12

W2 U2 V2

U1 V1 W1

W2 U2 V2

U1 V1 W1

(L3) (L1) (L3) (L1)

L1 L2 L3 L1 L2 L3

EN

Operating and assembly instructions RDF www.elektror.com

016315 03.14/07

Note!

The eye bolt on the motor must not be used to lift

the entire blower. This is used if the motor needs

to be (dis-)assembled.

2.2 Storage

• Ensure that the air intake connection and pressure

connection are closed.

• Store the blower

-> in its original packaging if possible

-> in a closed room

-> in a dry, dust-free and vibration-free area.

• Storage temperature range from -20°C to +60°C

• After a storage period of 6 months, the blower bearings

and/or motor bearings should be checked before they are

mounted in the blower.

3 INFORMATION ON TRANSPORT,

HANDLNG AND STORAGE OF THE

MACHINE

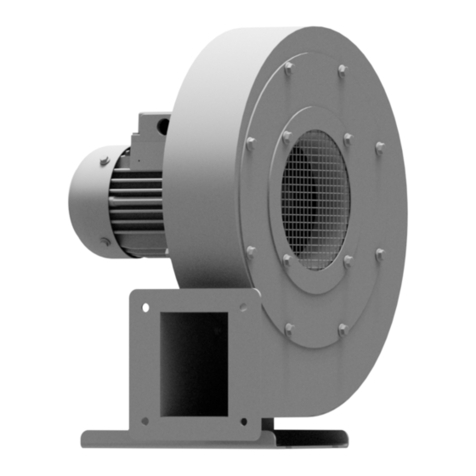

3.1 Installation and assembly

• Protect the blower from the weather and install it in a hori-

zontal position, see also 1.1. For outdoor use, protection

from the weather must generally be provided that fulfils

the requirements listed in 1.1 Intended Use and protects

the blower from the influences of the weather.

• Do not subject the blower subsequently to vibration or

impact loads during operation. Permissible vibrational load

on blower: refer to ISO 14694, BV-3.

• Bolt the base of the blower securely to the floor at the

place of use without vibration transmission or vibration

load. Make sure that the floor has adequate load bearing

capacity.

• Installation of standard blowers with a vertical drive shaft is

possible with RD F blowers up to the following models:

maximum to RD 64F.

• On open intake or discharge connections a hose or pipe

of a minimum lenght of 1m must be connected.

• Ensure adequate motor ventilation. Permitted ambient

temperature for:

Standard version with rated voltage

( voltage tolerance max. ±10% ) and a design frequency of

50 Hz or 60 Hz.

• Ambient temperature -20°C to +60°C

Special voltage, multi voltage motors, FU (frequency con-

verter) suitable versions, FUK (motor integrated frequency

converter) versions, units with air control:

• Ambient temperature generally -20°C bis +40°C

3.2 Electrical connection

Note!

The work described in this section may only be

performed by a qualified electrician. Connect ac-

cording to the wiring diagram placed in the termi-

nal box complying with relevant local regulations.

Three-phase or a.c. motors can be used as drive motors.

In the appliance designation, the letter D stands for three-

phase a.c. and the letter E for single-phase a.c.

• The drive motor must be protected using a motor overload

switch (this does not apply to frequency converter oper-

ated appliances). Where appliances are frequency-

converter-operated, the existing temperature sensor (PTC

resistor sensor) or temperature switch (normally closed

contact) must be connected to the converter and evalu-

ated.

• The safety earth terminal can be found in the terminal box.

• Install Electrical ON/OFF switches that can be locked as

maintenance / repair switches.

• Suitable electrical controlling must ensure the blower runs

long enough to clear the line system of any residual media

and avoid its blockage.

• Check that the mains voltage corresponds to the voltage

specified on the nameplate.

Note!

For operation of the drive motor with a frequency

converter, the following points should also be

noted:

• Motors may only be operated on a frequency

converter if they have “/FU” (which denotes

“frequency converter compatible”) marked on

the rating plate, or if they have been ordered as

“frequency converter compatible” motors and

confirmed.

