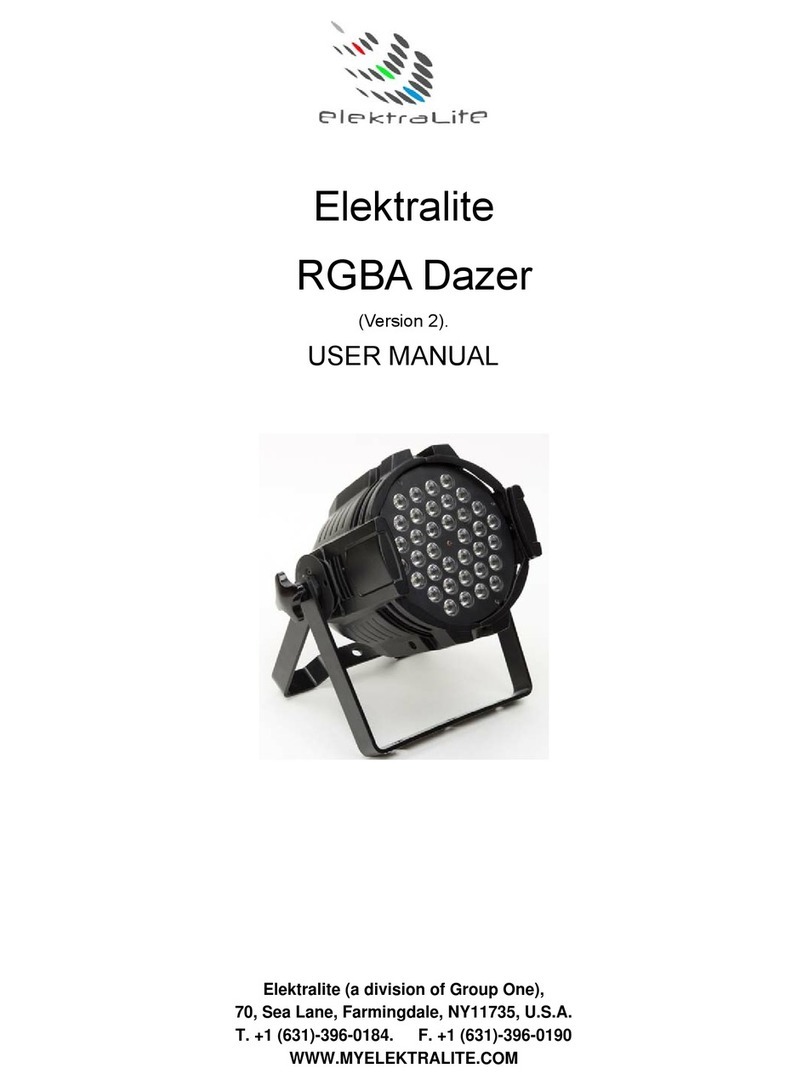

elektraLite LXE 700 Wash User manual

LXE 700 WASH USER MANUAL

(V2.10)

Elektralite (a division of Group One),

70, Sea Lane, Farmingdale, NY11735, U.S.A.

T. +1 (516)-249-3662. F. +1 (516)-249-8870

WWW.MYELEKTRALITE.COM

- 1- LXE700 wash

For your own safety, please read this user manual carefully before installing LXE 700 Wash.

Every person involved with the installation, operation and maintenance of LXE 700 Wash has to:

-be qualified

-follow carefully the instructions of this manual

Introduction:

Thank you for choosing LXE 700 Wash.

When you unpack LXE 700 Wash, there should be in the box the fixture, a DMX 5 pin XLR cable, and a safety

cable. Please check carefully that there is no damage caused in shipping. If you notice any damage then

immediately let your shipper know and the dealer from whom you purchased LXE 700 Wash.

Features:

operation mode is by DMX 512 utilizing (16 channels) or stand alone or sound activation.

pan and tilt movement :

8 bit and 16 bit resolution for smooth and precise motion

pan : 630° rotation / tilt : 265° rotation

speed of pan/tilt movement is adjustable

electronic beam shaping

strobe/shutter : high speed dual-blade shutter, 0-15Hz or random strobe

dimmer : mechanical adjustable from 0% to 100%

color : Full CMY Color mixing system.

Also a color wheel 1 has 8 dichroic filters plus white, with rainbow effect

Full linear Zoom function.

Color macros. 30 macros.

auto-program: 8 preprograms can be selected

display: can be inverted (180)° when LXE 700 wash is hung upside down.

local or remote resetting

lamp switches ON/OFF locally or remote, motor reset

auto test for all functions

value of each DMX-channel can be displayed

editable program:

edit and save a program to the “on board flash memory” using either the controls on the front panel or using

an external controller like an Elektralite CP-20. A maximum 48 scenes/cues/looks can be saved on board.

The resultant saved program can be played back from the “run” menu accessed from the front display panel

- 2- LXE700 wash

Safety Instructions.

