Elektronik Sachse ZDG 3.23 User manual

1

ELEKTRONIK

SACHSE

Elektronik Sachse GmbH & Co. KG

Installation Manual

Digital Ignition ZDG 3.23 (Moto Guzzi

Ducati Alternator)

Item: Z59-D

Contents

1 Function ................................................................ 1

2 Mounting ............................................................... 2

3 ElectricalConnections .................................................... 3

4 Settings ................................................................. 4

5 GeneralNotes/Troubleshooting .......................................... 8

1 Function

T

he d

i

g

it

a

l i

gn

iti

on k

it

ZDG3

r

ep

l

aces o

ri

g

i

na

l

e

l

ec

tr

on

i

c

i

gn

iti

on un

it

s as we

ll

as o

l

d po

i

n

t

s

including the weights advancer or manual advance wires.

Func

ti

on

:

Pe

r r

e

v

o

l

u

ti

on o

f t

he c

r

anksha

ft

s

t

a

rti

ng

fr

om

T

D

C

, t

he momen

t

a

ry

pe

ri

phe

r

a

l

speed

i

s de

t

e

r

m

i

ned and b

y t

h

i

s means

, t

he

ti

me up

t

o

i

gn

iti

on

i

s ca

l

cu

l

a

t

ed

.

Because

t

he

pe

ri

phe

r

a

l

speed

v

a

ri

es subs

t

an

ti

a

lly

du

ri

ng acce

l

e

r

a

ti

on

, t

h

i

s

l

ong measu

r

emen

t i

s se

l

ec

t

ed

in order to determine a relatively exact measurement.

The computation of ignition timing is divided into 4 ranges:

Range Function

0 – 400 rpm Starting range, ignition always at TDC

400 – 1000 rpm Idling range, 2° to 8° advanced ignition, depending on curve selection

