Elektral ThruScan Series User manual

1

Contents Page

PREFACE ........................................................................................................................ 4

Contents......................................................................................................................... 5

Before Use ..................................................................................................................... 6

1. GENERAL DESCRIPTION ............................................................................................ 8

1.1 ThruScan s3 Walk Through Metal Detector ........................................................... 9

1.3 ThruScan s6 Walk Through Metal Detector .........................................................10

1.3 ThruScan s9 Walk Through Metal Detector .........................................................11

1.4 ThruScan sX Walk Through Metal Detector .........................................................12

1.5 ThruScan sX-WP Walk Through Metal Detector ...................................................13

1.6 ThruScan s15-i Walk Through Metal Detector .....................................................14

1.7 ThruScan sX-i Walk Through Metal Detector........................................................15

2. INSTALLATION ..........................................................................................................16

2.1 Site Selection .........................................................................................................16

2.2 Assembling & Mounting......................................................................................... 16

2.2.1 Assembling..........................................................................................................16

2.2.2 Assembling..........................................................................................................17

2.2.3-4. Assembling .....................................................................................................17

2.2.- 5.6.7.8.9.10.11.12.13.14 Assembling ..............................................................17

3. CONTROL DISPLAY PANEL & INDICATION INFORMATION 18

3.1 Control Panel..........................................................................................................18

3.1.1 LCD Display.........................................................................................................18

3.1.2 Grafic (Alarm) Zone LEDs (Locater) ...................................................................18

3.1.3 VU Display (LED Array)........................................................................................19

3.1.4 UPS Indicator ...................................................................................................... 19

3.1.5 IRDA Remote Control Receiver ..........................................................................19

3.1.6 Traffic Indicator LEDs (Lights)............................................................................19

3.2 Touch Pads............................................................................................................ 19

3.2.1 ON- OFF Button...................................................................................................19

3.2.2 RUN(X) Button.....................................................................................................19

3.2.3 SEL(√) Button...................................................................................................... 20

3.2.4 Up-Down Buttons................................................................................................20

3.3 Traffic Lights...........................................................................................................20

3.4 Zone (Indicator) Light’s.......................................................................................... 20

3.5 Various Alarms .......................................................................................................20

3.6 Relay-Contact Outputs...........................................................................................21

3.7 Synchronization and Remote Control Outputs .....................................................21

4. PROGRAMMING & SET UP .......................................................................................22

4.1 Programming MENU .............................................................................................. 22

4.1.1 Security Level & Sensitivity Level Adjustments ................................................23

4.1.2 Security Level & Sensitivity Level, Zone Adjustment (sX Series) ..................... 25

4.1.3 Auto Detection & Auto Sensitivity Assignment (sX) ..........................................25

4.1.4 Alarm Volume & Tone Adjustment.....................................................................26

4.1.5 Alarm Counter.....................................................................................................26

2

4.1.5.1 ThruScan s3/s6/s9/sX/sX–WP .....................................................................26

4.1.5.2 Alarm Counter for ThruScan sX-i ....................................................................27

4.1.6 In-Coming / Out-Going Counter (Traffic Counts) ...............................................27

4.1.6.1 For ThruScan s3/s6........................................................................................27

4.1.6.2 For ThruScan s9/sX/sX-i/sX-WP ....................................................................28

4.1.7 Factory Settings .................................................................................................. 28

4.1.8 Language Selection............................................................................................29

4.1.9 Counter Visibility .................................................................................................29

4.1.10 New Password ..................................................................................................30

4.1.11 Environment Noise Level .................................................................................30

4.1.12 Pass Sensor...................................................................................................... 31

4.1.13 Alarm Tone Duration Select.............................................................................31

4.1.14 Operation Duration........................................................................................... 31

4.1.15 Random Alarm Rate Selection ........................................................................ 32

4.1.16 Alarm Rate and Operation Duration................................................................ 32

4.1.17 Selecting Operating Channels………..……………………………....……………..…..…...32

4.1.18 Date and Time Settings………………..………………………………….……..…….………...33

4.1.19 Major Error…………………………………...………………………………….…………….….…..33

4.1.20 SCADA Address…………………………….…………………………………….……………….....34

4.1.21 Panel Visibility…………………………………………………………………….…………………..34

4.1.22 SCD Statistics……………………………….…………………………………….………………….34

4.1.23 Statistics Menu…………………………………………………………………….…………………35

5. SYSTEM OPERATION ................................................................................................ 35

5.1 Normal Operating Mode ........................................................................................ 35

5.2 Routine Tests ......................................................................................................... 35

5.3 Alarm State............................................................................................................. 36

6. TECHNICAL SPECIFICATIONS ..................................................................................36

6.1 Electronics..............................................................................................................36

6.2 Detection Field ....................................................................................................... 37

6.3 Language................................................................................................................37

6.4 Self Test..................................................................................................................37

6.5-6.6 Sensitivity-Memory ..........................................................................................38

6.7-6.9 Traffic Counter- Regulatory Information ........................................................38

6.10 Infrared Sensor....................................................................................................38

6.11-6.12 Electromagnetic Noise & Interference Rejection-Masking ......................39

6.13 Synchronisation ................................................................................................... 39

6.14 –6.15 Electrical Requirements & Consumption Efficiency………………….…….. 40

6.17 Humidity ...............................................................................................................40

6.18 Throughput/Traffic Rate......................................................................................40

6.19 Weight .................................................................................................................. 40

6.20 Warranty Period ................................................................................................... 40

6.21 Dimensions ..........................................................................................................40

7. OPTIONS ...................................................................................................................41

7.1 SRC-SCADA Remote Control Package .................................................................. 41

7.1.1 SRC-SCADA Remote Control Software...............................................................41

7.1.2 Remote Control (by Modem) .............................................................................. 42

7.1.3 Remote Control (by Cable) .................................................................................42

3

7.2 Outdoor Package ...................................................................................................43

