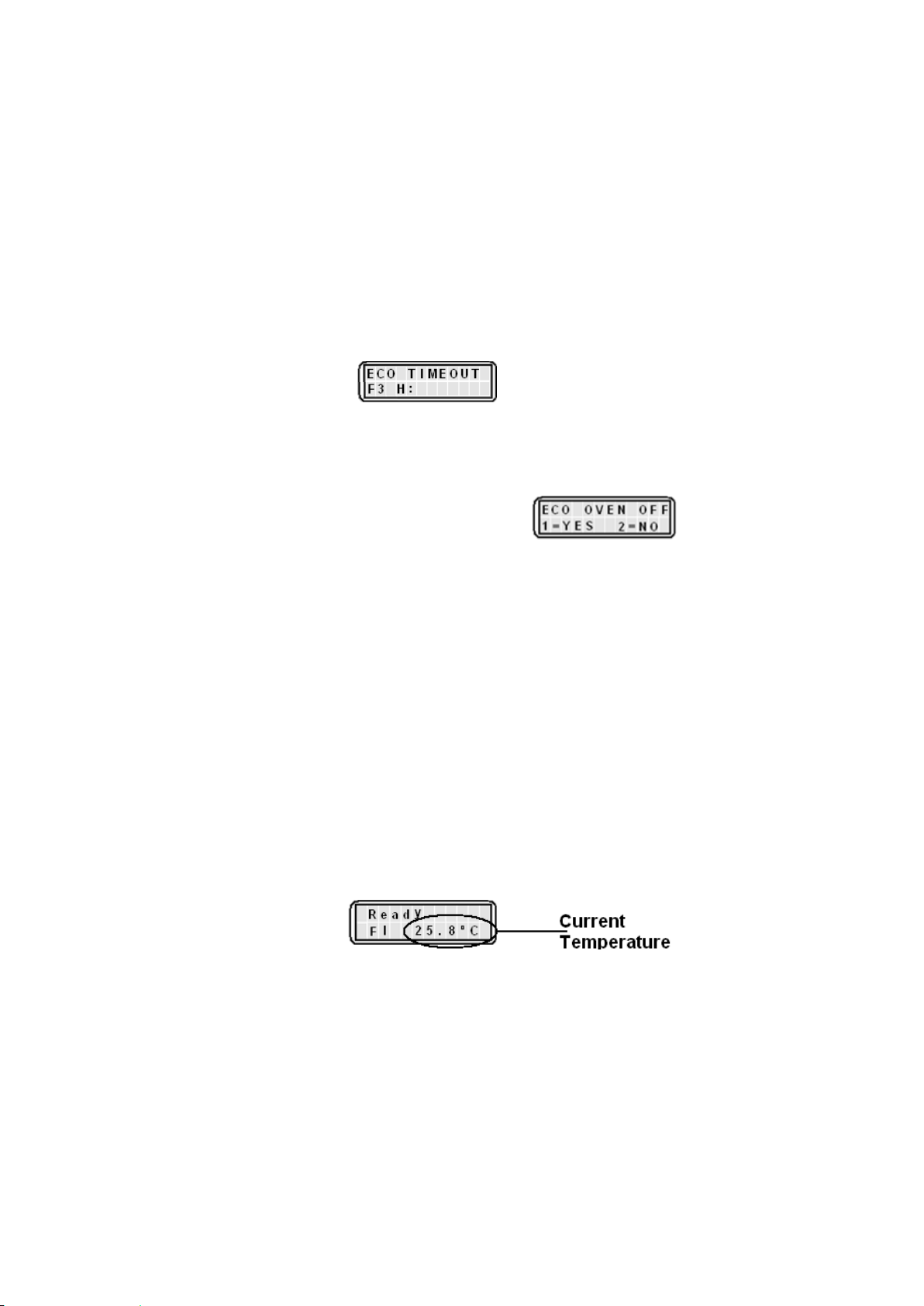

ECO Mode settings 9200

7.5.25. From the F1 home screen press the ‘Fn’ key twice to enter F3. Setup mode. Press

‘Enter’ key to select setup mode. You may now change the time and date (see 7.3) or

Press the ‘Fn’key again to enter ECO mode settings. . To decline

press the function key where you are taken back to the F1 home screen.

Page 20 of 40 M8144 Issue 2.0

Eco Mode is provided to save on power when the IA keypad remains untouched for a

pre specified length of time. The default setting is one hour unless adjustments are

made. Upon subsequent use the settings will be remembered until the IA is turned off at

the mains electrical supply. Power resumption will see the IA9200 return to the default

setting. As well as being able to select the ECO power off time the user can select

which functions of the ECO facility they wish to have operational. The default setting for

the oven on / off is always oven on.

7.5.26. Use the key pad to set the hours and minutes the required before the ECO mode

power saving cuts in. . (To enter 1 hour 30 minutes press 0130). By

entering H00 M00, ECO mode will never be activated. Press ‘Enter’ to accept the time

setting. Press clear to re-enter a different time. Note: The minimum settable time is 1

hour. The maximum is 12 hours.

7.5.27. You are now asked if you wish for the oven to be turned off as well as display and

back light LED’s. Press 1 for yes and 2 for no. The IA display will

revert back to the F1 home screen.

7.5.28. When the IA enters ECO mode the Oven illumination LED will turn off. The display

back light will also extinguish and depending on the selection made so may the oven.

To show the IA is in ECO sleep mode the display will either display ‘ECO Sleep Oven

off’ or ‘ECO sleep Oven on’ accordingly.

7.5.29. To awaken the IA press any key on the keypad. The IA will return to its pre sleep

condition.

7.6. IA9300 Operation.

7.6.1. Connect the IA to the power supply. It will perform a self check while displaying the

model, date and firmware version. The display will then turn to the home screen which

says ‘Ready’ and shows the IA ovens current temperature.

7.6.2. Function key operation. (Fn). The function key is used for scrolling through the sub

menus of the 9300 model. Each time the Fn key is pressed the IA will enter the next

sequential function screen. The main home screen is F1 from which settings are made

and melts are performed. From F1 press the Fn key and the sub menu F2 ‘Stored data’

appears. The F2 sub menu is used for recalling saved melt information together with

selecting data output methods. From F2 press the Fn key to access F3 the sub menu

the settings menu. Within the settings function the time clock can be access for making

time and date setting and adjustments. Pressing the Clear ‘C’ key from F2 or F3 will

return you to F1 home screen.

This manual suits for next models

3

Table of contents

Other Electrothermal Melting Machine manuals