1000 – 6200 rpm Partial load range, the spark advance adjustment occurs here

6200 – 12000 rpm Maximum load range, constant maximum advanced ignition, depend-

ing on curve selection

2

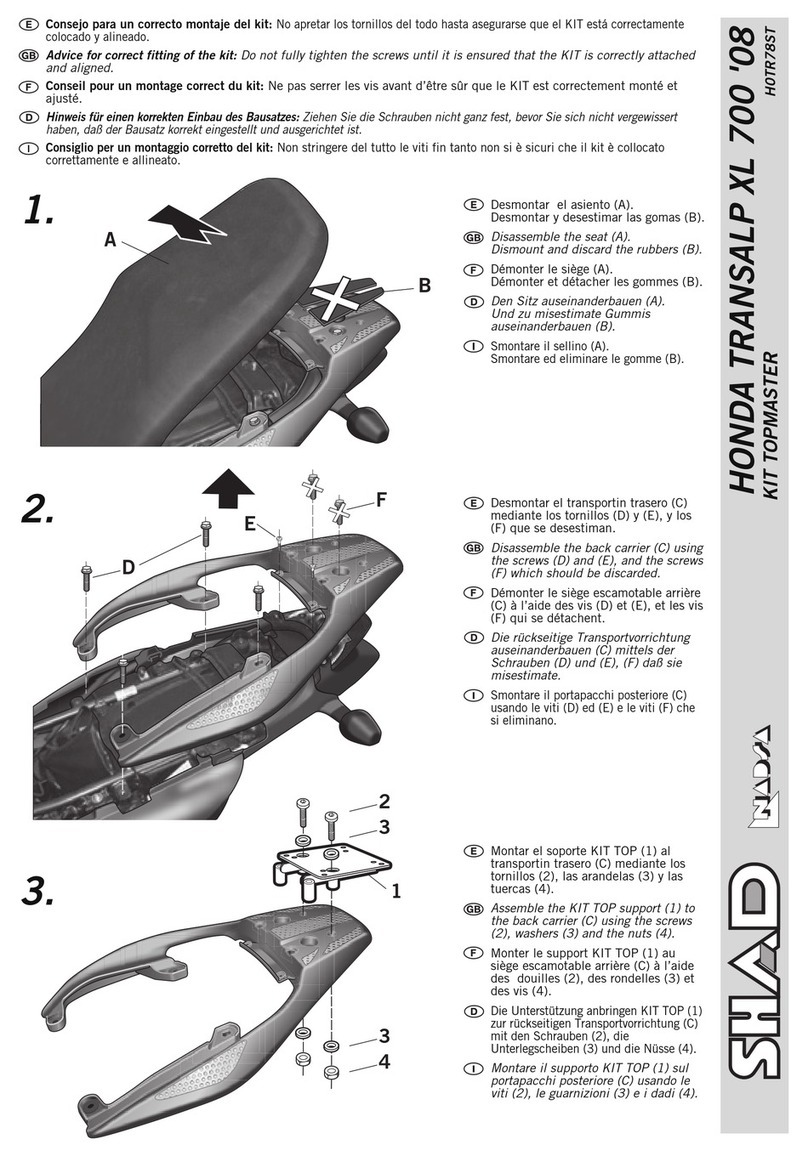

2 Mounting

•

T

he moun

ti

ng pos

iti

on o

f t

he p

i

ckup

i

s de

t

e

r

m

i

ned b

y t

he pos

iti

on o

f i

ns

t

a

ll

a

ti

on and

connec

ti

on o

f t

he s

t

a

t

o

r.

F

ir

s

t, r

emo

v

e

t

wo o

f t

he

t

h

r

ee M

5-

s

t

a

t

o

r

sc

r

ews and

r

ep

l

ace

them with the supplied threaded bolts and washers.

Figure 1 Threaded rods with spacer.

•

T

hen

r

emo

v

e

t

he cen

tr

a

l

nu

t fr

om

t

he

r

o

t

o

r

and

sc

r

ew aga

i

n

t

he d

riv

e

r

s

l

ee

v

e bu

t ti

gh

t

en on

ly

slightly.

Figure 2 Centre nut.

•

Now

t t

he p

i

ckup p

l

a

t

e on

t

o

t

he

t

h

r

eaded bo

lt

s and push

t

he mag

-

ne

ti

c d

i

sk so

f

a

r

on

t

o

t

he d

riv

e

r t

ha

t t

he magne

t

s

i

n

t

he d

i

sk a

r

e

i

n

the same height as the sensors.