7.2.1 Rain Protect Shelter/Hat...................................................................................43

7.2.2 Side Panel Protection Cover .............................................................................. 43

7.3 Battery Group.........................................................................................................43

7.4 WTMD Wheeler ...................................................................................................... 43

7.5 Carriage Bag...........................................................................................................43

7.6 IRDA Remote Control ............................................................................................. 44

7.7 Real-Time Visual Prosecution Unit .................................................................... 44

7.8 Alarm Output ..................................................................................................... 46

7.9 NILECJ Test Kit .................................................................................................. 48

7.10 LED Zone Indicators on Both Sides................................................................. 48

7.11 Object Sliding Table ........................................................................................ 48

7.12 Queue Barrier.................................................................................................. 48

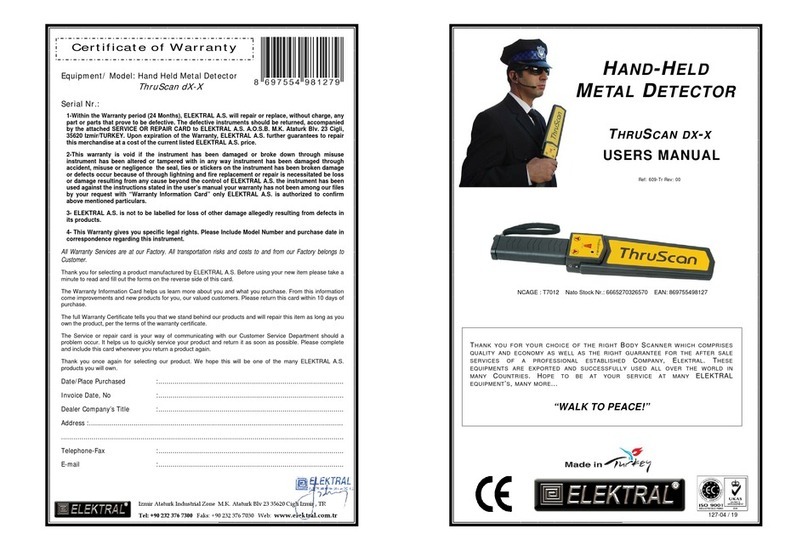

7.13 Hand-Held Metal Detector .............................................................................. 48

7.14 ShoeScan Metal Detector ............................................................................... 48

8. MAINTENANCE & REPAIR.........................................................................................49

8.1 Periodic Maintenance............................................................................................49

8.2 Repair .....................................................................................................................49

8.3 Module Replacement ............................................................................................ 49

8.4 Warranty Provisions ............................................................................................... 49

9. TROUBLESHOOTING.................................................................................................50

9.1 Frequently Asked Questions.................................................................................. 50

9.2 Installation Problems.............................................................................................51

9.3 Operational Problems ............................................................................................53

10. APPENDIX ...............................................................................................................55

10.1 Certificate of Expertise .......................................................................................55

10.2 SRC SCADA Remote Control ...............................................................................55

10.2.1 ThruScan s3/s6/s9 SRC SCADA Program Manual ........................................55

10.2.2 ThruScan sX/sX-i/sX-WP SRC SCADA Program Manual.................................56

10.3 IRDA Remote Control Unit Manuel .....................................................................57

10.4 Users Manuel For Wheeled Transportation Accessory …………………................ 58

10.5 Certificate of Warranty ........................................................................................60

© 2005 ELEKTRAL® A.Ş. –ThruScan Metal Detectors

All rights reserved. Protected by Law Number 4110 and Ideas and Works of Art Law 5846, unless a written consent by its copyright owner, ELEKTRAL® A.Ş. according to the 52. Article is provided, this manual, under no

circumstances may be processed, copied, its duplicated copies published, represented, presented, in any form or by any means by mechanical and/or electronic ways be transmitted or used.

4

PREFACE

Dear User;

You have taken some serious measures on entrance-control security in

environments where it’s required, with the Magnetic Walk Through Metal Detector -

(WTMD) you have purchased. Thank you for choosing an ELEKTRAL product with

ELEKTRAL’s warranty.

With ELEKTRAL ThruScan (s3/s6/s9/sX/s15-i/sX-i/sX-WP) Multizone Walk Through

Metal Detectors your security searches will be more effective and your estates will

be more secure, providing you peace of mind.

ThruScan metal detectors are in conformance with international norms and

regulations written in this field and approved by British and German companies as

well as other international market companies, with credible references.

ThruScan will earn your approval with quality, service guarantee and economic

prices.

Thank you for selecting a product manufactured by ELEKTRAL A.S.

We hope to earn your admiration through many other professional ELEKTRAL

products.

Please make sure you read this user manual carefully before switching on this

versatile electronic equipment.

ELEKTRAL Products are:

Produced in environmentally friendly modern facilities

Causing no harm to nature and living creatures.

Garrett, ceia, metor, rapidscan, white’s, ranger, scanna, highcom, control screening, enrico maggi, mag, erdem dincsoy

MADE IN TURKEY

ALTERATIONS RESERVED.

NO CLAIMS CAN BE ACCEPTED BY OUR FIRM REGARDING THE APPLICATIONS OF

THIS INSTRUMENT FROM SECOND OR THIRD PARTIES.

ALL RIGHTS RESERVED.

PLEASE FIND OUR “Conditions of Sales, Delivery & Warranty” on our website.

5

C O N T E N T S

Procedures and Safety Warnings before using ThruScan

Technical specifications of ThruScan

Preparation and mounting

ThruScan usage programming and relevant procedures

The arrow-end lightning symbol inside

the equilateral triangle informs the user

that in the context of the product, there

is enough amount of ‘uninsulated’

dangerous voltage to cause an electric

shock.