This device has left the factory in perfect condition. In order to maintain this condition and to ensure a safe

operation, it is absolutely necessary for the user to follow the safety instructions and warning notes written in

this user manual. LXE 700 Wash is a high voltage fixture. Be careful when dealing with high voltages.

Please read this manual. If you do not read this manual and damages occur to LXE 700 Wash, then it

could void the warranty.

During shipping, LXE 700 Wash may have been exposed to high temperature changes or humidity changes.

So, as a precaution, do not switch LXE 700 Wash on immediately. Condensation can damage LXE 700 Wash

so leave LXE 700 Wash switched off until it has reached room temperature.

The electric connection must be carry out by a qualified person and it is absolutely essential that LXE 700

Wash be grounded.

Always disconnect LXE 700 Wash from the power source, when the device is not in use or before cleaning it.

Only unplug LXE 700 Wash from the power cord. Never pull out the plug out by pulling on the power cord.

Take care, LXE 700 Wash will heat up when it is turned on and it will be very hot to touch.

Please keep LXE 700 Wash away from children and the general public. Please be intelligent and use common

sense when operating LXE 700 Wash.

General Guidelines.

LXE 700 Wash is a lighting fixture for professional use on stages, in theatres, arenas, churches and so on.

LXE700 Wash should only be operated at 120 volts and only indoors.

LXE 700 Wash should not be operated 24/7 (24 hours a day; 7 days a week). LXE 700 Wash needs operation

breaks to ensure that it will work for a long time without problems. Please do not shake LXE 700 Wash and

avoid using brute force when installing or operating it.

When choosing the location to install LXE 700 Wash, please make sure that it is not exposed to extreme heat,

moisture or dust. The minimum distance between LXE 700 Wash and the illuminated surface must be more

than 10 feet.

Always mount LXE 700 Wash with an appropriate safety cable. If you use the quick lock cam to hang LXE 700

Wash please make sure the 4 quick lock fasteners are locked into position correctly.

Operate LXE 700 Wash only when you are familiar with the features on the fixture. Do not permit operation by

persons not qualified for operating it.

All modifications to LXE 700 Wash will invalidate the warranty. There are absolutely no exceptions.

If LXE 700 Wash is operated in any way different to the one described in this manual, LXE 700 Wash maybe

damaged and the guarantee will be void.

- 3- LXE700 wash

Installation Instructions.