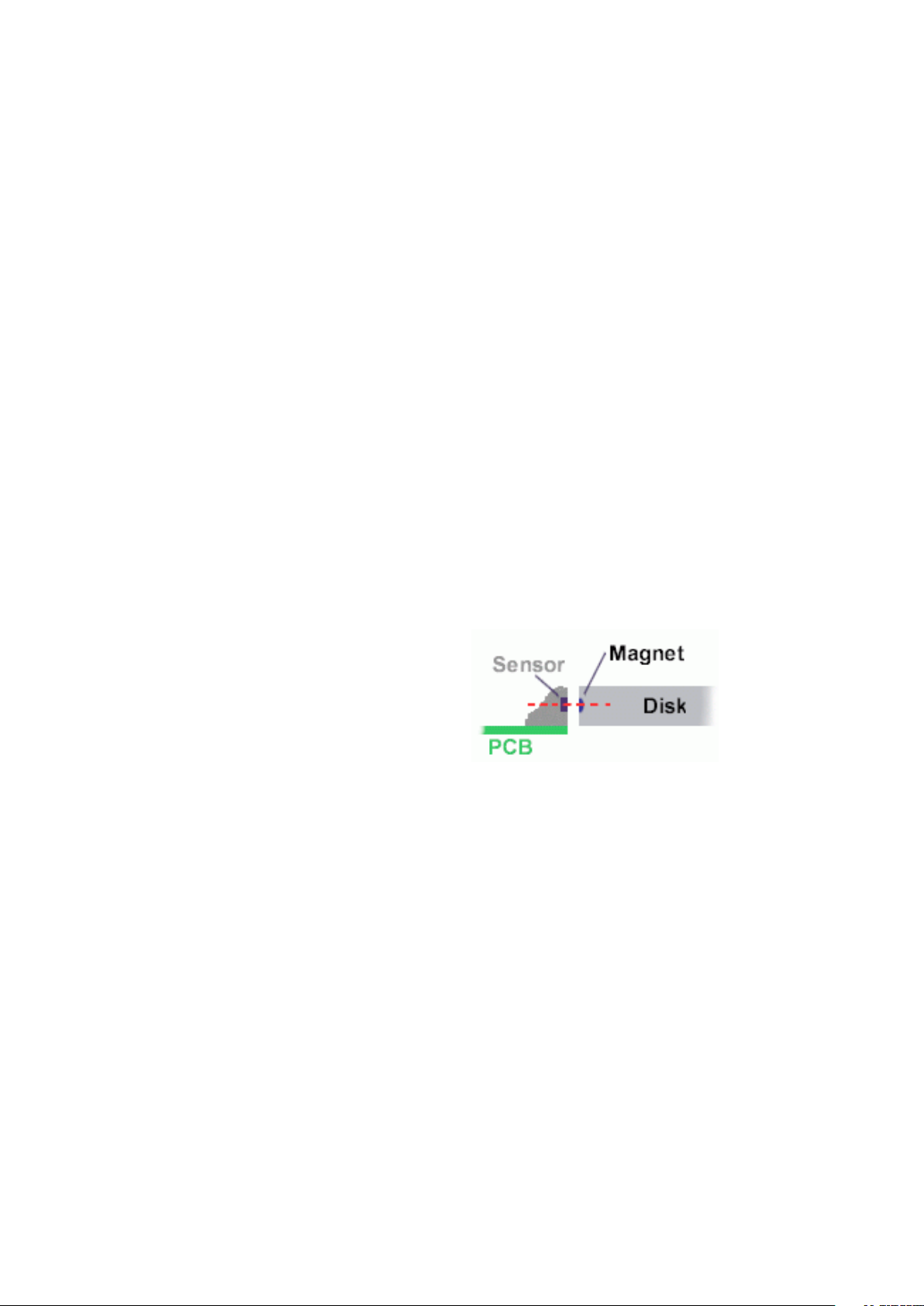

Figure 3 Sensor alignment.

•

If t

he d

riv

e

r

o

v

e

rl

aps

it

shou

l

d be

r

educed b

y t

h

i

s

amoun

t (l

e

,

ang

l

e g

ri

nde

r

o

r l

a

t

he

),

so

t

ha

t t

he

co

v

e

r

can be

tt

ed as c

l

ose as poss

i

b

l

e

. If

e

v

e

ry-

thing ts, then the driver will be fully tightened.

•

W

it

h a

littl

e pa

ti

ence and

t

a

l

cum powde

r t

he

p

i

ckup cab

l

e can be pushed

t

h

r

ough

t

he

r

ubbe

r

g

r

omme

t.

O

t

he

r

w

i

se an add

iti

ona

l

g

r

oo

v

e

f

o

r t

he

p

i

ckup

l

ead

(+

p

r

o

vi

ded g

r

omme

t)

mus

t

be made

i

n

t

o

t

he gene

r

a

t

o

r

co

v

e

r

ne

xt t

o

t

he e

xi

s

ti

ng g

r

om

-

met.

3

Figure 4 Connecting the pickup.

3 Electrical Connections

T

he w

ir

e c

r

oss sec

ti

on o

f t

he g

r

ound cab

l

e shou

l

d no

t

be be

l

ow

1.5

mm

2

and shou

l

d be kep

t

as sho

rt

as poss

i

b

l

e

. T

he w

ir

e c

r

oss

-

sec

ti

on o

f t

he o

t

he

r

cab

l

es shou

l

d no

t

be be

l

ow

0.5

mm

2

.