DO NOT OPEN ThruScan®

ELECTRONIC CASE

RISK OF ELECTRIC SHOCK

The exclamation mark inside the eqilateral triangle informs

the user that there are important instructions of useage and

information inside the booklets given with the equipment.

6

Necessary Procedures and Safety Warnings

Prior to Using ThruScan

Prevent direct light exposer to the infrared sensors (see Sec. 6.10) of

your ThruScan WTMD.

Leave minimum 1m of distance between your ThruScan and any

objects such as metal doors, X-Rays, turnstiles, as such.

Do not place any covers, plating or loads that would induce weight

over your ThruScan unless being recommended by the factory.

Do not drill any holes on the panels of your ThruScan under any

circumstances.

Your ThruScan is secured both by a mechanical lock and an

electronic PIN CODE as a precaution against unauthorized people. Do

not share your password. Contact the factory if you forget the

password.

Assemble your ThruScan on a horizontal and flat floor. Make sure it

is fixed firmly to the floor.

Do not assemble your ThruScan on an unstable or moving floor

surface.

Do not let unauthorized persons to intervene ThruScan’ s electronic

units. Contact your dealer or the factory for an authorized service

person.

Use soft, damp clothing to clean your ThruScan. Always unplug your

equipment during cleaning.

Never operate your equipment through mains without norm ground

ThruScan is designed to operate between 70~270 VAC / 50Hz~60

Hz.

7

CAUTION! Misuse of this equipment specified by the manufacturer may

damage the metal detector or injure people.

Technical Specifications:

Electrical : 70 –270 VAC (Electricity power supply should be earthed & stable)

10 Watts standby, 20 Watts max in alarm. A-Class Energy Save

Frequency: 50/60 Hz

Maximum Relative Humidity : 95% non-condensing

Operating Temperature : -20° ~ +70º C

WARNING:

If the

ThruScan

Metal Detector will be controlled from a distance via SRC-SCADA

Remote Control software on a PC, both the PC and the metal detector must be earthed

at the same power line. Otherwise issues causing breakdowns may occur.

Standards:

The units comply with NILECJ L/1-3 standards

ThruScan is within the magnetic emission limits approved by FDA (American Food & Drug

Administration). It has been certified by experts that has no effects on living creatures, cardiac

pacemakers, pregnant women as well as magnetic media. A “report of expertise”on this issue is

presented in Appendix-1. See Section 10.1.

Protect your ThruScan from direct rain, mist and/or condensation and place it on a stable, vibration

free floor.

DO NOT place the ThruScan close to telephone lines, television monitors, electric motors,

transformers, power cables, or control circuits; excessive electrical noise may cause false

measurements.

CAUTION!

ThruScan

has to be firmly fixed to the floor to reduce the risk of accidentally

falling over and injuring people or causing damage.

Do not drill holes into the side panels under any circumstances!

The walk through metal detector is ready to use once the green “ready LED” (Light Emitting Diode)

light is on.

Test your apparatus periodically, especially when physical environmental displacements have

occurred around it.

NOTE: Security metal detectors have been designed to be used within a

comprehensive security-screening plan. It is the user’s responsibility to define

the area coverage the overall plan and ensure that it operates effectively.