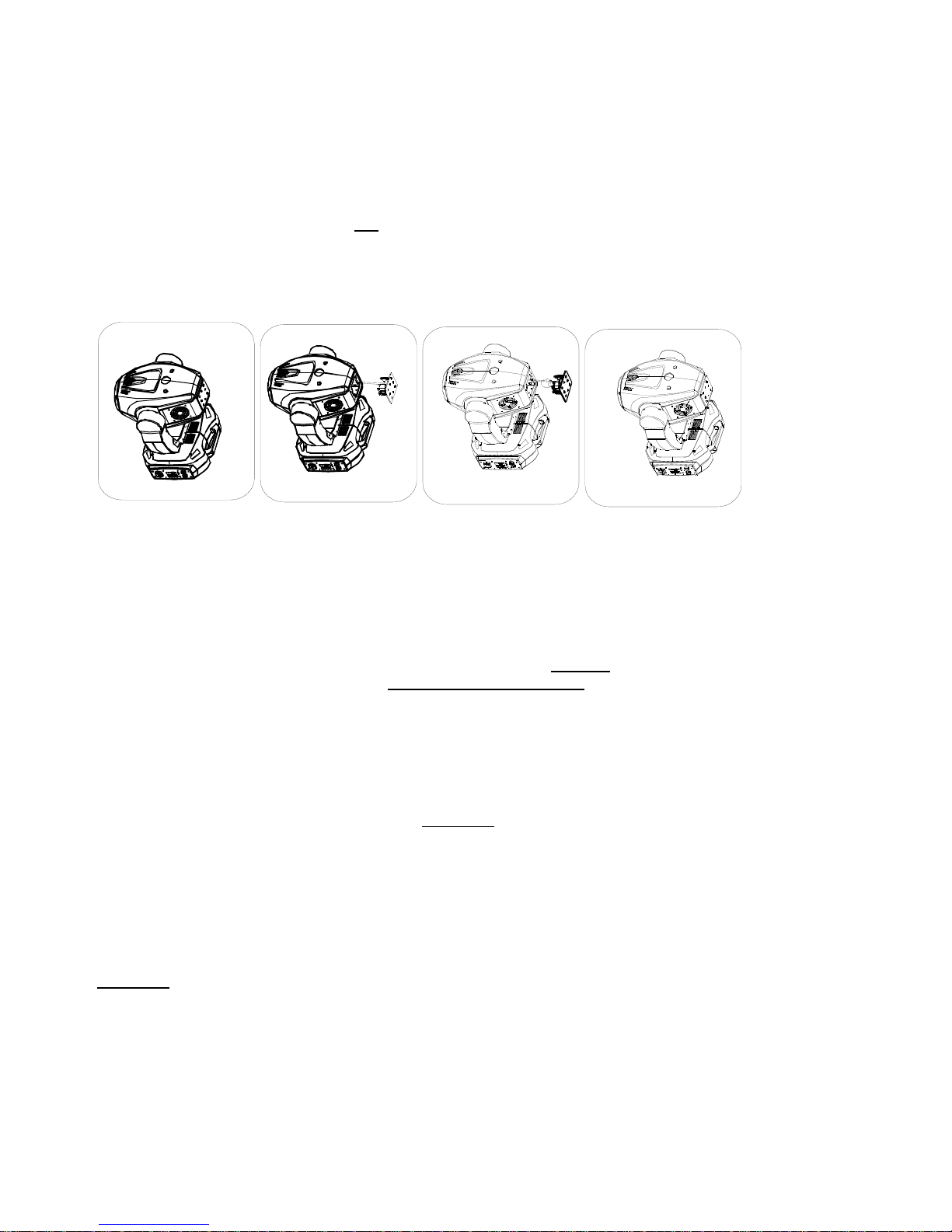

a) Installing or replacing the lamp

Only install the lamp when LXE 700 Wash is unplugged from 120 volts.

The lamps must be replaced when it has reached the end of its lamp life or if it is damaged or deformed.

Before replacing the lamp let the lamp cool down. During operation, the lamp can

reach very high temperatures.

During the installation of the lamp do not touch the glass bulbs with bare hands. Always use a cloth to handle

the lamps during insertion and removal.

Do not install lamps with a higher wattage. They generate temperatures higher than LXE 700 Wash operating

temperature.

For the installation of the new lamp :

1234

Please remember the lamp is not hot-restrike. You must wait approximately 10

minutes before you can restrike the lamp.

Do not ever operate LXE 700 Wash with the cover open. The lamp is a discharge lamp. All discharge lamps,

irregardless of the manufacturer or type, are very volatile and can explode. Great caution must be exercised

when working with these lamps otherwise serious injury can happen.

b) Mounting LXE 700 Wash

The installation of LXE 700 Wash has to be built and constructed in a way that it can hold 10 times the weight

for 1 hour without any deformation.

The installation must always be secured with a secondary safety device (a safety cable).

Never stand directly below LXE 700 Wash when mounting, removing or servicing LXE 700 Wash.

The installer should make sure that LXE 700 Wash is installed correctly and that the installation is checked by

an expert on a regular basis.

If you are a rental house utilizing LXE 700 Wash, then use the appropriate half couplers (½ cheeseboros) to

secure the fixture to the truss or pipe. Remember to tighten down the cheeseboros before raising the truss.

Don’t laugh! It has been done before now. Remember with yoke fixtures on a flown truss, when you move them

the truss can move too. It’s just obeying Newton’s third law of motion: “to every action there is an equal and

opposite reaction”. Please remember this when securing the LXE 700 Wash fixture.

Cautions:

LXE 700 Wash should be installed outside areas where people can reach it, walk by it or be seated

underneath it when being installed. Overhead mounting requires experience including, amongst other things,

calculating the working load limits and installation material being used. Periodic safety inspections should be

done of LXE700 Wash as the fixture does move. If you do not have the qualifications and experience, do not

attempt the installation. Improper installation can result in bodily injury to yourself or others.

Before mounting make sure that the installation area can hold a minimum point load of 10 times LXE 700

Wash’s weight.

Once installed then connect LXE 700 Wash to the correct power source. 120 volts A.C.