A

tt

en

ti

on

:

P

l

ease do no

t

sho

rt

en

t

he p

i

ckup

l

ead and use

i

nsu

l

a

t

ed w

ir

e end

f

e

rr

u

l

es on

the other cables!

Figure 6 Ignition circuit diagram, breaker points replacement

4

Figure 5 Ignition circuit diagram, Motoplat replacement

Connector Function

1 Ignition coil cylinder left −

2 Ground

3 Pickup lead, brown

4 Pickup lead, green

5 Pickup lead, yellow

6 Pickup lead, white

7 Output for electronic tachometer

8 +12 supply voltage, switched

9 Ground (same as #2)

10 Ignition coil cylinder right −

4 Settings

5

Figure 7 Adjust the sector disk so that the

LED toggles.

•Bring the right piston into TDC position.

•

Ro

t

a

t

e

t

he d

i

sk

i

n

r

o

t

a

ti

on d

ir

ec

ti

on un

til t

he

’

S

’-

ma

r

ked Magne

t i

s c

l

ose

t

o

t

he senso

r. T

ake ca

r

e

t

ha

t t

he magne

t

s

i

n

t

he d

i

sk a

r

e app

r

o

xi

ma

t

e

ly i

n

the same hight as the sensor.

Figure 8 Ensure correct alignment of mag-

net disk and sensor.

•Turn on the ignition switch.

•

Go on

r

o

t

a

ti

ng

t

he d

i

sk

. T

he

L

ED nea

r t

he senso

r

should light up when the ’S’-marking passes the

senso

r (r

ed a

rr

ow

). It i

s poss

i

b

l

e

t

ha

t t

he

L

E

D

s

already indicating at power on.

•

Ro

t

a

t

e

t

he d

i

sk s

l

ow

ly t

o

t

he

’

N

’-

ma

r

k

i

ng un

til

t

he

L

E

D

i

s sw

it

ch

i

ng o

. T

he d

i

sk

i

s

i

n

t

he co

rr

ec

t

pos

iti

on and can be

ti

gh

t

ened b

y t

he se

t

sc

r

ews

.

Make this adjustment very accurately!

•

No

ti

ce

: y

ou can

’t

sw

it

ch

t

he

L

ED on on

ly

b

y t

u

r

n

-

i

ng back

. T

he

r

e

f

o

r

e

t

he

i

gn

iti

on mus

t

be sw

it

ched o

/

on o

r t

he d

i

sc be

t

u

r

ned back

t

o

the ’S’ marked magnet.

•

If t

he eng

i

ne

i

s

r

unn

i

ng p

l

ease secu

r

e

t

he se

t

sc

r

ews w

it

h med

i

um s

tr

eng

t

h

t

h

r

ead

locker.

•At last, if possible, check the timing with a timing lamp.

T

he

D

I

P sw

it

ches can be

f

ound on

t

he

l

e

ft

s

i

de o

f t

he

i

gn

iti

on bo

x.

D

I

P sw

it

ch No

. 1

controls the rev limiter. It has two settings, up and down:

6

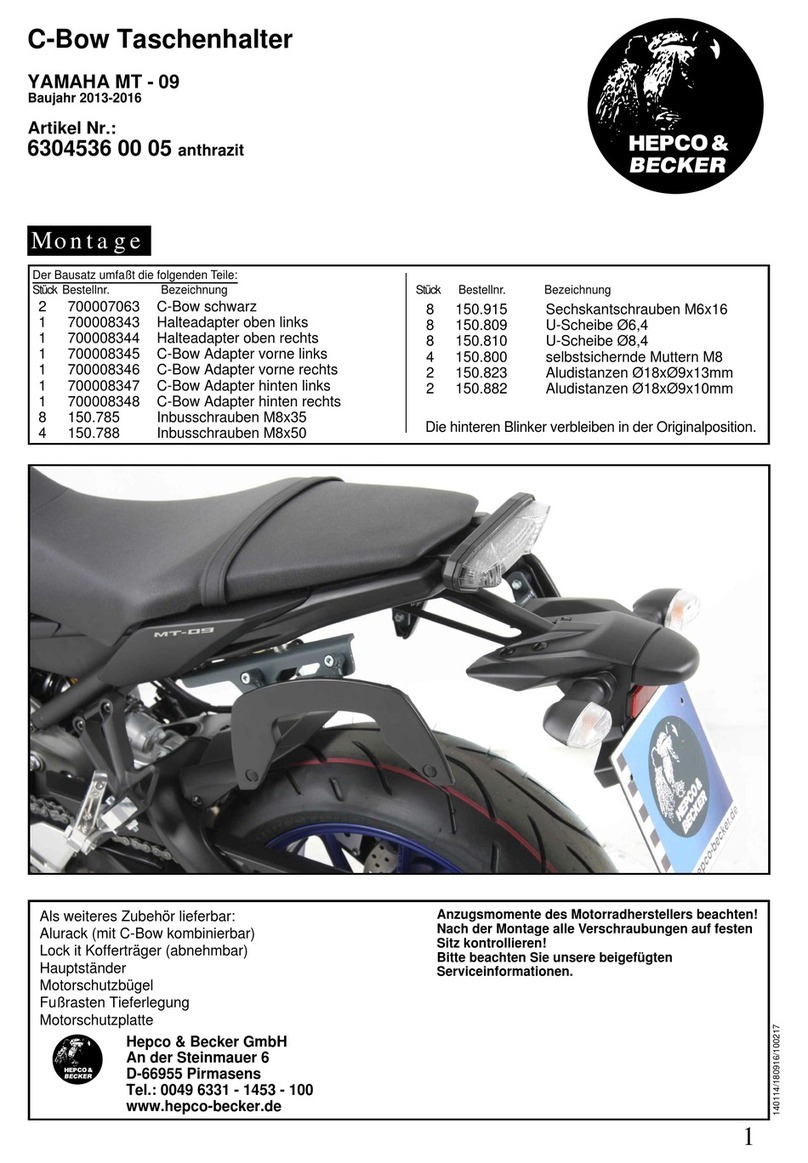

DIP switch 1 Rev limiter setting

up 8600 rpm

down 7800 rpm

Figure 9 DIP switches and rotary switch.

T

he

r

e

v li

m

it

e

r

D

I

P sw

it

ch No

.

2

i

s ne

xt t

o

D

I

P sw

it

ch

No

. 1

and ad

j

us

t

s

t

he

fr

equenc

y

o

f t

he e

l

ec

tr

on

i

c

t

achome

t

e

r t

ha

t

can be connec

t

ed

t

o

#7. If

no e

l

ec

-

tr

on

i

c

t

achome

t

e

r i

s connec

t

ed

t

h

i

s sw

it

ch can be

ignored.

D

IP switch No. 2 should be in the up position for

c

r

anksha

ft fr

equenc

y

se

l

ec

ti

on and down pos

iti

on

f

o

r

camshaft frequency selection:

DIP switch 2 Frequency setting

up crankshaft

down camshaft

T

he

i

gn

iti

on cu

rv

es can be se

t

us

i

ng

t

he

r

o

t

a

ry

d

i

a

l

on

t

he

l

e

ft

s

i

de o

f t

he bo

x, ri

gh

t

o

f

the DIP switches. Curve No. 0 is a test mode in which the box continually res without the

eng

i

ne

r

unn

i

ng

. T

h

i

s

t

es

t

s

t

he

i

ns

t

a

ll

a

ti

on o

f t

he un

it

and co

il

s

.

Bu

t it

doesn

’t t

es

t t

he p

i

ckup

.