8

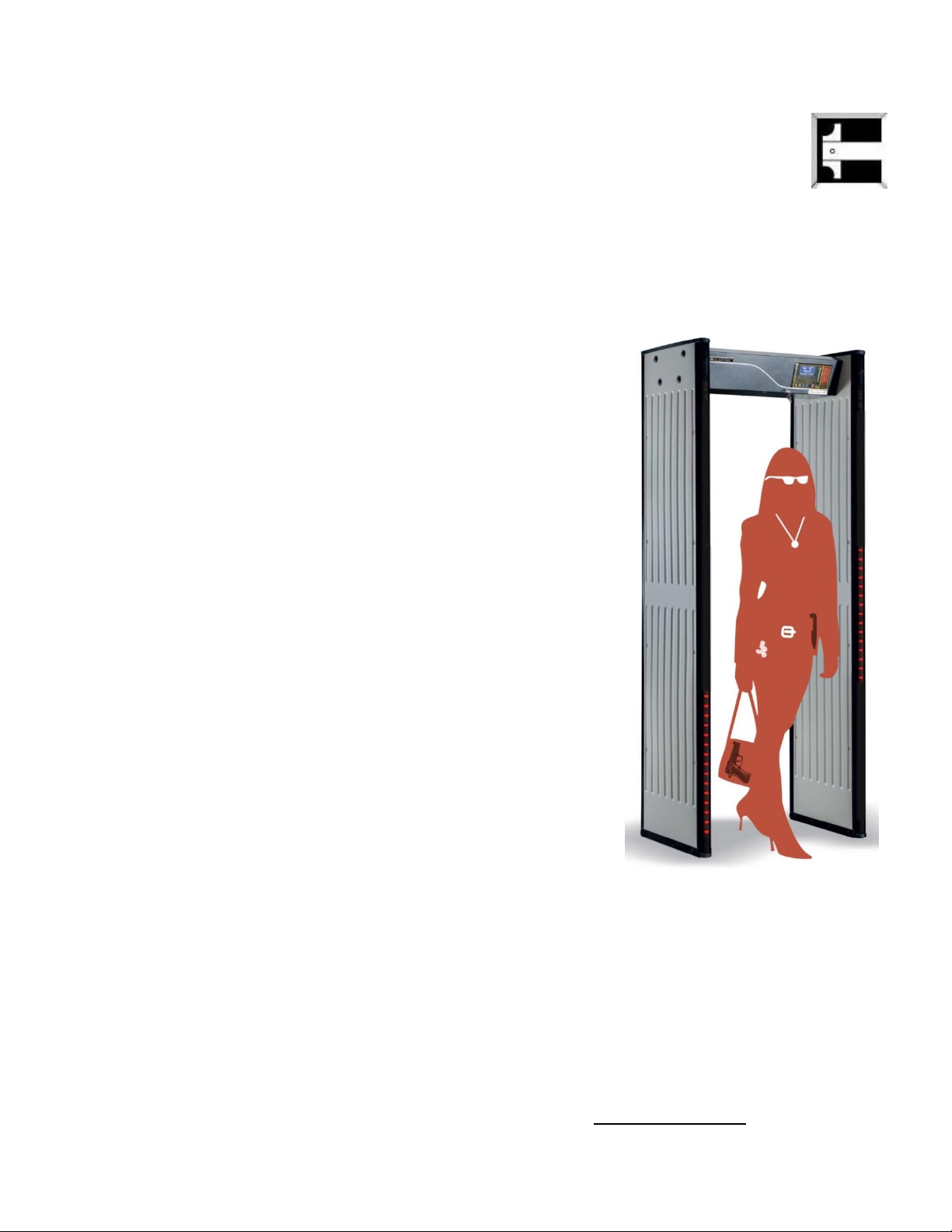

1. GENERAL DESCRIPTION

ThruScan WTMD’s are all easy to operate, advanced microprocessor controlled, with digital pulse

induction utilizing VLF Technology that provides superior metal discrimination and detection.

ThruScan sX/sXWP/s15-i/sX-i are versatile and easily portable walk-through metal detection units

providing high level of detection with a walk-thru rate of up to 60 persons per minute. (* for

ThruScan s3/s6 approx. 30 persons/min)

ThruScan s15-i/sX-i have fifteen / nine stable and homogeneous detection fields that comprise of

several horizontal and vertical zones, which can detect metal objects within separate scanning

zones of the WTMD. With widened, stable and homogeneous detection zones, the WTMD

determines the search locations for the target objects and displays them on the side panels with

LED lights and on the LCD display graphically, thus speeds up the walk through process

substantially. The operator needs to search only the indicated areas by ThruScan’s s9/sX/sX-i/sX-

WP on the side panels. See Section 3.4

A bright, highly visible LED VU display provides a visual indication of the level of detection of metals

within the field of detection. Operator may also approximate the magnitude of the metal by the

warning sound without looking the ThruScan’s VU-meter on the Control Panel.

Traffic LED’s (Green or Red) on the side panels (ENTER SIDE) show if WTMD is ready to pass

through. If the lights show green the gateway may be entered, if the lights show red the person

must not enter. See Section 3.3

(*for

ThruScan

s3/s6 traffic lights are under the Control

Panel at gateway)

Zone lights show the location of the metal object whether it is on the left, right, top, bottom or at

the centre of the body and are located on the side panels of the exit side of the gateway. Zone

lights originate from LED arrays of 2x6 to show 9 zones. These zones are being indicated on the

control panel also by “Graphic Zone LEDs (Locator)”.

(*for s3/s6 models, display is only at the

control panel)

A backlit LCD Display (monitor), (See Program MENU Section 3.1.1) is located on the overhead

Control Unit and displays operational information including program, alarm and sensitivity settings

as well as a traffic count of both in-coming and out-going passes.

A see through cover with mechanical lock

(* optional for

ThruScan

s3/s6)

enables access to the

Control Unit in order to prevent unauthorized tampering. Calibration and control settings are further

protected by a Programmable 4 digit PIN CODE. See Section 6.8

ThruScan (s9/sX/s15-i/sX-i/sX-WP) also incorporates an integral UPS battery backup

(*optional

for

ThruScan

s3/s6)

supply to protect the WTMD from power fluctuations and to maintain

operation for up to 2 hours (longer times optional) in case of mains failure. The WTMD

automatically shuts itself down in case of lack of required voltage.

Another unique feature of the ThruScan sX/sX-i/sX-WP is its ability to monitor up to 99 separate

(* for

ThruScan

s3/s6/s9 sixteen WTMDs for 1 PC)

ThruScan units remotely from a PC or

even remotely from anywhere in the world via a standard and satellite(thuraya) telephone lines

under a modem connection. The hardware for this feature is built in as a standard and the SCADA

software and connection cables are available separately as an option. See Section 7.1

Other features of the ThruScan include superior sensitivity, stability and silent operation ability.

All electronic components are built into the overhead Control Unit. Connection with the side panels

are done with sockets, reducing problems often associated with cable-connected console and

simplifying required intervention in case of a breakdown.

9

1.1 ThruScan s3

International Norms (NILECJ-0601.00 L1-3 / IP20/TS EN 60950-1, in accordance

with CE and and produced under ISO 9001: 2008 QMS

MULTIZONE, 3 “Real Detection Zones” (Left, Middle, Right),

Auto Calibration,

Compact Design,

VLF Technology- human friendly certification,

Green/Red Bicolour Traffic Through LEDs,

10 Sensitivity Levels, 246 adjustable levels at each, applicable to all zones,

separately + 1 standard pre-set international

security program,

Graphic Zone Display on control panel,

Display of Metal Density at 10 levels

(green/yellow/red) VU meter,

Environmental Magnetic Noise Level Display,

10 different and 10 level adjustable warning

tones,

Alarm Counter,

In Counter(one way) at 5 Digits

(Visible/Invisible),

4 Digit changeable PIN CODE,

Automatic Failure Display,

Reloading the Factory Default Settings by 1 touch

button,

Easy Programming & Monitoring with LCD display

Standard MENU in 4 Languages (English, German,

Turkish and Spanish),

Additional NO/NC Relay Output for peripheral

security apparatus as turnstiles, cameras,

recorders etc. during alarming

Switching Power Supply,

(*option UPS).

