12

EN

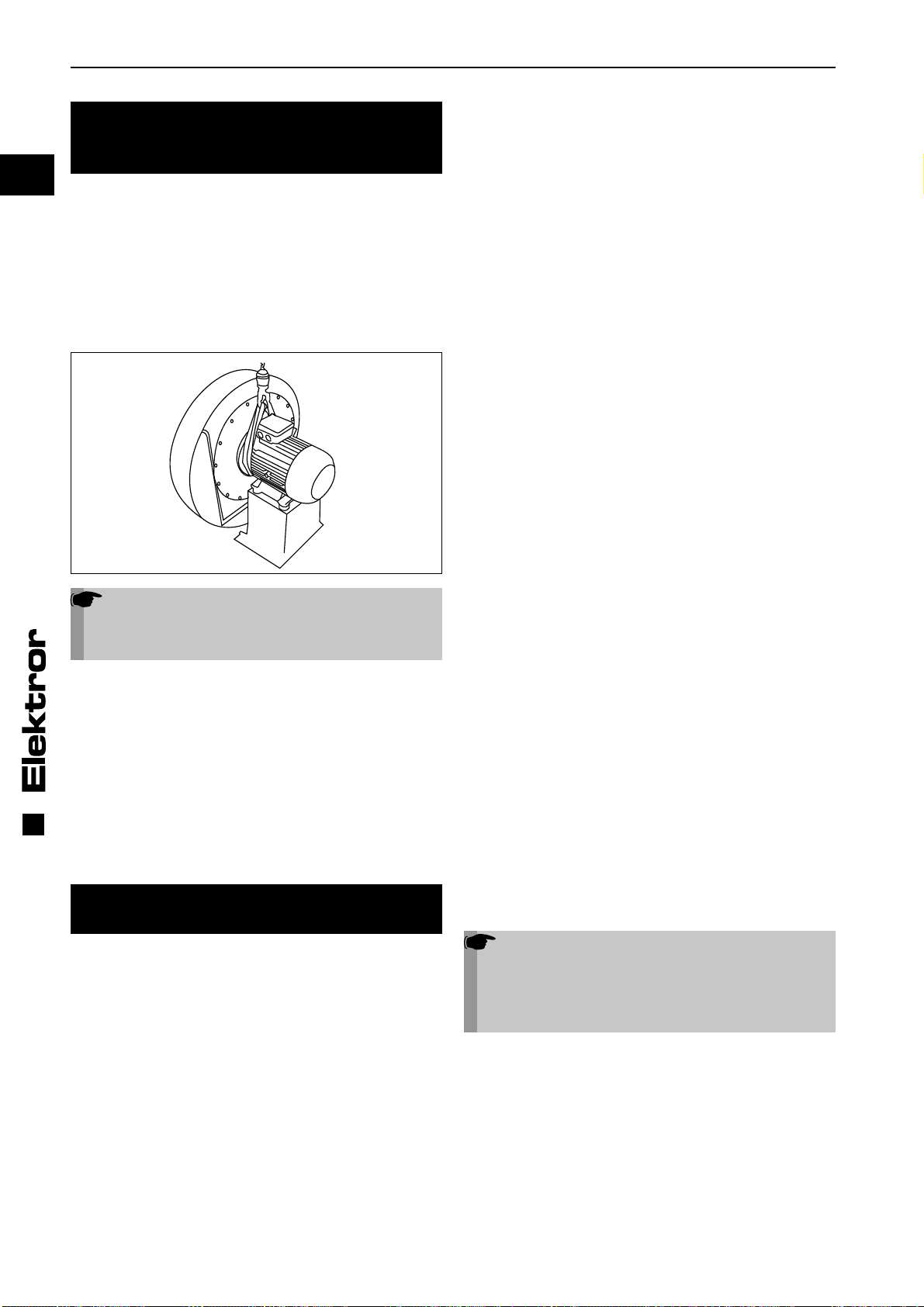

Operating and assembly instructions HRD www.elektror.com

016309 03.14/08

2 INFORMATION ON TRANSPORT,

HANDLNG AND STORAGE OF THE

MACHINE

2.1 Transportation and handling

• Before installation and putting into service, check all parts

for transit damage. A damaged blower is a potential safety

hazard and, therefore, should not be put into service.

• Do not leave the blower unprotected in the open

(protect against ingress of moisture).

• Attach hoisting gear securely. Only use hoists and load

suspension devices with sufficient load-carrying capacity.

Secure the route of transportation.

Note!

The eye bolt on the motor must not be used to lift

the entire blower. This is used if the motor needs

to be (dis-)assembled.

2.2 Storage

• Ensure that the air intake connection and pressure connec-

tion are closed.

• Store the blower

-> in its original packaging if possible

-> in a closed room

-> in a dry, dust-free and vibration-free area.

• Storage temperature range from -20°C to +60°C

• After a storage period of 6 months, the blower bearings

and/or motor bearings should be checked before they are

mounted in the blower.

