Elektor 6-Digit Nixie Clock version 2 User manual

6-Digit Nixie Clock version 2

Assembly Manual

Revision 1 – released 2 2 - 6- 2

This kit is designed for someone who has intermediate experience with assembling electronics.

Please take your time – it will take approximately 3 hours to complete this kit. Ensure your work

area is well lit (daylight preferred) and clean.

ssemble the parts in the order as stated in the instructions - read and understand each step

before you perform each operation for the best chance of success.

The following tools and materials will be required to assemble the clock:

• good quality soldering iron (25-40W) with a small tip (2-3 mm).

• Thin solder wire with no-clean flux. Do not use any flux or grease.

• set of small screwdrivers.

• small wire cutter for electronics.

• wire stripper.

• Long nose pliers.

• hot air soldering station / heat gun / lighter (or alternative).

• multimeter

Reading the entire manual before starting the project is highly advised and will help you

comprehend the overall project.

Disclaimer

ll pictures are for illustration purposes only. ctual product may vary due to product

enhancement.

Schematic and PCB Layout

Main and Display Circuit

Main PCB

Display PCB

Backlight Circuit

Backlight PCB

Assembling the Display PCB

Mount resistors R1, R2, R4, R5, R25 and R26,

27k (red – violet – orange – gold)

Mount resistors R3 and R24, 470k (yellow –

violet – yellow – gold)

Mount the angled pin headers K4, K6, K8, K10,

K12 and K14.

If you wish, you can now remove any excess

solder flux from the solder joints as these will

remain visible when the clock is finished. You

can use a commercial flux remover or isopropyl

alcohol (IP ) for this purpose. Make sure this

stuff never comes into contact with the acrylic

parts of the optional enclosure.

Have the IN-12 nixie tubes (V1 ... V6) and

optional tube socket pins ready for the next

step. Before starting the assembly you can put

the IN-12 nixie tubes temporarily on the PCB

(solder side) to see in which order they look

best. IN-12 nixie tubes have quite some

mechanical tolerances. You can mount the IN-12

nixie tubes with or without tube socket pins.

Mounting the tubes without tube socket pins

Put each IN-12 tube with its pins though the holes of the PCB from the solder side and solder them

temporarily in place by soldering the top pin of each tube.

Now turn over the board and take a look at the alignment of the tubes. If needed, you can still

make corrections by reheating the solder connections.

If you are satisfied with the alignment of the tubes, you can solder the remaining pins. Keep the

temperature of your soldering iron as low as possible and keep the soldering time as short as

possible.

Please note that it will be difficult to replace a defective nixie tube if the tubes are soldered

directly to the board.

Mounting the tubes with tube socket pins (recommended)

Pinch the tube socket pins between your fingers

so they will be more tight. In order to mount

the tubes, you can choose between two

options. You can either slide the tube socket

pins over the pins of the tube and push the tube

with socket pins through the holes of the PCB or

fit the tube socket pins to the PCB and push the

tubes in the socket pins. If you choose the latter

option, make sure the pins of the tubes are

correctly seated into the socket pins.

When all the tubes are in place, turn over the PCB and solder the tube socket pins from the

backside. Do not use too much solder and keep soldering time short.

Solder the small neon lamps L 1 and L 2 into place. The polarity doesn't matter. They shouldn't

protrude as much from the PCB as the nixie tubes.

The display PCB is now finished.

Assembling the Main PCB

Mount the components from low to high. Start

with the small signal schottky diodes D3 and D4,

B T46. Watch the polarity!

Mount the following resistors:

R27: 0,27 Ω (red – violet – silver – gold)

R12, R16: 1k (brown – black – red – gold)

R17: 5k6 (green – blue – red – gold)

R6 ... R9, R11, R23: 10k (brown – black – orange

– gold)

R13: 470k (yellow – violet – yellow – gold)

Mount schottky diodes D1, BYV26-C and D2,

1N5819. Watch the polarity!

Mount the IC sockets for IC7 (8 pins), IC1 ... IC3,

IC8, IC9 (16 pins) and IC4 (40 pins).

Mount the 47k/1 W resistor R28 (yellow – violet

– orange – gold) and trimmer potentiometer P1

(470K). The resistor is a bit of a tight fit. Mount

it so, it hovers a few millimeters above the PCB

as it will get hot when the clock is powered up.

Mount the ceramic capacitors C3, 470 pF and

C1, C4 ... C7, C15 ... C17, 100 nF. You may need

to bend the wires of C3 a bit to get it to fit on

the PCB.