Modem/RS232 Output, for Remote Data

Communication (SCADA SOFTWARE),

Unique Designs & in variety of colours,

Easy mounting/dismounting in aprx.15 minutes,

With the Outdoor Package can be used outside

(*optional),

Exported to 4 continents.

NOTE: You may access

ThruScan

s3 Photo Gallery through www.elektral.com.tr website.

10

1.2 ThruScan s6

International norms (NILECJ-0601.00 L1-3/IP20/EN60950-1) in accordance with

CE and produced under ISO 9001: 2008 QMS

MULTI-ZONE 6 Real Matrix Detection Zones (Up/Middle/Down & Left/ Right)

Modular Design

Auto Calibration (Automatically calibrates itself up to Environmental Conditions)

Human friendly VLF technology (Certified)

Green/red bicolor traffic through Lights on Control Unit and Light Indicators at

Control Panel

10 sensitivity levels, 246 adjustable steps at each + 1 standard pre-set international

security program

Superior Discrimination, Precise target location identification (No false alarms... vey

low rate..)

Graphic Zone Display & Display of metal density at 10-level-VU meter with

green/yellow/red LEDs

Environment magnetic noise level detection display

on LCD Screen

Integrated high-tech filter circuitry eliminates

magnetic&electrical interference

Alarm counter

5 Digit Incoming counter (Visible/invisible)

4 Digit changeable digital PIN CODE

Automatic Failure Display

Reloading the factory default settings by one-touch

button

Easy programming and monitoring with LCD display

Standard menu in English, German, Spanish and

Turkish

Relay output for recording CCTV, controlling

turnstiles, etc. on Alarms

Adjustable audio alarm at 10 tons/level

OPTIONAL - Modem and RS232 output for SCADA

remote data communication- Send Receive- Change

settings by direct cable or modem over Telecom

Lines by PC- Audible & Visual alarms can be

monitored by PC and can be logged into Hard Disk.

Software Optional

Certificate approved “Safe for wearers of

pacemakers and pregnant women” – No effect to

magnetic media (eg. Memory sticks, tape, proximity

cards)

Easy-to-mount and assemble walk through metal

detector (15 minutes) / No necessity for

maintenance

Unique Compact design-Grey color

Exported to more than 70 countries / Customer Specifications and OEM / ODM

orders welcome

NOTE: You may access

ThruScan

s6

Photo Gallery through www.elektral.com.tr website.

11

1.3 ThruScan s9

ThruScan s9 was chosen, “The Best Deal” in Dubai Safety Exhibition-2001, with

the norms it provides, its specifications, performance and economic advantages.

Here are some of the technical superiorities for ThruScan s9 :

International Norms (NILECJ-0601.00 L1-5 / IP44, EN60950-1) in accordance with

CE and produced under ISO 9001: 2008 QMS

MULTI-ZONE, 9 Real Matrix Detection Zones

Auto Calibration,

Compact Design,

VLF Technology- human friendly certified,

Green/Red Bicolour Traffic Through LEDs,

LED Illuminated Warnings at the Control and

Side Panels,

10 Sensitivity Levels, 246 adjustable levels at

each, applicable to all zones, separately + 1

standard pre-set international security program,

Graphic Zone Display on control unit,

Display of Metal Density at 10 level

(green/yellow/red) VU meter,

Environmental Magnetic Noise Level Display,

10 different and 10 level adjustable warning

tones,

Alarm Counter,

In & Outgoing Counters separately at 5 Digits

(Visible/Invisible),

Mechanical lock for control panel and 4 digit

changeable PIN CODE,

Automatic Failure Display,

Reloading the Factory Default Settings by 1

touch button,

Easy Programming & Monitoring with LCD display

Standard MENU in 4 Languages (English,

German, Turkish and Spanish),

Additional NO/NC Relay Output for peripheral

security apparatus as turnstiles, cameras,

recorders etc. during alarming,

UPS-Uninterrupted Switching Power Supply, 2 Hours operation without mains,

Modem/RS232 Output, for Remote Data Communication (SCADA SOFTWARE),

Unique Designs & in variety of colours,

Easy mounting/dismounting in approx.15 minutes,

With the Outdoor Package can be used at outside

(*optional),

Exported to 4 continents.

NOTE: You may access

ThruScan

s9 Photo Gallery through www.elektral.com.tr website.

12

1.4 ThruScan sX

ThruScan sX was introduced as “The Breaking News” at Abu Dhabi – Middle East

Security & Safety Exhibition-2003 with its innovative superior spec, compliance to

norms, contemporary design, performance and economic advantage, in comparison to

its counterparts. It’s widely used and preferred all around the world, protecting

millions of people against terrorism.

International Norms (NILECJ-0601 L1-5 / IP44/TS EN 60950-1) in accordance with

CE and produced under ISO 9001: 2008 QMS

MULTI-ZONE, 9 Real Matrix Detection Zone,

Auto Calibration,

VLF Technology- human friendly,

Green/Red Bicolour Traffic Through LEDs,

LED Illuminated Warnings at the Control and Side

Panels,

20 Sensitivity Levels, 246 adjustable levels at each,

applicable to all zones separately, fixed NILECJ –

sensitivity level, 7 fixed International Sensitivity

Standard Programmes,

Separate Zone Sensitivity Settings,

Automatic Sensitivity Program selects the correct

sensitivity for a specific weapon or test object-(fast

consistent calibration) “SMART DETECTOR”,

Graphic Zone Display,

Display of Metal Density at 10 level

(green/yellow/red) VU meter,

Environment Magnetic Noise Level Display,

10 different and 10 level adjustable warning tones,

Alarm Counter,

In & Outgoing Counters separately at 5 Digits

(Visible/Invisible),

Mechanical Lock For Control Panel and 4 Digit

changeable PIN CODE,

Automatic Failure Display,

Reloading the Factory Default Settings by 1 touch

button,

Easy Programming & Monitoring with LCD display,

Standard MENU in 5 Languages (English, German,

Turkish, Arabic and Spanish),

Additional NO/NC Relay Output for peripheral security apparatus as turnstiles,

cameras, recorders etc. during alarming,

UPS- Uninterrupted Switching Power Supply, 2 Hours operation without mains,

Modem/RS232 Output, for Remote Data Communication (SCADA SOFTWARE),

Modern, Contemporary,

Elinno

/Innovative Design,

Unique Designs & in variety of colours,

Easy mounting dismounting (15 Min.),

With the Outdoor Package can be used at outside

(*optional),

Exported to 4 continents.