3 INFORMATION ON COMMISSIONING

THE MACHINE

3.1 Installation and assembly

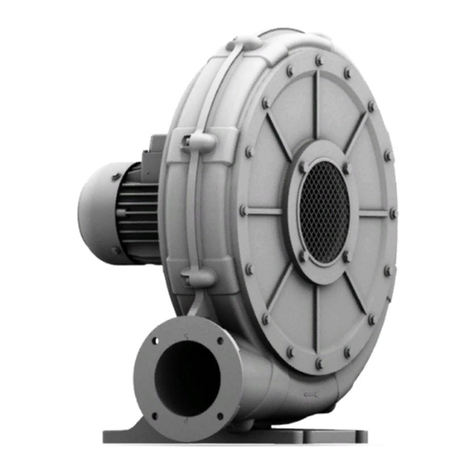

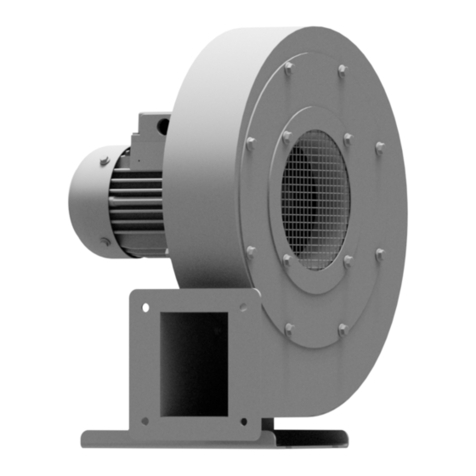

• Protect the blower from the weather and install it in a

horizontal position, see also 1.1. For outdoor use, protec-

tion from the weather must generally be provided that

fulfils the requirements listed in 1.1 Intended Use and

protects the blower from the influences of the weather.

• Do not subject the blower subsequently to vibration or

impact loads during operation. Permissible vibrational load

on blower: refer to ISO 14694, BV-3.

• Standard blowers with base: Bolt securely to a level

and firm surface at the place of use, making sure that the

surface has adequate load-bearing capacity and avoiding

vibration transmission or vibrational load.

• Standard blowers without base:

At the place of use, bolt the blower securely to a fixed

base having sufficient load capacity without transmitting

vibrations or vibrational load. In the case of HRD blowers

with suction and/ or pressure side connections, this is

possible with the following types:

up to max. HRD 1/5T or HTD 1T FU(K)-105/1,1,

up to max. HRD 14/5T or HTD 14T FU(K)-105/2,2,

up to max. HRD 2/3T or HTD 16T FU(K)-105-2,2 and

up to max. HRD 2T FU(K)-95/3,0.

• Blower units without motor and belt drive belt guard with

these models, the supplied blower base is intended only

for set-up of the blower unit. The purchaser (plant

engineer, operator or other customer) is responsible for

the secure and stable installation and attachment of the

blower in combination with the motor, belt drive and belt

guard to be supplied by the purchaser in compliance with

the applicable standards and regulations.

• Installation of standard blowers with a vertical drive shaft

is possible with HRD blowers up to the following models:

with flange housing: maximum to HRD 2/5T

FU/FUK blowers: maximum to HRD 60 FU(K)-105/4,0

maximum to HRD 65 FU(K)-100/4,0

• Cover open intakes or outlets with protective grating to

DIN EN ISO 13857.

• Make sure that adequate motor ventilation is provided.

Permissible ambient temperatures:

Standard version with rated voltage (max. +/-10% voltage

tolerance) and a design frequency of 50Hz or 60Hz.

• Ambient temperature -20°C to +60°C

Special voltages, multi-voltage motors, FU compatible

versions, FUK versions, UL certified appliances:

• Ambient temperature -20°C to +40°C

The performance of the drive motor’s ventilation system must

not be impaired by the installation situation.

3.2 Blower units without motor and belt drive

During assembly of the blower with the motor, belt drive and

belt guard supplied by the purchaser, in addition to the in-

structions given in Chapter 1, the purchaser / operator must

pay attention to the following:

• Exact alignment of the belt pulleys

• Exact axial parallelism of the belt pulley axes

• Correct belt type and belt tension

• Max. permissible forces

• The V-belt pulleys must be free from burrs, rust and dirt

• Correct V-belt profile and belt pulley type

• Max. permissible blower speeds

You will find the data relevant to your appliance tabulated in

section 11 and in section 5.4 (where applicable).

3.3 Electrical connection

Note!

The work described in this section may only be

performed by a qualified electrician. Connect the

appliance as per the circuit diagram in the termi-

nal box and in accordance with the relevant local

requirements.

Three-phase or a.c. motors can be used as drive motors.

In the appliance designation, the letter D stands for three-

phase a.c. and the letter E for single-phase a.c.

• The drive motor must be protected using a motor overload

switch (this does not apply to frequency converter operated

appliances). Where appliances are frequency-converter-op-

erated, the existing temperature sensor (PTC resistor sen-

sor) or temperature switch (normally closed contact) must be

connected to the converter and evaluated.

• Check that the mains voltage matches the ratings on the

nameplate.

• The safety earth terminal can be found in the terminal box.