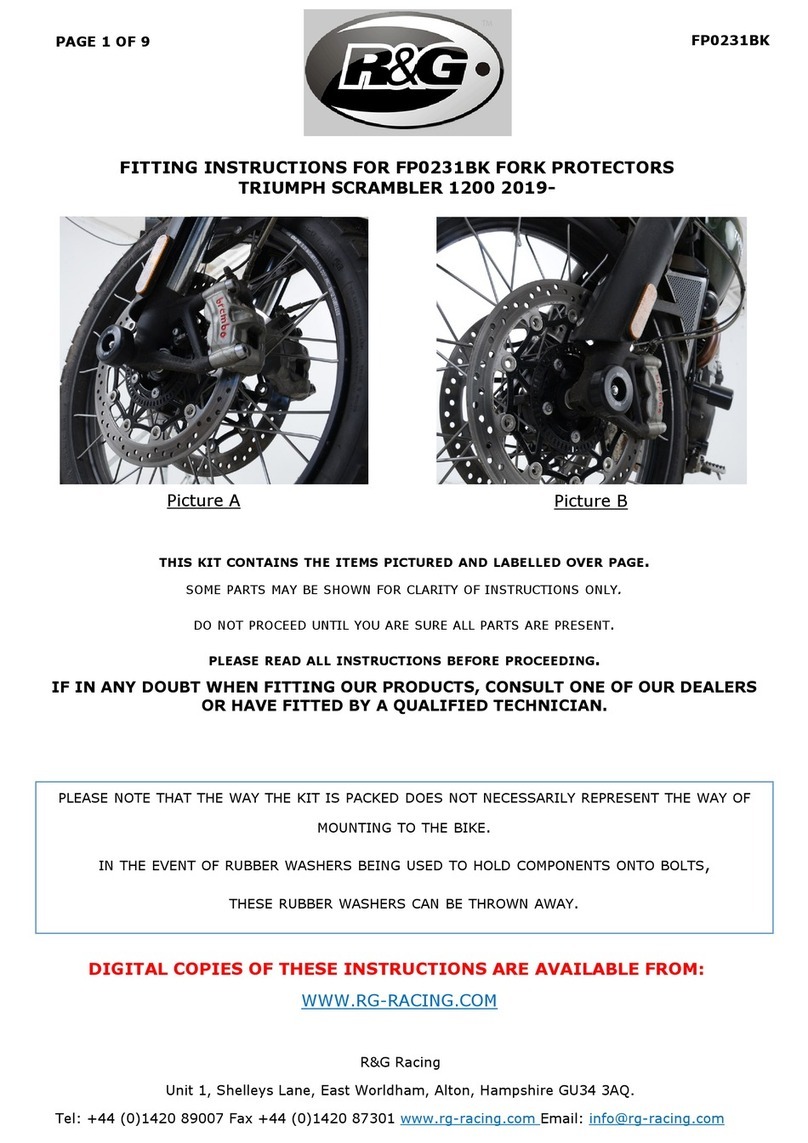

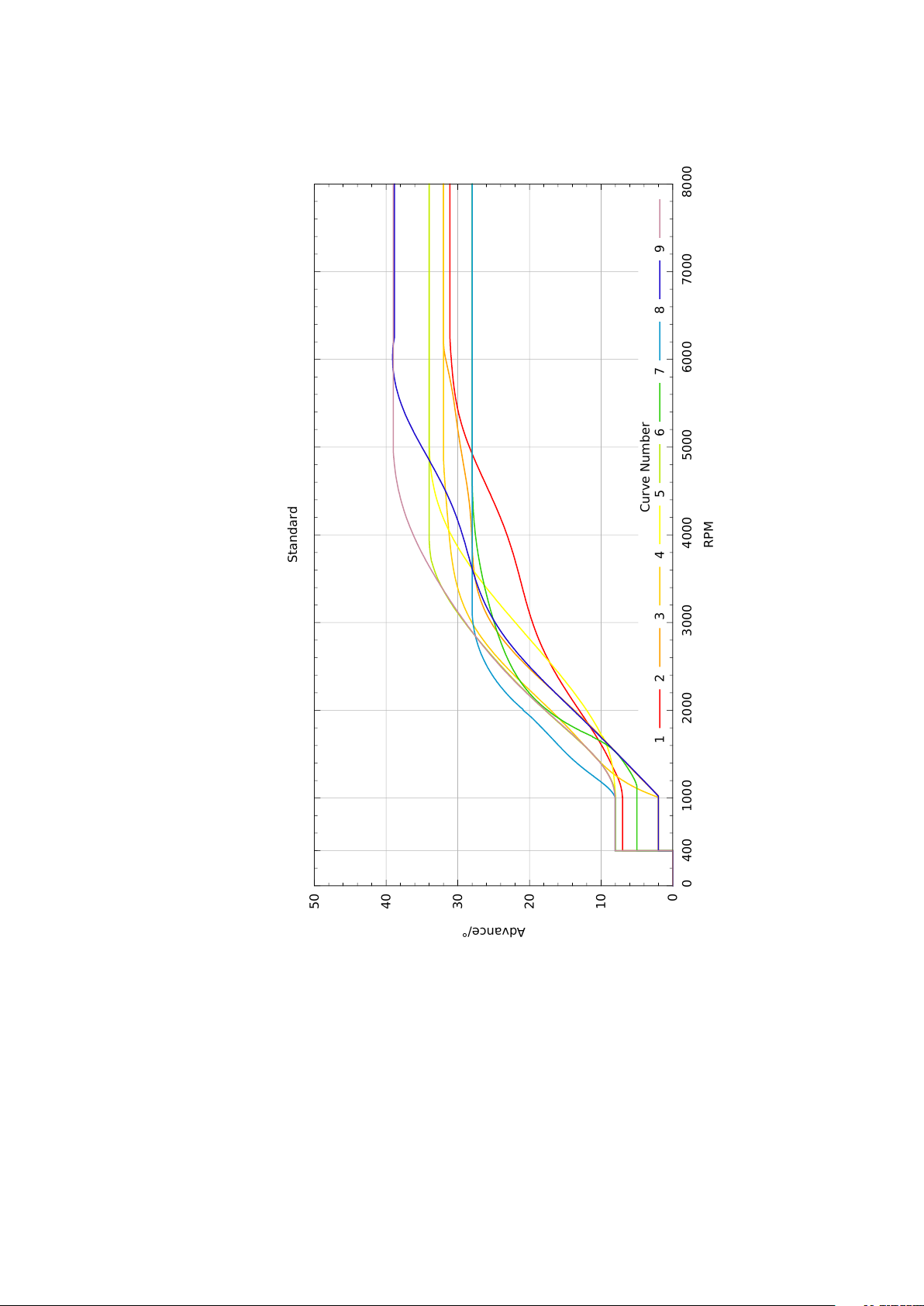

Rotary switch settings 1 – 9 are the dierent ignition curves.

7

0

10

20

30

40

50

4000 1000 2000 3000 4000 5000 6000 7000 8000

Advance/°

RPM

Standard

Curve Number

1 2 3 4 5 6 7 8 9

Figure 10 Selectable ignition curves.

8

5 General Notes / Troubleshooting

O

n

ly

use

i

n

t

e

rf

e

r

ence

-fr

ee caps

f

o

r t

he spa

r

k p

l

ugs

!

Recommended a

r

e N

G

K caps w

it

h

5

k

Ω

internal resistance.

D

oesn

’t

s

t

a

rt: If t

he eng

i

ne shou

l

d no

t

s

t

a

rt,

o

r t

he eng

i

ne k

i

cks back

, t

hen

t

he

i

gn

iti

on

co

il

s a

r

e m

ix

ed up

. If

so

,

swap

t

he

i

gn

iti

on cab

l

es wh

i

ch

l

ead

t

o

t

he spa

r

k p

l

ugs o

r r

econnec

t

t

he e

xt

e

r

na

l i

gn

iti

on co

il

s

.