- 4- LXE700 wash

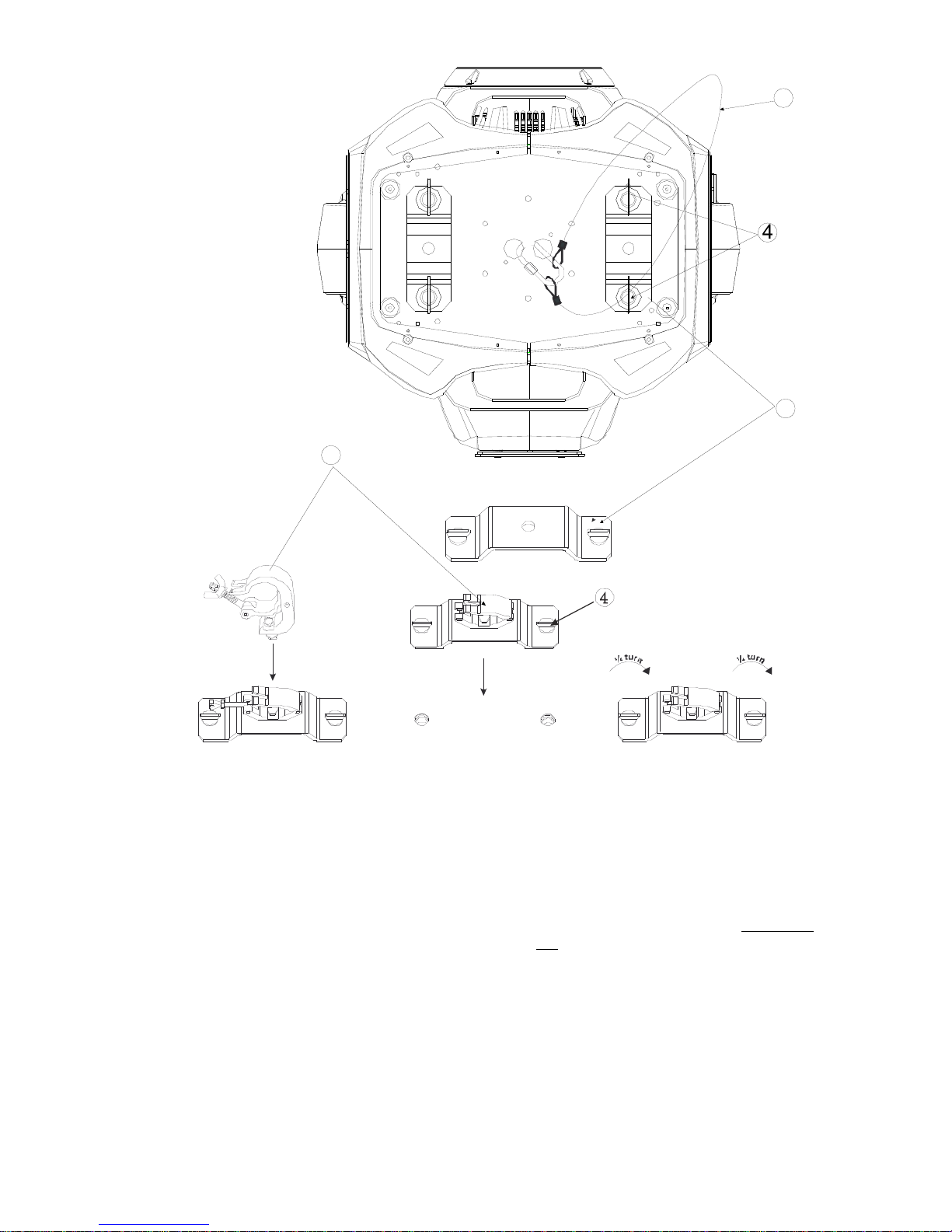

Installation via the Omega U Brackets.

1

2

3

4

(1)Omega-holders

(2)Clamp

(3)Safety-rope

(4)Quick-lock fastener

Screw one clamp (the clamp is not provided with LXE 700 Wash) onto each of the two Omega U brackets

supplied with LXE 700 Wash.

Insert the quick-lock fasteners of the first Omega bracket into the respective holes on the bottom of LXE 700

Wash. Tighten the quick-lock fasteners fully clockwise. Install the second Omega U bracket. Please do not use

pliers, crest wrenches and the like to turn the quick-lock fastener. If you do, there is very real likelihood that you

will break the Omega bracket. (These can be replaced at a substantial cost to your boss!)

Pull the safety cable through the holes on the bottom of the base and over the trussing or any secondary fixing

point. Do not clamp the cable to the U bracket or clamp. That is not a secondary safety point.

A secondary safety point is any point that will adequately hold LXE 700 Wash if the U brackets, clamps or the

fixtures base breaks or fails. Then the safety cable would be the backup and stop the fixture from falling to the

ground.

- 5- LXE700 wash

c) Locks for Pan and Tilt.

The LXE 700 Wash has two levers for locking the pan and the tilt function. These locks are engaged for

shipping.

The locks must be disengaged before turning on the fixture. The Pan lock is located in the middle of the yoke at

the base. While the tilt lock is located on one of the arms. The photo below shows the lock and unlock positions.

If the fixture is unlocked (and of course the fixture is not powered up) then the pan and tilt will move freely if you

push the head. If there is any resistance, recheck that you have unlocked the fixture completely.