• The frequency converter supply voltage must

only be a maximum of 400 V without the motor

filter. Appropriate measures, such as a motor

filter to protect the motor, must be installed on

the motor terminals with longer cables, higher

frequency converter supply voltages and/or if

the pulse voltages are exceeded (max. 1000 Vpk

for drive motors up to 0.75 kW, maximum 1300

Vpk for drive motors larger than 0.75 kW). Please

contact the converter supplier in this case. If a

motor filter is included in the delivery, this must

be installed between the converter and the motor.

Please ensure that there is sufficient space in the

switch cabinet and take into account the installa-

tion and assembly requirements in the operating

instructions of the frequency converter/motor

filter manufacturer.

• The wire running between the motor and the

frequency converter must not exceed a length of

20 m, configured as a suitable, shielded cable and

laid by as direct a route as possible, without any

additional plug/clamp connections.

• The braided screen in the connecting cable

must cover the full length of the cable on both

sides, i.e. be connected to the earthing system at

the frequency converter and to the motor using a

low electrical resistance. For this purpose, suit-

able EMC cable couplings must be used on the

motor side. They must contact the cable shield

around its full circumference and have a low

resistance.

For further information about EMV compliant installation refer

to the operating and assembly instructions of the frequency

converter’s manufacturer.

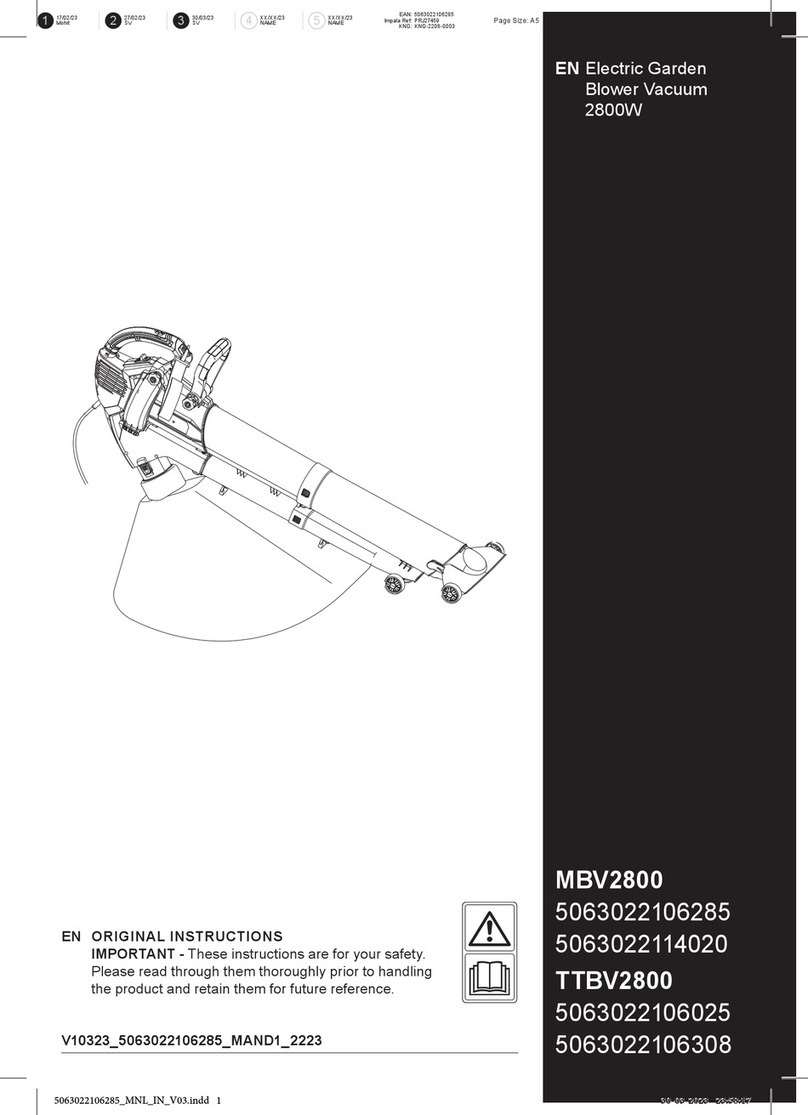

3.3.1 Configuration for three-phase current blowers

circuit Y circuit

(low voltage) (high voltage)

Checking the direction of rotation

Switch on the blower. The running direction of the impeller