A

s a gene

r

a

l r

u

l

e

:

each

ti

me when a p

i

s

t

on

r

eaches

T

D

C a

l

so

t

he co

rr

espond

i

ng p

l

ug mus

t

ha

v

e a spa

r

k

. T

o check

t

he cab

l

e connec

ti

ng and

t

he supp

ly

voltage turn the rotary switch to ’0’. Now the spark plugs must re continually. If now the

r

o

t

a

ry

sw

it

ch

i

s

t

u

r

ned aga

i

n on a

l

e

v

e

l y

ou can eas

ily

check

t

he

ti

m

i

ng w

it

h a s

tr

obe on

ly

b

y

ac

tiv

a

ti

ng

t

he s

t

a

rt

e

r (

w

it

hou

t

p

l

ugs

i

n

t

he c

yli

nde

r

s

). If t

he eng

i

ne shou

l

d no

t

s

t

a

rt

w

it

h

s

l

ow

ly t

u

r

n

i

ng s

t

a

rt

e

r,

p

r

obab

ly t

he ba

tt

e

ry v

o

lt

age

f

a

ll

s unde

r t

he m

i

n

i

mum supp

ly v

o

lt

age

of the ignition (approx. 7 V).

Irregular engine cutouts: If sometimes the engine suspends while driving for 2-3 seconds

and keeps

r

unn

i

ng

t

he

r

ea

ft

e

r

no

r

ma

lly. T

ha

t

means

t

ha

t t

he

i

gn

iti

on has been

r

ese

t. T

he

cause

f

o

r it

can be a de

f

ec

tiv

e cap o

r

a

l

oose

i

gn

iti

on cab

l

e

i

n

t

he co

il

o

r

cap

.

Bu

t i

n mos

t

cases

a bad con

t

ac

t i

n

t

he ope

r

a

ti

ng

v

o

lt

age supp

ly (

k

ill

sw

it

ch

,

s

t

a

rt

e

r l

ock

, f

use ho

l

de

r, t

e

r

m

i

na

l

s

e

t

c

.)

causes

t

h

i

s e

ec

t.

Fo

r

a

t

es

t y

ou can connec

t

a cab

l

e d

ir

ec

tly fr

om

t

he

i

gn

iti

on co

il

s

and

t

he

i

gn

iti

on bo

x t

o

t

he pos

itiv

e

t

e

r

m

i

na

l

o

f t

he ba

tt

e

ry.

A

l

so pu

t

a second cab

l

e

fr

om

t

he nega

tiv

e

t

e

r

m

i

na

l

o

f t

he ba

tt

e

ry t

o

t

he

i

gn

iti

on bo

x (

secu

r

e g

r

ound connec

ti

on

). If t

he

eng

i

ne

i

s

r

unn

i

ng we

ll

now

y

ou can assume an e

rr

o

r i

n

t

he w

iri

ng ha

r

ness

.

W

it

h con

t

ac

t

b

r

ake

r

s such a bad con

t

ac

t i

s no

t

no

ti

ceab

l

e

,

because a sho

rt

b

r

eak

f

o

r

a

f

ew m

illi

seconds o

f

the supply voltage does’t matter, electronics in contrast are more sensitively.

Elektronik Sachse GmbH & Co. KG

Kloster-Oeseder-Weg 37

49176 Hilter

Germany

phone: +49 (0) 5409 9069826

email: info@elektronik-sachse.de

Other manuals for ZDG 3.23

1

Table of contents

Other Elektronik Sachse Motorcycle Accessories manuals

Popular Motorcycle Accessories manuals by other brands

bitubo

bitubo KIT 117 Assembly instructions

SCHUBERTH

SCHUBERTH R2 BASIC manual

Thunderbike

Thunderbike STEEL installation instructions

National Cycle

National Cycle ZTechnik VStream Z2392 installation instructions

GRÜNSPECHT

GRÜNSPECHT 137-00 Instructions for use

hepco & becker

hepco & becker 6509502 00 01 Mounting instructions