- 6- LXE700 wash

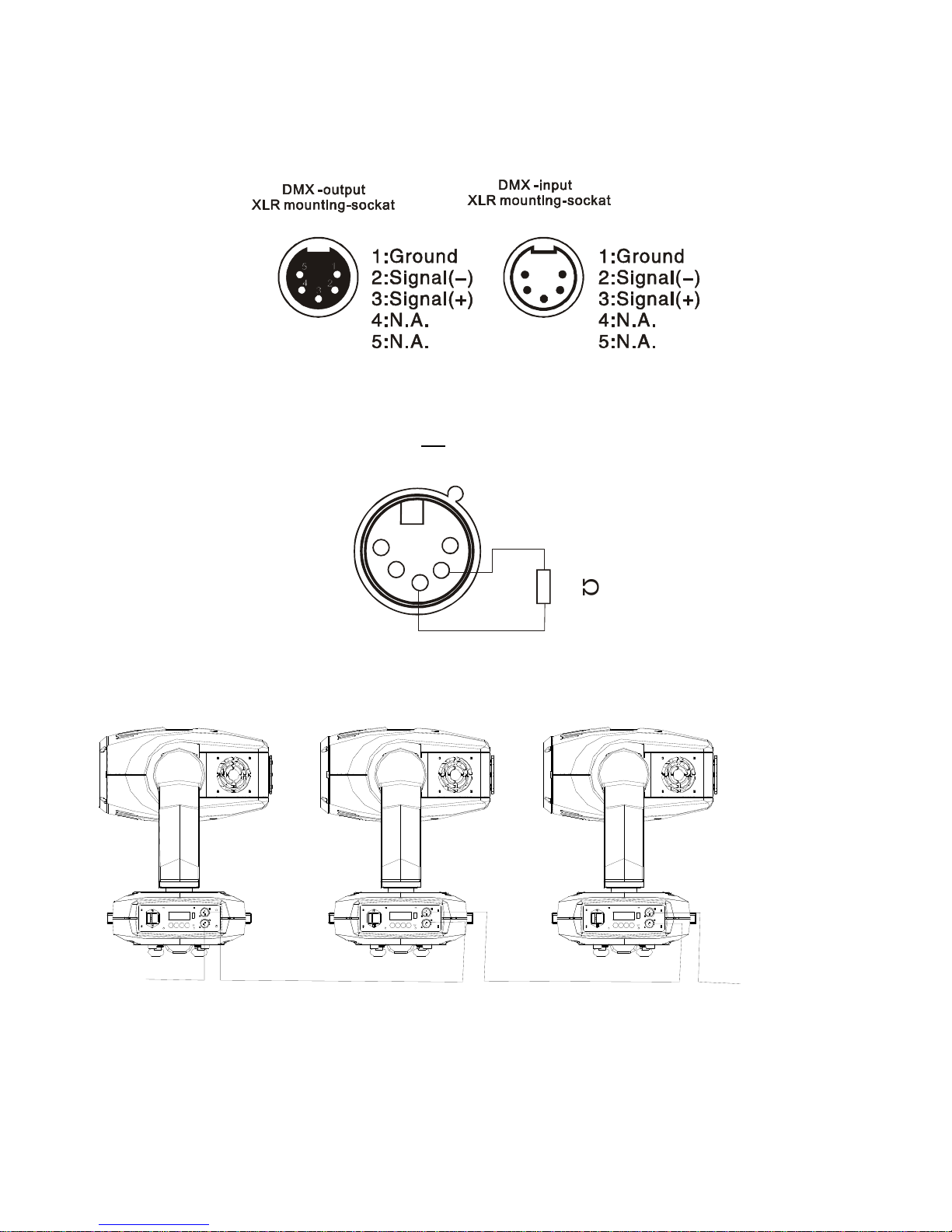

DMX-512 Control Connection

Connect the provided XLR cable to the female 5-pin XLR output of your Elektralite CP 20 or other DMX

controller. The other end should be connected to the male 5-pin XLR input of LXE 700 Wash. Then

daisy-chain out of the first LXE 700 Wash and into the next LXE 700 Wash or other dmx device. Never “Y”

split the DMX connection.

If you need more cable, then it should be two core, screened cable fitted with a 5 pin XLR input and output

connector. Please refer to the diagram below.

1

2

3

4

5

DMX-512 connection with DMX terminator

For installations where the DMX cable has to run a long distance or is in an electrically “noisy” environment, it

is recommended that a DMX terminator is used. This helps prevent corruption of the digital control signal. The

DMX terminator is simply a 5 pin XLR plug (male) with a 120 Ωresistor connected between pins 2 and 3. It is

then plugged into the output XLR socket of the last LXE 700 Wash or other dmx device in the chain. Please

see illustration below.

1

2

3

4

5

Ω

120

DMX line

- 7- LXE700 wash

Projector DMX start address selection

All LXE 700 washes need be given a DMX starting address when using a DMX signal, so that the correct LXE

700 Wash responds to the correct control signals. This digital starting address is the channel number from

which LXE 700 Wash starts to “listen” to the digital control information sent out from the Elektralite CP20 or

other DMX controller. The allocation of this starting address is done by setting the correct number on the

display located on the base of LXE700 Wash.

You can set the same starting address for all fixtures or group of fixtures, like all the LXE700 Washes in your

plot, or you can make different address for each individual fixture.

If you set the same address, all the fixtures will start to “listen” to the same control signal from the same

channel number. In other words, changing the settings of one channel will affect all the fixtures simultaneously.

If you set a different address, each unit will start to “listen” to the channel number you have set, based on the

quantity of control channels of the fixture. That means changing the settings of one channel will affect only the

selected fixture.

In the case of this LXE 700 Wash, which is a 24 channel fixture, you should set the starting address of the first

unit to 1, the second LXE 700 Wash to 25 (24 + 1), the third to 49 (25 + 24), and so on.