NOTE: You may access

ThruScan sX

Photo Gallery through www.elektral.com.tr website.

13

1.5 ThruScan sX-WP Walk Through Metal Detector for Outside Use

All it’s features are compatible with ThruScan sX model and measures have been taken to comply

with IP 55 protection on the electronic module and panels. Advanced measures have been taken

against natural events such as rain, snow and sun. This is a ThruScan sX model that has special

protection complying with international norms, providing robustness outside and security inside.

International Norms (NILECJ-0601.00 L1-5 / IP55/ TS EN 60950-1) in accordance

with CE and produced under ISO 9001: 2008 QMS

IP 55 –For Outdoor Usage,

MULTI-ZONE, 9 Real Matrix Detection Zone,

Auto Calibration,

VLF Technology- human friendly certified,

Green/Red Bicolour Traffic Through LEDs,

LED Illuminated Warnings at the Control and Side Panels,

20 Sensitivity Levels, 246 adjustable levels at each, applicable to all zones

separately,7 fixed International Sensitivity Standards,

Separate Zone Sensitivity Settings,

Automatic Sensitivity Program selects the correct

sensitivity for a specific weapon or test object-(fast

consistent calibration) “SMART DETECTOR”

Graphic Zone Display,

Display of Metal Density at 10 level (green/yellow/red)

VU meter,

Environment Magnetic Noise Level Detection Display,

10 different and 10 level adjustable warning tones,

Alarm Counter,

In & Outgoing Counters separately at 5 Digits

(Visible/Invisible),

Mechanical Lock For Control Panel and 4 Digit

changeable PIN CODE,

Automatic Failure Display,

Reloading the Factory Default Settings by 1 touch

button,

Easy Programming & Monitoring with LCD display,

Standard MENU in 5 Languages (English, German,

Turkish, Arabic and Spanish),

Additional NO/NC Relay Output for peripheral security

apparatus as turnstiles, cameras, recorders etc. during

alarm,

UPS- Uninterrupted Power Supply, 2 Hours operation

without mains,

Modem/RS232 Output, for Remote Data Communication

(SCADA SOFTWARE),

With/Without Cable connection 30 cm tandem operation of multiple WTMDs,

Power Supply; Switching Mode Power Supply (SMPS), low voltage usage feature,

Unique Designs & in variety of colours, Modern, Contemporary,

Elinno

/Innovative

Design,

Easy mounting /dismounting (15 Min.),

Exported to 4 continents.

NOTE: You may access

ThruScan

SX-WP Photo Gallery through www.elektral.com.tr website.

14

1.6 ThruScan s15-i

International Norms (NILECJ-0601.00 L1-5/ IP44/TS EN 60950-1),

ECAC.CEAC DOC 30 Compliance, in accordance with CE and produced

under ISO 9001:2008 QMS

MULTI-ZONE 15 Real Matrix Detection Zones,

Auto Calibration,

VLF Technology- human friendly certified,

Green/Red Bicolour Traffic Through LEDs,

LED Illuminated Warnings on the Control Panel

and Continuous LED’s on Side Panels,

20 Sensitivity Levels, 246 adjustable levels at

each, 10 fixed International Sensitivity

Standards, Jailhouse Detection Sensitivity

availability

Separate Zone Sensitivity Settings,

Automatic Sensitivity Program selects the

correct sensitivity for a specific weapon or test

object (fast consistent calibration) “SMART

DETECTOR”

Precise target location LED Graphic Zone Display,

Display of Metal Density at 10 level

(green/yellow/red) VU meter,

Environment Magnetic Noise Level Detection

Display,

10 different and 10 level adjustable warning

tones,

Record Statistics of Operation Duration, Number

of Visitors and Alarms (Real/Random Alarms

Separately)

In & Outgoing Counters separately at 5 Digits

(Visible/Invisible),

Mechanical Lock For Control Panel and 4 Digit changeable PIN CODE,

Automatic Failure - Error Code Display ,

Adjustable Alarm Duration (0,5s-2s),

IR Protection Feature enabling perfect low false alarm operation/ Continuous

Detection Mode Selection Enabled

Reloading the Factory Default Settings by 1 touch button,

Easy Programming & Monitoring with LCD display,

Standard Menu in 5 Languages (English, German, Turkish, Arabic and Spanish),

Additional NO/NC Relay Output for peripheral security apparatus as turnstiles,

cameras, recorders etc. during alarming,

UPS- Uninterrupted Power Supply, 2 Hours operation without mains,

With/Without Cable connection interference free tandem operation of two WTMDs

at a distance of min. 5 cm

RS232 Output for SCADA Remote Control Software - Send Receive- Change settings

by PC, Audio-Visual alarms can be monitored Real Time by PC and can be logged

into Hard Disk

Software Optional

Audio-Visual alarms are noticeable at a range of 4 meters

Adjustable Random Alarm feature to give alarm for clean visitors at a selected ratio.

