3

Table of Contents

Shipping Papers and Information ....................................................... 4

General Safety Overview ..................................................................... 5

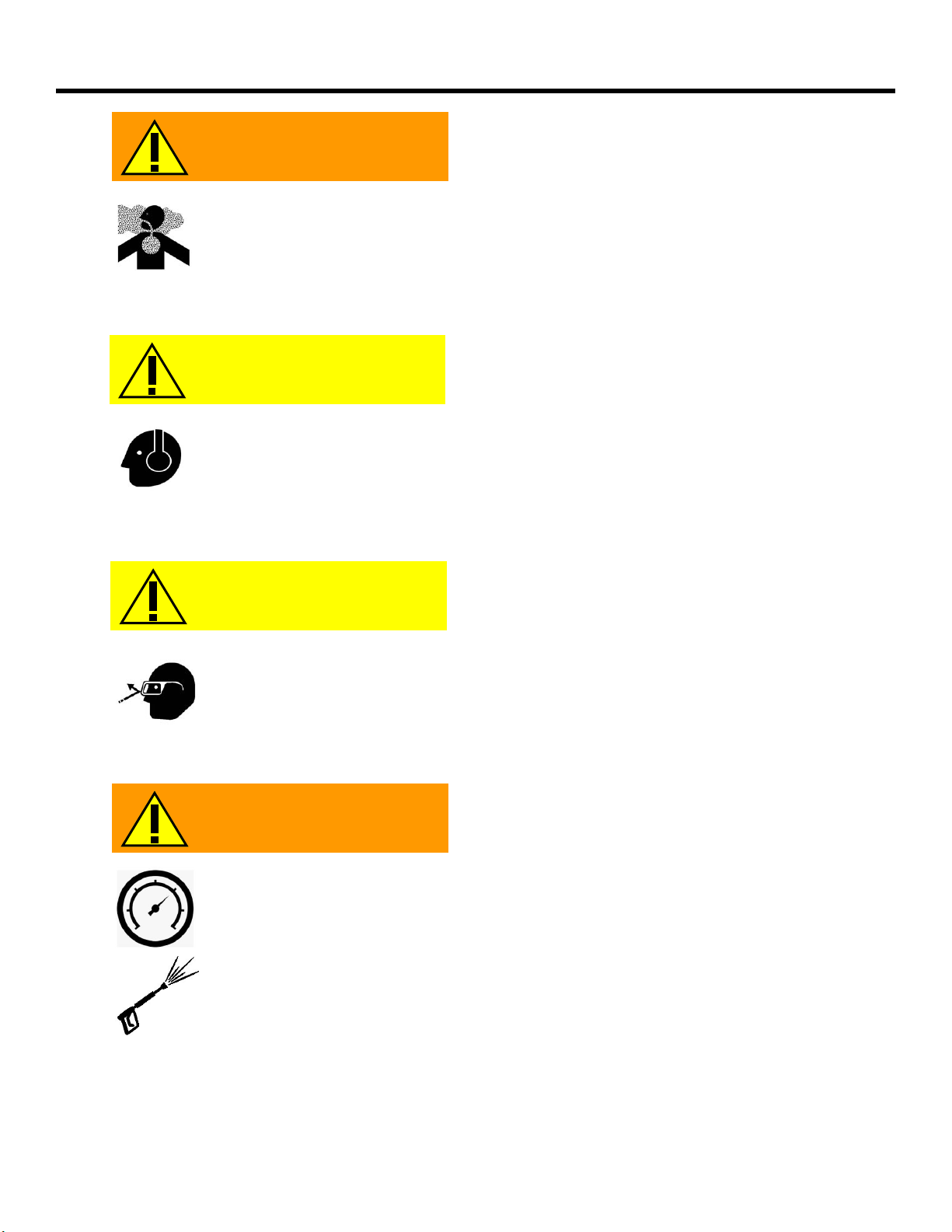

Signal Words in Manual....................................................................... 5

Hazards..............................................................................................6-9

Weights and Dimensions.............................................................. 10-11

Safe Operation.................................................................................... 11

Installation .....................................................................................12-15

Prior to Installation ...................................................................... 12

Raising the Boom Column........................................................... 12

Initial Start Up ............................................................................. 13

Lifting the X2............................................................................... 14

Securing the X2 .......................................................................... 15

Operating the X2 ...........................................................................16-18

Start Up..................................................................................16-17

During Operation......................................................................... 18

Shutting Down............................................................................. 18

General Maintenance ....................................................................19-23

Fuel............................................................................................. 19

Cleaning...................................................................................... 19

Engine service ............................................................................ 20

Compressor service .................................................................... 20

Maintenance schedule ........................................................... 20-21

Storage Preparation .................................................................... 22

Removal from storage................................................................. 23

Trouble Shooting...........................................................................24-25

Component Identification .............................................................26-31

Service Part List ............................................................................32-33

Notes..............................................................................................34-35

Warranty.............................................................................................. 36