Note:

After switching on, LXE 700 wash will automatically detect whether DMX 512 data is received or not. If the data is received, the display will

show "A.001" or whatever the address is set to, like “A.025” If there is no data received at the DMX-input, the display flashes "A001" with

the actually set address. This situation can occur if:

- the 5 PIN XLR plug (cable with DMX signal from the controller) is not connected to the input of LXE 700 Wash.

or

-the controller is switched off or defective.

or

-the cable or connector is defective

- 8- LXE700 wash

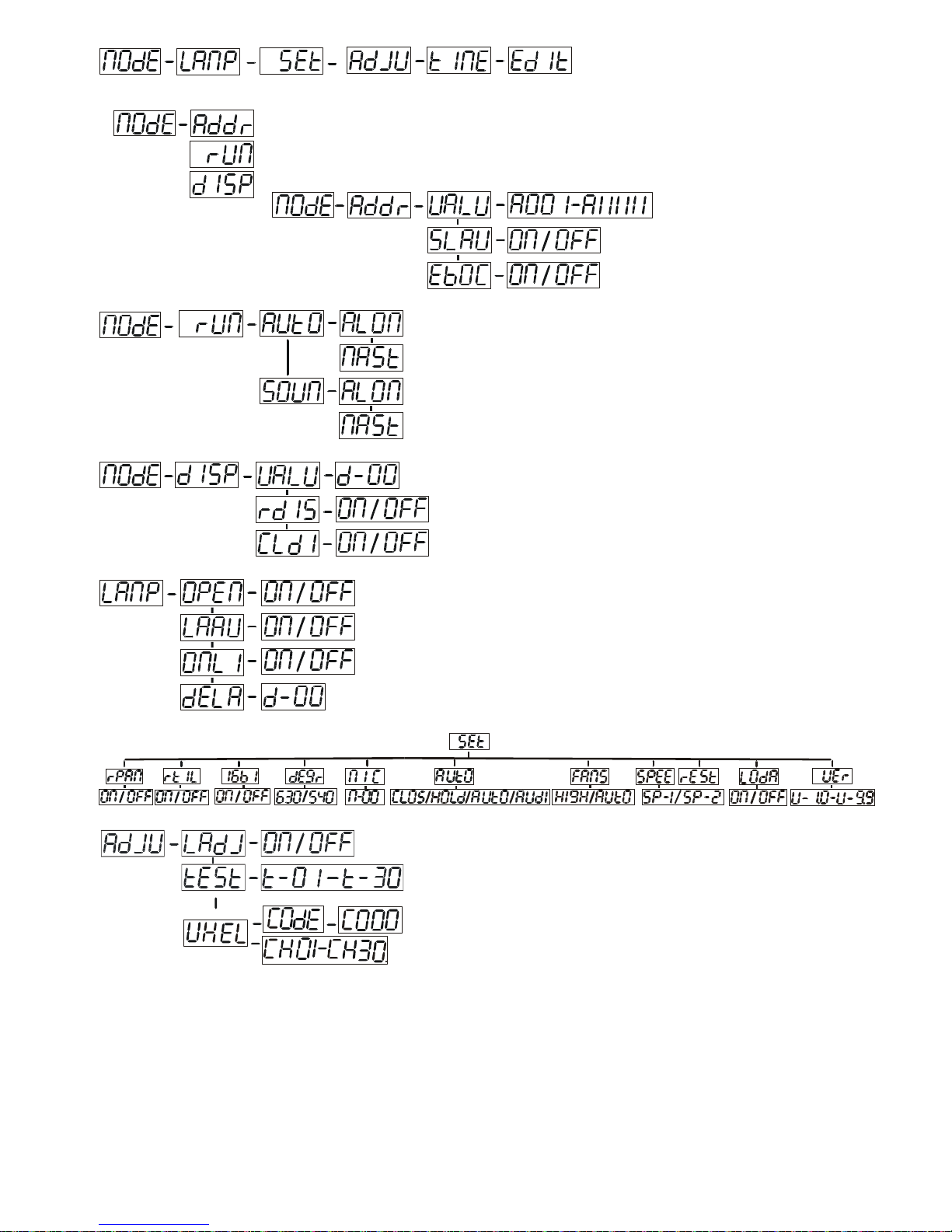

The Display Panel:

Default settings shaded.

VA L U A001~AXXX (AXXX) DMX address setting

SLAV SLA1/ SLA2/ SLA3 Slave setting

ADDR

EBOC ON/OFF Change DMX address via

external controller

ALON (AU-A) Automatic Run in Stand Alone

AUTO MAST (AU-M) Automatic Run as Master

ALON (SO-A) Sound-controlled Run in Stand

Alone

RUN

SOUN

MAST (SO-M) Sound-controlled Run as Master

VA L U D–XX D-00 (DXXX) Display the DMX 512 value of

each channel

RDIS ON/OFF Reverse display

0 MODE

DISP

CLDI ON/OFF Shut off LED display

OPEN ON/OFF Lamp on/off

LAAU ON/OFF Lamp automated on with power

ONLI ON/OFF Lamp on/off via controller

1 LAMP

DELA D–XX D-05 Delay lamp on

RPAN ON/OFF Pan Reverse

RTIL ON/OFF Tilt Reverse

16BI ON/OFF Switch 16 bit/8 bit

DEGR 630/540 Pan degree select

MIC M-XX Mic sensitivity

AUTO Clos/Hold/Auto/Audi No DMX Status

FANS HIGH/AUTO Fan’s mode select

SPEE SP-1/SP-2 Movement Mode Select

REST Reset

LODA ON/OFF Restore factory settings

2 SET

VER V-1.0~V-9.9 Software version

LADJ ON/OFF Lamp adjustment

TEST T–01~T–30 Test function of each channel

CODE CXXX Fixture code *code is “C050”