Mount pin headers for S1, Bz1 (2 pole), MOD1

(5 pole), K1 (6 pole) and K15 (7 pole).

Mount the socket headers K3, K5, K7, K9, K11

and K13 (2x5 pole).

Mount the bipolar transistors T1 ... T4, T8

(MPS 42) and T9 (BC557B). For esthetical

reasons and to facilitate mounting, the top of

the transistors should be flush with the top of

the pin and socket headers.

Mount the terminal block K2 and electrolytic

capacitor C18 (220 μF 16 V). Watch the polarity!

Mount the electrolytic capacitors C11, C12 (100

μF 25 V) and C13 (10 μF 25 V). Watch the

polarity.

Mount the red LED LED1. Watch the polarity!

The longest lead should go in the hole closest to

R12. Keep the soldering time as short as

possible as some LEDs are easily damaged by

excessive heat.

Mount the power inductor L1 (100 μH). It is

highly recommended to mount the inductor so

the start of the windings marked by a white dot

is connected to the switching node (D1 and T5).

s such, the outer windings on the ferrite core are connected to the power supply rail and act as

an EMI shield.

Mount the DC/DC step-down converter module

IC6 (OKI-78SR-5/1.5-W36C). The power inductor

on the module should point towards K1.

Mount MOSFET power transistor T5 (IRF644).

Please note that this is an electrostatic sensitive

device. It is recommended to touch an earthed

metal object before mounting the transistor. s

a better alternative, you can also wear an anti

static wrist strap and combine this with a

grounded ESD mat. The metal tab of the

transistor should point towards D1.

Mount the electrolytic capacitor C10 (10 μF 250 V). Watch the polarity!

Put IC7 (MC34063) in its socket. Watch the position of the notch!

Make sure trimmer potentiometer P1 is in its

middle position.

Power up the bord using a 9 V power supply

capable of delivering at least 500 m . lab

power supply with adjustable current limit is

preferable. Measure the nixie anode voltage

across 1 W resistor R28. djust the voltage to

approximately 170 V. Be careful not to touch the

170 V anode voltage and do not touch R28 as it

may get hot.

Now check the 5 V power rail voltage. You can

measure this voltage on pin header K1.

Do not continue the build of the clock if the

voltages are not correct but look for assembling

faults instead.

If everything is ok, disconnect the power supply.

Put the Russian nixie drivers IC1 ... IC3, IC8 and

IC9 (K155ID1 / 74141) in their sockets. Put PIC

controller IC4 (PIC18F44K22-I/P, PIC18F45K22-

I/P or PIC18F4420-I/P) in its socket.

Watch the position of the notches on all ICs!

Remove the GPS module from its anti static bag

and put it on a flat surface. Connect the GPS

patch antenna to the GPS module using the

coaxial micro RF connector. The connector

might be a bit of a tight fit but be careful not to

damage it.

Finally mount a 5 pole socket header on the

bottom side of the module.

Connect the GPS module to the main board and

fixate it using 2 M3X6 machine screws, 4 nylon

M3 washers and a 10 mm hex standoff. The

main board is now finished.

Putting the PCBs together

Connect the display board to the main board.

You can now connect a power supply again and

run a first test. fter power up, the nixie tubes

show the firmware version and should then

cycle between digits one after each other. Note

that the first nixie tube only can show numbers

between 0 and 3.

fter the cycling test, the clock will show a baud

rate 4800 and then 9600 when it tries to get the

time from the GPS module.

Shortly thereafter, the time is displayed. Depending on your local time zone, this may be or not be

correct but this can be adjusted later. Please note that dimming may be active too resulting in a

very dim display. This can also be adjusted later.

Installing the backlight PCB is optional. The nixie

clock can work without the backlight PCB too. If

you don't want to install the backlight PCB, you

can skip the following steps and go directly to

the wiring of the clock.

Mount a 3 pole pin header to the solder side of

the backlight board. This board comes

preassembled with the SMT parts already in

place.

Screw 2 plastic 8 mm standoffs to the mounting holes of the backlight board. If you are planning to

put the nixie clock into the designated acrylic enclosure from Elektor, you should use two M3x16

machine screws and two nylon M3 washers to hold the standoffs in place. The M3x16 machine

screws should protrude from the standoffs. Please note that the M3x16 screws are part of the kit

for the enclosure, they are not included with the nixie clock kit.