Option: Outdoor usage capability with the Optional Outdoor Pack

You may access

ThruScan

s15-i Photo Gallery through www.elektral.com.tr website.

15

1.7 ThruScan sX–i

International Norms (NILECJ-0601.00 L1-5/NIJ0601.02/IP65/TS EN

60950-1, EN60068, 60529), ECAC.CEAC DOC 30 Standard 2 Compliance, in

accordance with CE and produced under ISO 9001:2008 QMS

MULTI-ZONE 9 Real Parallel Detection Zones,

Auto Calibration

VLF Technology human friendly certified,

Contemporary Lines, Compact and Peculiar Elinno Design

Human friendly VLF technology (Certified)

Green/Red bicolour traffic through LED’s allow easy

sight from a distance

Continuous LED Zone Alarm Light indicator on side panel

from top to bottom

25 Sensitivity Levels, 246 adjustable levels at each, 10

fixed International Sensitivity Standards, Jailhouse

Detection Sensitivity availability

Separate Zone Sensitivity Settings

SMART DETECTOR Fast and consistent calibration,

Automatic Sensitivity Program selects the correct

sensitivity for a specific weapon or a test object

Superior Discrimination, Precise target location

identification / Graphic zone display

Metal Density-Mass, Signal Strength Display at 10-level-

VU meter with green, yellow, red LEDs easily allow sight

from a distance

Digital Environment magnetic noise level and visual

detection display on LCD Screen

Adjustable audio alarm at 10 tones/level or Soundless

(Mute) operation.

Record Statistics of Operation Duration, Number of

Visitors and Alarms (Real/Random Alarms Separately)

Five Digit IN/OUT Traffic Counters (Visible/Invisible)

Mechanical Lock for control panel and 4 Digit changeable

digital PIN CODE

Automatic Failure Error Code Display Function

Adjustable Alarm Period (0,5 s-2s)

IR Protection Feature enabling perfect low false alarm operation/ Continuous Detection

Mode Selection Enabled

Reloading the factory default settings by one-touch button

Easy programming and monitoring with wide LCD display

Standard menu in English, German, Spanish, Arabic and Turkish

Relay outputs for recording CCTV, Photo Taken-Recording, controlling turnstiles, etc. on

Alarms

Standard Uninterruptible Power Supply (UPS) enabling 2 hours operation without mains

With/Without Cable connection interference free tandem operation of two WTMDs at a

distance of min. 5 cm

RS232 Output for SCADA Remote Control Software - Send Receive- Change settings by

PC, Audio-Visual alarms can be monitored Real Time by PC and can be logged into Hard

Disk

Software Optional

Audio-Visual alarms are noticeable at a range of 4 meters

Adjustable Random Alarm possibilities to give alarm for clean visitors at a selected ratio.

Option: Outdoor usage capability with the Optional Outdoor Pack

NOTE: You may access

ThruScan

sX-i Photo Gallery through www.elektral.com.tr website

16

2 INSTALLATION

2.1 TRANSPORTATION AND SITE SELECTION

ThruScan WTMDs are being packed and shipped in two separate boxes “Control Unit” and “Side Panels”.

Control Unit, Back Fixing Crosspiece and screws with Allen Keys are packed in the Control Unit Box

(*Only for ThruScan/s3/s6/s9). Side Panels and Floor Fixing Metal Plates are being packed in the Side

Panels Box. During transportation the Position Signs indicating upside on the Boxes have to be taken

into account for the equipment to be delivered correctly. Improper transportation may result in physical

damages on your equipment. When there is a need to relocate the WTMD, the WTMD has to be

unassembled, packed and delivered as described above before assembling again.

Before choosing a site for

ThruScan

, it is important to consider the volume and throughput of

pedestrian traffic, space availability and overall environmental conditions.

Position and fix

ThruScan

on a flat, stable floor where it remains unaffected by the sun, rain, mist or

condensation. If the WTMD will be used for a short time in outdoor then use “Rain Protect Shelter (Hat)”

as well as outdoor package. (See Section 7.2).

ThruScan

sX-WP is produced for outdoor fulfilling IP55

standards.

To avoid external metal interference, ensure that there are no large metal items near

ThruScan

.

False alarms may be caused by nearby moving metallic objects such as an escalator or a revolving door

as well as due to an electrical interference from radio, telephones, television monitors, powerful

electronic motors and transformers.

Electrical installation of the WTMD should be from the ceiling.

Protect your WTMD from humidity and water since it is versatile electronic equipment or use our

Weather proof Model.

2.2

ASSEMBLING & MOUNTING

ThruScan WTMDs are designed for easy installation by the end users. Assembly can be done easily by

proceeding the below mentioned procedures. Also the Manufacturers contact details are provided in this

User’s Manual for further communication needs.

2.2.1 Verify that the following contents are included:

Left side panel

Right side panel

Main control & display unit

Back fixing crosspiece*

Mains power cord

Synchronization connection cable**

Rain Shelter***

4 floor fixing screws

8 panel fixing bolts

8 plastic bolt covers

Installation spanner (for panel fixing bolts)

Allen key (for floor fixing plates)

User’s manual

(*only for ThruScan s3/s6/s9)

(**optional)

(***only for ThruScan sX/WP)

Main Control & Display

Unit

Right

Side

Panel

Back fixing

crosspiece

Left

Side

Panel

17

2.2.2 Arrange the major components as shown above.

2.2.3 Lay the main Control Unit

(with the control panel facing down)

onto a soft, scratch free

surface

(the packing (bubbled pe) is ideal)

.

2.2.4 Remove the rear panel of the main Control Unit by undoing the two small fixing screws.

Retain these screws to screw them back in their places later

(Note: The arrow signs on the control unit and the panel parts, which are fixed on the

top of each other, have to point to the same direction)

.