3 ADJU

WHEL CH01~CH30 XXXX(-128~127) Motor Fix

LIFE 0000~9999(hours) Fixture running time

LAMP 0000~9999(hours) Lamp running time

CODE CXXX (Password is 038) Clear Timer Password

CLFE ON/OFF Clear fixture time

4 TIME

CLMP ON/OFF Clear lamp time

STEP S–01 ~S–48 Steps of Program Run

REC. RE.XX Auto Save Scene

C–01~C–30 0 1 XX(00~FFH)

3 0 XX(00~FFH) Edit the channels of each scene

TIME XXXX(000.2s~199.8s) Time for each scene

5 EDIT

SC01

~ SC48

CNIN ON/OFF Edit program via controller

- 9- LXE700 wash

- 10 - LXE700 wash

- 11 - LXE700 wash

Channel Functions:

CHANNEL 1 : color wheel 8 colors plus white, color cycle or rainbow effect

CHANNEL 2 : cyan color mixing

CHANNEL 3 : magenta color mixing

CHANNEL 4 : yellow color mixing

CHANNEL 5 : pan movement (max. 630°)

CHANNEL 6 : tilt movement (max. 265°)

CHANNEL 7 : speed of pan/tilt movement, or different blackout selection by wheels

CHANNEL 8 : Effect wheel. The beam shaper

CHANNEL 9 : Linear Zoom

CHANNEL 10 : Strobe effect maximum 15 flashes per second or random strobe, dimming and shutter

close/open control

CHANNEL 11 : Dimming effect 0-100% (only be activated while CHANNEL 10 is between

position 32 –63 DMX or between position 96-127 or between position 160-191 or

between position 224-255 values).

CHANNEL 12 : Speed of CMY and dimmer.

CHANNEL 13 : Color Macros. CMY and color wheel.

CHANNEL 14 : auto program control + lamp on, motor reset, lamp switch off

CHANNEL 15 : 16 bit pan movement (fine movement).

CHANNEL 16 : 16 bit tilt movement (fine movement).

- 12 - LXE700 wash

DMX Channel Function & Values:

Channel 1 - Color Wheel :

0-13 Open / white

14-27 Color 1

28-41 Color 2

42-55 Color 3

56-69 Color 4

70-83 Color 5

84-97 Color 6

98-111 Color 7

112-127 Color 8

128-189 Forwards rainbow effect fast to slow

190-193 No rotation

194-255 Backwards rainbow effect slow to fast

Channel 2 - Cyan Color Wheel :

0-255 Cyan (0-white, 255-100% Cyan)

Channel 3 - Magenta Color Wheel :

0-255 Magenta (0-white, 255-100% magenta)

Channel 4 - Yellow Color Wheel :

0-255 Yellow (0-white, 255-100% Yellow)

Channel 5 - PAN movement 8bit :

Channel 6 - TILT movement 8bit :

Channel 7 - Speed pan/tilt movement:

0-225 max to min speed

226-235 blackout by movement

236-245 blackout by all wheel changing

246-255 no function

- 13 - LXE700 wash

Channel 8 - Effect wheel (Beam Shaper).

0-70 Full Beam

71-230 Beam Shaper

231-255 Frost filter

Channel 9 - Zoom

0-255 Zoom 30 – Zoom 7

Channel 10 - Shutter, strobe:

0-31 Shutter closed

32-63 No function (shutter open)

64-95 Strobe effect slow to fast

96-127 No function (shutter open)

128-159 Pulse-effect in sequences

160-191 No function (shutter open)

192-223 Random strobe effect slow to fast

224-255 No function (shutter open)

Channel 11- Dimmer (intensity):

0-255 Intensity 0 to 100%

Channel 12 - Speed of CMY and Dimmer

0-255 Speed Maximum to Minimum

- 14 - LXE700 wash

Channel 13- Color Macros – CMY and Color

wheel

0-7 off

8-15 Macro 1

16-23 Macro 2

24-31 Macro 3

32-39 Macro 4

40-47 Macro 5

48-55 Macro 6

56-63 Macro 7

64-71 Macro 8

72-79 Macro 9

80-87 Macro 10

88-95 Macro 11

96-103 Macro 12

104-111 Macro 13

112-119 Macro 14

120-127 Macro 15

128-135 Macro 16

136-143 Macro 17

144-151 Macro 18

152-159 Macro 19

160-167 Macro 20

168-175 Macro 21

176-183 Macro 22

184-191 Macro 23

192-199 Macro 24

200-207 Macro 25

208-215 Macro 26

216-223 Macro 27

224-231 Macro 28

232-239 Macro 29

240-247 Macro 30

248-255 Random CMY

- 15 - LXE700 wash

Channel 14– Lamp on/off, reset, Int. Prog.