If you are not going to use the enclosure, mount the spacers to the backlight board using two

M3x6 screws and two nylon M3 washers.

ttach the backlight PCB to the display PCB. Use 2 8 mm standoffs if you are going to use the

Elektor enclosure. These are included with the kit for the enclosure. Otherwise, use two M3x6

machine screws and two nylon M3 washers.

Wiring the clock

If you are not going to use the backlight PCB,

you can as well skip this step.

Connect two 3 pole socket headers together

using 10 cm of green, black and red wire.

Insulate the solder joints using 14 mm pieces of

3.2 mm heat shrink tube.

Connect a 2 pole socket header to the push

button using 5 cm of black and red wire.

Insulate the solder joints using 14 mm pieces of

3.2 mm heat shrink tube.

Solder 5 cm pieces of black and red wire to the

DC connector. Insulate the solder joints using 14

mm pieces of 3.2 mm heat shrink tube. Strip the

other ends of the wires but do not tin them.

Solder the wires of the buzzer to a 2 pole socket

header. Insulate the solder joints using 14 mm

pieces of 3.2 mm heat shrink tube.

Connect the DC connector wires to terminal block K2. Watch the polarity! Connect the push button

to S1 and connect the buzzer to Bz1. Watch again the polarity!

If you are using the backlight PCB, connect it to K1 on the main board using the 3 pole socket

headers and wires we prepared a few steps earlier. Take care that the connections D, 0 and + on

the backlight PCB are connected to the same D, 0 and + pins of connector K1 on the main board.

You can now test your clock again if you wish to do so.

The construction of the electronics of your clock

has now been completed. Please read further, if

you want to put the clock in the acrylic

enclosure from Elektor.

Assembling the enclosure

Disconnect the DC connector, push button and buzzer from the main PCB.

Remove the protective finish from the front panel and slide it over the IN-12 nixie tubes and neon

lamps of the clock assembly and attach it to the display PCB using two M3x6 machine screws.

Remove the protective finish from the baseplate

and the acrylic support.

Mount the acrylic support to the baseplate

using an M3x12 machine screw and an M3 nut.

Do not over tighten the screw as the acrylic may

break. Use preferably a watchmakers or a

jewelers screwdriver as these will prevent you

from using too much force.

Screw two M3x8 machine screws all the way

from the bottom side through the base plate

and slide two 3 mm plastic spacers over the screw ends on the top side.

Position the main PCB on top of the baseplate so it fits over the earlier installed M3x8 screws and 3

mm spacers. Make sure the tabs on the front panel fit into the slots of the baseplate.

ttach the main PCB to the baseplate using four additional M3x8 machine screws and four 3 mm

spacers.

Remove the protective finish from the acrylic GPS patch antenna mounting plates. Place the

antenna between the acrylic parts and screw everything together using two nylon M4x12 machine

screws.

Remove the protective finish from the back

panel and attach the power connector using

two M2x6 machine screws and two M2 nuts.

Watch the orientation of the panel so the wires

protrude at the right side. The engraving should

end up at the inside of the enclosure. ttach the

push button to the back panel. 10mm socket

will come in useful here, if not pliers will do the

job. If you decide to use pliers, be careful not to

scratch the acrylic.

ttach the buzzer to the back panel using four

M2X6 machine screws and two 10 mm standoffs with internal M2 thread. Finally, attach the patch

antenna assembly to the back panel using a nylon M4x12 machine screw and a nylon M4 nut.

Connect the wires again to the main PCB and guide the tabs of the back plate through the slots of

the base plate.

Remove the protective finish of the side panels. It's best to remove the small pieces of the

protective finish inside engravings first and work your way from the inside to the outside of the

panels. The protective finish can be a bit difficult to remove but keep in mind that it was needed to

protect the acrylic from laser fumes during manufacturing.

Finally guide the tabs of the side panels into the slots of the base panel. The engraving on the

panels should face the inside of the enclosure.

Remove the protective finish of the top panel and fit it over the front, back and side panels, with

the engraving again facing the inside of the enclosure. Finally screw the bottom and top panel

together using the brass tubes, threaded rods, cap nuts and nylon M4 washers.

Congratulations!!! You've finished your clock.