2.2.5 Using the Eight Panel Fixing Bolts (4 on each side), screw two side panels to “Control Unit”

(

ThruScan

s3/s6/s9 two Screws on each panel) do not fully tighten at this stage.

2.2.6 Plug in the side panel connectors to the main Control Unit (take the numbers written on them

[sX-i] in consideration) as follows:

Left Side Panel –Connect the Side Panel Sockets in to the connector of the Control Unit

(ThruScan s3/s6/s9 models have two sockets)

Right Side Panel –Connect the Side Panel Socket to the Connector on the Control Unit

Note: This WTMD is designed to prevent false connector/socket connection.

2.2.7 Place back the rear panel of the main Control Unit using the three small fixing screws

previously removed

(see 2.2.4 above)

.

2.2.8 Attach the back fixing crosspiece using the remaining four panel fixing bolts (only

ThruScan

s3/s6/s9); do not fully tighten at this stage.

2.2.9 Remove four hex bolts holding the floor fixing plates at the bottom of each side panel using

the Allen key.

2.2.10 Use two or more people to lift your WTMD carefully to a vertical position and move to

desired location. Ensure the two side panels are perfectly aligned parallel to each other with 74cm

spacing between panels.

CAUTION! The WTMD will not operate fully functional if the side panels and the infrared

sensors are not aligned properly.

2.2.11 Carefully mark the Side Panel Erection Positions on the floor, and fix the floor fixing metal

plates onto the floor. Put the WTMD Side Panels into floor fixing plates making sure the plates will

fit inside the Side Panels, using Allen key

(see 2.2.9 above)

tighten the plates only to prevent from

moving; DO NOT over tighten. Stabilisation for ThruScan Sx-i model can be done using the holes at

the tip of each foot.

2.2.12 Ensure that ThruScan is physically stable.

2.2.13 Fully tighten all bolts with the installation spanner.

2.2.14 Finally, ensure that the Mains Power Cord is connected to the Connector at the back of the

Control Unit.

18

3. CONTROL (DISPLAY) PANEL & INDICATION INFORMATION

The control panel functions are protected from unauthorized tampering by a lockable

see through control cover in the overhead main Control Unit. Operators should not

normally need to adjust these controls, which should only be altered by a supervisor or manager in

order to change the sensitivity settings of ThruScan, reset counters, perform installation

adjustments and to switch the unit on /off etc.

3.1 CONTROL PANEL

The control display panel provides a visual indication of the status of the unit as well as all controls

necessary for the programming and operation of the unit. The following features can be found on

the display panel.

3.1.1 LCD (LIQUID CRYSTAL DISPLAY-SCREEN)

The LCD is an ongoing visual display located in the overhead Control Unit. The LCD displays the

security level settings and traffic count of both incoming and outgoing traffic. The display also

provides operational information, including program settings and adjustment information together

with fault indication and alarm displays.

3.1.2 GRAPHIC (ALARM) ZONE LED’s (LOCATOR)

The display panel gives a graphical indication of the area of any

alarm activation by indicating whether the point of detection is on

the right, left or centre of the body and also whether it is at a high,

middle or low level.

VU-METER

MMETREDIS

PLmmeterMete

r

GLCD

SCREEN

GRAPHIC ALARM (LOCATION

IDENTIFIER) LED’S

ON-OFF

BUTTON

IR REMOTE

CONTROL

SENSOR

UPS

TRAFFIC LIGHTS

INDICATOR

RUN / SEL/ UP/ DOWN

BUTTONS

LINK LIGHTS

Transparent Red

19

3.1.3 VU Display (LED array)

The LED VU comprises of five green, three yellow and three red LED’s providing a

graphical indication of the level of metal detection activity occurring within the

archway. The degree of detection intensity varies depending on the quantity and

composition of the metallic object(s).

Note: WTMD and thus the VU display will only operate whilst the infrared

beam is obstructed.

CAUTION! the first (green) led only indicate that the WTMD is on but not any

operational detection situation.

3.1.4 UPS INDICATOR

When the Mains Voltage is cut off the WTMD will continue to operate with power from

the Battery, the battery mode operation indication will be continuously active (yellow

LED); if the battery voltage drops under a certain level the Yellow LED indicator will

start flashing; and if the battery Voltage will no longer enable WTMD Operation, the

Yellow LED indication will be flashing Continuously, there will be an intermittent audio alarm tone

and then the WTMD will then automatically shut down itself.

3.1.5 IRDA REMOTE CONTROL RECEIVER

(*only for

ThruScan

sX/ s15-i/sX-i)

It is the receiving LED of the pilot Remote Control Unit.

3.1.6 TRAFFIC INDICATOR LEDS (LIGHTS)

The Traffic Light simulation on Side Panels and the Control Unit enables the Security

Staff to decide whether the WTMD is ready for detection and the passage is empty.

Green indicates “Walk”, Red indicates “Stop”.

3.2

TOUCHPADS

A total of five touchpad controls are located on the control unit as follows;

3.2.1 ON - OFF BUTTON

The ON-OFF touchpad button turns the WTMD on and off. At each start up a 10

second self test is being carried out, and during this time a ‘test tone’ will be heard.

Please wait for 1 minute after switching on before using the gateway in order to allow

the auto-calibration program to designate/memorize for metal objects around its

environment.

You can Turn Off your WTMD by pressing the ON-OFF button for 2 seconds and release. The

previous settings and adjustments would be stored when you turn off your WTMD and will be

displayed when turned on again.

3.2.2 RUN(X) BUTTON

The RUN(X) touchpad button returns the WTMD to RUN(X)/operation mode after

any programming changes are made using the SEL(√) button. It is also used as an

“ESC” button when no changes are made.

This manual suits for next models

7

Table of contents

Other Elektral Metal Detector manuals