0-19 color & gobo change normal

20-29 color change to any position

30-39 color & gobo change to any position

40-59 Lamp on

60-79 Lamp switch off

80-99 Motor reset

100-119 Internal program 1

120-139 Internal program 2

140-159 Internal program 3

160-179 Internal program 4

180-199 Internal program 5

200-219 Internal program 6

220-239 Internal program 7

240-255 Internal program 8

192-223 Pulse opening fast to slow

224-255 Pulse closing slow to fast

Channel 15 – Pan fine 16bit

Channel 16 –Tilt fine 16bit

- 16 - LXE700 wash

ERROR MESSAGE

When you turn on LXE700 Wash, it will reset first. The display may show “XXer” while there are problems with

one or more channels. “XX” stands for channel 1,2,3 and so on.

For example, when the display shows “01Er”, it means there is some error in channel1 (the color wheel. If there

are errors on channel 1, channel 2, channel 5 at the same time, you may see the error message “01Er”,

“02Er”,”05Er” flash repeatedly for 5 times, and then LXE 700 Wash will generate a second reset signal, This

reset with literally reset all the stepper motors. Usually after the second reset the error messages disappear

and the address number is displayed. Do not concern yourself if after the second reset that the address appear,

it is perfectly alright that the first reset fails. It is not a sign of a problem.

If the error message remains after performing reset after the second time, then the functions with the error will

not work but all other channels will more and the LXE 700 Wash will display its address number. The exception

to this rule is if the fixture has 3 errors or more. If this is the case then the fixture will not function until the

problem is sorted.

As an example of what to look for with an error message, here is the fault repair paradigm for 01Er:

01Er:

(Color-wheel 1 error) This message will appear after the reset of LXE 700 Wash if the magnetic-indexing circuit

malfunctions. This can mean a sensor failed or the magnet is missing or the color wheel stepping-motor is

defective or the drive circuit on the main circuit card for the motor is defective or the one (or more) wires

coming from the motor or sensor down to the circuit card is broken.

If any of the above happens then the color wheel will not be located in the default position after the reset.

CLEANING AND MAINTENANCE

The following points have to be considered during the inspection:

1) All screws, clamps etc. used to install LXE 700 Wash have to be tight and must not be corroded. Check

them regularly because, remember, LXE 700 Wash moves and so it will have an effect on whatever you are

using to hang the fixture.

2) There must not be any deformations on LXE 700 Wash’s housing and internal parts. Also check the points

where LXE 700 Wash is installed including such things as ceiling mounting points, truss, half couplers, C

clamps, safety cables and so on.

1) Mechanical moving parts must not show any traces of wearing and must rotate evenly.

2) The power input cable must not show any damage or material fatigue.

We recommend a frequent cleaning of the device. Please use a moist, lint- free cloth. Never use alcohol or

solvents. Pay particular attention to all the fans and their vents. That is where dust and debris can accumulate.

Accumulation of dust here can have a devastating effect on LXE 700 Wash. You must remove it regularly.

Failure to do so will cause overheating inside LXE 700 Wash. Overheating causes premature failure of the

lamp and other critical components. Do not use a air hose to clean the fans and vents. All you will do is bow the

dust right into the fixture and all over the dicroic colors and gobos.

There are no serviceable parts inside LXE700 Wash except for the lamp. Please refer to the

instructions under “Installation instructions” to change lamp.

Should you need any spare parts, please order genuine parts from your local dealer.

- 17 - LXE700 wash

TECHNICAL SPECIFICATIONS

Power Supply :

□120VAC,60Hz;

Power consumption : max. 800VI.

Lamp : HSR 700 (or MSR700/2)

Motors : 24 micro motors

Packing dimensions :30” x 22” x 18” (76.5mm x 55.5mm x 46.5mm)

Net weight : 75 pounds (34Kgs)

Please note, Elektralite is constantly improving their product range and we reserve the right to make changes

without prior notice.

Other Elektralite Products include :

[Also check out our website at www.myelektralite.com]

CP-20xt Controller.

- 18 - LXE700 wash

TurboFog + Fog Machine.

Turbohazer Haze Machine.

Table of contents

Other elektraLite Lighting Equipment manuals

elektraLite

elektraLite RGBA Dazer User manual

elektraLite

elektraLite Theatrical White Dazer User manual

elektraLite

elektraLite MY575w User manual

elektraLite

elektraLite eyeBall Quad led User manual

elektraLite

elektraLite eyeBall IP65 User manual

elektraLite

elektraLite eyeBall UV User manual

elektraLite

elektraLite MY 575.3 User manual