This manual suits for next models

2

Table of contents

Popular Clock manuals by other brands

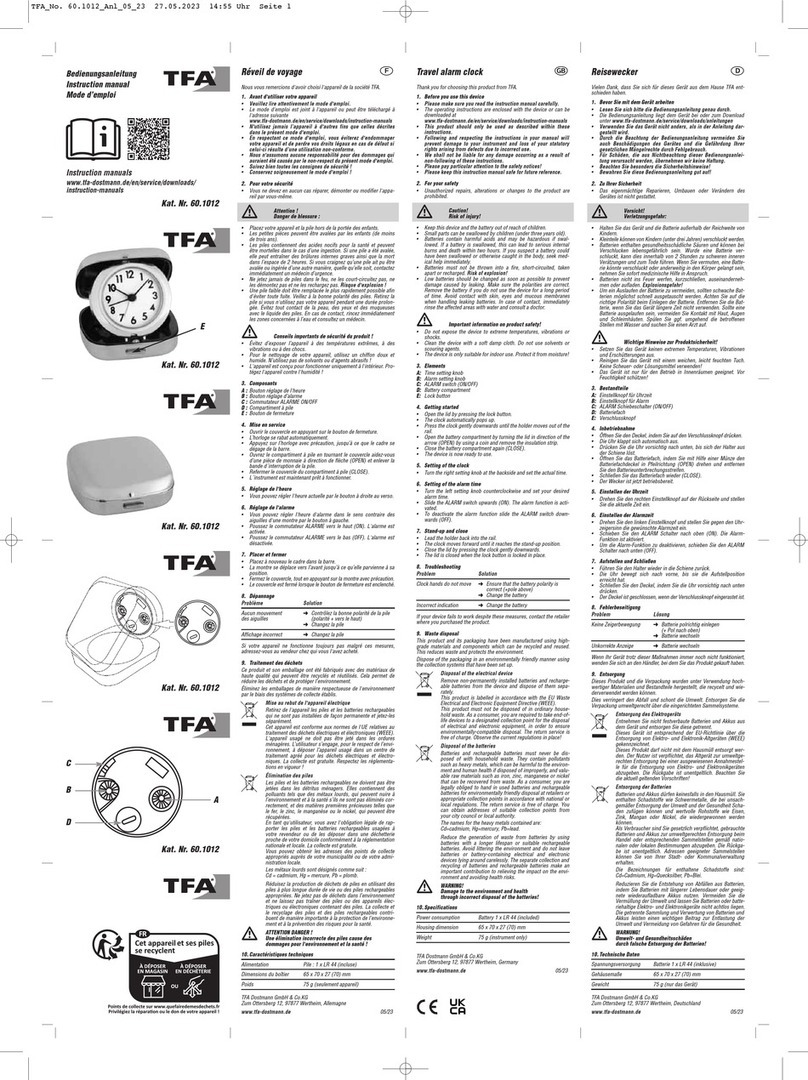

TFA

TFA 60.1012 instruction manual

Bodet

Bodet 5 Seconde Installation and operation manual

Sears

Sears D71 M64205 owner's manual

La Crosse Technology

La Crosse Technology WT-8005U manual

Eurochron

Eurochron 1561128 operating instructions

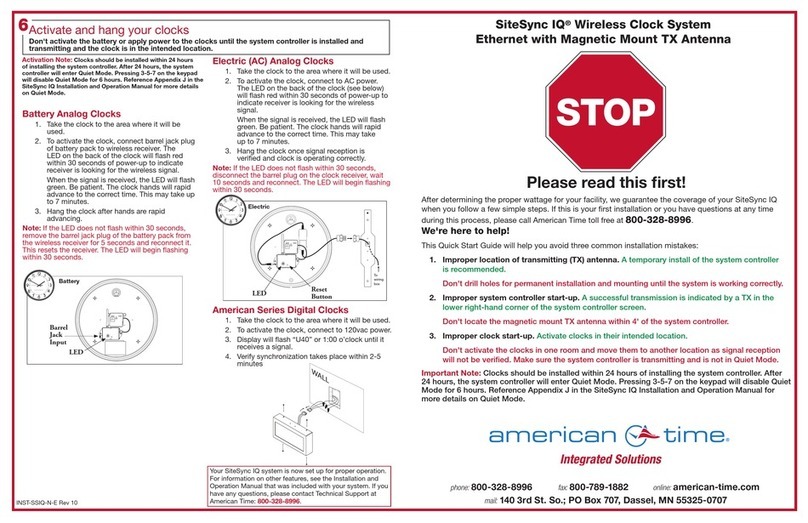

American Time

American Time SiteSync IQ Quick start installation guide